Article

citation information:

Ilewicz, G., Harlecki, A. Multi-objective

optimization of a medical robot model in transient states. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 99,

79-88. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.99.7.

Grzegorz ILEWICZ[1],

Andrzej HARLECKI[2]

MULTI-OBJECTIVE

OPTIMIZATION OF A MEDICAL ROBOT MODEL IN TRANSIENT STATES

Summary. The article describes the method for the

multi-objective optimization of a proposed medical robot model, which has been

considered in the form of a serial kinematic chain. In the assumed approach,

the finite element method was used in order to model the flexibility of

manipulator links. To speed up the optimization process, the response surface

method was applied, defining the so-called metamodel. In order to uncover the

optimal solution, a multi-objective genetic algorithm was used, guaranteeing

the optimality of the manipulator model in the Pareto sense. The optimization

process was carried out by analysing the selected case of the

manipulator’s dynamics. The proposed optimization method allows us to

minimize the mass of the manipulator while additionally ensuring the highest

possible stiffness of its structure and sufficient strength of its parts. Furthermore,

it offers the possibility to eliminate the natural frequency of vibrations of

the model close to the resonant frequency.

Keywords: medical robot;

dynamics; transient state; optimization; genetic algorithm; finite element

method

1. INTRODUCTION

Medical robots are used

in human surgical procedures all over the world, in such a way that

recovery is quick, postoperative scars are small and the surgery itself

involves no problems associated with classic endoscopic operations. Due to the

accuracy of positioning the endoscope, as well as the safety of the operation,

which is of paramount importance, the complexity of endoscopic surgery has

many technical problems, which remain unresolved and are constantly being

contemplated scientifically.

Issues related to the

dynamics of a medical robot (we can also include here the behaviour of the

robot in transient states), and in particular the problem with vibrations in

the effector (in the form of a surgical instrument), dominate medical practice.

When designing such types of robots, the aim is to minimize their mass (this is

tantamount to reducing the transverse dimensions of their parts, e.g., the

thickness of their walls). On the other hand, the goal is to increase the value

of the lowest (i.e., basic) natural frequencies of vibrations in the

manipulators, which in turn should require an increase, not a reduction,

in their mass. Thus, it can be seen that such set targets contradict each

other. Therefore, the weight of the robot should only be minimized in such a

way that its basic natural frequency of vibrations does not decrease beyond the

permissible (real) value, while the transverse dimensions of the parts should

not reduce their strength beyond the permissible limit.

Various models of the

dynamics of a medical robot have been published to date. For example, the

dynamics model of a robot was presented, which, including its control system,

was developed in MATLAB/Simulink. A dynamics model based on the usage of the

finite element method was also introduced. In [2], a model was presented, which

takes into account the surgical instrument load coming from the operated

tissue. Moreover, many other works have been published on the optimization of

the medical robot by consideration of the various criteria; among them, we can

indicate the following works: [1,3,4]. Meanwhile, equations used in finite

element methods can be found in the following section [6].

This work aims to

optimize the full model of the dynamics of the medical robot, taking into

account such criteria as mass, first natural frequency and static stress, as

well as stress in transient states with the adoption of restrictions on

criteria in the form of a safety coefficient and value of the first natural

frequency. The following dynamic equation is solved by using the finite element

method:

![]() ,

(1)

,

(1)

where:

![]() - is a mass matrix

- is a mass matrix

![]() - a damping matrix

- a damping matrix

![]() - a stiffness matrix

- a stiffness matrix

![]() - a displacement vector

- a displacement vector

![]() - a vector of external

forces

- a vector of external

forces

The

solution to Eq. (1) enables us to show the full strength of the model, which is

close to reality due to the consideration in subsequent iterations of

transitional states from previous forces and impacts.

Then,

on the basis of Eq. (2), we define the eigenvalue mechanical problem with

frequencies:

![]() ,

, ![]() (2)

(2)

where ![]() is the natural frequency. Eqs. (1) and

(2) are solved by using the finite element method.

is the natural frequency. Eqs. (1) and

(2) are solved by using the finite element method.

2. GEOMETRICAL MODEL OF A SURGICAL ROBOT

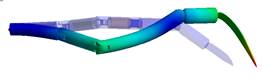

The

open kinematic chain of a medical robot considered in this work is shown in

Fig. 1. A medical robot has five links connected by three rotational

joints and one spherical joint.

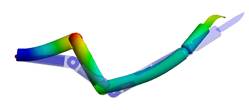

Fig. 1.

Serial chain of a medical robot with revolute and spherical joints in the RRRS

configuration

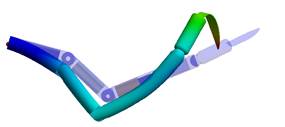

Fig. 2. Geometry model

of a medical robot with a serial chain

Fig.

2 shows the geometry of the robot’s kinematic chain whose dynamic is

deliberated in numerical experiments. The robot’s links are tubes, whose

wall thicknesses may change in the optimization experiment. The kinematic chain

with the presented configuration enables the tool to reach the back wall of the

operated organ or the serviced artificial organ inside the human body.

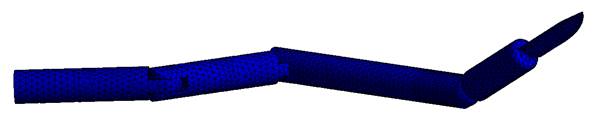

3. MODEL OF THE FINITE

ELEMENT METHOD

The geometric model of a

medical robot was discretized by a tetrahedral element of Solid 186. The robot

model was built of steel, due to its high strength as material of a real

object. It is important to obtain the required safety factor in order to

achieve the safety endurance of the robot. This task is extremely

intricate due to the minimization problems. This was shown in [7], where, due

to endurance reasons, the project of a Polish medical robot could not be

completed. Fig. 3 shows a geometric model with a mesh of finite elements.

Fig. 3. Mesh model of a

finite element method

The concurrence

of the numerical solution with the correct values was gained for the 26,778

nodes of the mesh model. This concurrence was acquired by increasing the number

of finite elements of the model until the value of the stress size stopped

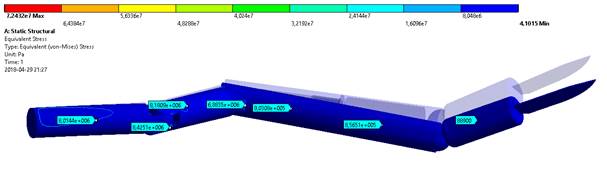

changing or was only slightly oscillated around this value. Fig. 4 shows a

diagram of reduced stress according to the Huber-Mises hypothesis in the

static state.

Fig. 4.

The value of reduced stress according to the Huber-Mises hypothesis for a

static load in the iso-tension chart

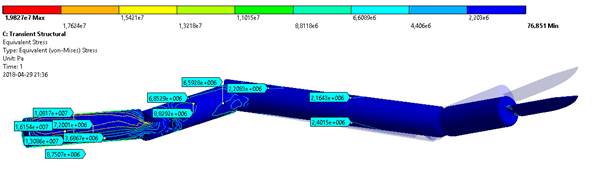

Fig.

5 shows the characteristics of tension for transient states. The system was

forced to move in the first degree of freedom at a velocity of 1 [rad/s].

A 20 force [N] originating from the interaction with tissue was applied to the

effector.

A

significant issue for the construction of a medical robot is the work in the

range of the resonance curve. It should be assumed that these vibrations

are not suppressed. They can come from propulsion systems, extortions from

tissue and functional activities, i.e., movements in the kinematic chain - in

other words, an effector movement over a given trajectory, which can be

displayed in T periods for a medical robot; as a function argument of a

frequency calculated as a number of oscillations per second, it may have a

resonant value in the quotient with an n. Therefore, it is important to

illustrate the models (shapes of vibrations and their qualities) during

resonance phenomena. Fig. 6 shows the first six shapes of vibrations for the

next natural frequencies that would appear during resonance phenomena.

Fig. 5.

The value of the reduced stress according to the Huber-Mises hypothesis for

transient states in the iso-stress chart for movement in the first joint

|

|

|

|

First

natural frequency of 401.19 [Hz] |

Second

natural frequency of 479.3 [Hz] |

|

|

|

|

Third

natural frequency of 517 [Hz] |

Fourth

natural frequency of 1,102 [Hz] |

|

|

|

|

Fifth

natural frequency of 1,398 [Hz] |

Sixth

natural frequency of 3,143 [Hz] |

|

Fig. 6.

Qualitative charts of displacements during resonance for the next natural

frequencies looking from left to right side and from top to bottom |

|

The

first and second forms of vibrations define the lateral and longitudinal

vibrations, as do the third and fourth, respectively. For higher frequencies

torsional vibrations and vibrations with a more complex character appear. The

numerical model of a medical robot is characterized by the tuning ability

from the resonant curve.

4.

STRUCTURAL OPTIMIZATION MODEL

The

multi-objective optimization problem is defined in terms of finding the Pareto

front for such criteria as mass, first natural frequency, safety factor, and

stress in static and dynamic states. The optimization model is used to control

the mechanical parameters in order to achieve the optimal properties desired in

the design process. The major values are safety factor (the most important

value due to the most vital criterion for the medical robot; also for any other

construction), safety, balanced stiffness by its own frequency as a measure of

an accurate positioning of the robot and repeatability, and stress at rest and

in transient states, in which we know there are reactions inside the structure

and displacements. The limitation in the first natural frequency, from

which results the inflexibility of the construction, is said to be 60 [Hz]

(12.5 [Hz] is the smallest natural frequency, which was found for the

clinically used PUMA 560 medical robot).

The

optimization function can be described as:

![]() .

(3)

.

(3)

The restrictions of the

model can be specified as:

![]()

![]() ,

,

![]()

![]() .

.

In addition, other

restrictions must be met:

![]()

![]() ,

,

![]() ,

,

where:

![]() - mass vector

- mass vector

![]() - vector of the first natural frequency

- vector of the first natural frequency ![]()

![]() - stress vector in the

static state

- stress vector in the

static state

![]() - stress vector in

transient states

- stress vector in

transient states

![]() ,

, ![]() - dimensions, resulting in the wall

thickness of the first and second links

- dimensions, resulting in the wall

thickness of the first and second links

Limitations

to the geometrical dimensions have a functional character, i.e.,

it is assumed that a space must be left inside the structure for

mechanical linkages causing the movement. The optimization model is solved by

using the multi-objective genetic algorithm (MOGA) [5].

To

speed up the optimization process, the response surface method was used to

define the so-called metamodel, which is specified through the matching of approximating

functions to a set of points originating from a numerical experiment.

There are statistical functions that verify the accuracy of this match (the

basic one is the correlation coefficient R2, which should reach a

value close to 1 in the case of a proper match). In general terms, the response

surface is the approximate analytical dependence between input and output

values, which replaces the complex calculation algorithm. The response surfaces

are identified by using the so-called Kriging method (also called as the

spatial interpolation method). Finding the optimal solution is achievable

thanks to the use of the MOGA. The applied algorithm includes optimality in a

Pareto sense, based on non-dominated solutions, and provides a result in the

form of a global Pareto front. In the accepted procedure, such variable and

decisional values as d1

and d2 are searched, where

the objective function f({d})

will guarantee the smallest mass of the manipulator, the maximum value of the

first natural frequency, and sufficiently low values of equivalent stress in

the case of the static and dynamic load of the manipulator.

4. RESULTS

Figs.

7-9 show the response surfaces for mass, the first natural frequency and the

equivalent stress (transient state), depending on the dimensions of the medical

robot links. A very good fitting of a metamodel was gained in relation to the

data from numerical experiments, i.e., the coefficient of correlation R2

was equal to 1 for all criteria.

Fig. 7.

The response surface for mass and dimensions

Fig. 8.

The response surface for frequency and dimensions

Fig. 9.

The response surface for equivalent stress (transient state) and dimensions

Fig.

10 shows a graph of sensitivity towards criterions when changing the geometric

dimensions for the optimal obtained solution. The graph should be read in such

a way that each criterion field is composed of the percentage effect of a

dimensional variable marked in colour on its value.

After

obtaining the metamodel, a genetic algorithm was used to select the optimal

non-dominated solution on the basis of the Pareto front.

Fig. 10.

The graph of sensitivity dimensions towards criterions

It

was agreed that the solution would be a Pareto point, for which the mass

is minimal, the first natural frequency is maximal and greater than 60 [Hz],

and the safety factor is greater than or equal to 4. Using the genetic

algorithm, the following values of mechanical quantities were achieved:

first natural frequency of 408.33 [Hz] and mass of 0.075 [kg]. At the same

time, a minimum static stress of 3.1E7 [Pa] and a minimum stress in transient

states equal to 4.1E7 [Pa] were gained. These were acquired for the

geometric dimensions d1=5.2 [mm] and d2=6.2 [mm] and a

safety factor equal to 7.8.

5.

CONCLUSIONS

This

work proposes a model of dynamics including the solution for a full

Newton’s equation for the deformable block in the non-inertial system.

The finite element method has been applied, which is characterized by a good

approximation of actual dynamics states in a numerical manner, as

well as being the basic method of choice for the structural analysis of systems

with complex geometry and load condition, taking into account the forces

appearing in the motion. Deformations from previous states were included in

each subsequent iteration of the analysis. To date, this medical robot model

has not been reported in the literature for which a multicriterion optimization

experiment has been carried out. The results of optimal mass and stiffness

for a medical robot were obtained for the given limits. The achieved numerical

model allows for the real object to be tuned from the resonant ranges. In

further works, the numerical model will be applied to a model with a DC motor

and a control system based on the PID regulator.

References

1.

Grebenişan

G., N. Salem. 2017. “The multi-objective

genetic algorithm optimization of a superplastic forming process, using

Ansys”. In: Proceedings of the International Conference

IMT Oradea. 27-29 May 2017. Baile Felix, Romania. ISSN: 2261236X.

DOI: 10.1051/matecconf/201712603003.

2.

Yang J., L. Yu, L. Wang, Z. Wang, W. Wang. 2017. “Dynamic

modeling and analysis of the instrument arm based on the physical properties of

soft tissues”. In: Proceedings of

the Institution of Mechanical Engineers Part C: article in press. ISSN:

09544062. DOI: 10.1177/0954406217715661.

3.

Li Jianmin, Shuxin Wang, Xiaofei Wang, Chao He. 2010.

“Optimization of a novel mechanism for a minimally invasive surgery

robot”. International Journal of

Medical Robotics and Computer Assisted Surgery 6 (1): 83-90. ISSN:

1478-5951. DOI: 10.1002/rcs.293.

4.

Miroir M., J. Szewczyk, O.Y. Nguyen, S. Mazalaigue, A.B. Grayeli, O.

Sterkers. 2009. “Mechanical design and optimization of a microsurgical

robot”. In: Proceedings of Eucomes 08, The Second

European Conference on Mechanism Science: 575-583. 17-20 September 2008.

Cassino, Italy. ISBN: 978-1-4020-8914-5.

DOI: 10.1007/978-1-4020-8915-2_69.

5.

Wang

Wei, Weidong Wang, Wei Dong, Hongjian Yu, Zhiyuan Yan, Zhijiang Du. 2015.

“Dimensional optimization of a minimally invasive surgical robot system

based on NSGA-II algorithm”. Advances

in Mechanical Engineering 7 (2): 83-90. ISSN: 1687-8140.

DOI: 10.1177/1687814014568541.

6.

Zienkiewicz

Olek, Robert Taylor, J.Z. Zhu. 2013. The Finite Element Method: Its Basis

and Fundamentals.

Oxford: Elsevier Ltd. ISBN: 9781856176330.

7.

Leniowska

Lucyna, Leniowski Ryszard. 2016. “Technological limitations of surgical

robotics on the example of a robot Roch-1”. Acta

Bio-Optica et Informatica Medica

2(3). ISSN: 1234-5563.

Received 29.02.2018; accepted in revised form 30.05.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License