Article

citation information:

Szczucka-Lasota, B., Węgrzyn,

T., Lukaszkowicz, K. Low alloy steel shaft surface

regenerative welding with micro-jet cooling. Scientific Journal of Silesian University of Technology. Series

Transport. 2019, 102, 205-215.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.102.17.

Bożena SZCZUCKA-LASOTA[1],

Tomasz WĘGRZYN[2],

Krzysztof LUKASZKOWICZ[3]

LOW

ALLOY STEEL SHAFT SURFACE REGENERATIVE WELDING WITH MICRO-JET COOLING

Summary. In this

paper, the effect of surface preparation after innovating welding technology

with micro-jet cooling was reported. Substantial information about parameters

of steel machine elements surfacing with the micro-jet cooling process was

given. Recorded evidence concerning the influence of various micro-jet

parameters on the metallographic structure of the machine shaft after surface

welding was taken. There were tested metallographic and tribology properties of

welds. The tribology interactions of a solid shaft surfaces were examined after

surface welding.

Keywords: welding, micro-jet cooling, metallographic

structure, wearing

1. INTRODUCTION

The purpose of metal

surfacing is to obtain the best possible coating of the welding element.

Usually, after regeneration, machine components regain good operating

properties. Crankshafts are subjected to wear due to prolonged friction with

cooperating parts. For example, the shaft of the gearbox should be regenerated

in many vehicles after passing 150 Mm, and the shafts of mining heading

machines regenerate only after 4 months of intensive exploitation, unless the

head of the combine has contact with hard increments (then exploitation time of

mining combine elements will be even shorter) [1,2]. The surface welding

process is mainly and often used to apply hardness or wear-resistant layer of

base metal [3]. It is a very important method of extending the life of

machines, tools, and construction equipment. The main goal of the paper is to

explore the possibilities of surfacing with micro-jet cooling. For welding, the

machine parts with the use of micro-jet cooling, only welding processes in

which no slag is formed can be used. The biggest application of micro-jet

cooling takes place in the Metal Inert Gas (MIG), Metal Active Gas (MAG) and

Tungsten Inert Gas (TIG) processes. The metallographic structure was analysed

in terms of micro-jet parameters. For getting various amounts of ferrite,

bainite and martensite in this welding method, it is necessary to determine the

main parameters of the process such as:

·

the diameter of the stream of the micro-jet injector.

·

type of micro-jet gas or gas mixture.

·

micro-jet gas

pressure.

·

a number of jets.

Welding with micro-jet

technology was very carefully tested for low alloy welding [4,5]. In low alloy

steel weld, mechanical properties of weld correspond with the chemical

composition and metallographic structure [6,7]. In the case of hardfacing, it

is important to obtain a martensitic structure in order to increase the

hardness of the coating and their resistance to abrasive wear [8-10].

The goal of this paper

is to describe the possibilities of shaft MAG surface welding process with

micro-jet cooling, which allows obtaining the various content of ferrite,

martensite, bainite. In the case of ferrite, it is important that the grain is

not as small as possible, which translates into better tribological properties

of regenerated shafts and does not lead to fissures. In weld metal deposit

there are three morphological varieties of ferrite: grain boundary ferrite,

side place ferrite and acicular ferrite, which is the most advantageous due to

the small grain size.

2. MATERIALS AND METHOD

A test stand for hardfacing was

made. To obtain the various amount of ferrite, martensite and bainite in shaft

surface weld, it was installed through a welding process with micro-jet

injector with a variable number of micro-streams. The diameter of streams was

on the level of 50 µm and 60 µm. To analyse the surface welding

with micro-jet cooling, there were chosen shafts of 40NiCrMo6 steel with a diameter

of 34 mm. An example of a machine shaft supplied for regenerative welding with

the use of micro-jet cooling is shown in Figure 1.

Surface weld was

prepared by welding with micro-jet cooling with varied parameters. Two

micro-jet gases (nitrogen and helium) were tested in the cooling process just

after surface welding. There were also other varied important micro-jet

parameters: gas pressure, micro-jet gas pressure and micro-jet diameter. The

main data about the parameters of welding were shown in Table 1. MAG surface

welding process with micro-jet cooling was carefully tested. Helium was chosen

for the micro-jet cooling because of its good cooling properties. Nitrogen was

used for the micro-jet cooling, under the assumption that there could be observed

slight nitriding of the surface welds.

Fig. 1.

A

machine shaft supplied for regenerative welding with the use of micro-jet

cooling

Tab. 1

Parameters

of the welding process.

|

No. |

Parameter |

Value |

|

1. |

Diameter of wire |

1.2 mm |

|

2. |

Standard current |

220 A |

|

3. |

Voltage |

24 V |

|

4. |

Shielding welding gas |

80%Ar+20%CO2 |

|

5. |

Kind of tested

micro-jet cooling gas |

1 – He |

|

6. |

Micro-jet gas pressure |

0.4 MPa |

|

7. |

Micro-jet diameter |

50 µm |

3. RESULTS AND DISCUSSION

A goal of the study was

to examine the varying structure of the typical surfacing shaft after welding.

Steels with a carbon content of about 0.3% should be preheated to a temperature

of about 200℃. The possibility of welding cracks

in these steel grades is caused by the presence of such structures in Weld

Metal Deposit (WMD) as martensite, bainite and grain boundary ferrite. Such a

structure can promote cracking after welding. Nevertheless, it was decided to

check the possibility of surface welding steel shaft without preheating due to

the use of micro-jet cooling, thinking that it might reduce the size of ferrite

significantly. Micro-jet gas could have both influence on cooling conditions

and the chemical WMD composition (nitrogen amount in WMD) (Figures 2, 3 and 4).

Important t8/5 welding parameter, which

informs about the cooling time between 800 and 500°C, where the most

important austenite transformation occurs, is the largest (on the level of 10

sec) when micro-jet cooling is not used.

In the case of t8/5

welding parameter, it is much smaller (on the level of 6 sec) when nitrogen

micro-jet cooling is used.

Fig. 2. Weld cooling conditions without micro-jet cooling

Fig. 3. Weld cooling conditions with micro-jet cooling, micro-jet gas (N2)

pressure is 0.5 MPa, one jet installed in the injector

Fig. 4. Weld cooling conditions with micro-jet cooling, micro-jet gas

(He) pressure is 0.5 MPa, one jet installed in injector

In the case of t8/5

welding parameter, it is also smaller (on the level of 4 sec) when helium

micro-jet cooling is used. Heat transfer coefficient of tested micro-jet gases

influences on cooling conditions of welds (Figures 3 and 4). This corresponds

to varied martensite content. This is due to the different conductivity

coefficients (λ·105), which for N2

and Ar, in the 273 K is on the level of 23.74 J/cm·s·K. Helium

gives much stronger cooling conditions due to the higher conductivity

coefficients (λ·105), which for He is 143.4

J/cm·s·K. A typical WMD had similar chemical composition in all

tested cases. The chemical composition of WMD after MAG welding with and

without micro-jet cooling is presented in Table 2.

Tab. 2

Chemical

composition of Weld Metal Deposit (WMD)

|

No. |

Element |

Amount |

|

1. |

C |

0.31% |

|

2. |

Mo |

0.2 |

|

3. |

Mn |

0.67% |

|

4. |

Si |

0.17% |

|

5. |

P |

0.014% |

|

6. |

S |

0.011% |

|

7. |

Cr |

1.8% |

|

8. |

Ni |

1.36% |

|

9. |

Cu |

0.07% |

|

10 |

Al |

0.22% |

|

11. |

V |

0.01% |

|

12. |

N |

55-70 ppm |

For standard MAG welding

without micro-jet cooling and for MAG welding with helium micro-jet cooling,

the amount of nitrogen was always on the level of 55 ppm. For MAG welding with

nitrogen micro-jet gas cooling, the amount of nitrogen was much higher, on the

level of 70 ppm. After chemical analyses, the metallographic structure was

given. Presence of such structures in WMD as martensite, bainite and grain

boundary ferrite were identified. Weld cracks were not observed in all examined

cases, especially where micro-jet cooling was used. An additional success of

the research was the possibility of controlling the martensite content. For the

sake of transparency in the interpretation of results, it was decided to

compare only the content of martensite in the weld. A piece of information

about martensite amount in WMD is shown in Tables 3 and 4.

Tab. 3

Martensite

in surface weld (helium used as a micro-jet gas)

|

Micro-jet diameter, µm |

Micro-jet gas

pressure, MPa |

Number of jets |

Martensite aprox, % |

|

- |

- |

- |

45 |

|

50 |

0.4 |

1 |

50 |

|

50 |

0.4 |

2 |

60 |

|

50 |

0.5 |

1 |

55 |

|

50 |

0.5 |

2 |

65 |

|

60 |

0.4 |

1 |

55 |

|

60 |

0.4 |

2 |

65 |

|

60 |

0.5 |

1 |

60 |

|

60 |

0.5 |

2 |

65 |

Tab. 4

Martensite

in surface weld (nitrogen used as a micro-jet gas)

|

Micro-jet diameter, µm |

Micro-jet gas

pressure, MPa |

Number of jets |

Martensite aprox, |

|

- |

- |

- |

45 |

|

50 |

0.4 |

1 |

50 |

|

50 |

0.4 |

2 |

55 |

|

50 |

0.5 |

1 |

55 |

|

50 |

0.5 |

2 |

60 |

|

60 |

0.4 |

1 |

55 |

|

60 |

0.4 |

2 |

60 |

|

60 |

0.5 |

1 |

60 |

|

60 |

0.5 |

2 |

65 |

Micro-jet cooling does

not have a greater influence on the chemical composition of the weld. In the

case of nitrogen micro-jet cooling, there was additionally observed traces of

nitrides. It was observed that the micro-jet cooling is able to increase the

content of martensite to 65% and seriously reduce the size of ferrite grains

(Figures 5 and 6).

It is not so easy to

precisely count martensite amount such as other typical low alloy steel weld

phases: acicular ferrite, grain boundary ferrite, side plate ferrite for low

alloy welding [11]. Martensite amount was only estimated. Cooling allows for the

increase of the content of the martensite in the weld from 45% to 65%. After

microscope observation, a microhardness was carried out (Figures 7, 8 and 9). Standard

surface welding could not guaranty high hardness (Figure will be able to be

integrated in 8).

Fig. 5. Martensite

(approximately 45%) in weld after MAG welding without micro-jet cooling (big

size of ferrite grains)

Fig. 6. Martensite (approximately.

65%) in weld after MAG welding with micro-jet cooling (ferrite

grain of various sizes)

Surface weld hardness of

the shaft was decreased in terms of the distance from weld face; the maximum

value was much below 450 HV. Much higher hardness values were observed after

welding with helium micro-jet cooling (Figure 8).

Surface

shaft welding with helium micro-jet cooling allowed to excide hardness even

above 450 HV. The effect of nitrogen micro-jet cooling on steel WMD hardness is

shown in Figure 9.

Surface

shaft welding with nitrogen micro-jet cooling allowed to excide hardness even

above 450 HV. This is translated by increased nitrogen content in WMD (from 55

ppm to 70 ppm). Finally, tribological tests were done using the Amsler machine. Results

of the Amsler tests are shown in Table 5.

Tab. 5

The tribological test

results

|

Properties |

Sample of surface weld without micro-jet cooling |

Sample of surface weld with helium micro-jet cooling |

Sample of surface weld with nitrogen micro-jet

cooling |

|

Critical Force |

300 N |

300 N |

300 N |

|

Critical unit

pressure |

9.74 N/mm2 |

9.74 N/mm2 |

9.74 N/mm2 |

|

Blurring time |

10 s |

25 s |

25 s |

|

Friction

coefficient |

0.548 |

0.397 |

0.380 |

|

Weight loss [g] |

0.0160 g |

0.0009 g |

0.0006 g |

Based on the results

stated in Table 6, it was found that the highest resistance to abrasive wear

has the sample taken after welding with micro-jet cooling. Favourable micro-jet

gases are nitrogen or helium.

After hardness analysis, Charpy

V impact test of the deposited metal was carried out. The Charpy tests were

done at temperature +20°C on 5 specimens having been extracted from each

weld metal (Table 6).

Fig. 7. Hardness of

standard MAG steel weld without micro-jet cooling

Fig. 8. Hardness of weld

after with micro-jet cooling with helium used as micro-jet gas

Fig. 9. Hardness of weld

after micro-jet cooling with nitrogen used as a micro-jet gas

Tab. 6

Impact toughness for MIG welding with varied

micro-jet gases

|

Welding process |

Impact toughness KV [J] |

|

MAG |

70 |

|

Mag with helium

micro-jet cooling |

75 |

|

Mag with nitrogen

micro-jet cooling |

65 |

The impact toughness of all WMD is comparable among

themselves. The impact toughness of this steel (with 0.31% C) is not very high,

however, the influence of micro-jet cooling on the elastic properties of steel

can be lightly noticed. Helium micro-jet cooling shreds the ferrite grain,

which can lead to a small increase in impact strength. Cooling with nitrogen

micro-jet cooling allows nitrogen to be increased in WMD, which adversely

affects elastic properties of the material. Helium with minimal could be

regarded as a good choice.

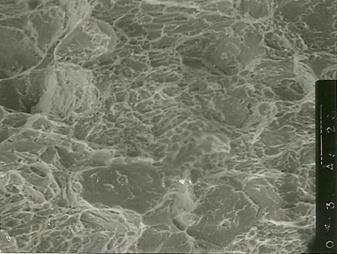

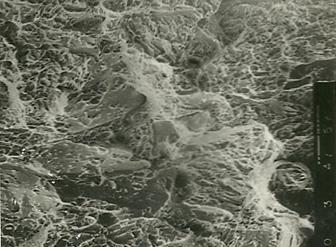

After

the impact toughness analysis, a fractography test was conducted. Fractographic

methods are routinely used to determine the cause of failure in engineering

structures. Figure 10 presents a typical fracture of the WMD after MAG welding

without micro-jet cooling. Figure 11 shows a typical fracture of the WMD after

MAG welding with helium micro-jet cooling.

Comparing

both drawings, it is possible to deduce that after welding with helium micro-jet cooling fracture of

WMD is more ductile than after welding with nitrogen micro-jet cooling.

Fig.

10. Scanning electron micrograph of small-sized

inclusions in the WMD after welding with nitrogen micro-jet cooling

Fig.

11. Scanning electron micrograph of small-sized

inclusions in the WMD after welding with helium micro-jet cooling

4. CONCLUSIONS

The micro-jet surfacing

technology was tested for surface welding with various micro-jet parameters.

Micro-jet technology could be treated as a very beneficial process during shaft

surfacing. Structure change was observed, especially the increase in martensite

content and ferrite fragmentation in the metal deposit.

On the basis of the

investigation it is possible to deduce that:

· micro-jet-cooling could

be treated as an important element of MAG welding process.

· it is possible to steer

the metallographic structure (martensite, nitrides).

· it is possible to steer

the weld harness by various micro-jet parameters.

· there is no great

difference between the influence of argon and helium on cooling conditions.

· nitrogen used for

micro-jet cooling (instead of argon and nitrogen) is responsible for the

highest hardness in all tested.

· there were observed

traces of nitrides when nitrogen was used for micro-jet cooling (instead of

argon when nitrides were not observed).

· the highest resistance

to abrasive wear has the sample taken after welding with micro-jet cooling.

· micro-jet cooling does

not have a noticeable influence on the impact toughness of WMD.

References

1.

Evans

G.M. 1994. ”Microstructure and

properties of ferritic steel welds containing Al and Ti”. Oerlikon-Schweissmitt 130: 21-39.

2.

Krayushkina

K., O. Prentkovskis, A. Bieliatynskyi, R. Junevičius. 2012. “Use of

steel slags in automobile road construction”. Transport 27(2): 129-137.

3.

Burdzik R., Ł. Konieczny, Z. Stanik, P. et al. 2014.

“Analysis

of impact of chosen parameters on the wear of camshaft”. Archives

of Metallurgy and Materials 59(3): 957-963. DOI:

10.2478/amm-2014-0161.

4.

Fornalczyk A., J. Willner, J. Cebulski et al. “Structure and

surface state of different catalytic conveters applied in cars”. The 5th

international Lower Silesia-Saxony conference “Advanced Metal Forming

processes in automotive industry (AutoMetForm 2016)”. Wroclaw, Poland, 28-29 June 2016. P. 327-333.

5.

Aleksić V., M. Dojčinović, L. Milović, I.

Samardžić. 2016. „Cavitation

damages morphology of high-strength low-alloy steel”. Metalurgija 55(3): 423-425.

6.

Kasuya T., Y. Hashiba, S. Ohkita, M. Fuji.

2001. “Hydrogen distribution in multipass submerged arc weld

metals”. Science and Technology of Welding and Joining 6(4): 261-266. DOI: 10.1179/136217101101538767.

7.

Hadryś

D. 2015. “Impact load of welds after micro-jet cooling”. Archives

of Metallurgy and Materials

60(4): 2525-2528.

8.

Bąkowski

H. 2018. “Wear Mechanism of spheroidal cast iron piston ring-aluminum

matrix composite cylinder liner contact”. Archives of Metallurgy and Materials 63

(1): 481-490. DOI: 10.24425/118965.

9.

Sozańska M., A. Maciejny, C. Dagbert et al. 1999. “Use of quantitive metallography in

the evaluation of hydrogen action during martensitic transformations”. Materials Science and Engineering 273-275: 485-490. DOI: 10.1016/S0921-5093(99)00333-0.

10.

Grazeviciute J.,

I. Skiedraite, V. Jurenas, A. Bubulis, V. Ostaševičius. 2008.

“Applications of high frequency vibrations for surface milling”. Mechanika (1): 46-49.

11.

Hadryś

D. 2016. “Mechanical properties of plug welds after micro-jet cooling”.

Archives

of Metallurgy and Materials 61: 1771-1775.

Received 09.10.2018; accepted in revised form 29.12.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License