Article

citation information:

Nemchinov, S., Khristenko, A. Stress-strain state of

pneumatic flexible shaft coupling for ball mill drives. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 99, 125-134.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.12.

Serge NEMCHINOV[1],

Alexander KHRISTENKO[2]

STRESS-STRAIN

STATE OF PNEUMATIC FLEXIBLE SHAFT COUPLING FOR BALL MILL DRIVES

Summary. The article explores the stress-strain state of the

pneumatic flexible shaft coupling of the tumbling mill drive using a software

of finite element analysis. The study has revealed that the stress-strain state

of the pneumatic flexible shaft coupling is characterized by an uneven general

and local distribution of stresses. Areas of maximum stress and strain in the

pneumatic flexible shaft coupling have been defined. The study allowed for

changing the geometry and reducing the mass of the disc of the pneumatic

flexible shaft coupling with a slight change in stresses and strains. The results

of the study can be applied to the design of pneumatic flexible shaft couplings

and serve as a basis for further research.

Keywords: pneumatic flexible

shaft coupling; finite element method; geometry; stress; strain; displacement

1. INTRODUCTION

Various couplings that serve to transmit rotary motion from one shaft to

another are widely used in many industries. Drive couplings may also perform

other important functions: compensation for small mounting misalignments of

units and assemblies, disconnection of shafts, automatic control of machine

operation, smooth coupling of shafts on machine start-up, protection of

machines from breakdowns in emergency mode etc [1]. In today’s mechanical

engineering context, couplings with non-metal flexible elements, which possess

high compensating and damping properties, are widely used [2]. However, these

couplings are generally applied for the transmission of low and medium torque

because of the low strength of rubber and polymers. The studies by Vinogradov

and Homisin show that pneumatic flexible shaft couplings are free from these

disadvantages and can transmit high torques with the possibility of adjusting

rigidity within a wide range [3-7]. At present, there are no recommendations

for calculating the mechanical strength and stiffness of pneumatic flexible

shaft couplings intended for ball mill drives.

Consequently, the study of the stress-strain state (SSS) and the choice

of a rational form of the pneumatic flexible shaft coupling at the design stage

are of great importance and involve not only technical but also economic

aspects.

In the last decade, numerical methods have been increasingly used for

the calculation of machine parts and mechanisms, with the finite element method

(FEM) taking a key place amongst them. As numerical research tools, proprietary

programming systems for finite element analysis (ANSYS, Nastran, SolidWorks,

Abaqus, Lira, Scad) and open-source software programs (CalculiX, Elmer, and

Code_Aster) are used today. These methods, unlike traditional ones based on the

postulates of the strength of materials and the theory of elasticity, allow for

a thorough study of a general SSS and the distribution of local stresses when

formulating two-dimensional and three-dimensional problems. In many cases, this

enables us to dispense with experimental studies, although the latter retain

their importance as a means of verifying the results of stress-strain analysis

[8-11].

Today, practically no experience has been reported of designing

pneumatic flexible shaft couplings, so, in most cases, they have been

calculated approximately, which can be explained by difficulties describing the

SSS and by structural features.

The purpose of the work is a stress-strain analysis of the pneumatic

flexible shaft coupling intended for use in ball mill drives and justifying the

choice of its possible rational geometry.

2. FORMULATION OF PROBLEM

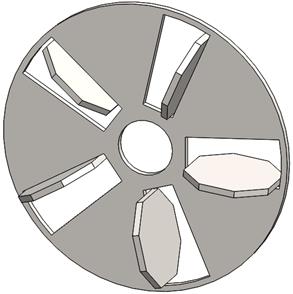

A pneumatic flexible

shaft coupling, whose geometric model is shown in Fig. 1, is subject to a

uniformly distributed load. It is necessary to determine its SSS.

A pneumatic flexible

shaft coupling is a structure of complex configuration; therefore, analytical

methods for its calculation are, in practice, unacceptable. Reliable results

can only be obtained by numerical methods implemented on a computer. Therefore,

to solve this problem of the theory of elasticity, we apply the FEM, which, in

our time, is obviously the world standard for calculations of strength,

stiffness and durability.

The FEM allows for

obtaining a system of algebraic equations:

![]() , (1)

, (1)

where ![]() is the stiffness matrix of the FEM,

is the stiffness matrix of the FEM, ![]() is the nodal displacement vector, and

is the nodal displacement vector, and ![]() is the vector of the nodal forces.

is the vector of the nodal forces.

Fig. 1. Geometric model of a

pneumatic flexible shaft coupling

Having solved the system

in (1), we find the displacement![]() ,

after which we find stress

,

after which we find stress ![]() and strain

and strain ![]() using the strain-displacement

relations (Cauchy) and stress-strain relations (Hooke’s law).

using the strain-displacement

relations (Cauchy) and stress-strain relations (Hooke’s law).

The application of the

FEM involves the simulation of the geometry of a structure and its meshing into

finite elements, the formation of a global stiffness matrix and solving large

systems of linear equations (5,000÷500,000). The above problems have

prompted the authors to apply the Salome-Meca platform-based, open-source

Code_Aster application as a tool of numerical simulation. Code_Aster software

allowed for the analysis of the SSS of the pneumatic flexible shaft coupling,

taking into account the features and modes of operation.

3. RESULTS OF NUMERICAL EXPERIMENTS

The study focused on a

numerical calculation of the SSS of a pneumatic flexible shaft coupling with

the overall dimensions of 2,200 x

Prior to the simulation

of a FEM, a solid-state spatial model of the pneumatic flexible shaft coupling

(Fig. 1) was created using the KOMPAS-3D system for three-dimensional

modelling. Taking into account the fact that the pneumatic flexible shaft

coupling consists of two identical parts, the stress-strain analysis was

performed on one part of the model.

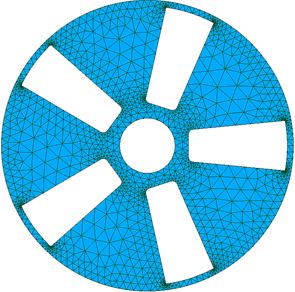

The created solid-state

model was then transferred to the Salome-Meca platform-based, open-source

Code_Aster, which was used to set the boundary conditions, loads and areas

where the load was applied, and to create a mesh of the FEM.

The boundary conditions

were set so as to exclude the displacements of the pneumatic flexible shaft

coupling as an absolutely rigid body. According to the working conditions, with

the dynamic factor taken into account, the load on the pneumatic flexible shaft

coupling was assumed to be 250 kN for every air spring. Fig. 2 presents the

calculation schematic with the loads and boundary conditions indicated.

a

b

Fig. 2. Calculation schematic (a)

and FEM (b) of the pneumatic flexible shaft coupling

Three-dimensional finite

elements with a maximum size of

The material selected

was DIN 1.1181 (C35E) steel with Young’s modulus ![]() ,

Poisson’s ratio ν=0.28, yield strength

,

Poisson’s ratio ν=0.28, yield strength ![]() ,

and tensile strength

,

and tensile strength ![]() .

.

As a result of a static

calculation, the following SSS parameters of the pneumatic flexible shaft

coupling were obtained: stress and strain along the corresponding axes;

principal stresses and corresponding strains; equivalent stresses ![]() calculated by Huber-Mises energy theory

of strength; total displacements; displacements along corresponding axes; and

factors of safety.

calculated by Huber-Mises energy theory

of strength; total displacements; displacements along corresponding axes; and

factors of safety.

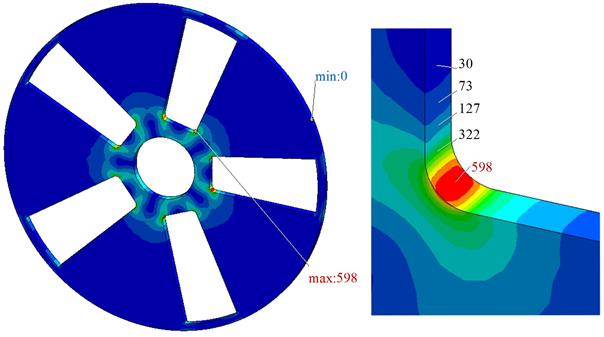

The results of the

calculation show that the SSS of the pneumatic flexible shaft couplings is

characterized by an uneven general and local distribution of stresses and

displacements (Fig. 3). It has been established that high equivalent stresses

(175 to 225 MPa) are observable in the areas located between the surface of the

openings and the mounting surface for the shaft. This indicates that these

areas need to be strengthened, that is, pneumatic flexible shaft couplings need

to have a hub. Over a large area of the disc, the magnitudes of equivalent

stresses are small and do not exceed 50 MPa. This indicates that the depth of

the disc can be reduced. The maximum equivalent stresses calculated by the

Huber-Mises theory are observed in the areas of abrupt changes in geometry

(Fig. 3a). The maximum equivalent stresses occurring in the fillets reach 598

MPa, i.e., ![]() .

It should be noted that the maximum equivalent stresses occur within a small

(in size) area (Fig. 3b), that is, they are localized and do not change

throughout the depth of the disc.

.

It should be noted that the maximum equivalent stresses occur within a small

(in size) area (Fig. 3b), that is, they are localized and do not change

throughout the depth of the disc.

a

b

Fig. 3. Iso-surfaces of equivalent

stresses ![]() ,

MPa (a) and the area of maximum equivalent stresses (b)

,

MPa (a) and the area of maximum equivalent stresses (b)

The study has also

revealed the following:

- A dependence ![]() of normal stresses was observed on a

significant surface of the disc

of normal stresses was observed on a

significant surface of the disc

- The values of tangential stresses

are much lower than the values of normal stresses

- The values of tangential stresses

![]() are higher than the values of tangential

stresses

are higher than the values of tangential

stresses ![]()

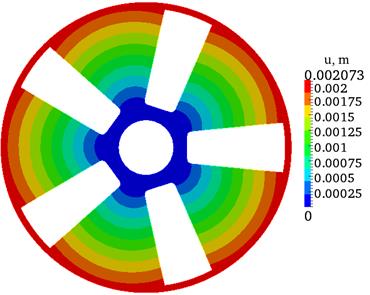

Fig. 4. Iso-surfaces of total

displacements ![]()

The total displacement u diagram, shown in Fig. 4, indicates

that total displacements vary linearly and equally over the entire surface,

with the maximum total displacement (

The

study shows that the maximum normal stresses (![]() ,

,

![]() ,

, ![]() ),

observed in zones with regular geometry and in zones of sharp geometry change,

do not exceed the permissible stress

),

observed in zones with regular geometry and in zones of sharp geometry change,

do not exceed the permissible stress ![]() for the selected

material. These

findings allow for changing the geometry of the disc of the pneumatic

flexible shaft coupling so as to reduce its weight. The authors have proposed a

pneumatic flexible shaft coupling, in which the thickness of

the disc was reduced to

for the selected

material. These

findings allow for changing the geometry of the disc of the pneumatic

flexible shaft coupling so as to reduce its weight. The authors have proposed a

pneumatic flexible shaft coupling, in which the thickness of

the disc was reduced to

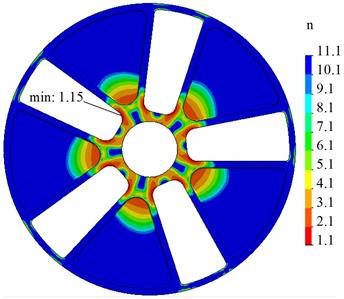

The analysis of the n diagram of the proposed disc

of the pneumatic flexible shaft coupling (Fig. 6) shows that the values of

factors of safety ranged from 1.15 to 11.1.

Thus, the study

indicates that the strength and stiffness of the proposed disc

of the pneumatic flexible shaft coupling are ensured. The changes in geometry

allowed for reducing the mass of the disc by almost 30%.

An analysis of the

experimental data (Fig. 3) revealed that the maximum normal stresses are

observed in areas of sharp change in geometry (in areas of stress

concentrators) and in the lower fibres of the curved surface of the disc, which

are located next to the trapezoid openings. Reducing the maximum stresses in

zones of sharp change in geometry is achieved by smooth transitions from one

surface to another.

Fig.

5. Safety factor diagram of the proposed

disc of the pneumatic flexible shaft coupling

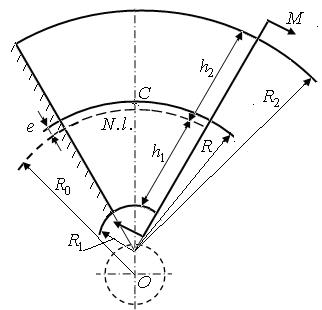

To determine the maximum

stresses, we have allocated a part of the disc, which was located between two

trapezoid openings. The selected part of the disc can be considered as a large

curvature beam (![]() ),

which undergoes pure bending (Fig. 6).

),

which undergoes pure bending (Fig. 6).

Fig. 6. Calculation scheme of the beam of great curvature

To determine the normal stresses in the selected part, the positions of the neutral layer were first determined by the following formula [4]:

![]() , (2)

, (2)

where  is the distance between the neutral layer and the layer passing through the centres of gravity of the sections of the beam,

is the distance between the neutral layer and the layer passing through the centres of gravity of the sections of the beam,  is the height of the curvilinear beam, and

is the height of the curvilinear beam, and is the radius of the layer passing through the centre of gravity of the sections of the curvilinear part.

is the radius of the layer passing through the centre of gravity of the sections of the curvilinear part.The radiuswas determined by the formula below:

, (3)

, (3)

whereand

are the radii of curvature of the inner and outer fibres, respectively, and

is the angle formed by the creations carried through the major sides of the trapezoid openings.

Substituting the values of the radii and the angle (,

,

) in (3), we find that

.

The resulting valueand height

of the curvilinear beam (

) are substituted in (2) and we find that

. It should be noted that the position of the neutral layer in the global coordinate system, whose centre is located in the centre of the shaft on which the disc is planted, is determined by the radius

, the value of which is equal to

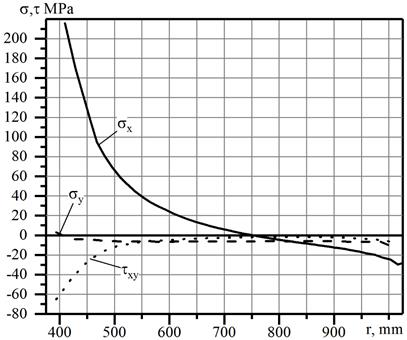

. From Fig. 7, constructed based on the results of finite element analysis, it is clear that

. Thus, the difference between the values obtained by two methods does not exceed

.

To calculate the strength, it is necessary to always determine the greatest stresses that arise in the cross section. In the curvilinear beam, the largest absolute magnitudes of normal stress occur in the extreme fibres of the cross section, which are located on the curved surface of the beam. We wish to draw attention to the fact that the largest absolute magnitudes of normal stress in the muff disc also arise in the extreme fibres located on the curved surface of the beam (Fig. 3а). To determine such stresses, we apply a known formula, i.e.:

![]() , (4)

, (4)

where ![]() is the

bending moment in the cross section,

is the

bending moment in the cross section, ![]() is the

distance between the neutral line and the inner fibre (Fig. 6),

is the

distance between the neutral line and the inner fibre (Fig. 6), ![]() is the

cross-sectional area, and

is the

cross-sectional area, and ![]() is the

radius of curvature of the internal fibre of the curved beam.

is the

radius of curvature of the internal fibre of the curved beam.

Substituting the values of all the quantities in (4) (,

,

,

), we find that

. From Fig. 7, constructed based on the results of finite element analysis, it is clear that

. Thus, the difference between the values obtained by the two methods does not exceed

.

Fig. 7. Graph showing the variation in the normal and tangential stresses in Section I-I

Consequently,

the calculations revealed that the values of the obtained values and by the

formulas in (2) and (4) almost coincide with the values of those obtained by

the finite element method. This indicates that the part of the coupling that is

limited by two trapezoid openings can be considered as a

beam of large curvature and, in the first stage of designing the formulas in

(2) and (4), used to determine the maximum normal stresses on which to determine

the required sizes. After the first stage of the design, it is necessary to

conduct a thorough finite element analysis of the SSS and, based on this

analysis, select the final shape and dimensions of the coupling.

4. CONCLUSIONS

The SSS of pneumatic flexible

shaft couplings, which was analysed by means of finite element modelling, is

characterized by an uneven general and local distribution of stress. Changes in

the total displacement were of a similar nature over the entire surface of the

pneumatic flexible shaft coupling. The results of the SSS analysis enabled us

to identify areas of maximum stresses in pneumatic flexible shaft couplings,

which proved to be the areas of abrupt changes in the geometry. It has been

found that the values ![]() and

and ![]() are higher than the values

are higher than the values ![]() . It has been established that the values

of the tangential stresses

. It has been established that the values

of the tangential stresses ![]() are higher than the values

are higher than the values ![]() ,

,

![]() .

The study allowed for changing the geometry and reducing the mass of the disc of the pneumatic flexible shaft coupling with a slight change in

stresses and strains.

.

The study allowed for changing the geometry and reducing the mass of the disc of the pneumatic flexible shaft coupling with a slight change in

stresses and strains.

The study also confirmed that, in determining

the stresses in the parts of the couplings located between the two holes, it is

possible to use the formulas for the large curvature bars, with which these

parts can be replaced. The findings will have a practical application in

designing new pneumatic flexible shaft couplings.

References

2.

Homišin

J. 2016. “Characteristics of pneumatic tuners of

torsional oscillation as a result of patent activity”. Acta Mechanica et Automatica 10(4):

316-323. ISSN: 1898-4088. DOI: 10.1515/ama-2016-0050.

3.

Годжаев

З.А., A.A.

Поповский, C.B.

Гончаренко 2011.

“Исследование

характеристик

пневматического

упругого

элемента

рукавного

типа в зависимости

от давления

воздуха, хода

и формы

поршня”. Вісник

СевНТУ 120: 306-311. ISSN: 2307-6488.

[In Russian: Godjayev Z.А., A.A. Popovskiy, S.V. Goncharenko. 2011.

“Research on the performance of the pneumatic elastic sleeve element

depending on air pressure, piston stroke and form”. Visnik SevNTU 120: 306-311. ISSN: 2307-6488.]

4.

Homišin J.,

P. Kaššay, M. Puškár, R. Grega, J. Krajňák,

M. Urbanský, M. Moravič. 2016. “Continuous tuning

of ship propulsion system by means of pneumatic tuner of torsional

oscillation”. International Journal

of Maritime Engineering: Transactions of The Royal Institution of Naval

Architects 158(A3): 231-238. ISSN: 1479-8751. DOI: 10.3940/rina.ijme.2016.a3.378.

5.

Поляков

В.С., И. Д. Барбаш,

О.А

Ряховский. 1974. Справочник

по муфтам.

Ленинград,

СССР:

«Машиностроение».

[In Russian: Polyakov V.S., I.D. Barbash, O.A. Ryakhovsky. 1974. Handbook of Couplings. Leningrad, USSR:

“Mechanical Engineering”.]

6.

Виноградов,

Б.В. 2012.

“Проблемы

создания

двухдвигательных

приводов

барабанных

мельниц”. Науковий

вісник Національного

гірничого

університету

5: 61-65. ISSN: 2071-2227.

[In Ukrainian: Vinogradov, B.V. 2012. “Problems in the creation

of a two-motor drive tumbling mill”. Scientific

Bulletin of National Mining University 5: 61-65. ISSN: 2071-2227.]

7.

Lušić Z., S. Kos, S. Krile. 2008. „Structural Analysis of Positioning Methods at Sea”. Nase More 55(1-2): 3-17.

8.

Gąska

D., T. Haniszewski, 2017. „Numerical Modelling

of I-Beam Jib Crane with Local Stresses in Wheel Supporting Flanges - Influence

of Hoisting Speed”. Nase More

64(1): 7-13.

9.

Gąska

D., T. Haniszewski, J. Margielewicz. 2017. "I-beam girders dimensioning

with numerical modelling of local stresses in wheel-supporting flanges". Mechanika 23(3): 347-352. ISSN

1392-1207.

10.

Weskamp

C., A. Koberstein, F. Schwartz, L. Suhl, S. Voss. 2018. “A two-stage

stochastic programming approach for identifying optimal postponement strategies

in supply chains with uncertain demand”. Omega. DOI: 10.1016/j.omega.2018.02.008. ISSN: 0305-0483.

11.

Wittek

A.M., D. Gąska, B. Łazarz, T. Matyja. 2014. "Automotive

stabilizer bar - stabilizer bar strength calculations using FEM, ovalization of

radial areas of tubular stabilizer bars". Mechanika 20(6): 535-542. ISSN 1392-1207.

Received 04.03.2018; accepted in revised form 02.06.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License