Article

citation information:

Wieczorek, A.N. Analysis of lubrication conditions for

angle planetary gearboxes applied in mining scraper conveyors. Scientific Journal of Silesian University of

Technology. Series Transport. 2018, 98, 191-199. ISSN: 0209-3324. DOI:

https://doi.org/10.20858/sjsutst.2018.98.18.

Andrzej N. WIECZOREK[1]

ANALYSIS OF LUBRICATION CONDITIONS FOR ANGLE PLANETARY GEARBOXES APPLIED

IN MINING SCRAPER CONVEYORS

Summary. The paper presents calculations of the

relative oil film value for the meshing of angle planetary gearboxes used in

mining scraper conveyors. Calculating the value of this parameter was made

using methodology that was compliant with ISO/TR 15144-1: 2014 (E). As a result

of the analysis, it was found that exploitation of mining gears takes place

under boundary or mixed lubrication conditions, with oil viscosity and surface

roughness having a significant influence on these conditions.

Keywords: scraper conveyor, planetary

gear, wear, lubrication

1. INTRODUCTION

The main purpose of

lubrication [1] is to transform the friction of external contacting elements

into the friction inside the lubricant layer. The formation of a relatively

permanent layer that separates mating surfaces may be caused by physisorption

of polar particles on friction surfaces, chemisorption of small boundary layers

generated as a result of tribochemical processes, or by hydrodynamic or

elasto-hydraulic effects.

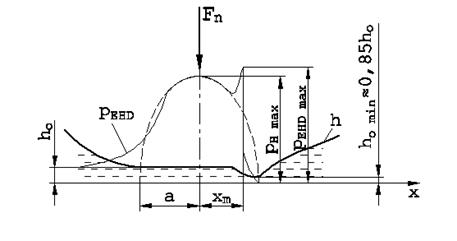

With respect to elements

of gearboxes, such as gear wheels, it is essential to create, under conditions

of elasto-hydraulic lubrication (a diagram of the elasto-hydrodynamic contact

zone of involute profile teeth, along with a specification of the actual

surface deformation, is presented in Figure 1), a layer that separates mating

surfaces in order to ensure their high operating durability. The thickness of

this layer is characterized by a certain parameter, i.e., the minimum design

thickness of the lubricant layer, hmin (also referred to in this paper as the

oil film thickness). This parameter is characterized by the size of the

lubrication gap formed as a result of the action of the load and the movement

of mating surfaces (Figure 2). The thickness of this layer depends on a number

of design and operational factors, as well on the parameters of the lubricant

(this problem is described in more detail in the next section). Lubrication

conditions depend not only on the thickness of the lubricant film, but also on

the roughness of mating surfaces.

Fig. 1. The zone of the

elasto-hydrodynamic contact of the teeth, taking into account the actual

deformation of the surface (a), pressure distribution (c) and temperature (d)

in the lubricant layer against the Hertzian distribution of static pressures

(e); designations: ω1, ω2 angular velocities

of gear wheels, v1, v2 tangential velocities in the

contact zone, Fn normal teeth load, bH width of the

elastic Hertzian deformation

The parameter

characterizing the degree of separation of mating surface irregularities, and

thus the type of friction occurring between these surfaces, is the relative

thickness of the oil film, λ, determined by the following relationship:

![]() (1)

(1)

where Rq1,2 is the surface roughness (RMS).

Fig. 2. Pressure

distribution pEHD and the shape of the lubrication gap h in the

elasto-hydrodynamic contact (EHD) between surfaces and the lubricant [1]

The parameter Rq can be

determined from the following formula [5]:

![]() (2)

(2)

Boundary lubrication

occurs when the parameter λ ≤ 1. A mixed friction occurs for the

following range of the oil film thickness: 1 <λ <3. In turn, in the

range of values λ = <3,10>, conditions for liquid lubrication EHD

are generated (a comprehensive description of the theory of the

elasto-hydrodynamic lubrication EHD can be found in [5]), which are

characterized by the occurrence of an oil film layer with a thickness exceeding

the surfaces irregularities. Above the relative value of the oil film

thickness λ> 10, liquid friction (HD) occurs [2-4].

2.

ASSUMPTIONS FOR CALCULATIONS AIMED AT DETERMINING THE MINIMUM THICKNESS OF

THE LUBRICANT LAYER

In this study, the

method described in the ISO/TR 15144-1: 2014 (E) [6] standard, which is based

on the Dowson and Higginson studies [3], was used to calculate the minimum

thickness of lubricant layer hmin.

In this method, Equation

(2) takes the following form:

![]() (3)

(3)

where R is the radius of

curvature, U is the speed parameter, W is the load parameter, G is the material

parameter and S is the temperature parameter.

In ISO/TR 15144-1: 2014

(E), the calculations of the relative value of the oil film thickness λ

are only carried out for five characteristic points on the engagement section

(Points A, B, C, D and E). For this study, it has been assumed that the values

of the oil film thickness are to be determined for 106 other points of the engagement

section.

In order to determine

the minimum thickness of the lubricant layer, hmin, geometrical parameters of

the teeth of the spur gear stage of a right-angle planetary gearbox (with the

gear ratio i=39; Figure 3), used in mining armoured face conveyors (Table 1

summarizes the geometrical parameters of the teeth), and the load values

corresponding to the power of driving motors (250, 315 and 400 kW; Table 2

shows the values of torque and rotational speed for this stage depending on the

power of the driving motor) were adopted for the calculations. In addition, a

decision was made to perform calculations for mineral oils in the range of

viscosity classes VG68VG460 (Table 3 summarizes the parameters of these oils)

and for the range of surface roughness Ra=0.15-2 μm.

Fig. 3. A view of the

right-angle planetary gearbox used in the drive of mining armoured face

conveyors

Tab. 1

Parameters of the gear

wheels subjected to various technological processes

|

Parameter |

Symbol |

Pinion |

Gear wheel |

|

|

Number of teeth |

z |

23 |

67 |

|

|

Module pitch, mm |

m |

7.5 |

||

|

Pressure angle, ° |

α |

20 |

||

|

Teeth width, mm |

b |

120 |

120 |

|

|

Tooth root filled radius |

ρ |

0.380ˇm |

||

|

Accuracy class |

- |

6 |

||

Tab. 2

Basic geometrical

parameters of gear wheels of the right-angle spur planetary gearbox

|

Driving motor power, kW |

250 |

315 |

400 |

|

Input torque of the gear stage, Nm |

5,760 |

7,255 |

9213 |

|

Input rotational speed of the gear stage, RPM |

414 |

||

Tab. 3

List of parameters

characterizing the examined mineral lubricating oils

|

Viscosity grade of oil |

Kinematic viscosity at

40°C, mm2/s (cSt) |

Kinematic viscosity at

100°C, mm2/s (cSt) |

Density at 15°C, kg/m3 |

|

VG68 |

68 |

8,7 |

887 |

|

VG100 |

100 |

11,4 |

891 |

|

VG150 |

150 |

15,0 |

887 |

|

VG220 |

210 |

18,5 |

895 |

|

VG320 |

320 |

25,0 |

903 |

|

VG460 |

460 |

30,8 |

904 |

3. CALCULATION RESULTS

When analysing possible solutions for the technical and economic problems mentioned, the calculation results

concerning the relative value of the oil film thickness λ, as a function

of the position of gear wheels of the gearbox on the engagement section, are as

presented in Figure 4.

When analysing the curve

presented in the figure above, it can be concluded that the smallest values of

the λ parameter are observed at a single-tooth engagement point (Point B)

of the engagement section. The lubrication

conditions of the gearbox just at this point of the engagement section were

adopted for the purposes of further analysis. Figure 5 shows plots of the

relative oil film thickness λ, as a function of the power of the driving

motor, and the viscosity grade determined for the roughness Ra=0.4 μm, while

the plots in Figure 6 refer to the roughness Ra=0.8 μm.

Figure 7 presents plots of the relative oil film thickness λ, as a

function of the surface roughness, and the viscosity grade determined for the

driving motor power P=315 kW.

Taking into account the results presented in Figures 5-7, the following

observations can be made:

- The relative thickness of the oil film determined

for the roughness Ra = 0.8 μm, regardless of the load and type of oil,

takes the values lower than 1 (λ <1)

- The relative thickness of the oil film determined

for the roughness Ra=0.4 μm, for the majority of the load and oil values

considered, takes values lower than 1 (λ <1); values λ> 1 are

observed only for the motor power range P=50-150 kW, and for the oil with the

viscosity grade VG460, as well as for the motor power P= 0 kW and for the oil

with the viscosity grade VG320

- The relative thickness of the oil film determined

for the motor power P=315 kW, for the majority of the load and oil values

considered, takes values lower than 1 (λ <1); values λ> 1 are

observed only for the viscosity grades VG150-460 and for the roughness Ra=0.15

μm, as well as for the oil with the viscosity grade VG460 and for the

roughness Ra=0.25 μm

Fig. 4. The plot of the relative oil film thickness

λ as a function of the position on the engagement section for the second

stage of the right-angle spur planetary gearbox

(the results obtained for motor power P=315 kW, viscosity grade VG320 and

roughness Ra=1 μm)

Fig. 5. Plots of the

relative oil film thickness λ at Point B of the engagement section as a

function of the power of the driving motor and the viscosity grade (the results

obtained for

Ra=0.4 μm)

Fig. 6. Plots of the

relative oil film thickness λ at Point B of the engagement section as a

function of the power of the driving motor and the viscosity grade (the results

obtained for

Ra=1 μm)

4. SUMMARY

Around the world,

research is being carried out to improve the durability and reliability of

machine parts [7-22].

As a part of this study,

the lubrication conditions of a typical mining gearbox used in drives of

longwall armoured face conveyors were determined using a modified calculation

method based on the ISO/TR 15144-1:2014 (E) standard. The spur gear stage of a

KPL-25 gearbox with the gear ratio i=39 was subjected to analysis. The values

of the relative oil film thickness λ were determined as a function of the

position on the engagement section. Based on the plot, it has been found that

the smallest values of the parameter λ are at the single-tooth engagement

point (Point B) on the engagement section.

For single-tooth

engagement Point B on the engagement section, the values of the relative oil

film thickness λ were determined as a function of load, oil viscosity

grade and roughness.

The scope of the

analytical work carried out allowed for the following conclusion to be made:

the gearbox under consideration operates unfavourable conditions of boundary

lubrication; only in some cases is it possible to create mixed lubrication

conditions.

Based on the data

presented, it is also possible to formulate a general recommendation to take

into account the operating conditions of gearboxes at the design stage and

select appropriate technological means, which ensure the best-possible

lubrication conditions.

Fig. 7. Plots of the

relative oil film thickness λ at Point B of the engagement section as a

function of the roughness and the viscosity grade (the results obtained for

power P=315 kW)

References

1.

Skoć

Antoni, Jacek Spałek, Sylwester Markusik. 2014. Basics of Machine Construction. Vol.

II. Warsaw: WNT. ISBN 978-83-2043-405-7.

2.

Lawrowski

Zbigniew. 1996. Lubrication Technology. Warsaw:

PWN. ISBN 978-830-1074-890.

3.

Dowson

D., G.R. Higginson. 1976. Elastohydrodynamic

Lubrication. Oxford, London: Pergamon Press. ISBN 978-148-318-1899.

4.

Hamrock

B.J., D. Dowson. Ball Bearing Lubrication.

1981. New York, Chichester, Brisbane, Toronto, Singapore: John Wiley &

Sons. ISBN 978-047-1035-534.

5.

Winiewski

M. Elastohydrodynamic Lubrication.

2000. Renningen-Malmsheim: Expert Verlag. ISBN 978-3-8169-1745-8.

6.

ISO/TR

15144-1:2014 (E) Calculation of Micropitting Load Capacity Of Cylindrical Spur

And Helical Gears Part 1: Introduction and Basic Principles.

7.

Bigo

P., J. Kužka, M. Mantič, M. Kopas. 2015. Comparison of local stress values

obtained by two measuring methods on blast furnace shell. Metalurgija 54(1): 101-104.

8.

Czech

P. 2013. Intelligent Approach to Valve Clearance Diagnostic in Cars. Activities of Transport Telematics. TST 2013. Communications in Computer and Information

Science 395: 384-391. DOI: https://doi.org/10.1007/978-3-642-41647-7_47.

9.

Czech

P., Mikulski J. 2014. Application of Bayes Classifier and Entropy of Vibration

Signals to Diagnose Damage of Head Gasket in Internal Combustion Engine of a

Car. Telematics - Support For Transport.

TST 2014. Communications in Computer and Information Science 471: 225-232.

DOI: https://doi.org/10.1007/978-3-662-45317-9_24.

10.

Figlus

T., J. Gnap, T. Skrucany, B. Sarkan, J. Stoklosa. 2016. The Use of Denoising

and Analysis of the Acoustic Signal Entropy in Diagnosing Engine Valve

Clearance. Entropy 18(7): 1-11. DOI:

https://doi.org/10.3390/e18070253.

11.

Figlus

T., S. Liscak. 2014. Assessment of the vibroactivity level of SI engines in

stationary and non-stationary operating conditions. Journal of Vibroengineering 16(3): 1349-1359.

12.

Grega

R., J. Homisin, M. Puskar, J. KuIka, J. Petroci, B. Konecny, B. Krsak. 2015.

The chances for reduction of vibrations in mechanical. System with

low-emission ships combustion engines. International

Journal of Maritime Engineering 157(A4): 235-240. DOI:

10.3940/rina.ijme.2015.a4.335.

13.

Harachová D. 2016

Deformation of the elastic wheel harmonic gearing and its effect on toothing.

Grant Journal Vol. 5, No. 1: 89-92,

ISSN: 1805-0638.

14.

Homiin

J., P. Kaay, M. Pukár, R. Grega, J. Krajňák, M. Urbanský, M. Moravič. 2016.

Continuous tuning of ship propulsion system by means of pneumatic tuner of

torsional oscillation. International

Journal of Maritime Engineering: Transactions of the Royal Institution of Naval

Architects 158(A3): 231-238. ISSN: 1479-8751. DOI:

10.3940/rina.ijme.2016.a3.378.

15.

Krajnák

J., J. Homiin, R. Grega, M. Urbanský. 2016. The analysis of the impact of

vibrations on noisiness of the mechanical system. Diagnostyka 17(3): 21-26.

16.

Kulka

J., E. Faltinová, M. Kopas, M. Mantič. 2016. Diagnostics and optimisation of

crane track durability in metallurgical plant. Diagnostyka 17(3): 41-46.

17.

Medvecká-Beňová

S. L. Miková, P. Kaay. 2015. Material properties of rubber-cord flexible element

of pneumatic flexible coupling. Metalurgija

54(1): 194-196.

18.

Puskar

Michal, Michal Fabian, Jaroslava Kadarova, Peter Blistan, Melichar Kopas.

2017. Autonomous vehicle with internal combustion drive based on the

homogeneous charge compression ignition technology. International Journal of Advanced Robotic Systems 14(5). DOI:

10.1177/1729881417736896.

19.

Puskar

Michal, Melichar Kopas, Jaroslava Kadarova. 2017. Ecological analysis related

to creation of gaseous emissions within transport focused on fulfilment of the

future emission standards. Transportation

Research Part D: Transport and Environment 57: 413-421. DOI:

10.1016/j.trd.2017.10.007.

20.

Vojtková

Jarmila. 2016. Benefits of application of spur gears with asymmetric profile.

Pomiary Automatyka Robotyka 2(20):

31-35. DOI: 10.14313/PAR_220/31.

21.

Zelić

A., N. Zuber, R. ostakov. 2018. Experimental determination of lateral forces

caused by bridge crane skewing during travelling. Eksploatacja i Niezawodnosc Maintenance and Reliability 20(1):

90-99. DOI: http://dx.doi.org/10.17531/ein.2018.1.12. ISSN: 1507-2711.

22.

Zuber

N., R. Bajrić. Application of artificial neural networks and principal

component analysis on vibration signals for automated fault classification of

roller element bearings. Eksploatacja i

Niezawodnoć - Maintenance and Reliability 18(2): 299-306. DOI:

10.17531/ein.2016.2.19. ISSN: 1507-2711.

Received 05.11.2017; accepted in revised form 09.01.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License