Article citation information:

Zioła, A. Verification of road accident simulation created with the use of PC-Crash software. Scientific Journal of Silesian University of Technology. Series Transport. 2018, 98, 211-221. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.98.20.

Artur ZIOŁA[1]

VERIFICATION

OF ROAD ACCIDENT SIMULATION CREATED WITH THE USE OF PC-CRASH SOFTWARE

Summary. The paper discusses an example of PC-Crash software usage for road accident reconstruction. Only a segment of the software capabilities is presented, together with a comparison of the visualized 3D simulation with the actual collision video record.

Keywords: PC-Crash, road accident reconstruction, road accident visualization, vehicles collision

1. INTRODUCTION

Traffic is inseparably connected to

road accidents. The amount of road accidents per million citizens and the

related mortality rates in Poland are among the highest in the EU. There is an

obvious need to carry out any possible actions that may lead to a decrease in

these numbers. The effectiveness of these actions depends, for example, on the

adequate assessment of collision reasons.

The appropriate assessment of

accident causes is vastly important in terms of determining criminal

responsibility and damage compensation.

This paper presents a comparison

between a simulation of a road accident based on trails left at the scene, as

prepared by the author using PC-Crash software, and the actual course of a

crash recorded by a car video recorder placed in a motor vehicle not involved

in the respective accident (the recording vehicle was moving behind one of the

colliding vehicles).

2. ROAD ACCIDENT RECONSTRUCTION

The main task of reconstruction is to recreate the course of an accident

in order to recognize the causes of a crash. First of all, one must conclude

and calculate the vectors and values of velocity affecting the colliding

vehicles. These conclusions can be made based on simulations and

reconstructions.

Impact simulation depends on appropriately calculating the parameters

characterizing vehicle movement in the first moment after impact. These

mathematical operations are based on data describing the moment just before

impact.

Reconstruction is an inversion of simulation. One can say that, during

simulation, time runs forward, as opposed to reconstruction, where time goes

backward.

The vectors and values of velocity at the start of collision can be

determined, based on calculations derived from the law of momentum:

![]() (1)

(1)

![]() (2)

(2)

![]() sin(α2-α1)

≠ 0,

sin(α2-α1)

≠ 0,

or based on calculations derived from the law of

angular momentum:

![]()

![]() (3)

(3)

![]() (4)

(4)

where V1, V2

are the values of velocity at the start of collision; V’1, V’2 are the values of velocity at the

start of post-collision movement; m1,

m2 represent the mass of the vehicles; α represents the angle of velocity vectors; Sx

is the impulse component in the ‘x’ direction of the accepted coordinates

system; Sy is the impulse component in the ‘y’ direction of the

accepted coordinates system; Δω1, Δω2 represent

the gain of angular velocity caused by the accident [1/s]; Jc is the moment of vehicle inertia in

relation to the vertical axis pierced by the vehicle’s centre of mass; and xc, yc are the centres

of the mass coordinates in relation to ‘z’.

The values of velocity at the

start of the post-collision movement are as follows:

![]() , (5)

, (5)

![]() . (6)

. (6)

The values of velocity at the

start of collision are as follows:

![]() (7)

(7)

![]() (8)

(8)

There is a number of simplified models that allow us to calculate the

linear and angular velocity of a vehicle at the start of its slipping movement.

These models can be used until the movement distance of the centre of mass and

the variations in the longitudinal axis rotation angle are known during the

whole motion.

The Marquard model is an example of these above-mentioned simplified

models. It was created for two-wheel vehicles, in which adequate coefficients

are set by averaging the calculation results in relation to the time of the

motion. These coefficients allow us to perform a reconstruction based on

simplified formulas with reasonably good approximation, based on the law of

kinetic energy and work balance.

For this study, estimating post-collision movement parameters is based

on the Marquard model (full slide movement):

![]() (9)

(9)

![]() (10)

(10)

![]()

![]()

![]()

where Vc’

represents the values of linear velocity in the centre of mass at the start of

the post-collision movement [m/s]; ω’

is the angular velocity value at the end of the impact [1/s]; μs is the slide

traction coefficient; S is the length

of the mass centre movement [m]; Vk

represents the values of linear velocity in the centre of mass at the end

of the post-collision movement [m/s]; g is

the gravitational constant; L is the axis gauge [m]; ic is the vehicle’s inertia

radius [m]; Δφ is the total

rotation angle in the post-collision movement [rad]; and

ks, kφ are Marquard’s

coefficients.

The Marquard model allows us

to estimate the velocity at the beginning of the post-collision movement. It

can be used in a situation when all wheels are blocked or no wheel can roll. In

reality, one will often confront the situation where only one or some of the

wheels will be blocked (e.g., as the cause of post-impact structural damage or

deformities).

The Burgard model [1] allows us to

calculate a vehicle’s movement parameters at the moment just after the end of

the impact by considering the impulse vector direction and the breaking force depending

on the wheel damage.

The value of the linear and angular

velocities in the centre of mass at the start of the post-collision movement

can be calculated with the use of the following:

![]() (11)

(11)

![]() (12)

(12)

although: ![]()

(a’ represents the effective delay of the post-collision movement)

where Vp’

represents the values of linear velocity in the centre of mass at the start of

the post-collision movement [m/s]; ωp’

is the angular velocity value at the end of the impact [1/s]; μs is the coefficient

of slide traction; S is the length of

the mass centre movement [m]; Vk

represents the values of linear velocity in the centre of mass at the end

of the post-collision movement [m/s]; m is

the mass of the vehicle [kg]; g is

the gravitational constant; fh is

the breaking force partition coefficient, whose value includes the amount of

force and the nature of the braking by the wheels; ωr is the rotation resistance

coefficient; l is the axis gauge [m];

Jc is the moment of

vehicle inertia in relation to the vertical axis, pierced by the vehicle’s

centre of mass [kgm2]; and

Δφ is the total rotation

angle in the post-collision movement [rad].

In the case of unblocked front wheels, their

angle of rotation from the longitudinal position may be essential. The precise

analysis of such a case can only by conducted by calculating the configuration

of unilinear derived functions of movement. Such analysis allows us to conduct

post-collision movement parameters by considering geometrical changes of the

vehicle, especially, the wheels’ dislocation caused by deformations.

3. PC-CRASH SOFTWARE

FOR RECONSTRUCTION CALCULATIONS

Currently, a wide variety of software

is available for use in reconstructing vehicle crashes and the dynamics of

movement calculations on a broad scale, such as PC-Crash, V-SIM, VirtualCRASH, CARAT and HVE [3]. One of the most popular

in Poland is PC-Crash (DSD PhD Steffan Datentechnik, Austria).

PC-Crash

software has been designed for carrying out mathematical calculations for the

purpose of reconstructing road accidents. The software allows us to simulate

the course of action in almost all eventualities, due to the integration of numerous

modules, in particular, vehicle databases, vehicles’ dynamic models, crashes

and multichunk arrangements, graphic modules and 3D animation sequences. It

specifically enables the simulation of movement and collision between two

vehicles (e.g., single- or double-track vehicles), and between vehicles and

environmental objects (e.g., trees, walls), foundations (e.g., when a vehicle

turns around, debris falling from scarps or trenches), and biomechanical

objects (e.g., pedestrians, passenger movements). The software also facilitates

time and space analysis of accident, which is essential for assessing the

correctitude of participants; actions in the moments before an event.

PC-Crash

allow us to simulate the course of action in general case, from the beginnings

of endangerment through the pre-collision, collision and post-collision

movements until the movement arrest. The software provides three accident models:

-

Kudlich-Slibar (classic or Newtonian)

-

Rigidness, using multichunk arrangements modelling

- Reticular,

external coating, represented by a deforming net

Simulation

is the base method of analysis. The Kudlich-Slibar model is used for simulation

in which the post-collision vehicle’s movement parameters are calculated, based

on data from the moment before impact. The model assumes that collision time is

infinitesimal, which is why vehicle movement during impact is neglected. An

impact vector is placed in one particular spot and all other external forces

(e.g., influence of the road on wheels) are disregarded [4].

4. CASE STUDY

This chapter presents a fact-based

crash reconstruction with the use of the Kudlich-Slibar model and PC-Crash

software. Data used in this case are taken from court files relating to a

particular road accident.

A Seat Leon driver attempted to

perform an overtaking manoeuvre in relation to multiple vehicles; however, this

individual did not pay regard to the horizontal P-3 traffic sign (unilateral

non-transgressing line). During the motion on the lane in the opposite

direction, the vehicle collided frontally with a VW Golf III passenger car. At

the time of the crash, the Seat Leon was placed beneath a hill peak and in

front of a road bend.

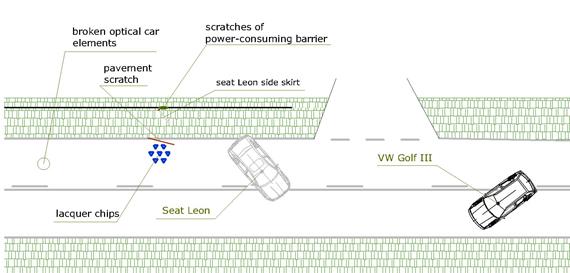

The

evidence left at the scene is indicated on Figure 1.

Fig. 1.

Scene sketch

The evidence

from both vehicles indicates that three events occurred at the time of the

accident:

1.

Frontal collision between the Seat Leon

and the VW Golf III

2.

Collision between the Seat Leon’s left-posterior corner and the

power-consuming barrier

3.

Collision between the VW Golf’s left-posterior bumper corner and a third

car at the level of the posterior-left wheelhouse shell

During the

latter impact, the VW Golf’s stern could have been lifted by around 0.5 m

(Figure 3), with the third vehicle moving in the opposite lane in the

appropriate direction.

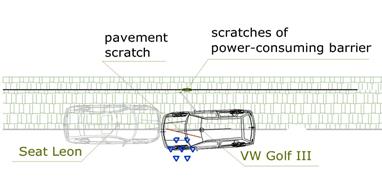

Fig. 2. The placement of the Seat

Leon and the VW Golf III at the time of frontal impact

Fig. 3. Relative placement of the VW Golf III and the

third vehicle (moving in the opposite lane) at the time of impact

During the

impacts, the vehicles sustained significant deformations (the computer software

provides the option to modify the geometry of the models). Those modifications

are included in the calculations of the post-impact movements (Figures 4-5).

a b

Fig. 4. The Seat Leon’s geometry

shift caused by deformation: a) fact-based photograph of the scene; b) model

used in the post-impact movement calculations

a b

Fig. 5. The VW Golf’s geometry shift

caused by deformation: a) fact-based photograph of the scene; b) model used in

the post-impact movement calculations

During the

initial simulations, difficulties with accurately recreating the VW Golf’s

second impact involving the left-posterior bumper corner occurred, i.e., during

the initial simulation, the car rear could not be lifted into the appropriate

position. The vehicle that took part in the accident was heavily used. There is

a probability that the rear-axis shock absorbers were not working as intended.

The PC-Crash software allows the user to define the suspension parameters:

after lowering the damping ratio of the rear-axis shock absorbers, the expert

witness applied the simulated course, which justified the revealed evidence.

Carrying

out these simulations allowed us to calculate the probable crash velocities: VW

Golf – 40.0-45.0 km/h; Seat Leon – 83.0-89.0 km/h. The lowest error value of

6.2% (weighted relative error) [4, 7] was determined for the

velocities for the VW Golf at 41.0 km/h and the Seat Leon at 85.0 km/h.

Being able

to create a 3D animated video of the accident, based on mathematical

calculation results, is an essential software requirement. A video of this kind

is particularly useful for the accurate evaluation by specialists in other

disciples (e.g., lawyers).

The course

of this accident was recorded by video camera in one of the cars in the column

overtaken by the Seat Leon.

The

figures below present a comparison of the real crash video and the 3D animation

of the discussed collision at the time of the accidence (Figures 6-8).

a

b

Fig. 6. Frontal crash involving the

Seat Leon and the VW Golf: a) film frame from the car video recorder; b) 3D

view from the simulation

a

b

Fig. 7. Collision of the Seat Leon’s left-posterior corner with the

power-consuming barrier: a) film frame from the car video recorder; b)

3D view from the simulation

a

b

Fig. 8.

Collision of the VW Golf’s left-posterior bumper corner with the third car,

which was moving in the opposite lane in the appropriate direction: a) film frame from the car video

recorder, b) 3D view from the simulation

5. CONCLUSIONS

Increasingly complex simulation

software is available, which allows for the course of accidents to be

recreated, as well as the presentation of results following the arduous and

complicated calculation of relevant parameters [5,6]. In the discussed case,

the author refers to PC-Crash. An additional option provided by this software is

the ability to present the accident as a short, animated movie, which can

accurately reflect the real accident.

Progress made in the area of

personal computers has enabled programmers to provide increasingly complex

calculation algorithms, together with other advanced tools involving, for

example, the finite element method and software used by expert witnesses [11,12,13].

Additionally, the actual progress of

artificial intelligence (AI) developments has meant that simulation software is

more commonly used for complex calculations. Its broad use can be observed,

including indirectly in the courts during cases that require the reconstruction

of road accidents.

The literature presents many

approaches to solving problems in the context of analysing images with AI [14-17].

The authors of AI-related papers have paid particular attention to the analysis

of the sensitivity of relevant models [18,19].

On the topic of road accidents, it

is noteworthy that a considerable amount of research has taken place on road

safety around the world, in which authors has focused on both human and

technical aspects in relation to the occurrence and course of road accidents

[3,20-22]. One needs to remember that a road accident is always the effect of

various factors, such as human, vehicle or environmental factors. It is also

important to bear in mind the numerous studies that have led to improvements in

the reliability of vehicle elements and their proper diagnostics [23-35].

We hope that, as a result of ongoing

technological progress, the increased accessibility of advanced algorithms and

relevant international studies will lead to a decrease in the number of road

accidents and improvements in their outcomes, or at least allow for their real

course of action and causes to be established at an easier stage.

References

1.

EVU

Unfallrekonstruktions-Programme, Bediengungshaandbuch, Auslauf – Analyse

rückwärts. EVU, Wiesbaden 1991.

2.

Marquard E. 1968.

“Fortschritte in der Berechnung von Fahrzeung-Zusammenstössen”. ATZ 3.

3.

Institute of

Forensic Research. 2011. Road Accidents.

Guidelines for Expert Witnesses. Cracow: Institute of Forensic Research

Publishers. ISBN 83-87425-32-X

4.

Wach Wojciech.

2009. Road Accidents Simulation with

PC-Crash Software. Cracow: Institute of Forensic Research Publishers. ISBN

83-87425-23-0.

5.

Wach Wojciech.

2014. Structural Creditability of Road

Accidents Reconstructions. Cracow: Institute of Forensic Research

Publishers. ISBN 83-87427-14-1.

6.

Wach Wojciech.

2009. “Reliability in establishing road accident cause”. Paragraf na drodze (Special Edition): 115-133. ISSN 1501-3520.

7.

Wach Wojciech.

2011. “Verification of vehicle collision simulation in respect of modelling

uncertainty”. Paragraf na drodze 2:

43-63. ISSN 1505-3520.

8.

Zębala Jakub,

Wojciech Wach, Piotr Ciępka, Robert Janczur, Stanisław Walczak. 2009.

“Verification of ABS models applied in computer program PC-CRASH”. Paragraf na drodze (Special Edition):

151-171. ISSN 1501-3520.

9.

Zębala Jakub,

Wojciech Wach, Piotr Ciępka, Robert Janczur,. 2013. “Simulation in PC-CRASH

program of car motion with reduced tyre pressure”. Paragraf na drodze (Special Edition): 309-323. ISSN 1505-3520.

10.

Zębala Jakub.

2017. “Simulation, in the PC-CRASH program, of movement of a car with no tire

pressure in one rear wheel”. Paragraf na

drodze (Special Edition):

337-346. ISSN 1505-3520.

11.

Wittek

Adam Marek, Damian Gąska, Bogusław Łazarz, Tomasz Matyja. 2014. “Automotive

stabilizer bar – stabilizer bar strength calculations using FEM, ovalization of

radial areas of tubular stabilizer bars”.

Mechanika 20(6): 535-542. ISSN 1392-1207.

12.

Gąska

Damian, Tomasz Haniszewski, Jerzy Margielewicz. 2017. “I-beam girders

dimensioning with numerical modelling of local stresses in wheel-supporting

flanges”. Mechanika 23(3): 347-352.

ISSN 1392-1207.

13.

Gąska

Damian, Czesław Pypno. 2011. “Strength and elastic stability of cranes in

aspect of new and old design standards”. Mechanika 17(3): 226-231. ISSN

1392-1207.

14.

Ogiela Lidia,

Ryszard Tadeusiewicz, Marek Ogiela. 2006. “Cognitive analysis in diagnostic

DSS-type IT systems”. In Proceedings of

the Eighth International Conference on Artificial Intelligence and Soft

Computing (ICAISC 2006). Zakopane, Poland. 25-29 June 2006. Book Series: Lecture Notes in Computer Science Vol. 4029: 962-971.

15.

Ogiela Lidia,

Ryszard Tadeusiewicz, Marek Ogiela. 2006. “Cognitive computing in intelligent

medical pattern recognition systems”. In D.S. Huang, K. Li, G. Irwin, eds., International Conference on Intelligent

Computing: Intelligent Control and Automation. Kunming, China. 16-19 August

2006. Book Series: Lecture Notes in

Control and Information Sciences Vol. 344: 851-856.

16.

Ogiela Marek, Ryszard

Tadeusiewicz, Lidia Ogiela. 2005. “Intelligent semantic information retrieval

in medical pattern cognitive analysis”. In O. Gervasi, M.L. Gavrilova, V. Kumar

et al., eds., Proceedings of the

International Conference on Computational Science and Its Applications (ICCSA

2005): Vol. 4. Singapore. 9-12

May 2005. Book Series: Lecture Notes in Computer Science Vol. 3483:

852-857.

17.

Tadeusiewicz

Ryszard, Lidia Ogiela, Marek Ogiela. 2008. “The automatic understanding

approach to systems analysis and design”. International

Journal of Information Management 28(1): 38-48.

18.

Smyczyńska U., J. Smyczyńska, M. Hilczer, R. Stawerska, R. Tadeusiewicz, A. Lewiński. 2018. “Pre-treatment growth and IGF-I deficiency as

main predictors of response to growth hormone therapy in neural models”. Endocrine Connections 7(1): 239-249. DOI: 10.1530/EC-17-0277.

19.

Tadeusiewicz

Ryszard. 2015. “Neural networks in mining sciences – general overview and some

representative examples”. Archives of

Mining Sciences 60(4): 971-984. DOI: 10.1515/amsc-2015-0064.

20.

Czech Piotr. 2017.

“Physically disabled pedestrians – road users in terms of road accidents”. In

E. Macioszek, G. Sierpiński, eds., Contemporary

Challenges of Transport Systems and Traffic Engineering. Lecture Notes in

Network Systems Vol. 2: 157-165.

Cham, Switzerland: Springer. ISSN: 2367-3370. DOI:

https://doi.org/10.1007/978-3-319-43985-3_14.

21.

Czech Piotr. 2017.

“Underage pedestrian road users in terms of road accidents”. In

G. Sierpiński, ed., Intelligent

Transport Systems and Travel Behaviour. Advances in Intelligent Systems and

Computing Vol. 505: 75-85. Cham Switzerland: Springer. ISSN: 2194-5357.

DOI: https://doi.org/10.1007/978-3-319-43991-4_4.

22.

Yannis G., P. Papantoniou, M. Nikas 2017. “Comparing young drivers speeding behavior at rural areas in

normal and simulation conditions”. Transport\Transporti

Europei 66(4)5: 1-13. ISSN: 1825-3997.

23.

Bigoš P., J.

Kuľka, M. Mantič, M. Kopas. 2015. “Comparison of local stress values obtained

by two measuring methods on blast furnace shell”. Metalurgija 54(1): 101-104.

24.

Czech P., Mikulski

J. 2014. “Application of Bayes Classifier and Entropy of Vibration Signals to

Diagnose Damage of Head Gasket in Internal Combustion Engine of a Car”. Telematics - Support For Transport.

Communications in Computer and Information Science 471: 225-232.

25.

Grega R., J.

Homisin, M. Puskar, J. KuI’ka, J. Petroci, B. Konecny, B. Krsak. 2015. “The

chances for reduction of vibrations in mechanical. System with low-emission

ships combustion engines”. International

Journal of Maritime Engineering 157(A4): 235-240. DOI:

10.3940/rina.ijme.2015.a4.335.

26.

Harachová D. 2016 “Deformation

of the elastic wheel harmonic gearing and its effect on toothing”. Grant Journal Vol. 5, No. 1: 89-92,

ISSN: 1805-0638.

27.

Homišin J.,

P. Kaššay, M. Puškár, R. Grega, J. Krajňák, M. Urbanský, M. Moravič. 2016.

“Continuous tuning of ship propulsion system by means of pneumatic tuner of

torsional oscillation”. International

Journal of Maritime Engineering: Transactions of the Royal Institution of Naval

Architects 158(A3): 231-238. ISSN: 1479-8751. DOI:

10.3940/rina.ijme.2016.a3.378.

28.

Krajnák J.,

J. Homišin, R. Grega, M. Urbanský. 2016. “The analysis of the impact of

vibrations on noisiness of the mechanical system”. Diagnostyka 17(3): 21-26.

29.

Kulka J., E.

Faltinová, M. Kopas, M. Mantič. 2016. “Diagnostics and optimisation of crane

track durability in metallurgical plant”. Diagnostyka

17(3): 41-46.

30.

Medvecká-Beňová

S. L. Miková, P. Kaššay. 2015. “Material properties of rubber-cord flexible

element of pneumatic flexible coupling”. Metalurgija

54(1): 194-196.

31.

Puskar Michal,

Michal Fabian, Jaroslava Kadarova, Peter Blist’an, Melichar Kopas. 2017.

“Autonomous vehicle with internal combustion drive based on the homogeneous

charge compression ignition technology”. International

Journal of Advanced Robotic Systems 14(5). DOI: 10.1177/1729881417736896.

32.

Puskar Michal,

Melichar Kopas, Jaroslava Kadarova. 2017. “Ecological analysis related to

creation of gaseous emissions within transport focused on fulfilment of the

future emission standards”. Transportation

Research Part D: Transport and Environment 57: 413-421. DOI:

10.1016/j.trd.2017.10.007.

33.

Vojtková

Jarmila. 2016. “Benefits of application of spur gears with asymmetric profile”.

Pomiary Automatyka Robotyka 2(20):

31-35. DOI: 10.14313/PAR_220/31.

34.

Zelić A., N.

Zuber, R. Šostakov. 2018. “Experimental determination of lateral forces caused by

bridge crane skewing during travelling”. Eksploatacja

i Niezawodnosc – Maintenance and Reliability 20(1): 90-99. DOI:

http://dx.doi.org/10.17531/ein.2018.1.12. ISSN: 1507-2711.

35.

Zuber N., R.

Bajrić. “Application of artificial neural networks and principal component

analysis on vibration signals for automated fault classification of roller

element bearings”. Eksploatacja i

Niezawodność - Maintenance and Reliability 18(2): 299-306. DOI:

10.17531/ein.2016.2.19. ISSN: 1507-2711.

Received 02.11.2017; accepted in revised form 20.01.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License