Article

citation information:

Puškár, M., Kopas, M.,

Puškár, D. Influence analysis of detonations

related to output characteristics and to damage level of engine parts in order

to eliminate potential risks and ensure reliability of the HCCI technology. Scientific Journal of Silesian University of Technology. Series

Transport. 2019, 102, 151-163.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.102.13.

Michal PUŠKÁR[1],

Melichar KOPAS[2], Dušan

PUŠKÁR[3]

INFLUENCE ANALYSIS OF DETONATIONS RELATED TO OUTPUT CHARACTERISTICS AND TO DAMAGE LEVEL OF ENGINE PARTS IN ORDER TO ELIMINATE POTENTIAL RISKS AND ENSURE RELIABILITY OF THE HCCI TECHNOLOGY

Summary. The engine output characteristic

offers very important information during the real application of the HCCI

technology. This kind of combustion process significantly influences the

wearing degree of the main engine components or even the engine damage. The

principle of the HCCI combustion is basically beneficial, however, it can also

be destructive. Described in this article are measurements of the engine output

characteristics in the case of an experimental piston combustion engine. These

measurements were performed by means of a data recording system, whereby the

detonation combustion was evaluated using a quantitative method. The real

values of atmospheric conditions and fuel mixture composition were added to the

measured values. The resulting values were visually compared with a degree of

the engine piston damage caused by the detonations. The final result is a limit

value, which represents a maximal number of the detonation units that are

permissible in order to ensure reliable operation of the HCCI engine.

Keywords: analysis, detonation,

reliability, HCCI technology

1.

INTRODUCTION

A normal

combustion is a regulated one of a mixture of fuel and air in a combustion

chamber. It is stable combustion, which develops at a spark plug and continues

in a combustion chamber in a three-dimensional way.

A detonation is

a phenomenon, which is classified as an abnormal combustion. It is an

auto-ignition of a residual mixture of fuel and air in a combustion chamber. It

occurs after a normal combustion. At an initial phase, there is normal mixture

combustion, then under the influence of high pressure and heat, there are the

spontaneous ignitions, hence, detonation combustion [1].

Detonations

induce high pressure in a combustion chamber. This pressure is very short time.

In a combustion chamber, the pressure behaviour seems to be normal with

increasing development and then the pressure increases evidently. The rapid

increase of pressure is indicated as the excesses in comparison with a normal

one. These excesses intensify the pressure which causes detonation combustion.

Also, the rapid increase of pressure amplifies the forces in a combustion

chamber which induces the resonances in the engine design. These resonances are

characterised for detonation combustion. The noise or vibrations present the

phenomenon, which is recorded with a detonation counter [2-10].

It is important

to know that detonation need not be necessarily destructive. Many engines work

with a certain number of detonations. Some engines can stand strong detonations

for a very long time without destruction. The control detonation combustion is

useful because it increases engine output performance. The aim of this

contribution is the measurement of output characteristics of a high-speed

racing engine, which was performed by means of a data-recording system and the

detonation combustion was evaluated using a quantitative method. Next aim was

to find a limit where an examined engine produces the highest performance but

which the detonation combustion does not damage its design components.

Furthermore, there is the consideration of the influence of detonation combustion

on maximum values of an output performance and torque as well as their

behaviours depending on the engine speed.

2. EXPERIMENTAL MODEL

AND MEASURING DEVICES

The detonations

are influenced by the design of the combustion chamber (a shape, a size,

geometry, a replacement of spark plug), compression ratio, proportion of air

and fuel in a combustion mixture, shape of the ignition curve, atmospheric

conditions and the octane number of the fuel [11]. If the surface of a piston

or the combustion space is damaged or destroyed, detonation combustion may

start also in such conditions, which are not critical, but this damage effects

directly as an initiator of detonation combustion. The engines, which are

exposed over time to detonation combustion, tend to overheat themselves which

initiates an avalanche effect. The higher the temperature, the faster the

detonation combustion and consequently, the faster the destruction. The piston

absorbs a great deal of heat, on four sides causing dilatation which can induce

destruction [12]. The combustion temperatures are very high in the moment of

detonation ignition which causes the melting down of the piston and combustion

space materials [13,14].

For this reason,

it is difficult to determine theoretically the limit for detonation combustion

and then prove its authenticity for a petrol engine. Although there is a

software for modelling of the processes operating inside a cylinder and an

exhaust system during combustion, the real results are seriously performed [15,16].

This is the reason the experiment was

used to achieve the main aim. It is necessary to choose the experimental model

for experimental measurements. The development was realised with this

experimental model. Furthermore, there is the need to choose the measurement

devices (to provide feedback; to give information about a real output

proposition for a concrete change in detonation combustion).

The petrol

combustion engine with capacity 125 cm3 was used as the experimental

model. Two testing and measuring devices were

developed for the need of the experimental measurements.

2.1. Engine Watch and Control

System (EW&C)

This is a data-recording system, that is, a device which scans and

stores information during a motorcycle ride (in real conditions, in real loading).

This device makes it possible to diagnose the parameters of a combustion

engine: an output performance, a torque and their behaviours, the temperature

of the exhaust system and its behaviour and other characteristics.

A number and a kind of scanned parameters are related to the types and

the number of sensors, which are installed on the combustion engine.

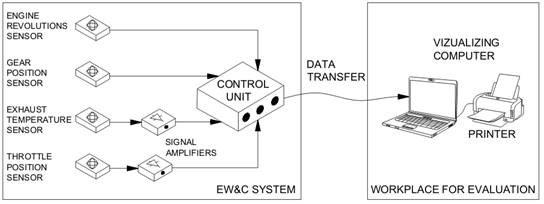

In Figure 1 there is the block diagram for data measurement, operating

and evaluation. The engine activity record is dependent on time as a result of

this system. The principle of the EW&C system consists of the measurement

of instantaneous engine revolutions; an instantaneous temperature of the

exhaust system and a reading of an active speed gear or throttle position in

the carburettor.

Fig. 1. Block diagram of

the EW&C system

The system does a functional record of the engine activity on the basis

of scanned and entered data (a wheel circumference, gear ratios of individual

speed gears, a curve of air resistance and a motorcycle weight). This record is

stored in the memory of the EW&C system. After concluding the measurement,

it is possible to copy the record into a PC.

2.2. Detonation Counter

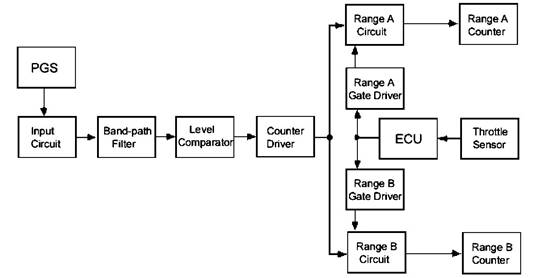

For the measurement of detonations, the detonation

counter was used. The detonation counter sensor picks up irregular

combustion, therefore, the detonation of the engine and provides a number of

detonation units. In Figure 2, there is the block

diagram for detonation measurement, operating and evaluation. As

shown in Figure 2, in Range A, detonation occurs at a high load (throttle

opening 50% to 100%), and in Range B, detonation occurs at a light load

(throttle opening close to 50%).

Fig. 2. Block diagram of

detonation counter

The PGS (plug gasket

sensor) is a pressure sensor which is made from a piezoelectric element and

outputs an electric charge according to pressure.

3. RESULTS AND DISCUSSION

The performed

measurements are intent on the analysis of the detonation combustion influence

with an output characteristic in consideration of the defined aim.

The aim of the

consecutive measurements was determined by the limit, expressed in a number of

detonation units per an overridden kilometre, where the combustion is

beneficial and helps to increase the output performance and does not cause

destruction in the design components of the engine.

In the experimental

model, these were applied the diagnostic devices, described in the

above-mentioned paragraph. The measurements were performed for a racing

circuit. The obtained results, which are presented in this paragraph, were

verified with multiple consecutive measurements to prevent any potential random

error.

In the introduction of

the previous paragraph which described the factors which influence detonation

combustion. These factors are the design of a combustion chamber (a shape, a

size, geometry, a replacement of spark plug), compression ratio, the proportion

of air and fuel in a combustion mixture, shape of the ignition curve, the

atmospheric conditions and the octane number of the fuel.

Paragraph 2 describes in

detail the used shape of an ignition curve and the design shape of a combustion

space. These shapes are equal for all measurements. Unleaded petrol with the

octane number 100 was applied as the fuel. In Table 1 are the scheduled

atmospheric conditions for each of the four measurements and as well as the

used compression ratios. In Table 2, there are recorded numerical presentations

of the fuel maps.

Tab. 1

Input Conditions

|

No. |

Atmospheric Conditions |

Compression Ratio |

||

|

Temperature [°C] |

Pressure [Pa] |

Humidity [%] |

||

|

1 |

27 |

97,3·103 |

37 |

14.46 |

|

2 |

21.2 |

98,2·103 |

36 |

14.43 |

|

3 |

17 |

97,5·103 |

65 |

14.67 |

|

4 |

18.8 |

97,2·103 |

44 |

14.71 |

Tab. 2

Fuel Maps

|

No. |

Throttle

Position [%] |

||||||||

|

0÷20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

|

|

1 |

106 |

106 |

132 |

160 |

188 |

215 |

240 |

265 |

289 |

|

2 |

106 |

106 |

132 |

160 |

188 |

215 |

240 |

265 |

289 |

|

3 |

98 |

92 |

130 |

160 |

188 |

215 |

242 |

267 |

292 |

|

4 |

106 |

109 |

137 |

165 |

193 |

219 |

244 |

269 |

293 |

Table 2

contains four fuel maps. In the upper row are the given percentage positions of

the throttle. In the left column there is the consecutive number of measurement,

so every row represents one map. The numerical value, given for the concrete

position of the throttle, represents a flow space. Through this flow space, the

fuel flows into the diffusor of the carburettor. Subsequently, in the diffuser,

there is an in-flow of fuel mixed with air. These values help in the comparison

of various alternatives for fuel maps. If a value is higher then it represents

a more overrich alternative for the concrete injection setup and on the other

hand, if a value is lower then the mixture is weakened. The fuel maps for the measurements No.1 and No.2

are equal. In the case of the map No.3, it is the mixture weaker at the

throttle position up to 40%. At the throttle position over 80%, it is the

mixture more overrich than for the maps No.1 and No.2. The map No.4 is fuel

overrich in the whole range of the opening with the throttle position from 30%.

The fuel volume at the complete opening of throttle position is regulated by

means of the main jet, which was 3% smaller at the measurements No.3 and No.4

than it was at the first two.

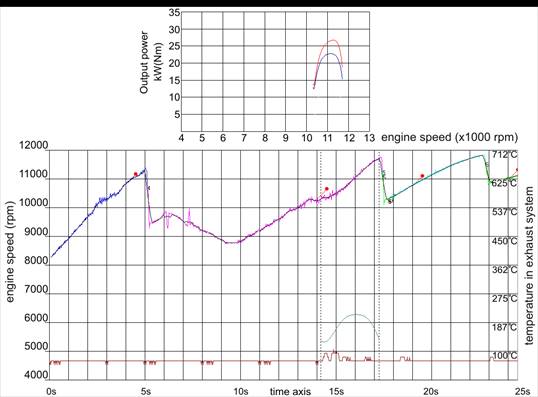

The

measurement No.1 was done during the first testing day in the racing circuit.

In Table 1, there are scheduled the input conditions of the measurement and the

fuel maps is given in Table 2. In Figure 3, it is illustrated in the record of

the EW&C system.

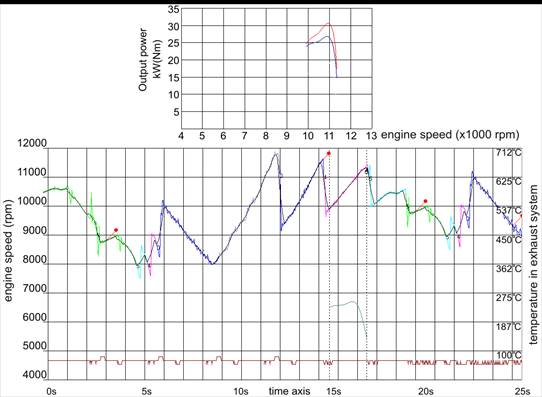

In Figure 3, it is shown

in the record of engine activity and the behaviour of engine performance is

dependent on the time axis. The time axis is represented in the bottom part of

the figure. The engine activity record is represented with an upper curve

(saw-tooth type).

On the left axis is the

engine speed (revolutions), which makes it easy to define the range of

operating speed which the engine operates in. The axis of temperature in the

exhaust system is on the right side. The temperature behaviour is represented

in the curve given in the lower section of the figure. In this case, the

illustrated curve is almost a line because the relevant sensor was inactive.

Fig. 3. Activity Record and

Output Behaviour of Engine at Measurement No.1

The concrete extent of

activity engine record was selected. This extent was terminated on both sides

(with dash vertical lines) and then analysed with regards to the output

performance. This analysis is illustrated by the graph on top of this figure.

The horizontal axis belongs to the engine speed (revolutions) and the vertical

axis is for the output performance.

The output

performance analysis was done for all measurements at the fourth speed gear.

From experience, it is this speed gear that has the highest output performance.

In the display of

the detonation counter, it is shown the number of detonation units after the

measurement number 1. The number 1545 indicates a total number of detonation

units during the whole ride. It is necessary to calculate the total number per

one overridden kilometre. In Table 3, there is a re-calculated number of

detonation units per an overridden kilometre for all four measurements.

Analysis of the output data from the EW&C system and the detonation counter

depicted in Table 3 was built up, where the input of the stated number of

detonation units per overridden kilometre as well as all the measured output

values therein. For the measurement, No.1 maximum output performance was 27 kW

and maximum torque 23 N·m.

Fig. 4. Undamaged Piston

The number of detonation

units is 8 per one overridden kilometre. After the complete analysis, it is

evident that the detonation combustion is out of the limit at this measurement.

This fact is also obvious in Figure 4 in which a piston is displayed. This

piston has not got any mark of damage or any black deposition. The output

characteristics were stable.

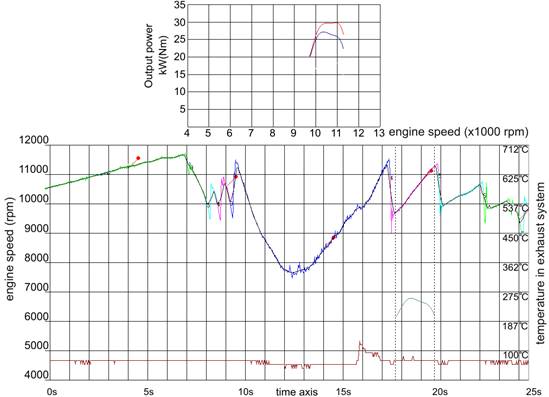

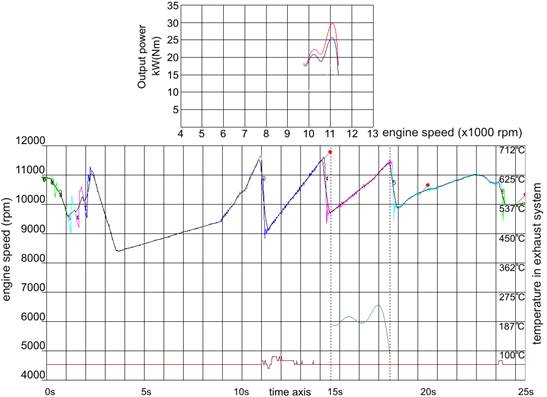

On the next testing day

which was done on measurement No.2 in the same racing circuit. The conditions

for the measurement No.2 are referred in Table 1 and Table 2. In Figure 5 was

the engine activity record. Maximum output performance was 29.5 kW and maximum

torque 27 N·m. The number of detonation units is 30 per one overridden

kilometre. Other measured data are in Table 3. The output parameters were

stable which means that they did not decrease during the testing ride.

Fig. 5. Activity Record and

Output Behaviour of Engine at Measurement No.2

This setup was

characterised by the large range of exploitable speed. The engine was set much

better than No.1, which is documented with higher maximum output performance

and torque and their ranges as well. After disassembling there was evidently no

significant damage of the piston, Figure 6.

Fig. 6.

Piston with Black Deposition

The

following measurement No.3 was performed with an effort to determine whether it

is possible to load the engine with an even greater rate of detonation

combustion and the extent of influence on the engine output parameters as well

as potential damage.

Fig. 7. Activity Record

and Output Behaviour of Engine at Measurement No.3

Likewise,

the testing circuit was the same and the input conditions, as well as the shape

of the fuel map, are stated in Table 1 and Table 2.

In

Figure 7 is the engine activity record. Maximum output performance was 32 kW

and maximum torque 27 N·m. The number of detonation units is 44 per one

overridden kilometre. Other measured data are in Table 3. Maximum output

performance increased in comparison with the previous measurement which was

caused by abnormal detonation combustion. It is important to know that this

performance is transient and the engine reached it only at the beginning of the

measurement. During the next kilometres, there were engine overheating with

small damage of the piston (Figure 8) and the loss of output performance.

Moreover, the range of exploitable speed decreased significantly.

Fig. 8. Piston with

Moderate Damage

In Figure 8 there is the black deposition

of the piston similar to one shown in Figure 6. But the moderate abrasive wear

is evident at the edge of the piston, where a pointer shows. This wear

indicates that the detonation combustion has definitely assumed a destructive

character.

During the measurement No.4, the engine

was exposed to extreme detonation combustion. This measurement was performed in

the same racing circuit. In Table 1 are the conditions for performance of the

measurement No.4, while in Table 2 is the fuel map. In Figure 9 there is the

record from the EW&C system.

Maximum output

performance was 29.5 kW and maximum torque 26 N·m. The number of

detonation units is 56 per one overridden kilometre. Other measured data are in

Table 3. The range of exploitable speed was very short. The engine reached

these values only at the initial phases of the testing ride before significant

overheating and expressive destruction occurred. The output performance was

transient in maximum extent.

Tab. 3.

Measurement results.

|

No. |

Number of

Detonation Units (NDU) [NDU/km] |

Maximum

Output /Engine Speed [kW/rpm] |

Range of

Speed for Output over 25kW [rpm] |

Maximum Torque/Engine

Speed [N·m/rpm] |

Range of

Speed for Torque over 20 N·m [rpm] |

|

1 |

8 |

27 / 11 200 |

700 |

23 / 11 100 |

900 |

|

2 |

30 |

29,5 / 10 800 |

1 300 |

27 / 10 300 |

1 600 |

|

3 |

44 |

32 / 10 900 |

1 200 |

27 / 10 800 |

1 300 |

|

4 |

56 |

29,5 / 11 100 |

500 |

26 / 11 050 |

900 |

In Figure 10 as

illustrated is a piston which is considerably damaged with detonation

combustion. The black deposition is throughout the surface of the piston

bottom. The pointer shows the spot with great damage where the material was

melted down with detonation combustion. Similarly, the combustion space and an

upper section of the cylinder are also damaged. The damaged design components

are not applied in practice anymore.

Fig. 9. Activity Record

and Output Behaviour of Engine at Measurement No.4

Fig. 10. Piston with

great damage

4. CONCLUSIONS

The measurements and intent on detonation combustion have brought many

interesting observations.

It is possible to theoretically assume that the higher extent of

detonation combustion provides even greater output performance at least in the

initial phase of the testing. However, the results indicate that neither the

output performance nor the torque was increased.

On the contrary, these values were decreased in comparison with

measurement No.3 where detonation combustion was weaker. This phenomenon is

caused by the fact that much energy is consumed for negative work. This work is

spent on a breaking down of resistances such as a high compression ratio. Figure

10 is a piston, which is significantly damaged with detonation combustion.

Throughout the whole surface of the piston bottom is saturate black deposition.

The pointer shows the spot with great damage caused by detonation combustion.

Similarly, the combustion space and an upper section of the cylinder are

already inapplicable.

Resulting from data of the measurements, it is necessary to keep

detonation combustion at a certain level. According to these results, there are

30 detonation units per overridden kilometre. This value is possible to reach

in various ways and the combinations of elements have influence on the

detonation combustion.

At this value, the engine permanently reached high output performance,

the large range of exploitable speed and detonation combustion did not cause

engine destruction. The utilisation of detonation combustion for the increase

of output performance is consider hazardous. Therefore, the measurements show

that through means of a change of atmospheric conditions that combustion can

occur. However, the combustion will be destructive. Detonation combustion has

got great significance which is also evident from the difference between the

measurement No.1 and No. 2 (Table 3). By means of detonation combustion for the

measurement No.2, the maximum output performance and torque in principle

is higher than for the measurement No.1.

Acknowledgements

This work was supported by the Slovak Research and Development Agency

under contract No. APVV-16-0259.

The article was written in the framework of Grant Projects: APVV-16-0259

“Research and development of combustion technology based on controlled

homogenous charge compression ignition in order to reduce nitrogen oxide

emissions of motor vehicles”, VEGA 1/0473/17 “Research and

development of technology for homogeneous charge self-ignition using

compression in order to increase engine efficiency and to reduce vehicle

emissions” and KEGA 041TUKE-4/2017 “Implementation of new

technologies specified for solution of questions concerning emissions of

vehicles and transformation of them into the educational process in order to

improve quality of education.”

References

1.

Toman R., M. Polóni, A. Chríbik. 2017. “Preliminary study on

combustion and overall parameters of syngas fuel mixtures for spark ignition

combustion engine”. Acta

Polytechnica 57(1): 38-48. ISSN 1210-2709. DOI:

http://dx.doi.org/10.14311/AP.2017.57.0038.

2.

Chríbik A., M. Polóni, J. Lach, B. Ragan. 2014. “The effect of adding hydrogen

on the performance and the cyclic variability of a spark ignition engine

powered by natural gas”. Acta

Polytechnica 54(1): 10-14. ISSN 1210-2709. DOI:

http://dx.doi.org/10.14311/AP.2014.54.0010.

3.

Czech

P., An Intelligent approach to wear of piston-cylinder assembly diagnosis based

on entropy of wavelet packet and probabilistic neural networks, 11th

International Conference on Transport Systems Telematics (TST 2011), Katowice

Ustron, Poland, October 19-22, 2011, Modern Transport Telematics,

Communications in Computer and Information Science, 2011, Vol. 239, P. 102-109.

4.

Czech

P., Determination of the course of pressure in an internal combustion engine

cylinder with the use of vibration effects and radial basis function -

preliminary research, 12th International Conference on Transport Systems Telematics

(TST), Katowice, Poland, October 10-13, 2012, Telematics in the Transport

Environment, Communications in Computer and Information Science, 2012, Vol.

329, P. 175-182.

5.

Czech

P., Diagnosing a car engine fuel injectors' damage, 13th International Conference

on Transport Systems Telematics (TST), Katowice, Poland, October 23-26, 2013,

Activities of Transport Telematics, Communications in Computer and Information

Science, 2013, Vol. 395, P. 243-250.

6.

Mikulski M., S. Wierzbicki, M. Smieja, J.

Matijosius. 2015.

„Effect of CNG in a fuel dose on the combustion process of a

compression-ignition engine”. Transport

30(2): 162-171.

7.

Ubartas M., V.

Ostasevicius, S. Samper, V. Jūrėnas, R. Daukševičius. 2011.

“Experimental investigation of vibrational drilling”. Mechanika 17(4): 368-373.

8.

Figlus T., M.

Stańczyk. 2014. “Diagnosis of the wear of gears in the gearbox using

the wavelet packet transform”. Metalurgija 53(4): 673-676.

ISSN: 0543-5846.

9.

Sebok M., M.

Gutten, J. Adamec, A. Glowacz, J. Roj. 2018. “Analysis of the electronic

fuel injector operation”. Komunikacie

(Communications - Scientific Letters of the University of Zilina) 20(1): 32-36.

10.

Kosicka

E., E. Kozłowski, D. Mazurkiewicz. 2015. „The use of stationary tests for analysis of monitored residual

processes”. Eksploatacja i Niezawodnosc – Maintenance and

Reliability 17(4): 604-609. DOI: http://dx.doi.org/10.17531/ein.2015.4.17.

11.

Magdolen

L., M. Masaryk. 2012. “Flywheel storage energy”. Conference

Gepeszet 2012, May 24-25, 2012, Budapest, Hungary. Conference proceedings, Budapest University of Technology and Economy

BME Budapest. ISBN 978-963-313-055-1.

12.

Blištan

P. et al. 2012. “Renewable energy sources and risk management”. SGEM 2012: 12th International

Multidisciplinary Scientific GeoConference. Conference proceedings: Volume

4. Albena, Bulgaria - Sofia: STEF92 Technology Ltd. P. 587-594.

13.

Medvecká-Beňová

S., Ľ. Miková, P. Kaššay. 2015. “Material

properties of rubber-cord flexible element of pneumatic flexible

coupling”. Metalurgija 54(1):

194-196. ISSN: 0543-5846.

14.

Ostasevicius V.,

I. Milasauskaite, R. Dauksevicius, V. Baltrušaitis, V. Grigaliūnas,

I. Prosyčevas. 2010. “Experimental characterization of material

structure of piezoelectric PVDF polimer”. Mechanika 86(6): 78-82.

15.

Kopilčáková

L., A. Pauliková. 2008. “Technický metabolizmus v

rámci orientovaného konštruovania”. [In Slovak:

“Technical metabolism within oriented design”]. Environmental management. 8th

Foreign Participation Conference (Review Proceedings). Bojnice, 5-6

December 2008. Žilina: STRIX. P.55-57. ISBN 978-80-89281-34-3.

16.

Puskar M., M.

Kopas, D. Puskar. 2018. “Diagnostic and management system specified for

control of engine equipped with the HCCI combustion technology”. Diagnostyka 19(4): 39-44.

DOI: 10.29354/diag/94808.

Received 24.10.2018; accepted in revised form 10.01.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License