Article

citation information:

Kuľka, J., Mantič, M.,

Kopas, M., Faltinová, E., Hrabovský, L. Simulation-expertise analysis of

ropes used in the horizontal belaying system. Scientific Journal of Silesian University of Technology. Series

Transport. 2019, 103, 53-67.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.5.

Jozef KUĽKA[1],

Martin MANTIČ[2], Melichar KOPAS[3],

Eva FALTINOVÁ[4],

Leopold HRABOVSKÝ[5]

SIMULATION-EXPERTISE

ANALYSIS OF ROPES USED IN THE HORIZONTAL BELAYING SYSTEM

Summary. This article

deals with a dynamic simulation of the movement and fall of persons working at

a height, using the rope belaying system. The input data, which are necessary

for a created simulation model, were obtained from experimental measurements

realised from the concrete belaying system. The simulation analyses were

performed for three different values of the rope pre-load level. Consequently,

the outputs from the simulations presented in this article were applied in a

real design proposal of the rope anchoring arrangement for a horizontal

belaying system.

Keywords: rope, horizontal belaying system,

safety, FEM analysis

1. INTRODUCTION

Modern methods and

approaches, when applied within the individual phases of a machine whole life

cycle, particularly, during the phase of projection, design, operation,

repairs, maintenance and recycling, must take into consideration the safety

requirements. Presently, there remains in operation, a large number of aged

machines that were projected and produced several decades ago.

Although these machines

are suitable enough from the viewpoint of durability and functionality, they

are no longer reliable from the aspect of labour safety and health protection

with regard to new safety rules; taking into consideration conditions determined

for the safe movement of workers on the supporting structure of the given

machine equipment. Every user of such machines and machinery has to ensure

correction of occurred faults.

Operation and

maintenance of overhead travelling cranes, which operate in open-air weather

conditions, are typical examples with the above-mentioned problems. Entrance

into the crane operator’s cab, which is usually situated at a height, as

well as maintenance activities performed during the winter period, are especially

dangerous with regard to the possibility of injury.

Therefore, it is

necessary to install some suitable belaying system into the given working area

in order to make the movement of the operating personnel safer. Described in

this article, is the horizontal belaying system based on the application of

steel wire ropes. This belaying system was successfully installed in a real

bridge crane operation.

Various relevant aspects

of the steel wire ropes are presented in the corresponding literature. The

publications [1, 2] dealt with steel wire ropes, taking into consideration the

general principles of their operation and safety.

Possible causes of rope

damage were explained in professional works [3, 4, 5, 6, 7]. Similarly,

analyses of the stress state and operational loading, as well as failure

analyses of steel wire ropes have been published in other articles [8, 9, 10].

These were described in

the papers [11, 12], the mathematical and geometrical models developed for

computer simulation of steel wire ropes. The dynamic non-linear simulations,

which were performed using the Finite Element Methods (FEM), were presented in

these articles [13, 14, 15, 16, 17].

Specific approaches to

the solution of mechanical vibrations as well as to the detection of failures

in the various mechanical systems are illustrated in these publications [18, 19,

20].

2. MATERIALS AND METHODS

In this work, a special

horizontal belaying system (HBS), the horizontal rope belaying system, which

was proposed and applied in a real metallurgical plant was described and

analysed. This plant consists of several production halls equipped with various

kinds of bridge cranes. There exist three possibilities on how to realise

anchorage of the proposed rope belaying system:

a) anchoring between steel

columns.

b) anchoring between concrete

columns.

c) anchoring without columns.

Bearing capacity of the

anchoring equipment of the type C category (category of the proposed system),

which is given as the dynamic force value, has to be 12 kN at least according

to the technical standard STN EN 795. Hence, it was necessary to determine the

real loading of the rope and connecting elements or more precisely, investigate

what heavy loading of the rope and joining elements corresponds to this force.

There were calculated

reactions in the connecting points of the main rope (that is, horizontal rope),

forces in the rope as well as the deflection of the rope during loading caused

by the vertical force 12 kN. This vertical force was acting in various

distances from the supports using a pre-load in the rope with the values of the

pre-load forces from 0.2 kN to 20 kN. Simultaneously, it calculated a change of

the pre-load due to increase or decrease of the ambient temperature. The

diameter of the applied main rope was 14 mm.

The calculations were

performed by means of the Finite Element Method (FEM) and utilising the

software product COSMOS/M, version 2.7. The main rope Æ14 was simulated using the bar elements of type TRUSS2D [21].

2.1. Calculation

Methodology during Dynamic Loading of Anchorage Rope

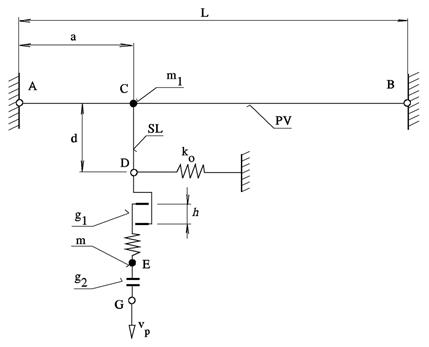

The calculation model of

HBS, which was proposed for simulation of the static and dynamic loading of the

guide, is schematically illustrated in Fig.1. The horizontal guide PV (that is,

the main rope) is simulated by means of two-nodal planar bar elements

considering a non-linear elastic material and large displacements. These

elements are specified in the software, COSMOS/M, under the designation TRUSS2D

[21]. The same elements were used for simulation of the attachment rope SL.

An advantage of FEM is

the possibility of relatively easy simulation concerning other related parts,

which are situated within the supporting structure, taking into consideration

the stiffness of the whole system. In the simplest case, it was enough to apply

a solid connecting for the ends of the guide, according to Fig.1.

Fig. 1. Calculation

model of HBS with a stiff support of guide

The calculation model

also includes the single-node elements of the type MASS in order to simulate

the concentrated masses that replaced a ballast weight, which represents a

falling person (that is, the mass m in Fig.1) as well as to replace the snap

hook m1 of the attachment rope.

Also implemented into

the calculation model were elastic springs, which limits the horizontal

displacements of the ballast weight in order to eliminate a singularity. The

stiffness of these springs is very small (the stiffness value is k0 » 10-5 N/mm), which means,

mathematically, that a very small numerical value is substituted into the diagonal

element of the stiffness matrix so that a singularity of the given matrix can

be eliminated.

A free fall of the

ballast weight from height h was simulated by means of the contact elements of

the type GAP. These elements are two-node elements, which carry the load

unilaterally, either in pressure or in tension. At the same time, it is

possible to simulate the stiffness-damping characteristics of these elements in

such a way that the carried force is given by the following relation:

![]() ,

(1)

,

(1)

where F0 is

pre-loading force, k is stiffness of the spring, urel

is relative displacement of the nodes, u0 is relative

displacement at the beginning of the contact, vrel is

relative speed of the nodes, the constants c and s are the

damping characteristics.

The above-mentioned

properties enable the application of the GAP elements (in the case of a

parallel connection) also for simulation of the fall dampers. The elastic

properties of the elements were considered in this case only, whereby the value

of stiffness k was chosen as the highest value with regard to a minimal

influence on the dynamic response of the analysed system.

The stiffness of the

element g1, which is

situated between the attachment rope and the ballast weight, was defined as

10-times higher than the stiffness of the attachment rope.

A free fall of the

ballast weight was simulated using the contact element g2 with the vertical displacement vp, which was given in advance.

The solution of the

system response consists of two phases. Overhang of the guide, which is caused

by own weight, was determined in the first phase, using a static analysis and

applying the given initial pre-load. The response after the fall of the ballast

weight from height h was investigated

during the second phase, utilising the dynamic analysis applied for the given

configuration. The free fall of the load was simulated by a prescribed movement

of the nod G downward, whereby the

movement speed was significantly higher than the free fall speed.

The geometrical and

physical non-linearity was also taken into consideration during the

calculation. The geometrical non-linearity was given due to the unknown new

configuration of the system in every calculation phase. Therefore, the created

equations are non-linear with regard to unknown node displacements. The

physical non-linearity results from a non-linear dependence between the

deformation and the force in the rope.

The dynamic analyses

were performed by means of Newmark’s method. This implicit method enables

the inclusion of the damping characteristics of the contact elements in order

to simulate a fall damper. The value of time increments was chosen with regard

to the accuracy and stability of the solution. Every implicit method, that is,

including the Newmark’s method, offers a numerical stability of

calculation only in the case of linear methods. The numerical stability of the

calculation process can be lost during the solution of the non-linear methods

if the time step is chosen improperly, that is if it is too long. A possible

compromise offers the time increment, which is chosen from the interval 10-5

÷ 10-4 s. This was also applied in several performed analyses of

the Rayleigh damping:

![]() ,

(2)

,

(2)

whereby, in the matrix of damping C, it was considered the

coefficient a,

which is associated with the initial matrix of stiffness K0.

This coefficient was chosen from the range 0.001 ¸ 0.05. The damping, which is related to the matrix of mass M, was neglected, so the

coefficient b = 0.

The main task of this

analysis was to investigate the individual characteristics of the horizontal

belaying system in order to consider a necessity of changes concerning the

individual constructional modifications of the given system, which is utilised

in practice by the operator of the crane.

The individual analyses

were based on information obtained from realised measurements, principally from

information about the stiffness properties of the individual ropes and suspended

components of the personal protective equipment applied in the constructional

modifications of the horizontal belaying system. The tensile test was performed

in the case of the attachment textile rope with the diameter 11 mm and length

570 mm, which is delivered together with the safety belts of the type TIMUS

SAFETY: 048/414082023.

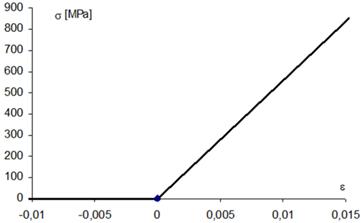

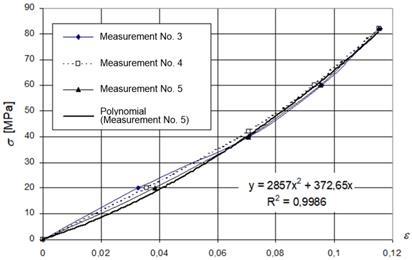

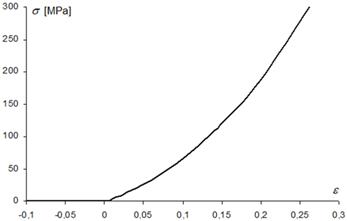

Working diagram of the

main rope Æ14 is presented in Fig.

2, working diagram of the textile attachment rope Æ 11 is given in Fig. 3 and the calculation of the working diagram of the

same rope is shown in Fig. 4.

The loading regimes of

the HBS were defined according to the technical standard STN EN 795. Evaluation

of the welding joints and screw joints in the individual constructional

modifications of the HBS was performed according to the STN EN 1993-1-8

(Eurocode 3: Design of steel structures. Part 1.8: Design of joints).

Fig. 2. Working diagram

of the rope Æ 14, used for

calculation

Fig. 3. Working diagram of the textile attachment rope Æ

11

Fig.4. Calculation of the working diagram of the textile attachment rope

Æ

11

2.2. Deflection of Rope

2.2.1 Deflection of Rope Caused by Own Weight

The technical standard

STN EN 795 determines a bearing capacity of the HBS of type C as the minimal

dynamic force 12 kN. The main task of the performed calculations was to

investigate what a heavy loading of the rope and joining elements corresponds

to this force. There were calculated reactions in the connecting points of the

horizontal rope, forces in the rope as well as the deflection of the rope

during loading by the vertical force 12 kN. This vertical force was acting in

various distances from supports using the pre-load of the rope with the values

from 0.2 kN to 20 kN. Simultaneously, it was calculated as a change of the

pre-load due to increase or decrease of the ambient temperature. The modulus of

elasticity, EL, of the rope was measured during the tensile test, basically

this value is EL = 55835 MPa. The used coefficient of thermal expansion was 1.2

x 10-5 K-1. The nominal cross-sectional area of the applied rope is 69.17 mm2

and own weight of the rope is 0.64 kg m-1, according to the

catalogue of the rope producer [22]. The rope was anchored between the steel

columns.

The calculations were

performed by means of the FEM method, applying the software product COSMOS/M,

version 2.7. The main rope Æ14 was simulated using

the bar elements of the type TRUSS2D [21].

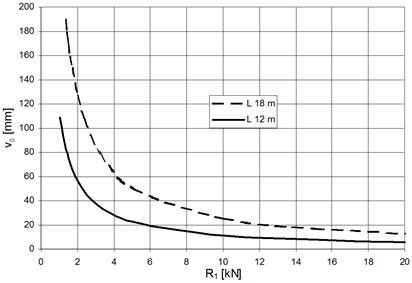

The values of the main

rope deflection, which is caused by own weight and by the pre-load forces

selected from the interval (0.2 kN ÷ 20 kN), are given in Tab. 1 (for

the rope with span length 12 m) and in Tab. 2 (for the rope with span length 18

m). Dependence of the main rope deflection on the pre-load force is illustrated

in Fig. 5.

These are the symbols

used in the tables:

L span length of the

rope.

F0 pre-load

of the rope at zero deflection (that is, pre-load without acting of the

weight).

v0 deflection of the rope

(deflection caused by the rope’s own weight).

v3 deflection

of the rope after increase of the ambient temperature about 50 K.

v4 deflection

of the rope after decrease of the ambient temperature about 50 K.

R1 force

in the rope at the deflection v0.

R3 force

in the rope after increase of the ambient temperature about 50 K.

R4 force

in the rope after decrease of the ambient temperature about 50 K.

Tab. 1

Deflection

of the rope with span length 12 m

|

L = 12 m |

|

|

|

|

|

|

|

F0 [kN] |

v0 [mm] |

v3 [mm] |

v4 [mm] |

R1 [kN] |

R3 [kN] |

R4 [kN] |

|

0,2 |

108,5 |

194,3 |

42,7 |

1,042 |

0,583 |

2,648 |

|

0,4 |

100,6 |

187,7 |

39,2 |

1,124 |

0,603 |

2,830 |

|

0,6 |

92,9 |

181,0 |

37,5 |

1,217 |

0,625 |

3,018 |

|

0,8 |

85,5 |

174,1 |

35,2 |

1,323 |

0,650 |

3,206 |

|

1 |

78,5 |

167,0 |

33,3 |

1,440 |

0,678 |

3,397 |

|

1,5 |

63,3 |

148,6 |

29,1 |

1,787 |

0,761 |

3,880 |

|

2 |

51,6 |

129,1 |

25,9 |

2,191 |

0,876 |

4,365 |

|

3 |

36,5 |

89,8 |

21,1 |

3,095 |

1,259 |

5,349 |

|

5 |

22,4 |

40,4 |

15,4 |

5,036 |

2,799 |

7,334 |

|

10 |

11,3 |

14,7 |

9,2 |

10,010 |

7,698 |

12,320 |

|

15 |

7,5 |

8,9 |

6,5 |

15,000 |

12,690 |

17,320 |

|

20 |

5,7 |

6,4 |

5,1 |

20,000 |

17,690 |

22,320 |

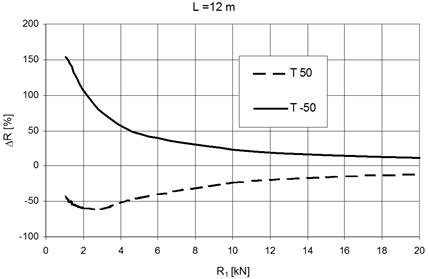

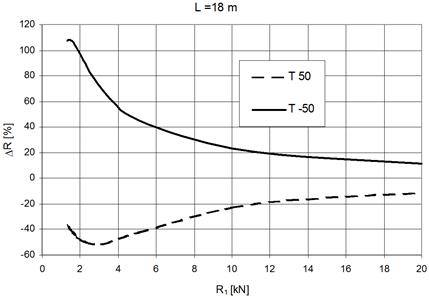

The graphs in Figures 6

and 7 illustrate rope deflection and influence of the changed temperature on

the pre-load value in the case of two rope lengths: 12 and 18 m. The line T 50

represents the percentage decrease of the force R1 after continual

increase of the rope temperature about 50 K, while line T –50

represents the percentage increase of this force after the decrease of the rope

temperature to about 50 K. It is evident that in the case of higher

pre-load level that there is reduced influence with the temperature changes.

Influence of the

temperature changes are important above all for such ropes, which are installed

out-of-door and exposed to weather conditions. The actual ambient temperature

should be taken into consideration during the initial pre-loading of the rope.

Tab. 2

Deflection

of the rope with span length 18 m

|

L = 18 m |

|

|

|

|

|

||

|

F0 [kN] |

v0 [mm] |

v3 [mm] |

v4 [mm] |

R1 [kN] |

R3 [kN] |

R4 [kN] |

|

|

0,2 |

189,5 |

304,8 |

91,4 |

1,343 |

0,836 |

2,783 |

|

|

0,4 |

179,1 |

295,7 |

86,1 |

1,420 |

0,862 |

2,953 |

|

|

0,6 |

168,9 |

286,4 |

81,3 |

1,507 |

0,889 |

3,128 |

|

|

0,8 |

158,8 |

276,9 |

76,9 |

1,602 |

0,920 |

3,306 |

|

|

1 |

149,5 |

267,2 |

72,9 |

1,707 |

0,953 |

3,487 |

|

|

1,5 |

126,6 |

242,4 |

64,4 |

2,010 |

1,050 |

3,949 |

|

|

2 |

107,4 |

216,6 |

57,5 |

2,367 |

1,175 |

4,423 |

|

|

3 |

79,4 |

164,7 |

47,2 |

3,201 |

|

5,388 |

|

|

5 |

50,1 |

87,0 |

34,6 |

5,080 |

2,924 |

7,355 |

|

|

10 |

25,4 |

33,0 |

20,6 |

10,020 |

7,717 |

12,330 |

|

|

15 |

16,9 |

20,0 |

14,7 |

15,010 |

12,700 |

17,320 |

|

|

20 |

12,7 |

14,4 |

11,4 |

20,010 |

17,690 |

22,320 |

|

Fig. 5.

Dependence of the rope Æ14 mm deflection on the pre-load force

Fig. 6. Influence of changed temperature on pre-load

of rope with the length 12 m

Fig. 7. Influence of changed

temperature on pre-load of rope with the length 18 m

2.2.2 Deflection of Rope Caused by the Loading

Force 12 kN

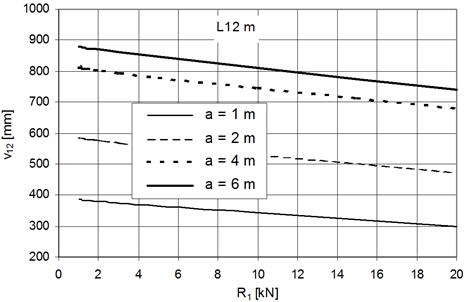

Deflection of the rope

in the point of action for the single vertical force with the value 12 kN

depends on the pre-load value R1 and on the point of action position

as well. Fig. 8 illustrates this dependence for the rope with length 12 m. The

symbol a, marks the distance of the point of action from the left end of the

rope. It is obvious that the position of the load influences the value of

deflection quite significantly, as such an influence of higher pre-load on

reduction of the deflection is non-significant.

Fig. 8. Dependence of

deflection on the acting point of the force 12 kN

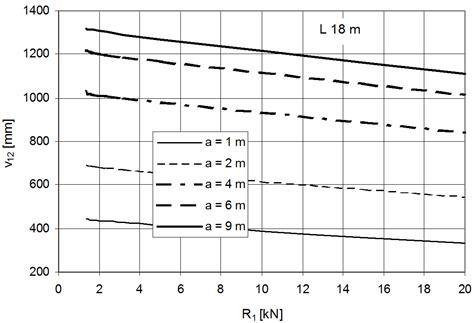

Analogical dependence of

the deflection on the load position, using various pre-load values for the rope

with length 18 m, is shown in Fig. 9.

Fig. 9. Dependence of

deflection on point of action position for the rope with span length 18 m

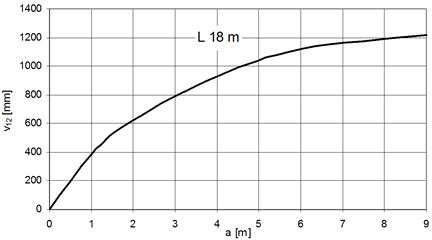

A maximal deflection is

recorded if the load is situated in the middle of the span length. Dependence

of the deflection on the load position (which is given by the distance a,

measured from the left support) is non-linear, according to Fig. 10.

Fig. 10. Dependence of rope deflection on position of

the load (using the pre-load value 10 kN and span length 18 m)

2.3. Horizontal Belaying

System with Rope Æ 14 mm

The following values of

the input parameters were used in order to simulate the process of capture in

the case of the falling load

·

span length of the anchoring guide 12 m

·

mass of the falling balance weight 200 kg

·

length of attachment rope 600

mm

·

number of attachment ropes 2

·

free-fall height 300

mm

These values were

applied during the performed calculations, the already obtained characteristics

of the steel wire rope, which is used as the anchoring guide and the

characteristics of the textile attachment ropes.

These mechanical

properties described earlier were measured during the experimental tests.

According to the calculated results, it is safe to assume that the force in the

anchoring guide, as well as the force in the attachment rope, together with the

maximal deflection of the balance weight, depends on the pre-load level in the

anchoring guide. This is also presented as an influence of the attachment rope

position on the anchoring guide.

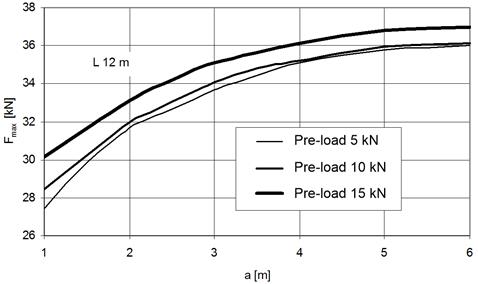

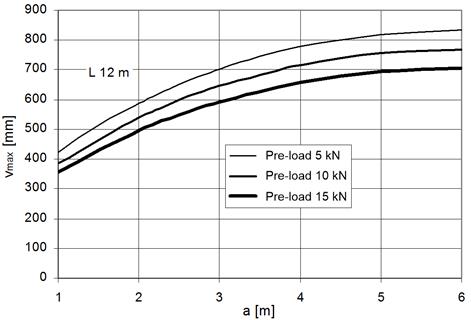

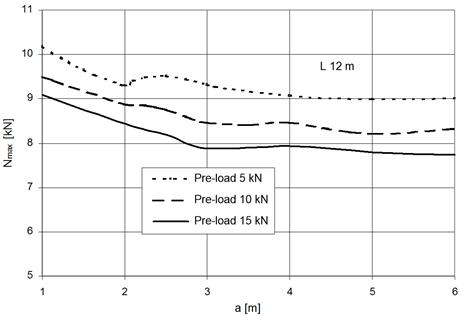

The graphs in Figures

11, 12 and 13 illustrate the influence of the attachment rope position, which

is given by the coordinate a (according to Fig. 1), on the dynamic response.

The highest force Fmax in the rope of the anchoring guide occurs in such

situation when the attachment rope is positioned in the middle of the guide

span length (Fig. 11). Analogically, the same is true for the maximal dynamic

deflection vmax of the ballast weight (Fig. 12). The highest force in the

attachment rope (in this case, it is a sum of the forces in the two attachment

ropes) occurs if the attachment rope is positioned at the end of the anchoring

guide (Fig. 13).

Fig. 11. Maximal force in the anchoring guide

rope with the span length 12 m

Fig. 12. Maximal deflection

of the rope with the span length 12 m

Fig. 13. Dependence of

maximal force in the attachment rope on its position

4. CONCLUSION

We introduced in this

article the possibility of increase labour safety of a specific machinery,

installed at a height, by means of a simple design solution and by use of

standard constructional components, for example, rolled shapes, rope, rope

clamps, rope sockets and tensioning screws.

The presented analyses were based on information

obtained from measurement of the stiffness properties of the ropes and

suspension elements which were utilised in the personal protective equipment

applied in the proposed design solutions of the HBS. It is presumed, according

to the obtained results, loading analyses and strength calculations of the given

HBS, that this system has the possibility of serving as anti-falling protection

for 2 or 3 persons. Hence, the dynamic loading of the HBS will be lower than as

defined in the technical standards [23] and [24].

The most unfavourable situation occurs if the

vertical loading force F is acting in the middle of the span length. The

limited application possibility of HBS is defined by internal prescriptions

based on the above-mentioned analyses and this requires an experimental

verification of the strength by means of a real test.

Acknowledgements

This article was elaborated in the

framework of the Grant Project VEGA 1/0110/18.

References

1.

Boroška Ján, Jozef

Hulín, Oldřich Lesňák. 1982. Oceľové laná. [In Slovak: Steel ropes]. Bratislava: Alfa. Publishing of technical and

economic literature.

2.

Boroška Ján. 2000. „Činitele ovplyvňujúce životnosť a bezpečnosť prevádzky oceľových lán”. Výskum, výroba a

použitie oceľových lán. [In Slovak: “Factors affecting the service life

and safety of the operation of steel ropes”. In Research, manufacture and use of wire ropes]. Faculty of Mining,

Technical University, Košice, Slovakia. ISBN: 80-7099-592-0.

3.

Torkar

M., B. Arzenek. 2002. „Failure of crane wire rope”. Engineering Failure Analysis 9(2):

227-233. ISSN 1350-6307.

4.

Costello

George A. 2003. „Mechanics of wire rope”. In Wire

& Cable Technical Symposium. 73rd

annual convention: 56-63. Wire

Association International, Inc. May 2003. Atlanta, Georgia, USA.

5.

Costello

George A. Theory of wire rope. New

York. Springer. ISBN 0-357-98202-7.

6.

Chaplin

Christopher Richard. 1995. „Failure mechanisms in wire ropes”. Engineering Failure Analysis 2(1):

45-57. ISSN 1350-6307.

7.

Starikov Maxim, Andrey

Beljatynskij, Olegas Prentkovskis, Irina Klimenko. 2011. “The use of

magnetic coercivity method to diagnose crane metalware”. Transport 26(3): 255-262.

8.

Velinsky

S.A. 1985. „General nonlinear theory for complex wire rope“. International Journal of Mechanical Sciences

27(718): 497-507. ISSN0020-7403.

9.

Giglio

Marco, Andrea Manes. 2005. „Life prediction of a wire rope subjected

to axial and bending loads”. Engineering

Failure Analysis 12(4): 549-568. ISSN 1350-6307.

10.

Imrak C. Erdem, Erdönmez Cengiz. 2010. „On the problem of wire rope model

generation with axial loading”. Mathematical

and Computational Applications 15(2): 259-268. DOI:

https://doi.org/10.3390/mca15020259.

11.

Stanova

Eva, Gabriel Fedorko, Michal Fabian, Stanislav Kmet. 2011. „Computer

modelling of wire strands and ropes Part I: Theory and computer

implementation”. Advances in

Engineering Software 42(6): 305-315. ISSN 0965-9978. DOI:

https://doi.org/10.1016/j.advengsoft.2011.02.008.

12.

Stolle Cody S., John Douglas Reid. 2011. „Development of a wire rope model

for cable guardrail simulation”. International

Journal of Crashworthiness 16(3): 331-341. ISSN 1358-8265. DOI:

10.1080/13588265.2011.586609.

13.

Velinsky,

S.A., G.L. Anderson, George A. Costello. 1984. „Wire rope with complex

cross sections“. Journal of

Engineerig Mechanics 110(3): 380-391. ISSN 0733-9399.

14.

Imanishi Etsujiro, Takao Nanjo, Takahiro Kobayashi. 2009. „ Dynamic simulation of wire rope with contact”. Journal of Mechanical Science and Technology 23(4): 1083-1088. ISSN 1976-3824.

15.

Paris

A.J., C.C. Lin, George A. Costello. 1992. „Simple cord composites“.

Journal of Engineerig Mechanics

118(9): 1939-1948. ISSN 0733-9399.

16.

Rudawska Anna, Hubert Debski. 2011.

„Experimental and numerical analysis of adhesively bonded aluminium alloy

sheets joints”. Eksploatacja i Niezawodnosc – Maintenance and Reliability

1(49):

4-10. ISSN 1507-2711.

17.

Gajdoš Ivan, Ján

Slota, Emil Spišák, Tomasz Jachowicz, Aneta Tor-Swiatek. 2016. „Structure and tensile

properties evaluation of samples produced by Fused Deposition Modeling”. Open Engineering 6(1): 86-89. ISSN 2391-5439. DOI: https://doi.org/10.1515/eng-2016-0011.

18.

Czech Piotr. 2011.

„Diagnosing of disturbances in the ignition system by vibroacoustic

signals and radial basis function - preliminary research”. Communications in Computer and Information

Science 239: 110-117. 11th International Conference on Transport Systems

Telematics (TST 2011). Katowice-Ustron, Poland, October 19-22, 2011. Modern Transport Telematics.

19.

Czech Piotr. 2012.

„Determination of the course of pressure in an internal combustion engine

cylinder with the use of vibration effects and radial basis function -

preliminary research”. Communications

in Computer and Information Science 329: 175-182. 12th International

Conference on Transport Systems Telematics (TST 2012). Katowice-Ustron, Poland,

October 10-13, 2012. Telematics In The

Transport Environment.

20.

Figlus Tomasz, Marcin

Stanczyk. 2016. “A method for detecting damage to rolling bearings in

toothed gears of processing lines”. Metalurgija 55(1): 75-78. ISSN:

0543-5846.

21.

Manual

to the software product COSMOS/M.S.R.A.C. Los Angeles. 2001.

22.

Product

catalogue of steel wire ropes. Wire and rope production factory

DRÔTOVŇA a.s., Hlohovec, Slovakia. 2001.

23.

STN EN 795: 1996. Osobné ochranné prostriedky proti pádu z výšky. Kotviace zariadenia. Bratislava. Úrad pre normalizáciu, metrológiu a skúšobníctvo Slovenskej republiky. [In

Slovak: STN EN 795: 1996. Personal fall

protection equipment. Anchor devices. Bratislava. Slovak Office of

Standards, Metrology and Testing].

24.

STN EN 364+AC(832622): 1997. Osobné ochranné prostriedky proti pádu z výšky. Kotviace zariadenia. Bratislava. Úrad pre normalizáciu, metrológiu a skúšobníctvo Slovenskej republiky. [In

Slovak: STN EN 364+AC(832622): 1997. Personal

fall protection equipment. Testing methods. Bratislava. Slovak Office of Standards, Metrology and Testing].

Received 03.03.2019; accepted in revised form 21.05.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License