Article

citation information:

Homišin, J. Static optimisation of

mechanical systems based on the method of extremal regulation. Scientific Journal of Silesian University of

Technology. Series Transport. 2019, 103,

15-29. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.2.

Jaroslav HOMIŠIN[1]

STATIC

OPTIMISATION OF MECHANICAL SYSTEMS BASED ON THE METHOD OF EXTREMAL REGULATION

Summary. A change in torsional stiffness of pneumatic tuners

can be achieved by changing the pressure of the gaseous medium in the course of the mechanical systems'

operation or while idle. Based on this statement, we tuned mechanical systems with torsional

vibration when they are either idle or when they reach stable condition during operation. The principle

of tuning mechanical systems with

torsional vibration during operation when their condition is stable lies

in the appropriate adaptation of basic dynamic properties (dynamic torsional

stiffness and damping factor) of the pneumatic tuner to the dynamics of the

system. This was achieved with a control system that helps create a closed

control feedback loop. In this way, we can continuously change, that is, adapt

the dynamic properties of the pneumatic tuner to the dynamics of the mechanical

system so that no dangerous torsional vibrations occur while the system is in

operation mode.

Keywords: static optimisation of

mechanical systems, method of extremal regulation, continuous tuning of

mechanical systems

1. INTRODUCTION

Change

in the torsional stiffness of pneumatic tuners can be achieved by changing the

pressure of the gaseous medium, either in the course of operation or when the

mechanical systems are idle. This implies the two proposed ways of tuning

mechanical systems with torsional vibration (MSTV):

o

tuning mechanical systems with torsional

vibration when idle, thus ensuring the condition of tuning the said systems.

o tuning

mechanical systems with torsional vibration during operation when they are in

stable condition, thus ensuring the condition of continuous

tuning of the said systems.

The principle of tuning

the mechanical systems during operation when their condition is stable lies in

the appropriate adjustment of the pneumatic tuner’s basic dynamic

properties (dynamic torsional stiffness and damping coefficient) to the

dynamics of the system. This is ensured with a control system that helps create

a closed control feedback loop. In this way, we can continuously change, that

is, adapt the dynamic properties of the pneumatic tuner to the dynamics of the

mechanical system so that no dangerous torsional vibration occurs during the

system operation mode.

The proposed methods of

tuning mechanical systems are possible to apply due to the control circuits and

control systems, for which the author has been granted patent protection[2], and they can be

implemented as follows:

· via a control system

that ensures a continuous change in the characteristics of the pneumatic

couplings.

· by means of a control

system that enables a continuous tuning of the mechanical system.

· by applying a pneumatic

coupling with an additional control system.

· through static optimisation based on the method

of extremal regulation.

· by using a

self-regulating pneumatic coupling.

2. BASIC PRINCIPLE AND FOUNDATION

OF STATIC OPTIMISATION OF MECHANICAL SYSTEMS BASED ON THE METHOD OF EXTREMAL

REGULATION

As already mentioned,

dangerous torsional vibration is very common in mechanical systems driven by

pistons, acting in the role of either the driving or the driven aggregates.

Intense torsional vibration causes excessive dynamic stress to the entire

machine. For this reason, a justified need exists to control dangerous

torsional vibration in these mechanical systems and the mechanical jitter

generated thereby. Currently, this problem is solved by the appropriate

adaptation of dynamic properties of the flexible shaft coupling to the dynamics

of the system. This means that the mechanical system must be suitably

dynamically tuned in advance to the main harmonic componet of the piston

machine.

The aim is to achieve

the right resonance from the main harmonic component, that is, the critical

speed exists at a sufficient distance from the working speed range of the

machine in question.

However, the present

tuning method will only be suitable if there are no unforeseen (accidental)

failure effects during the system's operating mode. That is, if there is no

mechanical failure, especially of the piston machine.

In the event of failure

of the piston machine [1], [2], [3], [4], [5], [6] highly intense resonance of

components with minor – lower harmonic excitation occurs in the operating

mode, resulting in critical speed.

It can be deduced from

the dynamic point of view that it is possible to characterise the MSTV as

systems most often operating in the supercritical region with relatively fast

transition upon their start up and shut down. In terms of control, however,

they belong to a group of controlled systems with incomplete information.

Incompleteness of information is manifested mainly in the area of unforeseen

failure effects, that is, in the area of accidental failures.

Drawing on the MSTV

characteristics, as well as on the advantages and disadvantages of the current

solution to the given problem in the area of dangerous torsional vibration [7],

[8], we proposed to control the torsional vibration and the mechanical

vibration generated thereby through static optimisation (direct optimisation) based on the method of extremal regulation during stable operating condition.

Our main criterion for optimising any MSTV is to

achieve minimum torsional vibration values and minimal mechanical vibration

generated consequently.

In this respect, it

should be noted that the static optimisation

of MSTV by the method of extremal regulation is currently, not being

practically implemented at all. This is mainly due to the fact that basic

conditions have not yet been established for the possible implementation of

this method. However, the existence of a pneumatic torsional vibration tuner, that is, an element that is able

to change its basic characteristics during operation, in particular, its

dynamic torsional stiffness, provides all the prerequisites for enabling

extremal regulation in MSTV.

Implementing static optimisation in MSTV requires the

following conditions be met:

v

MSTV must meet the basic requirements for continuous tuning, that is,

tuning the system while it is running in a stable condition.

v

It is not necessary to know the mathematical model controlling the MSTV

to carry out their static optimisation.

Nevertheless, it is necessary to know whether the purpose function of the system (function of input and output

variables) has an extreme [9], [10],

[11], [12], [13], [14], [15], [16].

2.1. Characteristics and

execution of continuous tuning of mechanical systems with torsional vibration

Drawing on the nature of

the patents[3], it is clear that the

system at hand must include a pneumatic torsional tuner[4] regulated by the

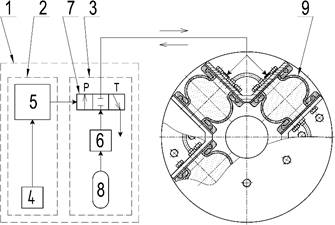

control system[5] of Fig.1.

Fig.

1.

Schematic representation of the regulation of continuous change in the characteristics

of the pneumatic tuner by means of a control system.

Fig.1 is a schematic representation of

the control system and a schematic representation of how the pneumatic

torsional tuner is controlled.

The control system (1)

consists of a controlling (2) and an actuating subsystem (3). The

controlling subsystem (2) features a

microprocessor (5) and a piezoelectric sensor of mechanical vibration

acceleration (4). The sensor (4), located on the mechanical

system, sends an electrical signal to the microprocessor (5),

proportional to the system's mechanical vibration. The actuating subsystem (3)

consists of an electromagnetic switchboard (7), which is connected to

the gaseous medium reservoir (8) via a control valve (6). By

switching the two-position electromagnetic switchboard (7), the

microprocessor (5), which constitutes the basic control component of the

entire control system (1), causes it to move, thereby increasing or

decreasing the pressure of the gaseous medium in the compressive space of the

pneumatic torsional vibration tuner through the supply circuit P or

discharge circuit T.

When the mechanical

system operates in an unfavourable operating mode, the whole system starts

jittering due to the magnitude of torsional vibration, the acceleration of which

is measured by a mechanical vibration sensor (4). After the

microprocessor (5) receives and evaluates the electrical signal

proportional to the system's mechanical jitter, the switchboard (7) is

switched to the supply position P or a discharge position T. As a

result, the pressure of the gaseous medium in the pneumatic elastic elements (9)

of the pneumatic tuner's compression space changes, which represents a

continuous change in its basic dynamic properties, that is, dynamic torsional

stiffness, while the mechanical system is running.

The result of the

operation of the control system is that, due to a continuous change in the

pressure of the gaseous medium in the pneumatic tuner, a change in its basic

dynamic property, that is, dynamic torsional stiffness is achieved. By changing

the dynamic torsional stiffness, the intrinsic frequency of the system changes,

thus, adapting to the frequency of the i-th harmonic component of the load

torque so that the system does not operate in resonance with any torque excitation

component, that is, until the following condition is met:

![]() (1)

(1)

2.2 The trend of the special purpose

function of the implemented mechanical system with

torsional vibration

As part of the basic requirements set out, in the static optimisation of MSTV implemented through the application of extremal regulation, it

is necessary to know in advance whether the trend of the system's special

purpose function will have an absolute or a relative minimum in the set

operating mode. With respect to the above requirement, the trend of the special

purpose function at the implemented MSTV was to be identified and verified. The

trends of the special purpose function were established theoretically, that is,

by calculation, based on the theoretical model and practically, on the basis of

experimental measurements performed.

2.2.1 Special purpose function's trends

established by calculation

The calculated trends of the MSTV special

purpose function are shown in Fig. 2a,

b, c. They represent the resonance curve of the twist angle φd of the pneumatic tuner

dependent on the pressure of the gaseous medium ps inside of it. The twist angle φd ,

expressed by relation (2),

characterises the output, that

is, the controlled quantity, and

the pressure of the gaseous medium ps, the input, that is ps say, the action causing

variable.

![]() (2)

(2)

The amplitude value of the

harmonic component of the twist angle, expressed by (3), mostly depends on the frequency ratio of the i-th

harmonic component of the load torque and the intrinsic frequency of the system

(![]()

(3)

(3)

The intrinsic frequency ![]() is influenced by

the dynamic torsional stiffness, which according to (4), is a function of the

pressure of the gaseous medium ps in the pneumatic tuner.

is influenced by

the dynamic torsional stiffness, which according to (4), is a function of the

pressure of the gaseous medium ps in the pneumatic tuner.

![]() (4)

(4)

a)

b) c)

Fig. 2. The trends of the special

purpose functions of the dynamic twist angle φd dependent on the pressure of ps gaseous medium ps in the pneumatic

torsional tuner.

The trends of the

special purpose function were construed at constant excitation speed n =

400 min-1 (Fig.

2a), n = 760 min-1 (Fig. 2b) and n = 1100 min-1 (Fig. 2c) with a simulated fault

variable characterised by uneven excitation of the individual compressor

cylinders. In the present case, it was understood that the first and third

cylinders operate at 15%

greater power and the second cylinder at 15%

less than the average power per cylinder.

Based

on the above-mentioned trends of the special purpose function of the modelled

MSTV, it can be stated that they have clear relative minimums.

2.2.2 Trends of the special purpose

function of the system established experimentally

Practical measurements were made on the mechanical system implemented as

per Fig. 3. The trends of the

dynamic load torque component were measured by a torque sensor (8) and

simultaneously, the jitter generated in the mechanical system was measured by a

piezoelectric sensor (12).

Fig.

3.

Implemented mechanical system with schematic interconnection of the measuring

apparatus applied.

The measurements were

made assuming balanced excitation of the individual compressor cylinders at a

constant speed of n = 760 min -1. The pressure of the gaseous

medium in the pneumatic tuner was changed during the measurements to the extent

of ps = 0 ÷ 700 kPa with a change after 100

kPa.

After amplification by

the amplifier (9) and filtering by the band frequency filter (10),

the electrical signal from the torque sensor (8) was recorded by a

measuring tape recorder (11). Similarly, the electrical signal from the

piezoelectric sensor (12), located on the torque sensor bearing housing,

was simultaneously recorded by the tape recorder (11) after

amplification by the amplifier (13) and the band frequency filter (14).

The recorded signals

were further processed by a narrowband spectral analyzer, with the output in

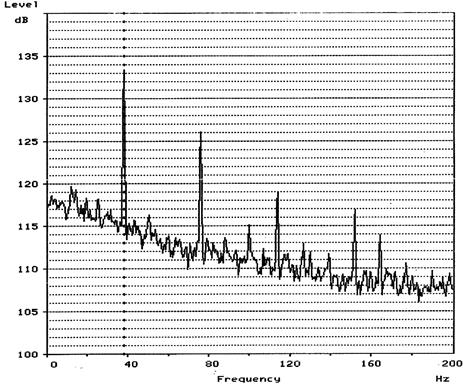

the form of the frequency spectrum characteristic trends of the AM

dynamic load torque component (Fig. 4)

and the jitter amplitudes of the ACH system (Fig. 5).

Fig.

4.

Frequency spectrum characteristic of torque load AM when

applying a pneumatic tuner with gaseous medium pressure ps = 400 kPa.

Fig.

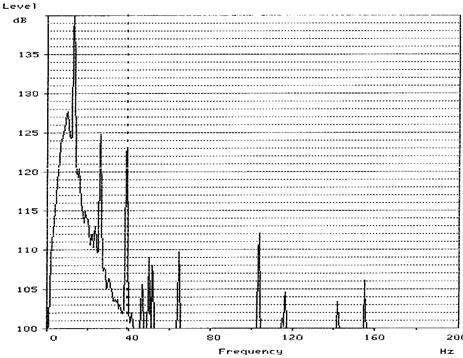

5. Frequency

spectrum characteristics of the ACH amplitudę jitter

when applying the pneumatic tuner with the gaseous medium pressure of ps

=

400 kPa.

From the results of the practical measurements, it is clear that the

most significant amplitudes were at the first, second and third harmonic

components of the speed frequency. Since the amplitudes of the first and second

harmonic components were influenced by the imbalance of the rotating parts and

the misalignment of the shafts of the given system, the evaluation will show

the results of

the frequency spectrum characteristics of the torque amplitude AM

(Fig. 4) and the mechanical jitter of the ACH system (Fig.

5) shall relate to the amplitude of the third

harmonic component. The reason behind this is the fact that the third harmonic

component of the rotational frequency manifests itself mainly by the action of

the torsional vibration generated in the mechanical system (by the action of

the excitation device, in our case the compressor).

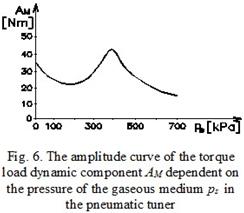

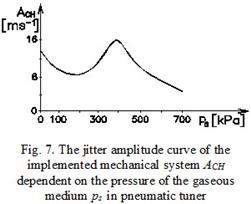

Amplitude curves of the load torque's dynamic component AM were processed from the frequency spectrum characteristics obtained (Fig. 6) and from the ACH jitter amplitude (Fig. 7) dependent on the pressure of

the gaseous medium in the pneumatic tuner.

The trend of Fig. 6 or Fig. 7 is understood to be the

trend of the output variable AM or

ACH,

dependent on the input variable ps, hence, as a special purpose function of

the implemented MSTV. The figure shows that the dependence of AM =

f(pS) and ACH

= f(pS) has its minimum extreme in the range of the

gaseous medium pressures between ps = 200 kPa and 700 kPa.

2.2.2. Control circuit and control

algorithm to ensure static optimisation of mechanical systems with torsional vibration

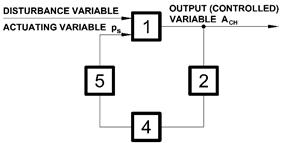

Static optimisation of MSTV can be achieved by the method of extremal

regulation by step change in the action variable according to the control

circuit as shown in Fig. 8[6].

The control circuit (Fig. 8) consists

of a controlled MSTV (1), a piezoelectric sensor of mechanical jitter (2),

which sends an electrical signal to an extremal controller (4),

proportional to the mechanical jitter of the ACH. Through

built-in control algorithm (Fig. 9), the extremal regulator processes the

electrical

signal and with the aim to search for the minimum extreme, it controls the

actuator (5), characterised in Fig.

1, through a two-position electromagnetic switchboard (7). By

controlling the actuator, we regulate the action variable ps, that is, by supplying the gaseous

medium or by discharging it, we increase or reduce the pressure in the

pneumatic tuner.

Fig. 8.

A control circuit to ensure extremal control in a mechanical system with

torsional vibration.

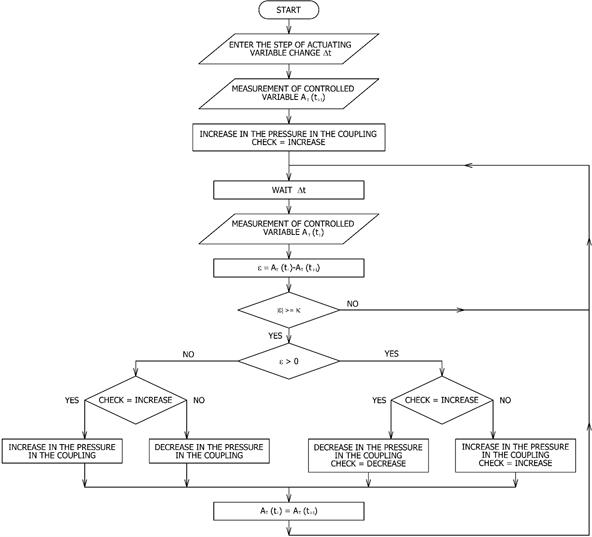

It is obvious from the

control algorithm (Fig. 9) that after determining the time between two

consecutive measurements ∆t and after determining the bandwidth of

the controlled variable u deadband, either the first value

of torsional vibration AT (ti–1) or of

mechanical jitter ACH (ti–1) is measured. After

measuring another AT (ti) or ACH (ti ) value,

the static optimisation of the MSTV, controlled by the

extremal regulation, will comply with the said algorithm.

Fig. 9.

Algorithm controlling the extremal regulation.

3. results of the application of extremal

regulation to the implemented mechanical system WITH TORSIONAL VIBRATION

Fig.

10 shows

the dynamic tuning of the implemented mechanical system by pneumatic torsional

vibration tuner, via the amplitude curves of the dynamic components of the

twist angle of the pneumatic tuner dependent on the speed (a, b, c). At

the same time, the figure also shows the influence of the secondary harmonic

components on the magnitude of the torsional vibration of the mechanical

system, which is presented as dynamic characteristics trends b, c.

Trend a shows the

dynamic characteristic in case of a trouble-free operation of the piston

machine. The failure rate of the piston machine is shown as characteristics of

the trend b, c. The trend b characterises the failure of

uneven excitation of the individual cylinders of the piston machine (in the

range ± of 15%), while the trend c is characterised by the failure of one

cylinder that ceased to operate. The individual trends are processed in the

above figure with the pressure of the gaseous medium in the pneumatic tuner

being ps = 700 kPa.

Fig. 10. Amplitude

curves of dynamic components of the twist angle φd of the pneumatic tuner dependent on the speed n.

Fig.10 shows that the

condition of removing the critical speed to a sufficient distance from the

operating speed range is met by the trends of all characteristics. This means

that MSTV has been suitably dynamically tuned in advance to the main harmonic

component (i = 3) of the torque load.

Within the operating

speed range (n =1000 ÷ 2500 min-1), the dynamic

characteristic is of decreasing nature and the magnitude of torsional

vibration, characterised by a dynamic twist angle, ranges from φd = 0,65° ÷

0,25°. This is due to the fact that, in case of trouble-free operation of the

piston machine, the secondary harmonic components (i=1 and 2) have a very low

torsional excitation potential. Their potential increases if failure of the

piston machine occurs (characteristics b, c). In the event of uneven

excitation of the individual compressor cylinders, at the critical speed

locations for i = 2 , the magnitude of the torsional vibration increases

almost 13-fold compared to the

failure-free operation of the piston machine, which represents

the dynamic twist angle φd = 1,15° (φd = 0,7° for i=1),

while in the case one cylinder is out of order, it reaches up to 60-fold value, which causes an

increase in the dynamic twist angle to φd =4,1° (φd = 3° for i=1).

The momentary reduction

of dynamic load by controlling the torsional vibration would be of great

importance for each MSTV in such cases.

The presentation of how

torsional vibration was controlled, as well as mechanical jitter of the system

at hand by static optimisation

based on the method of extremal

regulation was performed under the following conditions:

· during stable operating

mode of a given system, that is, at constant operating speed in the range of n

= 1000 ÷ 2500 min-1 characterised in Fig. 11 and Fig. 12 in positions (1) to

(10).

· provided the piston

machine fails when one cylinder stops working.

Fig.

11. The

result of the static optimisation of the implemented system, characterised by

the change in the value of the action variable pS at the speed range n, dependent on the discrete time

k.Dt.

Fig.

12. The

result of the static optimisation of the implemented system, characterised by a

change in the value of the controlled variable AT, at the operating speed range

n, dependent on the discrete time k.Dt.

The results of the

static optimisation are achieved by controlling the pressure of the gaseous

medium ps in the pneumatic tuner (Fig.11) and then regulating the

torsional vibration magnitude of the AT system (Fig.12),

that is, by stabilising it, particularly, in ten random operating modes. Given

that this is a simulation of extremal regulation, any change in the working

mode, that is, the operating speed is in this case at hand done by a jump.

Let us assume the MSTV

operates, for example, in the fifth operating mode, characterised by the speed n5

= 2500 min-1. In this case, the pressure of the gaseous

medium in the pneumatic tuner stabilised at pS5 = 278 kPa

and in terms of torsional vibration, the system is stabilised when the value of

AT5 = 0,01 rad (0,57°). By changing the operating

mode from n5 = 2500 min-1 to n6 =

1400 min-1, the magnitude of torsional vibration increases from AT5

= 0,01 rad to AT6 = 0,03 rad (2°).

Through monitoring the given system, the optoelectronic sensor sends an

electrical signal to the extremal controller. Based on the results of the

control algorithm (Fig. 9) of

the extremal regulator, the pressure of the gaseous medium is reduced from

pS5 =278 kPa to the stable value of pS6*=219

kPa. By varying the overpressure of the gaseous medium, the dynamic

torsional stiffness of the pneumatic

tuner kd,

is regulated, resulting in a change in the system's inherent frequency![]() . The amplitude value of the dynamic component of the pneumatic tuner

twist angle according to (2)

depends basically on the frequency ratio of

the i - th harmonic component of the torque load and the

intrinsic frequency of the system (iw/W0). This means that the

magnitude of the torsional vibration of the mechanical system AT, characterised by the dynamic component of the twist angle, will

depend on the change in the pressure of the gaseous medium in the compressor

space of the tuner.

. The amplitude value of the dynamic component of the pneumatic tuner

twist angle according to (2)

depends basically on the frequency ratio of

the i - th harmonic component of the torque load and the

intrinsic frequency of the system (iw/W0). This means that the

magnitude of the torsional vibration of the mechanical system AT, characterised by the dynamic component of the twist angle, will

depend on the change in the pressure of the gaseous medium in the compressor

space of the tuner.

In this particular case,

the reduction of the pressure of the gaseous medium (pS5 to pS6*)

as an action variable causes a reduction in the magnitude of the torsional vibration,

that is to say, the controlled quantity from the AT6 = 0,035 rad to the stable value of AT6*=

0,025 rad (1,4°).

It can be inferred from

the above that in the sixth operating mode, in terms of torsional vibration

magnitude, the MSTV stabilised at the value of AT6* = 0,025 rad.

Since the parameters of

regulating the system's dynamic characteristics are not yet known (they are

currently being established in experimental measurements), the values (n, pS , AT) are shown in Fig. 11 and Fig. 12, respectively, depending on the discrete time k.Dt for 400 simulation steps.

4. CONCLUSION

Among other things, the results of this paper confirm that dangerous

torsional vibration of any mechanical system can be reduced to an acceptable

level by suitably adapting the dynamic properties of the pneumatic torsional

tuners. This means that mechanical systems with torsional vibrations need to be

pre-tuned or tuned in advance. In order to tune the mechanical systems with

torsional vibrations, it is necessary to do a detailed dynamic calculation in

terms of torsional vibration. If powerful turbocharged diesel engines are used

in mechanical systems, the dynamic calculation is not sufficient only for

balanced excitation of the individual engine cylinders. It must be borne in

mind that during a system operation mode, unforeseen (accidental) fault effects

may occur, most often characterised by a failure of the piston device itself.

The excitation of individual cylinders of the diesel engine is practically

uneven, and at the same time, a cylinder that stops working is a very frequent

failure effect of the piston device. As a result of this, there is a clear

increase in torsional vibration of the mechanical system and the entire device

jitters. This causes increased dynamic stress on the individual parts of the

mechanical system and, in particular, of the flexible shaft coupling, as being

relatively the weakest part of the mechanism.

Reining in dangerous torsional vibration of mechanical systems operating

with a wide range of revolutions is currently done by using very flexible

couplings with appropriately chosen nonlinear characteristics. Only some types

of flexible couplings are able to meet this requirement because not all types

of couplings enable reaching sufficiently low torsional stiffness while

maintaining sufficiently suitable strength properties. The torsional stiffness

and strength properties depend on the shape of the elastic element and the

material from which the elastic element was made. At the same time, it should

be noted that any linear or non-linear flexible coupling currently used has

only one characteristic. This fact then translates into only one trend of its

inherent speed frequencies in the Campbell diagram. To change the

characteristics of the flexible coupling to fit its dynamic properties with the

dynamics of the system means to use another element of the flexible coupling or

to use another flexible shaft coupling. In any case, fatigue and ageing of

elastic materials cannot be overlooked, which ultimately greatly affect the

original dynamic properties of the coupling. Thus, the transience of dynamic

properties of elastic couplings caused by ageing and fatigue of their elastic

elements, as well as the frequent failure of some other members of the system, causes

the pre-tuned mechanical system with torsional vibration to misalign. In such a

case, its tuning member, that is, the flexible shaft coupling is in no position

to eliminate or reduce increasingly dangerous torsional vibration.

In view of the above and with the aim of tuning the

mechanical systems with torsional vibration to limit dangerous torsional

vibration, we have proposed using the pneumatic torsional tuners developed by

us. These pneumatic tuners do not have one, but a whole range

of characteristics, as well as a range of the typical ones. The properties of

these tuners are mainly influenced by the change in the pressure of the gaseous

medium in its compression space.

Based on the results of the

experimental verification, we noted that by changing the pressure of the

gaseous medium in the compressor space of the pneumatic tuner, change in its

dynamic torsional stiffness was achieved, which had a decisive influence on the

system's inherent frequency. The essence of the principle of tuning mechanical

systems with torsional vibration with pneumatic tuners lies in the adaptation

of the intrinsic angular frequency of the mechanical system to the excitation

angular frequency, so no resonance condition emerges during the system's

operating mode and consequently, no dangerous torsional vibrations occur.

Based on the results of the analysis of balanced excitation, uneven

excitation of individual engine cylinders and the failure of one cylinder,

which stopped working, it can be stated that the introduced pneumatic tuner has

met all the requirements for its application in mechanical systems with

torsional vibration with constant operating speed and operating speed range. At

the same time, it was also confirmed that it is possible to reduce the

unfavourable consequences of unforeseen breakdown effects occurring in

mechanical systems by optimising the mechanical systems with torsional vibration as

proposed. The optimisation in question is a static optimisation of the

mentioned system during operation in a stable condition, which we proposed to

ensure that by using the method of extremal regulation through the step change

in the action variable. The results of the simulation confirmed that the static

optimisation of the mechanical systems by using the indicated method translates

into reduction in dangerous torsional vibration in any mechanical system with

torsional vibration.

Finally, it can be argued that the proposed manner of tuning (continuous system

tuning) in operation can be applied wherever the need to prevent dangerous

torsional vibrations of mechanical systems exists. The presented results

confirm that these tuning methods can contribute to increasing the technical

level and operational reliability of all mechanical systems with torsional

vibration into which they are incorporated.

Acknowledgements

This paper was written within the framework of the Grant project VEGA

1/0473/17 “Research and development of technology for homogeneous charge

self-ignition using compression in order to increase engine efficiency and to

reduce vehicle emissions.“

References

1.

Böhmer Jürgen. 1983. „Einsatz elastisher

Vulkan-Kupplunen mit linearer und progressiver Drehfedercharakteristik”.

[In German: „Use of elastic volcano couplings with linear and progressive

torsion spring characteristics”]. Motortechnische Zeitschrift 44(5): 21-24.

2.

Lunke Martin, Beeftink g. Bernd.

1983. „Einsatz hochelastischen Kupplungen in energiesparenden

Schiffsantriebsanlangen”. [In German: „Use of highly flexible

couplings in energy-saving marine propulsion systems”]. Schiff und Hafen 4(35): 23-32.

3.

Zoul Václav.

1982. „Některá hlediska vývoje pružných

spojek pro soustrojí s naftovými motory”. [In Czech: „Some

aspects of development of flexible couplings for diesel engines”]. Strojírenství

32(6/7): 21-28.

4.

Lacko Pavol, Vladimír

Lacko. 2000. „Continuously driven rezonance”. Strojárstvo 42(3/4): 127-135.

5.

Zoul V., P.

Utěkal. 1978. „Výskum vlastností nelineárni

pružné spojky”. [In Slovak: „Research of properties of nonlinear

flexible coupler”]. Strojírenství

28(5): 25-34.

6.

Ubartas M., V. Ostaševičius, S. Samper, V. Jūrėnas,

R. Daukševičius. 2011. „Experimental investigation of

vibrational drilling”. Mechanika

4: 368-373.

7.

Kubík S. 1982. Teorie

automatického řízení II. (Optimální,

adaptivní a učíci se systémy). [In Czech: Theory of Automatic Control II. (Optimal,

Adaptive, and Learning Systems)]. Praha:

SNTL.

8.

Rastrigin A.A. 1974. Sistemy extremaľnogo upravlenija. [In Rusian: Extreme management systems]. Moscow: FML.

9.

Pešík L., Němeček P. 1997. Identification of the dynamic system of a machine with an elastic base.

McNU 97, Chicago, USA.

10.

Yubao S., W. Jihong, Y. Dianlong, W. Xisen. 2013. „Analysis and

enhancement of torsional vibration stopbands in a periodic shaft system”.

Journal

of Physics D: Applied Physics No 46

145306: 7-13. ISSN 0022-3727.

11.

James D. Van de Ven, J. Cusack. 2014. „Synthesis and baseline

testing of a digital pulse-width-modulated clutch”. Mechanism and

Machine Theory 78: 81-91. ISSN 0094114X.

12.

Mehlan A. 1996. „Hochelestische Kupplungen”. [In German:

„Highly elastic couplings”]. Antriebstechnik 35(11): 27-33.

13. Sága M., L.

Jakubovičová. 2014. „Computational analysis of contact stress

distribution in the case of mutual stewing of roller bearing rings”. Novel Trends in Production Devices and

Systems, Applied Mechanics and Materials 474: 363-368.

14.

Czech P. 2011. „Diagnosing of disturbances in the ignition system

by vibroacoustic signals and radial basis function - preliminary

research”. Communications in

Computer and Information Science 239: 110-117. 11th International

Conference on Transport Systems Telematics (TST 2011). Katowice-Ustron, Poland,

October 19-22, 2011. Modern Transport

Telematics. DOI: https://doi.org/10.1007/978-3-642-24660-9_13.

15. Ostaševičius

V., I. Milašauskaitė, R. Daukševičius, V.

Baltrušaitis, V. Grigaliūnas, I. Prosyčevas. 2010.

„Experimental characterization of material structure of piezoelectric

PVDF polimer”. Mechanika 6:

78-82.

16. Leskova Andrea, Hubert

Jurjewicz, Patrik Lenghart, Peter Bacik. 2018. “Current challenges of

digital technologies”. Komunikacie

1a. ISSN: 1335-4205.

Received 21.02.2019; accepted in revised form 19.05.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License