Article citation information:

Urbanský, M. Comparison of piston and tangential pneumatic

flexible shaft couplings in terms of high flexibility. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 99, 193-203.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.18.

Matej URBANSKÝ[1]

COMPARISON OF PISTON AND TANGENTIAL PNEUMATIC FLEXIBLE

SHAFT COUPLINGS IN TERMS OF HIGH FLEXIBILITY

Summary. The

optimal tuning of mechanical systems in terms of torsional vibration magnitude

is a very important function in flexible shaft couplings. Therefore, a flexible

coupling with suitable dynamic properties, particularly dynamic torsional

stiffness, has to be carefully chosen for each specific application. The

current trend in the field of flexible shaft couplings, and the most noticeable

in the automotive industry, is the development and utilization of highly

flexible couplings, which means flexible couplings with a very low value of

relative torsional stiffness. The aim of this article is to introduce a new

type of flexible shaft coupling: a piston pneumatic flexible shaft coupling.

This coupling was developed to improve the properties of pneumatic flexible

couplings, especially the maximum angle of twist, in order to create a highly

flexible pneumatic coupling. For illustration purposes, the piston pneumatic

coupling is compared with the tangential pneumatic flexible shaft coupling of

Type 3-1/110-T-C in terms of high flexibility characteristics, whereby the

characteristic dimensions of both couplings are the same. Given that the piston

pneumatic coupling has not been manufactured to date, only a computational

model of this coupling was used. The results show that the design of the piston

pneumatic flexible shaft coupling combines the advantages of a highly flexible

and pneumatic shaft coupling.

Keywords: pneumatic flexible shaft couplings;

high-flexibility characteristics, comparison

1. INTRODUCTION

Nowadays, reducing vibration and noise in

machinery is a highly important task, mainly in terms of human health and the

lifetime and safety of machines, e.g., [2-6,8,9,13]. Flexible shaft couplings

are the most used machine parts for the flexible transmission of load torque

and mechanical energy in mechanical systems. Another highly important function

performed by them is the dynamic tuning of mechanical systems in terms of

torsional vibration magnitude. Therefore, a flexible coupling with suitable

dynamic properties, particularly dynamic torsional stiffness, has to be

carefully chosen for each specific application to ensure that dangerous

torsional vibration does not occur in a mechanical system, e.g., [8,9,12]. From the point of view of the

aforementioned dynamic tuning, the development and utilization of highly

flexible couplings are particularly advantageous and most noticeable in the

automotive industry nowadays (dual-mass flywheels). A highly flexible

coupling possesses a very low relative torsional stiffness k0. Relative torsional stiffness is expressed by the

following formula:

![]() , (1)

, (1)

which

is defined as the ratio of the nominal dynamic torsional stiffness of a

coupling kDN (at MN) to the nominal torque MN of a coupling. Common

flexible couplings have a relative torsional stiffness value in the range of

10÷30 rad-1. Shaft couplings marked as highly flexible

have a relative torsional stiffness value lower than 10 rad-1.

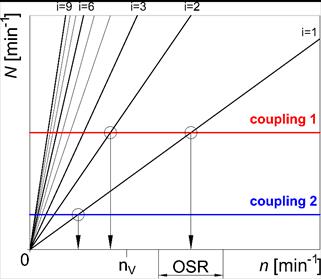

With the application of a highly flexible coupling in a mechanical system

(Coupling 2 in Fig. 1), the resonances from the individual harmonic

components of a torsional vibration excitation can be moved from the operating

speed (n) range (OSR) of the system

to the low-speed area, which is far enough under the idle operating speed nV, e.g., [6,9]. This

low-speed area can be quickly run across at the start-up of a mechanical

system, as shown in Campbell’s diagram of a mechanical system (Fig. 1),

where i represents the order of

the harmonic component of a torsional vibration excitation.

Nowadays, the flexible elements of flexible

shaft couplings are made of various materials. During the operation of

mechanical systems, rubber and plastic flexible elements experience fatigue and

ageing, while metal flexible elements of applied flexible couplings also

experience ageing and wear and tear [1,7,15]. Consequently, an applied flexible

coupling loses its original dynamic properties and thus its ability to carry

out important functions in a torsional oscillating mechanical system. Flexible

shaft couplings from the pneumatic flexible shaft couplings group (to which the

following couplings belong, according to the granted patents:

SK 288455 B6, SK 288344 B6, SK 288341 B6,

SK 278750 B6, SK 278653 B6, SK 278152 B6) are

able to facilitate the flexible transmission of mechanical energy without the

loss of their characteristic properties, because the gaseous medium in the

compression volume of couplings does not suffer from fatigue or ageing. The

main advantage of pneumatic couplings is the possibility to change their

torsional stiffness, which depends on the pressure value of the gaseous media.

Based on the aforementioned grounds, the development of flexible couplings,

with the benefits of both pneumatic and highly flexible couplings, is very

advantageous.

Fig. 1. Campbell’s

diagram of a mechanical system

From the point of view of physics, a flexible

coupling with a low torsional stiffness must have a large twist angle in order

to transmit a high load torque. This is the next prerequisite for creating a

highly flexible coupling. Therefore, the aim of this article is to introduce a

piston pneumatic flexible shaft coupling, which was developed to improve the

properties of pneumatic flexible couplings, especially the maximum angle of

twist, in order to create a highly flexible pneumatic coupling. For

illustration purposes, this coupling is compared with the tangential pneumatic

flexible shaft coupling of Type 3-1/110-T-C in terms of high-flexibility

characteristics, in which the characteristic dimensions of both couplings are

the same.

2. EXAMINED PNEUMATIC FLEXIBLE SHAFT

COUPLINGS

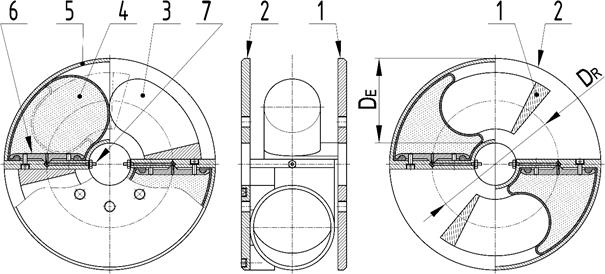

In the

following, the piston pneumatic flexible shaft coupling of Type 2-1/110-P-C[2]

(Fig. 2) is compared to the tangential pneumatic flexible shaft coupling

of Type 3-1/110-T-C[3]

(Fig. 3), manufactured by the FENA company in cooperation with our department. Both

couplings are designed to transfer load torque in one sense (their pneumatic

flexible elements must be pressed), have the same pitch diameter, DR=180 mm, and the same

outer diameter of pneumatic elastic elements, DE=110 mm. Given that the piston pneumatic coupling has

not yet been manufactured, only a computational model of this coupling was

used.

2.1. Piston pneumatic flexible shaft

coupling of Type 2-1/110-P-C

The piston

pneumatic flexible shaft coupling (Fig. 2) consists of a driving flange (1),

a driven flange (2), pneumatic flexible elements (4), curved hollow cases

(5), curved piston bodies (3), fastening flanges (6) and valves (7). The

compression volume of the coupling is created from two pneumatic flexible

elements (4), which are motionlessly placed in the hollow cases (5), which are

attached to the driven flange (2). The piston bodies (3) are attached to the

driving flange (1). The pneumatic flexible elements (4) are inflated to the

required overpressure of gaseous media through the valves (7), and the basic

position of the piston bodies and the driving flange (1) in relation to the

driven flange (2) is herewith defined (Fig. 2a). The transmission of load

torque causes a twist in the driving flange (1) in relation to the driven

flange (2), and the piston bodies (3) are therefore pushed into the pneumatic

flexible elements (4) so that the piston bodies (3) are coated with the

pneumatic flexible elements (4) (Fig. 2b). The design of the coupling allows for

a maximum angle of twist of 76°.

|

|

|

|

a) |

b) |

Fig. 2. The piston pneumatic flexible

shaft coupling of Type 2-1/110-P-C: a) unloaded state; b) partially

loaded state

The compression of gaseous media in

the pneumatic flexible elements (4) is proportional to the load, resulting in

the flexible transmission of load torque in mechanical systems.

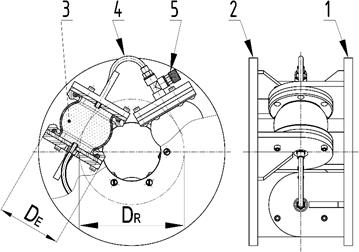

2.2. Tangential pneumatic flexible shaft

coupling of Type 3-1/110-T-C

By this coupling (Fig. 3), load

torque is transmitted flexibly from the driving flange (1) to the driven flange

(2) by the compression volume of the coupling. The compression volume is

created from three pneumatic flexible elements (3), which are tangentially

positioned around the perimeter of the coupling and completely interconnected

with the hoses (4). The gaseous medium streams into the compression volume of

the coupling through the quick-acting pneumatic fitting (5). The design of the

coupling allows for a maximum angle of twist of 15°.

|

|

|

Fig. 3. The tangential

pneumatic flexible shaft coupling of Type 3-1/110-T-C

3. DETERMINING THE BASIC

CHARACTERISTIC PROPERTIES OF THE COUPLINGS

3.1. Dependence of

pressure in the pneumatic couplings on their twist angle

As for

pneumatic flexible shaft couplings, load torque is transmitted flexibly from

the driving flange to the driven flange by pneumatic flexible elements. As the

transmission of load torque causes a twist in the driving flange in relation to

the driven flange, the compression volume of a pneumatic coupling is

compressed. The compression of gaseous media in the pneumatic flexible elements

is proportional to the load.

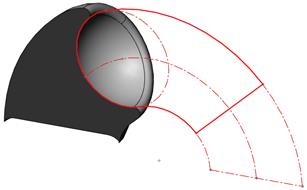

|

|

|

Fig. 4. The principle of modelling

the air volume deformation caused by the piston body, as a section view |

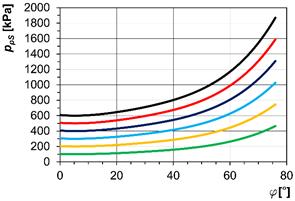

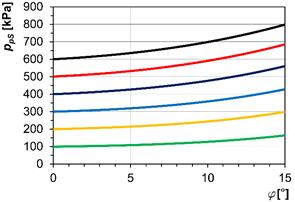

In Fig. 5,

we can see the dependencies of air overpressure ppS in the compression volume of the pneumatic couplings

on their angle of twist φ.

Initial air overpressure values (at φ=0º)

in the couplings were ppS0=100÷600 kPa.

For the tangential coupling, the dependencies in Fig. 5b were measured and the

maximally allowed ppS

value was 800 kPa [10]. For the piston coupling, the dependencies in Fig.

5a were computed as follows:

1. The dependence of the air volume V on the twist angle φ was determined using 3D CAD

software (Fig. 4)

2. The dependence of the air overpressure ppS in the pneumatic coupling

on the twist angle φ was

determined by considering isothermal compression using the following formula:

![]() , (2)

, (2)

where pa is the atmospheric pressure (pa=101,325 Pa).

|

|

|

|

a) |

b) |

Fig. 5. The

air overpressure ppS in

the couplings, which is dependent on the twist angle φ at various values of ppS0:

a) piston coupling of Type 2-1/110-P-C; b) tangential coupling of

Type 3-1/110-T-C

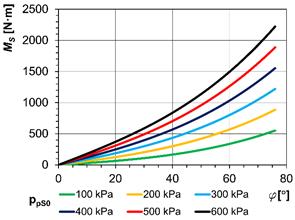

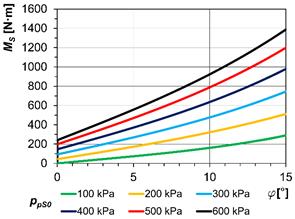

3.2. Static load characteristics

According

to the standard [16], the static load characteristic of a flexible coupling is

the dependence of the coupling twist on load torque during slow change in the

load torque. The loading and unloading of a coupling should be performed

smoothly at a constant speed <0.002 rad/s-1.

Five cycles of loading and unloading should be performed and the static

characteristic should be obtained as the loading part of the fifth cycle. The

coupling should be loaded up to the maximum static load torque MSmax, which can be defined,

for example, according to the maximum twist angle of a flexible coupling. The

condition is not to damage the coupling. In Fig. 6, we can see the static

characteristics of both couplings at initial air overpressure values in their compression volume ppS0=100 ÷ 600 kPa. The

static characteristics of the tangential pneumatic coupling (Fig. 6a) were

determined in the laboratory of our department and the static characteristics

of the piston pneumatic coupling (Fig. 6b) were computed from the equality of

the works of the gaseous medium and torque:

![]() . (3)

. (3)

|

|

|

|

a) |

b) |

Fig. 6. The static load

characteristics at various values of ppS0:

a) piston coupling of Type

2-1/110-P-C; b) tangential coupling of Type 3-1/110-T-C

The

static load characteristics of both couplings are slightly non-linear and can

be described by cubic equations in the form, MS=a0·φ + a3·φ3. The coefficients a0 and a3

(Tab. 1) were determined by the method of least squares.

Tab. 1.

The coefficients a0 and a3 of static load characteristic equations

|

Piston coupling 2-1/110-P-C |

Tangential coupling

3-1/110-T-C |

||||

|

ppS0 |

a0 |

a3 |

ppS0 |

a0 |

a3 |

|

100 kPa |

820.0 |

3,858.9 |

100 kPa |

168.4 |

140.5 |

|

200 kPa |

1,434.8 |

5,178.2 |

200 kPa |

338.4 |

187.0 |

|

300 kPa |

1,959.6 |

7,718.2 |

300 kPa |

508.4 |

233.6 |

|

400 kPa |

2,506.6 |

9,851.8 |

400 kPa |

678.3 |

280.1 |

|

500 kPa |

3,030.4 |

11,563.2 |

500 kPa |

848.3 |

326.6 |

|

600 kPa |

3,532.3 |

12,414.5 |

600 kPa |

1,018.3 |

373.1 |

According

to the standard [16], the nominal torque MN

of a flexible coupling can be determined as the third of its maximum static

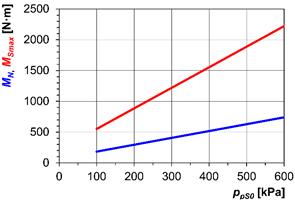

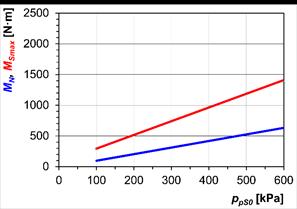

load torque MSmax. In Fig.

7, we can see the MSmax

and MN dependencies on

initial air overpressure ppS0 for the piston pneumatic coupling

(Fig. 7a) and tangential pneumatic coupling (Fig. 7b).

|

|

|

|

a) |

b) |

Fig. 7. Maximum static

torque MSmax and nominal

torque MN, which are

dependent on initial air overpressure ppS0:

a) piston coupling of Type 2-1/110-P-C; b) tangential coupling of

Type

3-1/110-T-C

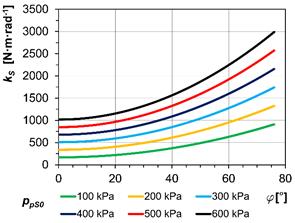

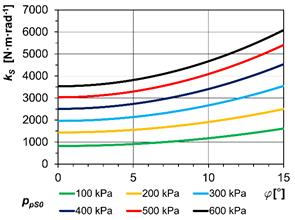

3.3. Static torsional stiffness

The

dependence of the static torsional stiffness kS of a flexible coupling on the twist angle φ can be computed by deriving the equation of the static

characteristic of a flexible coupling.

In Fig.

8, we can see the static

torsional stiffness kS,

which is dependent on the twist angle φ

of the couplings at initial air overpressure values in the pneumatic couplings ppS0=100÷600 kPa

for the piston pneumatic coupling (Fig. 8a) and tangential pneumatic

coupling (Fig. 8b).

|

|

|

|

a) |

b) |

Fig. 8. The dependence of

the static torsional stiffness kS

on the twist angle φ at various

values of ppS0:

a) piston coupling of Type 2-1/110-P-C; b) tangential coupling of

Type 3-1/110-T-C

4. HIGH-FLEXIBILITY CHARACTERISTICS

OF THE COUPLINGS

In order to compute the relative torsional

stiffness values k0 of the

pneumatic couplings, the values of the dynamic torsional stiffness kDN of the pneumatic

couplings at the nominal torque MN

need to be determined. According to the research, the kDN values of the pneumatic couplings can be determined

by the following formula:

![]() , (4)

, (4)

where kSN is the value of the static torsional stiffness of

the pneumatic coupling at the nominal torque MN at a certain value of initial air overpressure in the

pneumatic coupling in the range of ppS0=100÷600 kPa.

Finally,

the relative torsional

stiffness k0 of the

couplings can be determined according to Eq. (1). In Fig. 9, we can see the

relative torsional stiffness k0,

which is dependent on

initial air overpressure in the pneumatic couplings ppS0=100÷600 kPa for the piston pneumatic

coupling (Fig. 10a) and the tangential pneumatic coupling (Fig. 10b).

|

|

|

|

a) |

b) |

Fig. 9. The relative

torsional stiffness k0,

which is dependent on initial air overpressure ppS0: a) piston coupling of Type 2-1/110-P-C;

b) tangential coupling of Type 3-1/110-T-C

As we can see from Fig. 9, the

piston pneumatic flexible coupling of Type 2-1/110-P-C meets the requirements

for high flexibility in the whole range of the initial air overpressure ppS0 within its compression

volume, while the tangential pneumatic flexible coupling of Type

3-1/110-T-C can be marked as highly flexible at approximately ppS0>150 kPa.

5. CONCLUSION

With the transfer of load torque by

the compression volume of pneumatic flexible shaft couplings filled with a

gaseous medium, we achieve the compression of the medium proportional to load.

This is how the continuous flexible load torque transmission in the driving and

driven machine system is characterized. Gaseous media throughout their lifetime

are not subject to ageing, meaning that pneumatic couplings do not lose their

initial positive dynamic properties.

From the above-presented graphs and

tables, we can see that the Type 2-1/110-P-C piston pneumatic coupling, in

comparison with the Type 3-1/110-T-C tangential pneumatic flexible coupling,

offers the following advantages:

·

It

has lower values of torsional stiffness (Fig. 8), while its transmission

ability is higher (Figs. 6-7), thanks to its large maximum twist angle. The

piston pneumatic coupling is able to transmit about 160% larger torque by the

same pitch diameter DR.

The outer diameter of both couplings is approximately the same too.

·

According

to Fig. 9, both compared pneumatic couplings are highly flexible. The piston

coupling has much smaller values of relative torsional stiffness (Fig. 9),

which means that it has a higher flexibility than the tangential coupling.

·

The

design of the piston coupling allows for MS=0

at φ=0 (Fig. 6); in other words,

the piston coupling do not have initial torsional rigidity unlike the

tangential coupling.

Meanwhile, the piston coupling has

the following disadvantages:

· An unconventional pneumatic flexible

element needs to be developed and manufactured for the piston pneumatic

coupling.

· To achieve the presented

transmission ability (Figs. 6-8), the piston coupling needs to work with

relatively high levels of overpressure in its compression space (Fig. 5).

Both compared couplings are designed to transfer load torque in one

sense, while their pneumatic flexible elements are pressed. Therefore,

neglecting the influence of the rubber-cord coating of pneumatic flexible

elements [14], the difference between static and dynamic torsional stiffness in

the pneumatic couplings is mainly caused by a polytrophic process in their

compression volume under dynamic load [11]. Under dynamic load, pneumatic

flexible elements do not generate too much heat, unlike the flexible elements

made of rubber and plastic [7]; therefore, the pneumatic couplings can work

with large amplitudes of twist at high frequencies.

References

2.

Czech P. 2013.

“Intelligent Approach to Valve Clearance Diagnostic in Cars”.

Activities of Transport Telematics. TST 2013. Communications in Computer and Information Science 395: 384-391.

DOI: https://doi.org/10.1007/978-3-642-41647-7_47.

3.

Czech P., Mikulski

J. 2014. “Application of Bayes Classifier and Entropy of Vibration

Signals to Diagnose Damage of Head Gasket in Internal Combustion Engine of a

Car”. Telematics - Support For Transport. TST 2014. Communications in Computer and Information Science 471: 225-232.

DOI: https://doi.org/10.1007/978-3-662-45317-9_24.

4.

Figlus

Tomasz, Jozef Gnap, Tomas Skrucany, Branislav Sarkan, Jozef Stoklosa. 2016.

„The Use of Denoising and Analysis of the Acoustic Signal Entropy in

Diagnosing Engine Valve Clearance”. Entropy

18(7). Article Number: 253.

5.

Figlus

Tomasz, Stefan Liscak. 2014. „Assessment of the vibroactivity level of SI

engines in stationary and non-stationary operating conditions”. Journal Of Vibroengineering 16(3):

1349-1359.

6.

Grega Robert,

Jozef Krajňák, Lucia Žuľová, Gabriel Fedorko,

Vieroslav Molnár. 2017. “Failure analysis

of driveshaft of truck body caused by vibrations”. Engineering Failure Analysis 79: 208-215. ISSN: 1350-6307.

DOI: 10.1016/j.engfailanal.2017.04.023.

8.

Homišin

Jaroslav. 2016. “Characteristics of

pneumatic tuners of torsional oscillation as a result of patent

activity”. Acta Mechanica et

Automatica 10(4): 316-323. ISSN: 1898-4088.

DOI: 10.1515/ama-2016-0050.

9.

Homišin

Jaroslav, Peter Kaššay. 2014. “Optimal tuning of

torsional oscillating mechanical systems”. In: Proceedings of the 54th International Conference of Machine Design

Departments: Modern Methods of Construction Design: 63-69. Department of

the Design of Machine Elements and Mechanisms, Technical University of Liberec,

Czech Republic. 10-12 September 2013. Hejnice, Czech Republic. ISBN:

978-3-319-05203-8. DOI: 10.1007/978-3-319-05203-8_9.

12. Kyslan K., M. Rodič, Ľ. Suchý,

Ž. Ferková, F. Ďurovský. 2017. “Industrial controller-based dynamometer with dynamic

emulation of mechanical loads”. Electrical

Engineering 99(4): 1245-1254. ISSN: 0948-7921.

DOI: 10.1007/s00202-017-0626-z.

13. Liptai Pavol, Marek Moravec, Ervin Lumnitzer, Marcela

Gergeľová. 2017. “Proposal of the

sound insulating measures for a vibrational sorter and verification of the

measured effectiveness”. Advances

in Science and Technology-Research Journal11 (3): 196-203. ISSN:

2299-8624. DOI: 10.12913/22998624/76068.

14. Medvecká-Beňová Silvia, Ľubica

Miková, Peter Kaššay. 2015. “Material

properties of rubber-cord flexible element of pneumatic flexible

coupling”. Metalurgija

54(1): 194-196. ISSN: 0543-5846.

15. Samociuk W., Z. Krzysiak, G. Bartnik, A. Skic, S.

Kocira, B. Rachwal, H. Bakowski, S. Wierzbicki, L. Krzywonos. 2017. „Analysis

of explosion hazard on propane-butane liquid gas distribution stations during

self tankage of vehicles”. Przemysl

Chemiczny 96(4): 874-879. DOI: 10.15199/62.2017.4.29.

This paper

was written within the framework of the KEGA 041TUKE-4/2017 grant project

“Implementation of New Technologies Specified for Solving Questions

Concerning the Emissions of Vehicles and Their Transformation in Educational

Processes in Order to Improve the Quality of Education”.

This article

was created with support from the project for PhD students and young

researchers project entitled “Solution of a Control System Element for

Mechanical Systems’ Continuous Tuning”.

Received 24.02.2018; accepted in revised form 16.05.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License