Article

citation information:

Shpachuk, V., Chuprynin, A.,

Suprun, T., Kovalenko, A. Multiple-factor analysis of the dynamic

interaction between railroad cars and joint irregularity. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 99, 183-192.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.17.

Vladimir SHPACHUK[1],

Aleksandr CHUPRYNIN[2],

Tatiana SUPRUN[3],

Andriy KOVALENKO[4]

MULTIPLE-FACTOR

ANALYSIS OF THE DYNAMIC INTERACTION BETWEEN RAILROAD CARS AND JOINT IRREGULARITY

Summary. Mechanical models of “railroad

car-track” transport system for each phase of motion are developed.

Particularities of dynamic interaction between the four-axle car and the track

are studied by considering four phases of motion over joint irregularity.

Methods for solving differential equations of the discrete-continuous system

fluctuation are developed. Numerical analysis is used to determine deflections

of the trailing rail under the first sleeper for each phase of motion depending

on motion phases, and car load and speed.

Keywords: railway rolling stock;

four-axle car; track; ballast; joint irregularity; trailing rail; facing rail

1. INTRODUCTION

The

issues of optimizing performance characteristics and developing efficient

design solutions, which enhance reliability and increase the longevity of rail

transport, are becoming of crucial importance nowadays under conditions of

rapid development in transportation technologies. The operating life of railway

rolling stock and track structure depends on the interaction between elements,

which is affected by mechanical, design and geometrical characteristics [4,5,15].

The

operating performance of the track under railway rolling stock depends on the

type of rail fastening, the stiffness of the track structure elements and

operational conditions. Reducing the parameters of dynamic interaction between

the railroad car and the track, in particular, at the joints, allows for the

transition to durable, reliable, comfortable and fast rail transport.

The

ballast draft under sleepers in rail joint areas is the most informative index

of mechanical interaction in the “wheel-rail” system [15]. It is at

rail joints that the rail is typically exposed to the largest impact load,

which leads to rail creeping and sagging, and the emergence of gapless and

elongated joints. Thus, elastic and permanent residual deformations of the

ballast under rail supports determine the operation and service life of the

track.

2. LITERATURE REVIEW AND RESEARCH

OBJECTIVE

According to the analysis of the research

dealing with issues of mechanical interaction between the four-axle car and the

track [15],

insulated rail joints are the weakest link in the examined system. Besides,

having to take into account phases of the car motion over joint irregularity is

emphasized, as well as characteristics of the ballast stiffness [7,17]. In

addition, an emphasis is placed on issues relating to the combined action of

railway rolling stock and the track, which determines the particularities of

their static and dynamic interaction [10] while the car passes over the

joints.

As

different factors, which change during the operation of the track, stipulate

the application of the multiple-factor model, research that focuses on

improving existing models of interaction between the car and the track

structure is modern and of topical interest.

The

load of rolling stock elements and track structure determine the parameters of

longevity [188],

durability and stiffness of the track [8]. These parameters have an impact on

operation and service life. The experience of operating rail transport shows [145] that

indices of reliability and longevity in the “car-track” mechanical

complex greatly depend on particularities of interaction between the track and

the rolling stock and operational conditions of the system above. Besides, the

interaction above affects the system ability to withstand the destructive

action of emerging impact and vibration loads [8], which are of a cyclically

recurrent nature.

To

analyse dynamic interaction between rolling stock and track structure, it is

necessary to solve several interrelated problems, namely, static, impact and

dynamic problems. Particular attention is being paid to the issues above, and

new sufficient research in this field is being undertaken.

When

we consider topical research in this field, when concerning the track, much of

it focuses on particular aspects of design and operation. To ensure the

application of a complex approach, it is necessary to use a generalized tool

integrating different aspects of design and operational conditions, which

allows for the complex assessment of track dynamics [9]. Several models have

been developed to analyse and predict structural behaviour. The traditional

approach is to apply the finite element method, involving commercially

available software packages [16], which requires considerable financial costs

in the course of designing. Besides, closed-source code does not facilitate the

analysis of all interaction aspects [14].

The

finite element method is also applied to the ballast model [11], which involves

transmitting load from the wheel to the soil where the track is built [13].

Thus, some countries are using reinforced concrete when building roadways [2], but

the cost of their construction is significantly higher compared to the standard

ballast track design. Another approach is to increase ballast thickness, which

leads to decreasing deflection under the load and causes lower stress in the

soil. This improves the performance and lifespan of the track [1]. The

large number of suggested design solutions prompts several questions as to the

efficient ways in which to solve the set tasks. The analysis of modern research

demonstrates that the application of a multiple-factor system analysis, which

takes into account the phases of motion of the car over joint irregularity and

characteristics of track stiffness, represents a current trend in the

developing theory of mechanical interaction between the four-axle car and the

track. Thus, we can state the need to create an adequate and easy-to-use model

of the train-track interaction and the corresponding methods of their dynamic

interaction analysis, where the railroad car is considered as a

multidimensional discrete system and the track structure is viewed as a

continual system.

The

purpose of the present research is to study the dynamic interaction between the

railroad car and the track structure to improve parameters of the

discrete-continuous system by means of rational choice and optimization of the

parameters of its components.

Thus, the objectives of the study are as follows: to

develop a complex model and method of analysis of the

interaction between the four-axle car and the track on the basis of a systemic

approach and general correlations of the dynamics, taking into account phases

of car motion over joint irregularity; to apply methods of numerical analysis

in order to determine and analyse the interaction between the elements of the

transport systemic discrete-continuous mechanical complex; and to determine new

patterns of mechanical interaction between the four-axle car and the track when

the four-axle car passes over joint irregularity with respect to motion phases

in order to develop efficient design solutions.

3. MODEL AND METHODS FOR

ANALYSING THE DYNAMIC INTERACTION BETWEEN THE TRACK AND THE RAILROAD CAR

A

multiple-factor dynamic discrete-continuous model of the four-axle car is

analysed in the present research. The four-axle car can be represented by

either a tram car, or a passenger or freight wagon. The model takes into

account the design parameters and load of the vehicle, connection conditions of

the trailing and facing rails through a rail joint plate, and ballast

stiffness. The car passing over joint irregularity is considered for all phases

of motion. Thus, in the first phase, all the wheel sets are positioned on the

trailing rail; in the second phase, three wheel sets remain; in the third

phase, there are only two wheel sets; and, in the fourth phase, there is only

one wheel set. In the present paper, a mechanical schematic, using the example

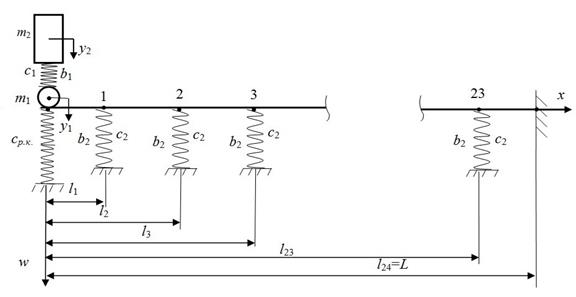

of the first phase of motion, is given in Fig. 1.

Fig. 1. Schematic for passing over joint irregularity

The

label descriptions are as follows: 1) a railroad car of the transportation

vehicle; 2-5) corresponding wheel of the wheel set; 6-7) central suspension of

the car; 8) facing rail; 9) trailing rail; 10) elastic elements of the ballast

under sleepers; 11) elastic element that simulates stiffness of the trailing

rail at the end.

Calculation

of the interaction at other phases differs according to the number of wheels on

the facing and trailing rails. The results of the study concerning other phases

of motion are presented as characteristic curves and finite analysis. The

suggested integrated approach provides for the consecutive solution of

interrelated tasks, as presented in the structural and logical scheme

in Fig. 2, which implements the suggested scheme of a consecutive static

and dynamic calculation method.

Block 1 - static calculation. Here

mechanical characteristics of railway rolling stock and the track

and the car load, as well as phases of the car passing and calculating error,

are defined. As a result, we obtain the size of the step upstairs and the

stiffness of the rail at the end.

Block 2 - calculation of the impact

interaction of the wheel and the facing rail. At this stage,

mechanical characteristics of the car, trolleys, wheels and rail are specified,

as well as the size of the step upstairs, design speed and stiffness of the

rail at the end, which allows us to define the after-collision speed of the

joint motion of the wheel and the facing rail.

Block 3 - dynamic calculation. At

this stage, mechanical properties of the examined system, initial conditions,

after-collision speed, static deflection of the facing rail and the phase of

the car passing over the joint irregularity are defined. As a result of the

calculations, we obtain the maximum deflections of the facing rail under the

first sleeper.

By

conducting static calculations, we can define rail stiffness at the end as one

of the elastic supports (Block 1 [15]). In total, static calculations

enable us to define the deflections of the trailing and facing rails

(transferred to Block 3), as well as the size of the step (transferred to Block

2). In Block 2, the impact interaction between the wheel and the facing rail is

considered. In addition to motion parameters (speed and car load), these

calculations define the size of the step. On examining the impact interaction,

we can define the vertical speed of the wheel and the facing rail. These values

are transferred to Block 3, in which the oscillations of the facing rail,

during the phase of increasing its deflection under the first sleeper, are

calculated. The data on static and impact interaction are used in this boundary

value problem. Static deflection of the facing rail and its vertical speed, as

calculated in Blocks 1 and 2, respectively, are used as initial conditions.

Fig.

2. Structural scheme for the calculation method

3.1. Impact interaction

Let us consider the

impact interaction of the wheel and the facing rail in accordance with the

structural scheme in Fig. 2. At the beginning of the calculations, the

mechanical parameters of the transportation vehicle, and the track and connection

conditions

of the rails are defined as well as the results of the static calculations of

the size of the step upstairs (Block 1 in Fig. 2). At this stage, the

parameters of the impact momentum, to which the facing rail is exposed during

its impact interaction with the wheel, are defined using the change-of-momentum

theorem of the system [15]. Further, the assumption is that, on

collision, the facing rail is bent at the same curve as in the case of static

load. Then, the motion speed of the rail after collision at the contact point,

depending on the load and phase of the car motion over joint irregularity, is

defined. The obtained data are transferred to Block 3 (Fig. 2).

3.2. Dynamic interaction

The calculated

mechanical schematic of dynamic interaction for the facing rail during the

first phase of the car motion is shown in Fig. 3.

The label

descriptions are as follows: с1, b1 - suspension stiffness and

damping coefficient; с2,

b2 - ballast stiffness and

damping coefficient; сp.k - stiffness of the rail at its

end (calculated

in Block 1 in Fig. 2);

m1, m2 - reduced masses of the

wheel and the car, taking into account the load; у1; у2 - displacement of

reduced mass of the wheel and the car; and li (і=1-24) - geometrical coordinates of the elastic supports.

While

calculating the deflections of the discrete-continuous system, mechanical and

geometrical characteristics, static deflections and after-collision speed for

the facing rail are defined. Differential equations for

oscillations in the mechanical schematic in Fig. 3 are given below [37]:

(1)

(1)

where:

δ(х) - impulse function; w

- rail deflection; ![]() - the coordinate of the

relevant rail;

- the coordinate of the

relevant rail; ![]() - the coordinate of the

relevant wheel on the facing rail; K -

the number of wheels on the facing rail corresponding to the phase of motion; F, ρ

- the cross-sectional area and density of the rail material; and

- the coordinate of the

relevant wheel on the facing rail; K -

the number of wheels on the facing rail corresponding to the phase of motion; F, ρ

- the cross-sectional area and density of the rail material; and ![]() - bending stiffness.

- bending stiffness.

Fig. 3. Calculated mechanical

schematic of dynamic interaction for the facing rail during the first phase of

the car motion

The

system deflections are viewed as a superposition of the first five eigenmodes. Using a model with

energy dissipation is undoubtedly feasible under these conditions. However, the

damping properties of the ballast are neglected in most calculations due to the

fact that the rail deflection is only considered during the phase when it increases.

The solution to the

system (1) is performed using the Fourier method for the separation of

variables [3] and the Laplace-Carson

transform. In the case above, the solution to the problem with

the facing rail oscillation is reduced to a superposition of eigenmodes. As a result, the rail

deflection, when considering the sprung mass and non-zero initial conditions

taken from the static rail deflection (Block 1 in Fig. 2) and after-collision

speed (Block 2 in Fig. 2), can be represented by the following expression [3,6]:

w(t,x)=![]() . (2)

. (2)

where: Ds -

coefficients from mode orthogonality [145] when

jointly considering the after-collision speed of the rail with the wheel, ![]() ;

; ![]() - eigenmode and natural

oscillation frequencies of the system;

- eigenmode and natural

oscillation frequencies of the system; ![]() -

dissipation factors of the appropriate form;

-

dissipation factors of the appropriate form; ![]() - reduced mass of the rail; and

- reduced mass of the rail; and ![]() - reduced resistance factor.

- reduced resistance factor.

All the

above allows us to define the function of the deflections, which is used to

obtain the maximum deflection under the first sleeper (х=l1)

of the facing rail at the initial time t=0. When

increasing the time gap, the deflection starts to grow until it reaches its

maximum value. After that, the deflection starts to decrease, which confirmed

that the searching for its maximum values has ended.

4. RESEARCH RESULTS

In accordance with the suggested model, a

numerical analysis of the parameters of dynamic interaction between a four-axle

car and the track in the area with isolated joint irregularity of the “gap”

type has been performed. Calculations have been made on the basis of the

variation in operational factors, namely, car load and speed during the

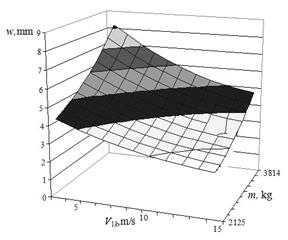

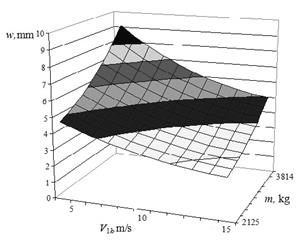

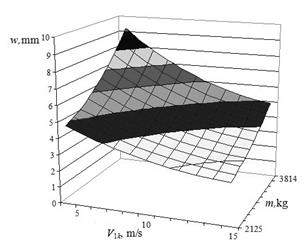

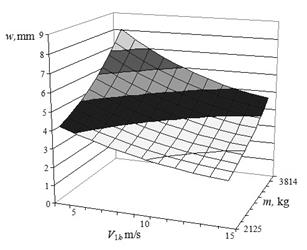

relevant phases of the car motion over irregularity, as shown in Figs. 4-7. As

a result, we have obtained correlations of maximum deflection under the first

sleeper by taking into account the fastening of the trailing and facing rails

to rail joint plates, and the geometrical and mechanical

characteristics of the rails, plates, sleepers and ballast.

The

analysis has been performed in accordance with the calculation pattern in Fig.

2, which has allowed us to define the function of the deflections by solving

the differential equations for discrete-continuous system fluctuation (1) in

the case of mechanical energy dissipation (2). The

results obtained show that the biggest deflections occurred during the second

and third phases of the car motion over joint irregularity.

|

Fig. 4. Facing rail deflection during the

first phase of motion |

Fig. 5. Facing rail deflection during the

second phase of motion |

|

Fig. 6. Facing rail deflection during the

third phase of motion |

Fig. 7. Facing rail deflection during the fourth phase of

motion |

The calculations have

been performed using the geometrical and mechanical characteristics of the P-65

rail, with the T-3 tram as an example [1],

where: the modulus of elasticity of the rail material is Е=2.6·1011 N/m2; the moment

of inertia of the rail cross section, relative to the neutral axis, is J=3573 cm4; the

suspension and ballast stiffness are с1=4.225·105 N/m, с2=1·108 N/m;

and the resistance factors for suspension and ballast are b1=24·103 kg/s,

b2=60·103 kg/s. The

car’s empty weight was reduced to one wheel (=m1+m2=2,125 kg)

and the maximum weight of a loaded car, i.e., with 193 passengers (m=m1+m2=3814 kg;

m1=1,100 kg).

Meanwhile, ![]() =150 kg represents the reduced

mass of the rail, which corresponds to the operational conditions and the design

characteristics of the railway rolling stock, and the track and joint plates of

real objects.

=150 kg represents the reduced

mass of the rail, which corresponds to the operational conditions and the design

characteristics of the railway rolling stock, and the track and joint plates of

real objects.

5. CONCLUSIONS

The numerical

calculation results for the parameters of the dynamic car-track interaction in

the area of joints are given, with reference to operational, mechanical and

geometrical factors. The relevant models are also offered. The research allows

us to define new patterns of interaction between the four-axle car and the

track while passing over joint irregularity, as well as improving the operational

performance and characteristics of the car and the track structure by means of

rational choice and optimization. The findings can be applied when developing

design solutions in order to improve track joints, defining operation modes of

tram cars depending on the state of the track, and developing experimental and

theoretical complexes for the purpose of researching, calculating and

optimizing the parameters of rail transport knots.

References

1.

Allan James. 2012. “Soil

mechanics of high speed rail tracks”. In: First Civil and Environmental Engineering Student Conference:

206-212. 25-26 June 2012. Imperial College London.

3.

Бабаков

И.М. 1968. Теория

колебаний.

Москва:

Наука. [In Russian:

Babakov I. M. 1968. Theory of

Oscillations. Moscow: Nauka.]

4.

Bakowski H. J. Piwnik. 2016.

„Quantitative and qualitative comparison of tribological properties of

railway rails with and without heat treatment”. Archives Of Metallurgy

And Materials 61(2): 469-474. DOI: 10.1515/amm-2016-0037.

5.

Bakowski H., A. Posmyk, J. Krawczyk. 2011.

„Tribological properties of rail steel in straight moderately loaded

sections of railway tracks”. Archives Of Metallurgy And Materials 56(3):

813-822. DOI: 10.2478/v10172-011-0090-0.

6.

Черногоров Е.П.

2013. Колебания

механических

систем.

Челябинск:

Ю-УГУ. [In Russian:

Chernogorov E. P. 2013. Fluctuations

of Mechanical Systems. Chelyabinsk: South Ural State

University.]

7.

Domin R., I. Domin, G. Cherniak, A.

Mostovych, V. Konstantidi, P. Gryndei. 2016. “Investigation of the some

problems of running safety of rolling stock on the Ukrainian railways”. Archives Of Transport 40(4): 15-27.

8.

Gursky V., I. Kuzio. 2016.

“Strength and durability analysis of a flat spring at vibro-impact

loadings”. Eastern-European Journal

of Enterprise Technologies 5/7(83): 4-10. ISSN: 1729-3774. DOI:

10.15587/1729-4061.2016.79910.

10.

Лазарян В. А.

1964. Динамика

вагонов.

Устойчивость

движения и

колебания.

Москва:

Транспорт. [In Russian: Lazaryan V. A. 1964. Car Dynamics: Stability of Movement and

Fluctuations. Moscow: Transport.]

12.

Nuzzolo A., Comi A. 2015. “Modelling the demand for rail

in an urban context: some methodological aspects”. Transport\Transporti Europei 57(3).

13.

Rose J.G., P.F. Teixeira, N.E.

Ridgway. 2010. “Utilisation of asphalt/bituminous layers and coatings in

railway trackbeds”. In: 2010 Joint

Rail Conference: 239-255. 27-29 April 2010. Urbana, Illinois. ISBN: 978-0-7918-4906-4.

15. Shpachuk V., A.

Chuprynin, T. Suprun, A. Garbuz. 2018. “A multifactor analysis of the

rail transport car that passes over a joint unevenness with respect to the

phases of its motion”. Eastern-European

Journal of Enterprise Technologies 1/7(91): 55-61. ISSN: 1729-3774. DOI:

10.15587/1729-4061.2018.121584.

16. Srihari, P.,

Azad, D., Sreeramulu, D. 2014. “Optimization of rail inserts

using finite element analysis”. International

Journal of Engineering, Science and Technology 6(2): 65-75. ISSN:

2141-2839. DOI:

http://dx.doi.org/10.4314/ijest.v6i2.5.

17. Вериго М. Ф.,

А. Я. Коган. 1986. Взаимодействие

пути и

подвижного

состава.

Москва:

Транспорт. [In Russian: Verigo M. F., A.Ya.

Kogan. 1986. Interaction of Track

and Rolling Stock. Moscow: Transport, 559.]

Received 20.02.2018; accepted in revised form 17.05.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License