Article

citation information:

Medvecká-Beňová,

S. Designing

pitch curves of non-circular gears. Scientific

Journal of Silesian University of Technology. Series Transport. 2018, 99, 105-114. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.10.

Silvia MEDVECKÁ-BEŇOVÁ[1]

DESIGNING PITCH

CURVES OF NON-CIRCULAR GEARS

Summary. The paper examines the design and generation of gear

drives with non-circular gears. Gearings with a changing transmission gear

ratio are used for the purposes of practical experimentation, even though

“standard” gearings with a constant transmission gear ratio are

used more often. In this paper, the author presents the design for the shape of

a pitch outline for a specific requirement, that is, continuous change in gear

ratio during one rotation. The gearing is designed such that the pitch curve is

composed of an ellipse. The article also presents some kinematic properties of

the designed non-circular gearing.

Keywords: gear; non-circular;

ellipse; pitch outline; variable transmission ratio

1. INTRODUCTION

Gearboxes belong to the most used transmission mechanisms. The history

of gears is probably as old as civilization itself. The earliest description of

gears was written in the fourth century BCE by Aristotle, who wrote that the

“direction of rotation is reversed when one gear wheel drives another

gear wheel”. In practice, the most commonly used “standard”

toothed gears are characterized by a constant gear number and circular wheel

shape. Non-circular gears are not well known, even though the idea behind them

originates from the pioneers of engineering thought. For example, such gears

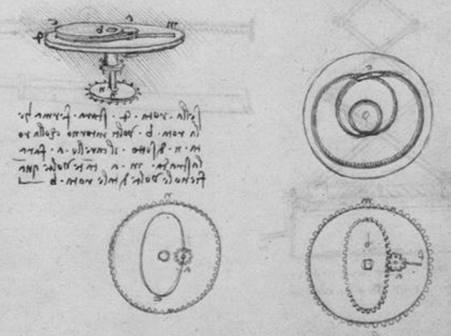

were sketched by Leonardo da Vinci (Fig. 1) [1], while, in the late 19th

century, Franz Reuleaux ordered a series of non-circular gear models from the

Gustav Voigt Mechanische Werkstatt in Berlin to help with the study kinematics.

These historical gears comprised simplified tooth shapes and, for this reason,

the meshing conditions were not always correct.

Fig. 1. Sketch by Leonardo da Vinci [1]

Non-circular gears are

presented as a curiosity from the gear industry history, due to their complex

design and manufacturing difficulties. Nowadays, performance modelling and

simulation software, advanced CNC machine tools and non-conventional manufacturing

technologies enable non-circular gear design and manufacture.

As mechanisms used to

generate variable motion laws, in comparison with cams, linkages, variable

transmission belts, Geneva mechanisms and even electrical servomotors,

non-circular gears are remarkable due to their advantages, such as the ability

to produce variable speed movements in a simple, compact and reliable way, the

lack of gross separation or decoupling between elements, fewer parts in the

design phase, and the ability to produce high strength-to-weight ratios [2-4].

The applications of

non-circular gears include textile industry machines, for improving machine

kinematics resulting in process optimization [5,6], window shade panel drives,

for introducing vibrations that interfere with natural oscillations and

cancelling them out [7], high-torque hydraulic engines for bulkhead drives

[8-11], and mechanical presses, for optimizing work cycle kinematics. They are

also used as high-power starters, mechanical systems (providing progressive

torque for easier start-ups of machines, where progressive torque helps to

overcome the start-up inertia) and forging machines (optimizing the work cycle

parameters and reducing pressure dwell time). The use of non-circular gears in

industry certifies their effective performance, while prompting new ideas for

improved working conditions. Non-circular gears are also used on oval gear

flowmeters [12], which are categorized as positive displacement flow technology

devices. Positive displacement flow technology allows for precise flow

measurements of most clean liquids, regardless of media conductivity.

The generation of

non-circular gears is usually developed from a hypothetical basis, such as the

law of driven gear motion, variation in the gear transmission ratio, and the

design of the driving gear pitch curve [13-14]. The studies for the design and

manufacture of non-circular helical gears are highly limited.

The first step in the non-circular

gear virtual design process is the generation of the conjugate pitch curves,

starting from a predesigned law of motion for the driven element or a

predesigned geometry for the driving gear pitch curve. The current paper is

dedicated to this problem.

2. conditions OF proper meshing

The industry standard

involute tooth shape has been chosen for use in non-circular gears. Thus, the

existing involute gearing standards and methods can be adopted and applied. The

design of correct meshing must be based on the basic conditions that are

imposed on gearing. The tooth profiles, which form a shape bond, must have a

designed continuous meshing. Otherwise, in order to transmit a uniform rotary

motion from one shaft to another by means of gear teeth, the normals to the

profiles of these teeth at all points of contact must pass through a fixed

point (point P in Fig. 2.) in the

common centre line (O1O2

in Fig. 2.) of the two shafts. The fixed point is, of course, the pitch point;

and, for involutes, the normals (line n

in Fig. 2.) fall onto the line of action. The instantaneous normals to the

profiles of these teeth at all points of contact must pass through a fixed

point in the common centre line of the two shafts to transmit any rotary motion

from one shaft to another by means of gear teeth t. The pitch curves (k1 and k2 in Fig. 2.) correspond to the pitch circles in

“standard” circular gears.

Fig. 2. Condition of the

meshing of non-circular gears

Fig. 3 depicts

non-circular gears as two rollers rolling together without slippage, provided

there it is no addendum modification and the nominal axle distance (parameter a in Fig. 3.) is used. Roll lines (pitch

curves) are divided into z parts,

which are p long, where z is the gear’s number of teeth

and p is the pitch. The gear is

represented by two pitch curves k1

and k2 with centres in

points O1 and O2. The variable pitch curve

radii, r1(φ) and r2(φ), of the

non-circular gears are determined by the required course of the transmission

ratio i and therefore the ram

kinematics:

![]() (1)

(1)

where ω1(φ) and ω2(φ)

are the angular velocity functions for Gears 1 and 2, respectively.

With a given constant

centre distance:

![]() (2)

(2)

the transmission

function ψ´(φ)

describes the relation between the pitch curves of the non-circular gears. In

the case of an aperiodic non-circular gear, angular positions of the members

are limited [17-19]. Usually, a specific ratio function is used, for example, a

logarithmic function.

Fig. 3. Example of

non-circular pitch curves

3. Eccentric Elliptical Gearing

3.1. Characteristic of non-circular

gearing

The generation of this non-circular gear

was developed from a hypothetical basis, such as the law of driven gear motion,

variation in the gear transmission ratio and the design of the driving gear

pitch curve. This model of non-circular gear was designed for a variable

transmission ratio in the range u=0.25 to 4.0. This transfer should be formed by

two identical wheels with the number of teeth z1=z2=40 and gearing module mn=4 mm, where distance a=160 mm, and for one direction of

rotation.

3.2. Design of pitch curves

The first step in the non-circular gear

design process is the generation of the pitch curves, starting from a

predesigned law of motion for the driven element or a predesigned geometry for

the driving gear pitch curve. For a non-standard gearing, an eccentric

elliptical gear drive with a continuously changing transmission gear ratio was

applied; that is, the ellipse was used as the pitch curve (Fig. 4.). For the

given distance, the pitch ellipse had a large half-axis ae=80 mm, which is half of the axial distance. The

position of ellipse focus was determined by considering the desired

continuously changing transmission gear ratio. For the given variable

transmission ratio in the range u=0.25 to 4.0, the position of the ellipse

focal point (centre point O of

rotation) is determined by the ratio lengths x1: x2, which are equal to 1:4. The second

half-axis, be=64 mm, is

determined by the distance from the focus point ae=80 mm for the transmission ratio u=1.

Fig. 4. Pitch ellipse for gear

ratio u=0.25 to 4

In this case, one of the conditions of a

correct mesh is that the measurements of the pitch on the ellipse pitch must be

kept constant. A geometric separation of the pitch ellipse into 40 identical

sections (the number of teeth z1=z2=40)

is mathematically much more difficult than in the case involving standard

gear pitch circles.

Fig. 5. Design of the non-circular

pitch curves

Fig. 5 presents the

pitch ellipses of a designed eccentric elliptical gear drive with a

continuously changing transmission gear ratio for given parameters. Torque

transmission ensures shape-bonding between the meshing gears. The gearing

consists of two identical gears. The toothed number is shown for the drive

wheel; for the driven wheel, this numbering is the same. Wheels are designed

for only one direction of rotation. The pitch ellipses must meet the condition

that, for each tooth, the sum of the radii is equal to the axial distance

(Tab. 1.).

![]() (3)

(3)

where r1-i and

r2-j are the radii of mesh

points.

3.3. Kinematic properties of

non-circular gearing

In pursuit of kinematic ratios for the

proposed gearings, we assumed the right mesh conditions. Kinematic conditions

were processed for the drive wheel (centre of rotation at point O1) and the driven wheel

(with the centre of rotation at point O2).

On the relevant graph, the two gears are shown in a state of kinematic

dependence (initially, on the horizontal axis of the wheel teeth). In Tab. 1, the

dimensions of the spacing radii at the individual points of contact are

designated as r1-i,

respectively, while r2-j,

where Index 1 applies to the drive

wheel, Index 2 for the driven wheel,

and Index i or j corresponds to the order number of the engaging tooth (Fig. 5) at

one turn of the drive and driven wheel.

Tab.

1.

The kinematic properties of elliptical gearing

|

Meshing teeth input - output |

Radius of mesh points |

Centre distance a=r1-i + r2-j (mm) |

Transmission ratio ui=r2-j/r1-i |

Rotational speed ω2i=ω1/ui

(s-1) |

|

|

r1-i (mm) |

r2-j (mm) |

||||

|

1-21 |

128 |

32 |

160 |

0.250 |

400 |

|

02-20 |

127.25 |

32.75 |

160 |

0.257 |

388. 550 |

|

03-19 |

125.08 |

34.92 |

160 |

0.279 |

358. 190 |

|

04-18 |

121.67 |

38.33 |

160 |

0.315 |

317. 428 |

|

05-17 |

117.24 |

42.76 |

160 |

0.365 |

274.181 |

|

6-16 |

112.03 |

47.97 |

160 |

0.428 |

233.542 |

|

07-15 |

106.24 |

53.76 |

160 |

0.506 |

197.619 |

|

08-14 |

100.01 |

59.99 |

160 |

0.600 |

166.711 |

|

09-13 |

93.5 |

66.5 |

160 |

0.711 |

140.601 |

|

10-12 |

86.79 |

73.21 |

160 |

0.844 |

118.549 |

|

11-11 |

80 |

80 |

160 |

1 |

100 |

|

12-10 |

73.21 |

86.79 |

160 |

1.185 |

84.353 |

|

13-9 |

66.5 |

93.5 |

160 |

1.406 |

71.123 |

|

14-8 |

59.99 |

100.01 |

160 |

1.667 |

59.984 |

|

15-7 |

53.76 |

106.24 |

160 |

1.976 |

50.602 |

|

16-6 |

47.97 |

112.03 |

160 |

2.335 |

42.819 |

|

17-5 |

42.76 |

117.24 |

160 |

2.742 |

36.472 |

|

18-4 |

38.33 |

121.67 |

160 |

3.174 |

31.503 |

|

19-3 |

34.92 |

125.08 |

160 |

3.582 |

27.918 |

|

20-2 |

32.75 |

127.25 |

160 |

3.885 |

25.737 |

|

21-1 |

32 |

128 |

160 |

4 |

25 |

|

22-40 |

32.75 |

127.25 |

160 |

3.885 |

25.737 |

|

23-39 |

34.92 |

125.08 |

160 |

3.582 |

27.918 |

|

24-38 |

38.33 |

121.67 |

160 |

3.174 |

31.503 |

|

25-37 |

42.76 |

117.24 |

160 |

2.742 |

36.472 |

|

26-36 |

47.97 |

112.03 |

160 |

2.335 |

42.819 |

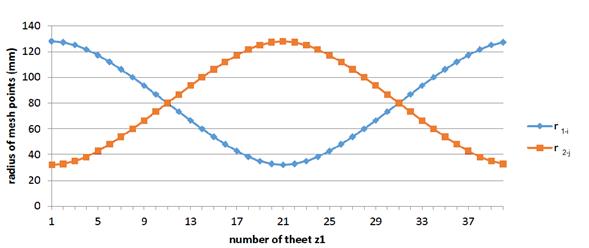

Fig. 6 represents the course of a

continuously changing gear ratio in one mesh generated by an elliptical gear,

which continuously varies in the range from u=0.25

to u=1.0 until u=4.0, and back. Thus, the gear ratio changes over the duration of

one revolution. A gear ratio value that is less than 1.0 signifies that this is an overdrive, while a gear ratio value

greater than 1.0 signifies a speed

reduction.

Fig. 6. Transmission gear ratio

Fig. 7 shows the progress of the meshing

radii at the individual points of contact, designated as r1-i, respectively, while r2-i, where Index 1

applies to the drive wheel, Index 2

to the driven wheel, and Index i or j corresponds to the order number of the

tooth.

Fig. 7. Radius of the mesh points

The rotational speed of the drive wheel

gear and the driven wheel gear is constant for standard spur gears. For the

designed elliptical gearing with variable transmission, the angular velocity of

the driven wheel is not constant but changed according to the continuous

changing of the gear ratio. This is shown in Fig. 8, where the angular velocity

is on the drive wheel (ω1=100

s-1) and the driven elliptical wheel (ω2i).

Fig. 8. Rotational speed

in non-circular gearing

3.4. Modification the pitch ellipse

when changing the gear ratio

For changes in gear ratio, for example, the variable

transmission ratio, in the range u=0.5

to 2, the modification of the pitch

ellipse is necessary. Fig. 9 presents the shape of the pitch ellipse for the

non-circular gear, which is defined by the number of

teeth z1=z2=40

and gearing module mn=4 mm,

where the distance a=160 mm and the

gear ratio is u=0.5 to 2.

Fig. 9. Pitch ellipse for the gear

ratio u=0.5 to 2

The position of ellipse focus is

determined by considering the desired continuously changing transmission gear

ratio. For the gear ratio in the range u=0.5

to 2, the position of the ellipse

focal point (centre point O of

rotation) is determined by the ratio lengths x1: x2, which are equal to 1:2. The second

half-axis be=75.42 mm is

determined by the distance from the focus point ae=80 mm for the transmission ratio u=1. The position of the pitch ellipse focus is consistent with the

variable gear ratio.

4. CONCLUSION

This article describes how to optimize the

design of pitch curves of non-circular gears for given parameters. Non-circular

gearing consists of two identical gear wheels. For a non-standard gearing, an

eccentric elliptical gear drive with a continuously changing transmission gear

ratio was applied. The kinematic properties of this gearing are different from

the properties of standard circular gears, i.e., spur gears. Thus, the gear

ratio changes over the duration of one revolution.

Non-circular gears synthesize the

advantages of circular gears and cam mechanisms, as well as offer a combination

of high output power and excellent accuracy with continuously variable transmission.

Non-circular gears have been applied to construction machinery, machine tools,

and the automotive, aerospace and other fields.

References

1.

Walter

Isaacson. 2017. Leonardo da Vinci.

Simon & Schuster. ISBN: 1-4744-6676-7, 599.

2.

David

Dooner, Seireg Ali. 1995. The Kinematic

Geometry of Gearing. John Wiley & Sons. ISBN: 978-0-471-04597-7, 472.

3.

Kowalczyk

Leon, Stanislaw Urbanek. 2003. “The geometry and kinematics of a toothed

gear of variable motion”. Fibres & Textiles in Eastern Europe

11, 3(42): 60-62.

4.

Zhang

Xin, Shouwen Fan. 2016. “Synthesis of the steepest rotation pitch curve

design for noncircular gear”. Mechanism

and Machine Theory 102: 16-35. DOI: 10.1016/j.mechmachtheory.2016.03.020.

5.

Mundo

Domenico. 2006. “Geometric design of a planetary gear train with

non-circular gears”. Mechanism and

Machine Theory 41: 456-472.

6.

Figlus

Tomasz, Marcin Stańczyk. 2014. “Diagnosis of the wear of gears in

the gearbox using the wavelet packet transform”. Metalurgija 53(4):

673-676. ISSN: 0543-5846.

7.

Doege,

Eckart, John Meinen, Tobias Neumaier. 2001. “Numerical design of a new

forging press drive incorporating non-circular gears”. Journal

of Engineering Manufacture 215:

467-471.

8.

Tong

Shihhsi, Yang Daniel. 1998. “Generation of identical noncircular pitch

curves”. Journal of Mechanical

Design 120: 337-341.

9.

Bošanský

Miroslav, Miroslav Vereš. 2012. Neštandardné

ozubené prevody. Bratislava: STU v Bratislave. ISBN:

978-80-227-3717-5.

10.

Litvin

Feonid et al. 2008. “Design and investigation of gear drives with

non-circular gears applied for speed variation and generation of

functions”. Computer Methods in

Applied Mechanics and Engineering 197: 3783-3802.

11.

Kapelevich

Alexander. 2000. “Geometry and design of involute spur gears with

asymmetric teeth”. Mechanism and Machine Theory 35(1):

117-130.

12.

Liu,

Youyu. 2015. “Study of optimal strategy and linkage-model for external

non-circular helical gears shaping”. Proceedings

of the Institution of Mechanical Engineers Part C: Journal of Mechanical

Engineering Science 229(3): 493-504.

13.

Dyakov

I., O. Prentkovskis. 2008. “Optimization problems in designing

automobiles”. Transport 23(4):

316-322.

14.

Rincon

Femandez, Fernando Viadero, 2013. “A model for the study of meshing

stiffness in spur gear transmissions”. Mechanism and Machine Theory 61: 30-58.

This paper was written within the framework

of the following grant projects: “VEGA 1/0290/18 - Development of New

Methods of Determination of Strain and Stress Fields in Mechanical System

Elements by Optical Methods of Experimental Mechanics”; “KEGA

041TUKE-4/2017 - Implementation of New Technologies Specified for the Solution

of Questions Concerning Emissions of Vehicles and Their Transformation in the

Educational Process in Order to Improve Quality of Education”; and

“APVV-16-0259 - Research and Development of Combustion Technology Based

on Controlled Homogenous Charge Compression Ignition in Order to Reduce

Nitrogen Oxide Emissions of Motor Vehicles”.

Received 11.02.2018; accepted in revised form 19.05.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License