Article

citation information:

Szczucka-Lasota, B., Kamińska,

J., Krzyżewska, I. Influence of tire pressure on fuel consumption in trucks with installed

tire pressure monitoring system (TPMS). Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 103, 167-181. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.13.

Bożena

SZCZUCKA-LASOTA[1],

Joanna KAMIŃSKA[2],

Iwona KRZYŻEWSKA[3]

INFLUENCE

OF TIRE PRESSURE ON FUEL CONSUMPTION IN TRUCKS WITH INSTALLED TIRE PRESSURE

MONITORING SYSTEM (TPMS)

Summary. In recent years, the development of IT systems for fleet

monitoring was observed. Tire pressure monitoring systems are constantly

improved. Decreased values in tire pressure can cause deformation of tires.

Monitoring of tire pressure is an important function in oversized transport

trucks. Tire pressure and rolling resistant influence fuel consumption. The

purpose of this paper was to determine the impact of tire pressure on fuel

consumption in a fleet of trucks with tire pressure monitoring system installed

and to determine the impact of other factors that may affect fuel consumption,

such as the vehicle weight, brake usage and cruise control usage. The results

of the research were developed using a multiple regression model describing the

above dependence.

Keywords: tire, pressure, monitoring, TPMS, fuel consumption

1. INTRODUCTION

The development of technology, especially technology

for measuring vehicle exploiting parameters, moving at the direction of

increasing efficiency, reliability and reducing exploiting costs related to

fuel consumption, thus reducing the emission of harmful pollutants. The basic

parameter enabling the increase of usage properties in a tire is the selection

of the proper tire pressure depending on the vehicle weight, ambient conditions

(temperature, external pressure), and the mode of exploitation. The development

of civil engineering and transport allows the use of increasingly better

consumables, fuel mixtures and measurement systems of selected parameters to

ensure higher reliability and efficiency [1-3].

Based

on the literature review so far, it should be stated that tire pressure is an

important factor affecting the passive safety of vehicles. First, it was

noticed that depending on the tire pressure level, the tire is subject to

greater or lesser deformations. Such deformations affect the stability

exploiting of tires causing, for example, irregular tread wear [4-5]. Figure 1

presents tires with different pressure values.

Fig. 1. Tire deformations in a) low pressure, b) high

pressure, c) proper pressure [5]

Low tire pressure causes tire deformations from the

inside in such a way that contact with the ground occurs only on the outer

surface. Then there is a danger of the tire warming up quickly (increase of

temperature) and damage its structure, which may lead to shorter tire life. Too

high tire pressure values cause it to contact the ground only in the middle

part.

In the third case, the tire pressure is correct. The

tread consumption is regular, which affects the driving comfort and increases

the tire life and shorter braking distances [5]. According to Mathai, correct

tire pressure and temperature values allow for lengthening the life of the tire

by 30%. The authors of the study [6] even indicate the value of 50%. In turn,

Reiter et al. calculated that the exploiting of vehicles with lower tire

pressure has the impact of shortening the tire life by up to 5% [7-8].

In recent years, the impact of tire pressure values on

fuel consumption and rolling resistance has been analysed. The results of

scientific and research work [12-21, 23] clearly indicate the relationship

between these parameters. Tests carried out by Varghese and Schmeitz, indicate

that as tire pressure increases, rolling resistance decreases with the same

value of vehicle speed and weight [10-11]. In his scientific works, Jansen

noted that the decrease in pressure in passenger car tires by 0.03 MPa caused

an increase of 6% in rolling resistance while fuel consumption increased by 1%

[11]. Similar relationships have been shown in publications [7-8, 22] where,

with a drop in pressure in truck tires by 0.02 MPa, fuel consumption increased

by 1.5%.

In turn, the work of Jasarevic and Reiter stated that

the pressure drop of 0.05 MPa in the tires increased the rolling resistance by

15%, which determines an increase of fuel consumption in the range of 2-5% in

vehicles [7-9]. Based on the analysis of the literature data, it can be stated

that tire pressure is the basic factor affecting the efficiency of the use of

vehicles, rolling resistance and the amount of fuel consumption. In addition,

as demonstrated in a number of scientific and research works in Poland and

around the world, the exploitation of vehicles at tire pressure other than

recommended by manufacturers affects the condition of tires, causing premature

wear.

The relationship between the decrease of tire pressure

in passenger cars and the tire life has been investigated, among others by

Wagner et al. [7-8].In these publications, the authors showed that the

exploitation of vehicles with reduced tire pressure by about 7 kPa causes the

tire life to be shortened by almost 2%. The published data of the research

projects carried out confirmed this relationship. The results of scientific and

research work indicate a reduction of tire life by 30% in the exploitation of

vehicles with reduced tire pressure by 20% of the pressure recommended by

manufacturers [7-8].

The purpose of this paper is to determine the impact of

tire pressure on fuel consumption in a fleet of trucks with tire pressure

monitoring system installed and to determine the impact of other factors that

may affect fuel consumption, such as the vehicle weight, brake usage and the

cruise control usage. The results of the research were developed using a

multiple regression model describing the above dependence.

1.

MATERIALS

AND METHODS

In the considered transport company realising the

transport of oversized cargo, the truck fleet consists of 50 vehicles including

tractors and trailers. Among the vehicles, there are three types of tractors

and six types of trailers. From among all available vehicles in the truck

fleet, 10 vehicles consisting of three-axle tractors with 6x2 motor and Mega

Tele type trailers were selected for basic tests, as it was found that for

these vehicles, the exploiting conditions will be the closest in terms of route

length, weight of transported loads, etc. In addition, these vehicles are the

most used in the considered company.

Vehicles (tractor + trailer) are marked in sequence

with letters A to E. The test material is truck tires. For the needs of the

work, new tires were purchased (Michelin companies) and installed in all tested

vehicles. Truck tires used for transport in the fleet of the considered company

differ in size:

• 22.5 inches for tractors,

• 17.5 inches for trailers.

During the tests, the tires were not damaged, changed

or transferred to another arrangement in the axles of the vehicle.

Remote tire pressure measurements were made using a

tire pressure monitoring system. In the selected vehicles, a tire pressure

monitoring system was installed while the vehicle was working, which made it

possible to track the measured exploiting parameters continuously on the online

platform, and every 30 days the data was transferred to the files for further

analysis. On the basis of the obtained data, statistical calculations and

graphs of fuel consumptions versus tire pressure were made.

The results of average fuel consumption measurements

have been recorded on the Nawi24 website, which is used to monitor vehicles

using GPS. The fuel quantities were controlled by CAN sensors, additionally, on

the basis of the received data from the system, sections of the route were

calculated, which allowed for relatively precise determination of the average

of fuel consumption by the system. As part of the work, the average fuel

consumption values were taken from the system in the form of files and then

compiled and analysed.

Data collected from the Scania online platform

concerned, for example, average fuel consumption in monthly summaries, and

eco-driving, which is a modern and eco-friendly driver's style. All drivers

have been trained on the impact of eco-driving on fuel consumption during

vehicle exploiting. The factors controlled by the Scania Driving Service system

include: using the cruise control [%], using the brake [number], the weight of

the vehicle [Mg] and average speed [km/h]. Data collected from the Scania

platform was compiled and then analysed in terms of their significance on the

fuel consumption of tested vehicles.

2.

RESULTS

3.1. Influence of tire pressure on fuel

consumption

The influence of tire pressure on the average fuel

consumption in vehicles with tire pressure monitoring system was examined. The

measurements of average fuel consumption on the test day and the average

pressure in all tires in the vehicle were compiled. Measurements of average

fuel consumption were registered automatically in the system Nawi24, a platform

for monitoring the truck fleet. Average fuel consumption values were taken into

account in only those that concerned a route longer than 50 km. The obtained

values were related to the main line. The CAN system uses a fuel probe to

provide data from the amount of fuel consumed. The pressure values were

recorded on the remote online platform of the tire pressure monitoring system,

then averaged from each axis on each day of vehicle exploiting and averaged

from all axles on a given day. The research was conducted from November 2017 to

August 2018. The data from each month were compiled on a chart, the regression

curve, the R2 coefficient and the equation of this curve were

derived. Linear regression was used in the studied relationship.

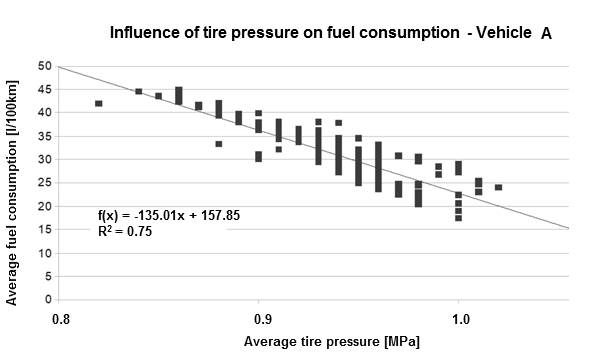

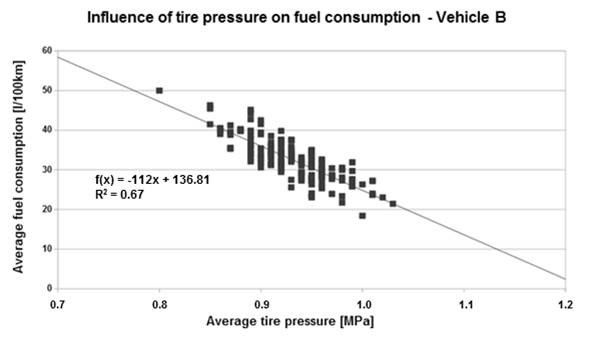

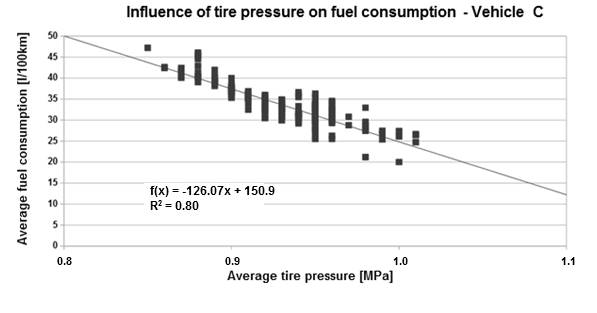

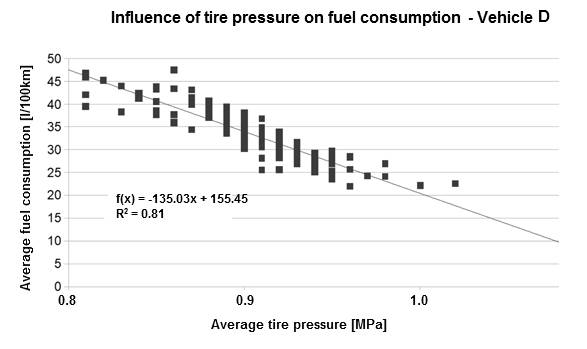

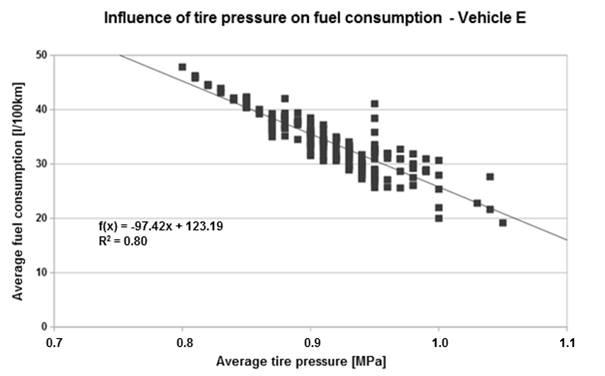

Analysis of the obtained data shows that the results

of calculations of the average amount of fuel consumption in vehicles A-E and

average tire pressure in a given day are arranged in diagrams linearly (Fig.

2-6), and the observed dependence is inversely proportional.

This means that as the tire pressure increases, the

average fuel consumption in the tested vehicles decreases. For the linear

regression model used, the determined R2 coefficient is 0.67 for

vehicle B, indicating a moderate correlation (Fig. 3). The R2

coefficient was the lowest for the analysed vehicle. For vehicle A, the

determined R2 coefficient was 0.75, which also indicated a moderate

correlation (Fig. 2). The R2 coefficient determined (Figures 4-6) in

the other analysed cases was about 0.80, which indicates a strong positive

correlation between the analysed variables.

Fig. 2. Influence of tire pressure on fuel consumption

– vehicle A

Fig. 3. Influence of tire

pressure on fuel consumption – vehicle B

Fig. 4. Influence of tire

pressure on fuel consumption – vehicle C

Fig. 5. Influence of tire pressure

on fuel consumption – vehicle D

Fig. 6. Influence of tire

pressure on fuel consumption – vehicle E

3.2. Influence of other parameters on fuel

consumption

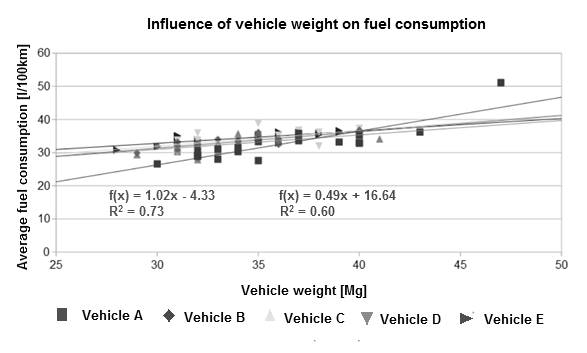

In order to identify other factors that may impact

fuel consumption, the following measurements were compiled:

• weight of the

vehicle (average weight of the truck; the vehicle together with the transported

load) [Mg],

• brake usage (the

number of brakes use over the distance of 100 km of the route)

[number / 100 km],

• use of cruise

control (percentage of cruise control) [%],

• average speed

[km/h].

All measurements were registered by a special platform

to manage the Scania Fleet Management truck fleet, where all monitored vehicle

data were sent in an automated manner. The data of vehicles were downloaded

from the platform in a file, ready for further analysis and comparisons.

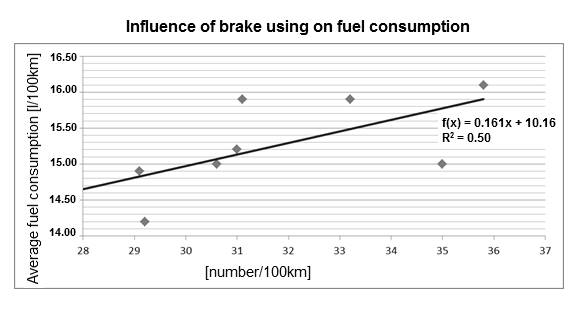

The measurements and calculations were aimed at

checking the impact of other exploiting parameters on fuel consumption in

monitored vehicles and determining which of the parameters significantly affect

the amount of fuel consumed. The analysis of the test results shows that the

strongest correlation was demonstrated between these parameters: the weight of

vehicle and fuel consumption (Fig. 7).

Along with the increase in the weight of vehicle, the

fuel consumption in vehicles also increased (according to the linear law),

which is consistent with the literature data. Determined R2

coefficients in the analysed cases were from 0.60 to 0.73.

Slightly lower correlation was observed between such

parameters as the registered number of braking and its effect on fuel

consumption (Fig. 8) during vehicle exploiting and in the case of observation

of the impact of the use of cruise control on fuel consumption.

Fig. 7. Influence of vehicle

weight on fuel consumption

Fig. 8.

Influence of brake usage on fuel consumption

In both cases, the low linear

correlation coefficient of the independent variable with the dependent variable

(the amount of fuel consumption) was recorded. However, these results do not

determine the removal of these variables from the set of predictors. In order

to make an unambiguous assessment of the impact of each of the explanatory

variables on the variability of the explained variable (fuel consumption),

statistical analyses should be carried out, determining partial and

semi-partial correlation coefficients. Observed results indicate that the

percentage use of cruise control in vehicles was high, in the range of 57 to

91%.

Considering the data

analysis, it could be concluded that in addition to the tire pressure, the most

significant impact on the amount of fuel consumption during the exploration of

the trucks is affected by the following: the vehicle weight, brake usage and

use of cruise control. For these variables, linear regression was assumed. The

correlation was considered to be strong for the dependence between the

parameters: vehicle weight and average amount of fuel consumption, while the

average or weak correlation was recorded in the case of the analysis of the

dependence of the registered number of brake and cruise control usage on the

average amount of fuel consumption.

In the first step,

linear relationships between variables were examined to determine whether: fuel

consumption depends linearly on other variables (explanatory) given that

explanatory variables do not depend strongly on each other.

Table 1 summarises the

values of basic statistics and Pearson's linear correlation coefficients for

the considered variables.

The presented values of

the correlation coefficient (Table 1) indicate a strong, statistically

significant, negative relationship between fuel consumption and tire

pressure(-0.73) and also a statistically significant positive relationship

between fuel consumption and vehicle weight.

Among the explanatory

variables, there were also several statistically significant linear

relationships (marked in red in the table). The strongest is the negative

relationship between brake usage and use of cruise control, which has a causal

effect. This means with increase use of cruise control on the route, the number

of brake usage decreases.

It should be noted that

the low linear correlation coefficient of the independent variable with the

dependent variable does not determine the deletion of the variable from the

predictor set. In order to make an unambiguous assessment of the impact of each

of the explanatory variables on the variability of the explained variable (fuel

consumption), the coefficients of partial and semi-partial correlation should

be determined. Partial correlation expresses correlation between a given

independent variable, taking into account its correlation with all other

variables (dependent and independent). This is the correlation between the rest

after considering all independent variables. The partial correlation represents

the unique contribution of a given independent variable when predicting the

value of the dependent variable. On the other hand, semi-partial correlation

determines the correlation of a given independent variable, given its

correlating with all other variables and the dependent variable (without

considering its correlation with other variables).

Statistically

significant at the level of α = 0.05 Pearson's linear

correlation coefficients were marked in red.

Thus, partial

semi-correlation is the correlation of the residuals of a given independent

variable after considering the influence on other variables with the dependent

variable without taking into account the influence of other variables.

In the analysed case,

the semi-partial correlation coefficient is a better indicator of the

"actual impact" of the predictor than the partial correlation because

it scaled (referred to) the total variability of the dependent variable (fuel

consumption). Values of partial correlation coefficients and semi-partial

correlation coefficients are presented in Tab. 2.

The values of partial

semi-correlation coefficients indicate the greatest impact of the pressure and

vehicle weight on the variability of fuel consumption. The effect of brake and

cruise control is similar. The value of Pearson's correlation coefficient (high

positive relationship between these variables) indicates their redundancy

(tolerance coefficient equal to 0.19 and 0.21, respectively – Tab. 3).

Tab. 1

Basic descriptive

statistics and Pearson's linear correlation coefficients

|

Variable |

Variable |

|||||

|

Average speed [km/h] |

Use of Cruise control [%] |

Brake usage [number/100km] |

Vehicle weight [Mg] |

Pressure [MPa] |

Fuel consumption [l/100km] |

|

|

Average |

59.20 |

71.80 |

23.0 |

34.20 |

0.93 |

32.93 |

|

Standard deviation |

4.87 |

16.90 |

11.1 |

3.18 |

0.03 |

2.40 |

|

Fuel consumption [l/100km] |

0.01 |

-0.09 |

0.11 |

0.57 |

-0.73 |

1.00 |

|

Pressure [MPa] |

-0.14 |

0.10 |

-0.01 |

-0.41 |

1.00 |

|

|

Vehicle weight [Mg] |

0.16 |

0.07 |

-0.09 |

1.00 |

|

|

|

Brake usage [number/100km] |

-0.35 |

-0.88 |

1.00 |

|

|

|

|

Use of cruise control [%] |

0.25 |

1.00 |

|

|

|

|

|

Average speed [km/h] |

1.00 |

|

|

|

|

|

Tab.

2

Partial

and semi-partial correlation coefficients of variables considered in the model

|

Variable |

Partial correlation coefficients |

Semipartial correlation coefficients |

|

Pressure [MPa] |

-0.69 |

-0.55 |

|

Vehicleweight [Mg] |

0.44 |

0.28 |

|

Brake usage [number/100km] |

0.24 |

0.14 |

|

Use of cruise control [%] |

0.21 |

0.13 |

|

Average speed [km/h] |

-0.13 |

-0.08 |

Tab. 3

The

values of the Pearson correlation coefficient for a variables set

|

Variable |

Actual variable in

equation; DV: Fuel consumption [l/100 km] |

|||

|

Partial

correlation |

Semi-partial

correlation |

Tolerance |

R2 |

|

|

Pressure [MPa] |

-0.69 |

-0.55 |

0.79 |

0.21 |

|

Vehicle weight [Mg] |

0.44 |

0.28 |

0.73 |

0.27 |

|

Brake usage [number/100km] |

0.24 |

0.14 |

0.19 |

0.81 |

|

Use of cruise control using [%] |

0.21 |

0.13 |

0.21 |

0.79 |

|

Average speed [km/h] |

-0.13 |

-0.08 |

0.82 |

0.18 |

Therefore, only one of

them can be included in the model as an explanatory variable. Due to the

higher Pearson's correlation coefficient between brake usage and fuel

consumption, it was decided to introduce this variable into the model. The

average speed and use of cruise control were considered to have a slight impact

on the variability of fuel consumption and were not included in the model. For

a set of variables in the model, the semi-correlation and tolerance values were

again determined to verify the correctness of the selection. The results are

summarised in Tab. 4.

Semi-correlation values after

been removed from the set of redundant variables

|

Variable |

Partial correlation |

Semi-partial correlation |

Tolerance |

|

Pressure [MPa] |

-0.67 |

-0.54 |

0.83 |

|

Vehicle weight [Mg] |

0.46 |

0.31 |

0.82 |

|

Brake usage [number/100km] |

0.21 |

0.13 |

0.99 |

The tolerance

coefficients indicate that none of the variables is redundant, so the set of

explanatory variables is correctly specified.

The linear model equation was

determined by the multiple regression method with the minimisation of the error

functions using the least squares method:

![]()

![]()

The standard error of

the estimation of this model is 1.479 l / 100 km. The R2 coefficient

is 0.64. The correctness of the model was assessed on the basis of the

distribution of residuals, that is, the differences between the actual

(empirical) and model values. For a well-constructed model, the rest should

have a normal distribution. The correctness of the model presented in the work

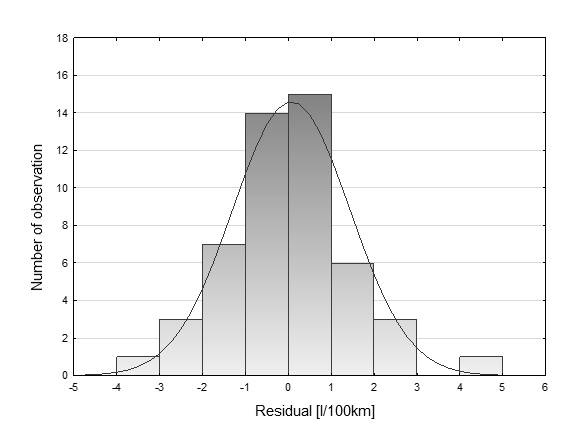

confirms the distribution of residuals shown in Fig. 9.

Fig. 9. Residual histogram for the model

(pattern number)

According to figure

(Fig. 9), all residue values are arranged according to the frequency of normal

distribution. For a more accurate assessment of the compatibility of the

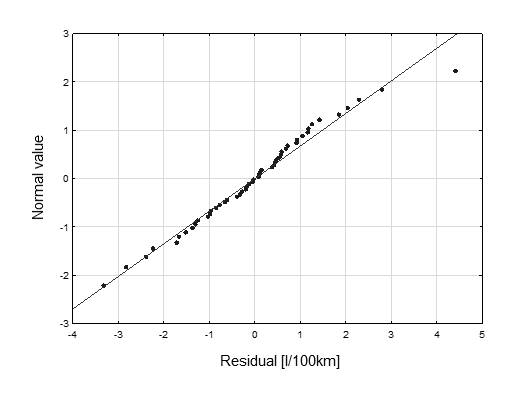

distribution of residues with the normal distribution, a normality diagram of

the residuals is shown (Fig. 10). It can be seen that all points

representing the rest of subsequent cases are arranged on a line representing

the normal distribution.

In Fig. 10, one point is

visible, for which the rest is significantly higher than expected. This is the

last measurement of the last vehicle. This value may result from measurement

error but we cannot verify this hypothesis, therefore we left the result of

this measurement in the data set. The presented results confirmed a strong

relationship between these parameters.

However, the limitations

of inference based on the proposed and presented model should be considered.

The tire pressure value is limited in advance by the maximum value specified by

the manufacturer. According to the literature data, if the tire pressure is too

high, the tire wear pattern also changes. Too high tire pressure causes the

contact of tires with the ground only in the middle part. Such deformations may

lead to irregular use of the tread, which may also lead to a shorter time of

safe tire use [5].

Fig. 10. Normality diagram of residuals

3.

CONCLUSION

In recent years, scientific research clearly indicated

a strong relationship between rolling resistance, tire pressure and fuel

consumption. Moreover, low and high values of tire pressure can create the

deformation of the tire. In this paper, the influence of tire pressure on fuel

consumption was investigated. Model regression was used in data analysis of

other parameters which can affect fuel consumption. Analysis of the results

obtained for other vehicles confirms that the adopted linear regression model

was correct. It can, therefore, be noted that:

• the influence of tire pressure on fuel consumption was

observed,

• dependence of fuel consumption on tire pressure was

inversely proportional; with the increase of tire pressure in the tested range

(0.7-1.1 MPa), fuel consumption decreased.

It can, therefore, be asserted that maintaining tire

pressures at appropriate values has an impact on lower fuel consumption.

It should be noted that in all examined vehicles,

inversely proportional dependence of fuel consumption on tire pressure was

performed. Thus, already at this stage of the research, it is justified that

with the increase of tire pressure, the value of average fuel consumption

decreases. Values of R2 correlation coefficients indicated in some

cases a moderate relationship between the parameters examined, while in the

majority of cases a strong correlation was observed.

In conclusion, the tire

pressure [MPa] has the greatest impact on the reduction of fuel consumption.

With the pressure increase by 0.1 MPa, fuel consumption decreases by an average

of 5.15 l / 100 km. Presence of a tire pressure monitoring system can help in

initiating a rapid response when values of tire pressure decrease.

References

1.

Chomka Grzegorz, Jerzy Chudy, Maciej Kasperowicz. 2012.

„Techniczne aspekty regeneracji opon samochodowych”. [In Polish:

„Technical aspects of car tire regeneration”]. Autobusy. Technika. Eksploatacja. Systemy transportowe 5: 110-115.

2.

ZSSPLUS. „Wheels and tires”. Available at:

https://www.zssplus.pl/transport/pin/Ogumienie.pdf.

3.

Rzeczoznawcy TOMIR. „The tire and shield vademecum”.

Available at: http://rzeczoznawcy-tomir.pl/portal/wademecum-opon-oraz-tarczy-k%C3%B3%C5%82.pdf.

4.

Oduro Seth Daniel, Timothy Alhassan, Prince Owusu-Ansah, Prince Andoh.

2013. “A mathematical model for predicting

the effects of tyre pressure on fuel consumption”. Research

Journal of Applied Sciences, Engineering and Technology 6(1): 123-129. ISSN:

2040-7459. DOI: 10.19026/rjaset.6.4046.

5.

Caban Jacek, Paweł Droździel, Dalibor Barta, Stefan Liscak.

2014. “Vehicle Tire Pressure Monitoring System”. Diagnostyka 15(3): 11-14. ISSN:1641-6414.

6.

Mathai Asha, Vanaja

Ranjan. 2015. “A new approach to

tyre pressure monitoring system”. International

Journal of Advanced Research in Electrical, Electronics and Instrumentation

Engineering 4(2): 866-872. DOI: 10.15662/ijareeie.2015.0402067.

7.

Reiter Marc, John Wagner. 2010. “Automated automotive tire inflation

system – effect of tire pressure on vehicle handling”. IFAC Proceeding

Volumes 43(7): 638-643. DOI:

https://doi.org/10.3182/20100712-3-DE-2013.00013.

8.

Toma Marius, Cristian

Andreescu, Cornelia Stan. 2018. “Influence of tire inflation pressure on

the results of diagnosing brakes and suspension”. Procedia Manufacturing 22: 121-128. DOI:

https://doi.org/10.1016/j.promfg.2018.03.019.

9.

Jasarevic Sabahudin, Ibrahim Mustafic, Fuad Klisura. 2014.

“Introduction and application of tire pressure monitoring system”. 3rd Conference “Maintenance

2014“ Zenica, B&H, June 11-13, 2014.

10. Varghese Alexander. 2013. “Influence of tyre inflation pressure on fuel

consumption, vehicle handling and ride quality modelling and simulation”.

Master's thesis. Chalmers University of Technology, Göteborg, Sweden.

11. Jansen Sven, Antoine Schmeitz. 2014. “Study on some safety-related aspects of tyre

use”. Stakeholder information and

discussion document MOVE/C4/2013-270-1. Directorate-general

for Mobility and Transport. May 27th 2014 Brussels.

12.

Torretta Vincenzo, Elena

Cristina Rada, Marco Ragazzi, Ettore Trulli, Irina Aura Istrate, Lucian Ionel

Cioca. 2015. “Treatment and disposal of tyres: Two EU approaches. A review”. Waste

Management 45: 152-160. DOI: http://dx.doi.org/10.1016/j.wasman.2015.04.018.

13.

Skarbek-Żabkin

Anna, Ewa Kamińska. 2015. „Kierunki zagospodarowania zużytych

opon samochodowych”. [In Polish: „Directions for the management of

used car tires”]. Transport

Samochodowy 1: 79-87.

14.

Jacyna Marianna (Eds.). 2014. Kształtowanie

systemów w wybranych obszarach transportu i logistyki. [In Polish: Shaping systems in selected areas of

transport and logistics]. Warcow: Warsaw University of Technology

Publishing House. ISBN: 978-83-7814-300-0.

15.

Jacyna Marianna. 2009. Modelowanie

i ocena systemów transportowych. [In Polish: Modeling and evaluation of transport systems]. Warcow: Warsaw

University of Technology Publishing House. ISBN: 978-83-7207-808-7

16.

Jacyna M., M. Wasiak, K.

Lewczuk, G. Karoń. 2017. “Noise and environmental pollution from transport: decisive problems in

developing ecologically efficient transport systems”. Journal of Vibroengineering 19:

5639-5655. DOI: doi.org/10.21595/jve.2017.19371.

17.

Januszewicz

K., M. Melaniuk, M. Ryms, E. Klugmann-Radziemska. 2010. „Możliwości wykorzystania całych używanych opon”. [In Polish: „Opportunities to use

all used tires”]. Archiwum

Gospodarki Odpadami i Ochrony Środowiska 12(4): 53-60.

18.

Holka

Henryk, Tomasz Jarzyna. 2010. „Aspekty

energetyczne dekompozycji opon samochodowych metodą Water-Jet”. [In Polish: „Energy aspects of car tire decomposition

using the Water-Jet method”]. Inżynieria

i aparatura chemiczna 5: 43-44.

19.

Sobota

Aleksander, Renata Żochowska, Emilian Szczepański, Paweł

Gołda. 2018. „The influence of tram tracks on car vehicle speed and

noise emission at four-approach intersections located on multilane arteries in

cities”. Journal of

Vibroengineering 20(6): 2453-2468.

20.

Jacyna-Gołda

Ilona, Mariusz Wasiak, Mariusz Izdebski, Konrad Lewczuk, Roland Jachimowski,

Dariusz Pyza. 2016. „The evaluation of the efficiency of supply chain

configuration”. Proceedings of the

20th International Scientific Conference Transport Means 2016. Transport Means

- Proceedings of the International Conference: 953-957.

21.

Naish

Daniel A., Matthew Fleet, Devaraj Arumugam. 2017. „Feasibility assessment

of various TL-5 safety noise barrier (SNB) designs“. Road & Transport Research: A Journal of Australian and New Zealand

Research and Practice 26(2): 5-21.

22.

Naish

Daniel A. 2016. „Dynamic simulation of a truck impact with a side entry

arrester bed system“. Road &

Transport Research: A Journal of Australian and New Zealand Research and

Practice 25(1): 3-17.

23.

Nishiuchi

H., Y. Kobayashi, T. Todoroki. 2018. Public

Transport 10: 291. DOI: https://doi.org/10.1007/s12469-018-0185-3.

Received 06.01.2019; accepted in revised form 29.05.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License