Article

citation information:

Kaššay, P. Effect of torsional

vibration on woodchip size distribution. Scientific

Journal of Silesian University of Technology. Series Transport. 2018, 99, 95-104. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.9.

Peter KAŠŠAY[1]

EFFECT OF

TORSIONAL VIBRATION ON WOODCHIP SIZE DISTRIBUTION

Summary. Nowadays, there is increasing demand for the use of

renewable energy sources such as woodchips. One of the important qualitative

parameters of woodchips is the size distribution. The aim of this article is to

determine the effect of a woodchipper disc’s torsional vibration on the

evenness of woodchip length, as well as propose a mathematical solution to this

problem by assuming one harmonic component of disc speed and the uniform feed

of chipped material. The presented mathematical solution can be used to

determine the unevenness of woodchip length when the parameters of torsional

vibration are known.

Keywords: mathematical model;

size distribution; torsional vibration; uneven chip length; woodchips

1. INTRODUCTION

Nowadays, there is increasing

demand for the use of renewable energy sources such as woodchips. One of the

important qualitative parameters of woodchips is size distribution. From the

usability point of view, it is important to achieve homogeneous properties of

woodchips because heterogeneous material can cause problems with bridging over

openings [6], high emissions from burning [9,10], storing and drying [7].

Woodchip size distribution is

affected by dimensional inaccuracies in the woodchipper, feeding speed,

geometry of the cutting tool and the properties of the chipped material [1,2].

We assume that woodchip size

distribution may be also affected by torsional vibration of the

woodchipper’s disc, especially in the case of the inappropriate tuning of

the mechanical system drive. The purpose of this paper is to mathematically

express the influence of the torsional vibration of the disc chipper on the

unevenness of woodchip length.

2. KINEMATICS OF THE

WOODCHIPPER DISC

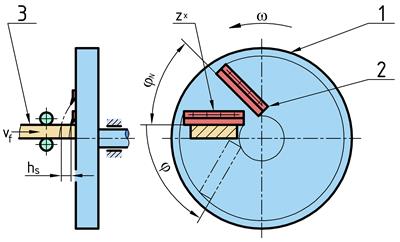

The use of a disc

chipper, whose principle is illustrated in Fig. 1, is considered. The

disc (1) rotates with the mean angular speed w

[rad/s-1]. The disc has z

knives (2) applied uniformly to the face of the disc. All consecutive knives

are rotated relative to one another by the pitch angle jN. Material with a

constant width (3) is fed to the knives at the uniform feeding speed vf [mm·s-1],

the value of which must be adjusted so that the chip is cut before touching the

disc face in order to avoid energy loss from friction [1].

Fig. 1. Scheme of the disc chipper

The length of chip hs [mm] depends on the disc

angular speed w, the feeding speed vf [mm·s-1]

and the number of knives z. The disc

angle is labelled as j [rad]. The time course

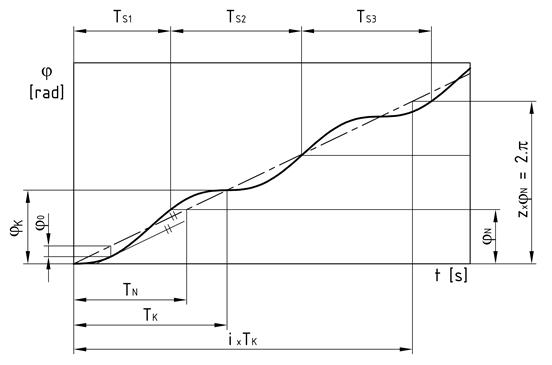

of the disc angle is shown in Fig. 2. The disc rotates at

the mean angular speed w and simultaneously

performs a harmonic torsional vibration with the angular frequency i·w.

The nominal cutting frequency with the constant angular speed w is equal to z·w.

The disc angle,

according to Fig. 1Fig. 2, can generally be

expressed by the following equation:

|

|

(1) |

where:

t - time [s]

j0 - disc angle amplitude

[rad]

i - order of torsional

vibration [-]

g -

phase of torsional vibration [rad]

Fig. 2. Time course of the disc angle

The angular velocity ![]() [rad·s-1] is obtained as a time

derivation of the disc angle (1):

[rad·s-1] is obtained as a time

derivation of the disc angle (1):

|

|

(2) |

For the limit disc angle

amplitude j0=F0, the stopping of the

disc is considered. For larger amplitudes, the angular velocity of the disc can

reach negative values. By fitting zero angular velocity for t=0 and g=0

into Eq. (2), we obtain the value

of limit disc angle amplitude:

|

|

(3) |

The relative size of

torsional vibration k [-] can be

expressed with the ratio of the disc angle amplitude j0 to the limit disc angle

amplitude F0 as:

|

|

(4) |

where k ![]() .

.

According to Fig. 2, pitch angle jN [rad] can be computed

as:

|

|

(5) |

In turn, the disc’s angle of

rotation during one period of torsional vibration can be computed as:

|

|

(6) |

Then, the nominal period of cutting

TN [s] can be computed

from the nominal cutting frequency:

|

|

(7) |

In turn, the period of torsional

vibration TK [s] can be

computed from the frequency of torsional vibration:

|

|

(8) |

The woodchip length hS [mm] can be determined

from the feeding speed vf and time between the moments of touching

the chipped material by two consecutive knives TS [s] corresponding to the pitch angle jN, as shown in Fig. 1 and Fig. 2, by expression:

|

|

(9) |

The nominal woodchip

length hN [mm] can be

computed as:

|

|

(10) |

As the times TS are not constant and differ from nominal cutting

period TN (see Fig. 2), the woodchip length

will also not be constant. Therefore, we can say that torsional vibration may

cause woodchip length unevenness.

3. COMPUTING WOODCHIP

LENGTH UNEVENNESS

Woodchip length

unevenness can be expressed by the proportional chip length n [-], as a ratio of the woodchip

length hs (9 to the nominal woodchip

length hN (10:

|

|

(11) |

The relationship in (11 shows that the

proportional chip length n depends on times TS and TN.

Next, a parameter of the

frequency ratio h [-], representing the

ratio of the frequency of torsional vibration to the cutting frequency, is

introduced:

|

|

(12) |

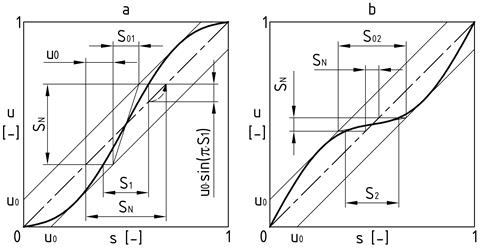

To simplify the

derivation of relationships, we introduce the dimensionless parameters of

torsional vibration and woodchip length. The dimensionless representation of

torsional vibration is shown in Fig. 3, where dimensionless

time s is related to the period of

torsional vibration TK:

|

|

(13) |

and a dimensionless rotation angle u is related to the disc’s angle

of rotation during one period of torsional vibration jK:

|

|

(14) |

Dimensionless woodchip

length S will be related to the

nominal period of torsional vibration TK:

|

|

(15) |

The nominal

dimensionless woodchip length can be obtained as a ratio of nominal period of

cutting TN (7 to the period of

torsional vibration TK (8, which will be equal to

frequency ratio h, see relationship (12:

|

|

(16) |

The dimensionless

amplitude of torsional vibration u0

can be obtained as a ratio of torsional vibration amplitude j0, expressed in the

formula in (4, to the disc’s

angle of rotation during one period of torsional vibration jK (6:

|

|

(17) |

Then, the proportional

woodchip length can be computed from dimensionless values S and SN as:

|

|

(18) |

The woodchip length will

reach the limit values when it is located symmetrically around points where the

actual speed of the disc is at its maximum (Fig. 3a) or minimum (Fig. 3b).

Fig. 3. Dimensionless representation of

torsional vibration

The actual value of the

length of each woodchip will lie between these limit values. The range (0; 1)

in Fig. 3, on the horizontal

axis, corresponds to one period of torsional vibration TK, while, on the vertical axis, it corresponds to the

disc’s angle of rotation during one period of torsional vibration jK.

According to Fig. 3, we can express the nominal

dimensionless woodchip length as:

|

|

(19) |

and the envelope of limit values of

dimensionless woodchip length as:

|

|

(20) |

By modifying Eq. (19, we obtain a formula for

the limit values of dimensionless woodchip length:

|

|

(21) |

Now, we can express the

limit values of the proportional woodchip length as the ratio of S1,2 from Eq. (20 to SN from Eq. (16, and by using the

formula in (17 as u0:

|

|

(22) |

By introducing

substitutions into the formula in (22, the limit values of

the proportional woodchip length n1,2 are finally obtained as:

|

|

(23) |

where:

d0 - the limit envelope value of the

proportional woodchip length:

|

|

(24) |

x1,2 - the limit envelope

value of proportional woodchip length:

|

|

(25) |

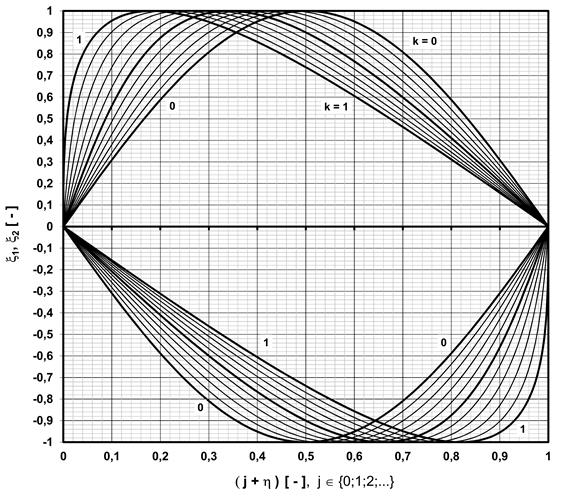

However, we need to

express the value of x1,2 depending on SN. Therefore, the inverse function to (19 should be fit into Eq. (25. The graphical solution

is shown in Fig. 4. The functions x1,2 are periodic, with the

period of frequency ratio h=2. As the shape of x1 and x2 functions are identical, and the phase shift between

them is equal to 1, only a half-period is shown in Fig. 4. We also do not need to

know which line exactly represents x1 and x2, because we only need

to know that the actual proportional woodchip length will lie between these

limit values.

Fig. 4. Limit envelope value of the proportional woodchip

length

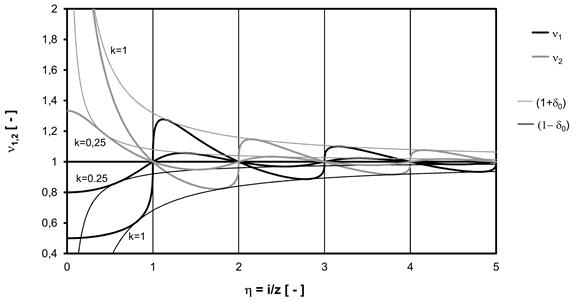

Fig. 5 shows the limit values

of the proportional woodchip length, according to the formula in (23, depending on frequency

ratio h, in terms of different

relative sizes of torsional vibration k.

Fig. 5. Limit values of the proportional woodchip length

4. DISCUSSION

According to Fig. 5, the influence of the

following torsional vibration parameters on woodchip length unevenness can be

stated thus:

(1)

Frequency ratio h

If the frequency ratio

between the cutting frequency and the torsional vibration frequency is an

integer, unevenness in woodchip length cannot arise.

This can be accomplished

by using a mesh drive with a proper gear ratio (e.g., gear, timing belt, chain

drives). With a friction drive, due to slippage, this goal cannot be

accomplished.

The frequency ratio is

influenced by the following parameters:

(1a)

Frequency of torsional vibration excited by the woodchipper’s disc

The frequencies of the

torsional vibration harmonic components excited by the disc will be an integer

multiple of the number of knives. This means that the unevenness of woodchip

length, due to the woodchipper’s disc excitation, cannot theoretically

arise.

(1b)

Frequency of torsional vibration excited by the drive

This includes harmonic

components excited by the engine (most likely, a piston combustion engine) or

fluctuations in the gear ratio (e.g., due to the use of a cardan joint, shaft

misalignment) [4]. For these influences,

it is advisable to keep the engine torque constant (use of electric motor) or

to maximize the order of the main harmonic component (choosing a piston engine

with a larger number of cylinders).

(1c)

Frequency of self-excited vibration

The frequency of

self-excited vibration is close to the natural frequency of the mechanical

system [3]. In this respect, it

is advantageous to have the frequency of self-excited torsional vibration

(natural frequency) as high as possible. As such, it is necessary to avoid an

integer ratio of natural frequency to cutting frequency in order to avoid

resonance in the system [11].

(1d)

Number of knives

Woodchip length

unevenness reaches the highest values in the case of low values of the

frequency ratio, i.e., for low frequencies of torsional vibration and a high

number of knives.

Therefore,

it is advantageous to choose as low a number of knives as possible.

(2) Size

of torsional vibration amplitude

Woodchip length

unevenness increases depend on the rising torsional vibration amplitude.

Therefore, it is the best to keep the amplitude as low as possible. The highest

value of vibration amplitude occurs in the case of resonance, i.e., when the

frequency of the exciting torque is equal to the mechanical system’s

natural frequency. This can be avoided by the proper tuning of the

system’s dynamic parameters (i.e., torsional stiffness, mass moment of

inertia, damping coefficient) [5].

4. CONCLUSION

The method presented in

this paper is suitable for determining woodchip length unevenness caused by

torsional vibration of the disc chipper. In order to use this method, it is

necessary to know the parameters of torsional vibration (frequency and

amplitude), which can be obtained theoretically by dynamic analysis or by

measurement.

In the future, it will

be necessary to examine the realistically achievable range of woodchip length

unevenness caused by torsional vibration, based on the dynamic analysis of

currently produced disc chippers.

References

1.

Abdallah

Rami, Sébastien Auchet, Pierre Jean Méausoone. 2011. “Experimental study about the effects of

disc chipper settings on the distribution of wood chip size”. Biomass and Bioenergy 35(2): 843-852.

ISSN: 0961-9534. DOI: 10.1016/J.BIOMBIOE.2010.11.009.

2.

Abdallah

Rami, Sébastien Auchet, Pierre Jean Méausoone. 2014. “A dynamic measurement of a disc chipper

cutting forces”. Biomass and

Bioenergy 64: 269-275. ISSN: 09619534. DOI: 10.1016/J.BIOMBIOE.2014.02.033.

4.

Grega

Robert, Jozef Krajňák, Lucia Žuľová, Gabriel

Fedorko, Vieroslav Molnár. 2017. “Failure

analysis of driveshaft of truck body caused by vibrations”. Engineering Failure Analysis 79:

208-215. ISSN: 1350-6307. DOI: 10.1016/j.engfailanal.2017.04.023.

5.

Homišin

Jaroslav, Matej Urbanský. 2015. “Partial results of extremal control of

mobile mechanical system”. Diagnostyka

16(1): 35-39. ISSN: 1641-6414.

6.

Jensen

Peter Daugbjerg, Jan Erik Mattsson, Pieter D. Kofman, Achim Klausner. 2004. “Tendency of wood fuels from whole trees,

logging residues and roundwood to bridge over openings”. Biomass and Bioenergy 26(2): 107-113.

ISSN: 0961-9534. DOI: 10.1016/S0961-9534(03)00101-6.

7.

Kristensen

Erik Fløjgaard, Pieter D Kofman. 2000. “Pressure resistance to air flow during

ventilation of different types of wood fuel chip”. Biomass and Bioenergy 18(3): 175-180. ISSN: 0961-9534. DOI:

10.1016/S0961-9534(99)00089-6.

8.

Mickevicius

T., S. Slavinskas, S. Wierzbicki, K. Duda. 2014. „The effect of

diesel-biodiesel blends on the performance and exhaust emissions of a direct

injection off-road diesel engine”. Transport

29(4): 440-448. ISSN: 1648-4142.

10.

Paulrud

Susanne, Calle Nilsson. 2004. “The

Effects of particle characteristics on emissions from burning wood fuel

powder”. Fuel 83(7-8): 813-821.

ISSN: 0016-2361. DOI: 10.1016/J.FUEL.2003.10.010.

11. Wilson Wiliam Ker. 1967. Practical Solution of Torsional Vibration

Problems – Volume 1.

London: Chapman & Hall Ltd.

This

paper was written within the framework of the KEGA 041TUKE-4/2017 grant project

“Implementation of New Technologies Specified for Solving Questions

Concerning the Emissions of Vehicles and Their Transformation in Educational

Processes in Order to Improve the Quality of Education”.

This

article was created with support from the project for PhD students and young

researchers project entitled “Solution of a Control System Element for

Mechanical Systems’ Continuous Tuning”.

Received 14.02.2018; accepted in revised form 11.05.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License