Article citation information:

Šarkan, B., Skrúcaný, T., Semanová, Š., Madleňák, R., Kuranc, A., Sejkorová, M., Caban, J. Vehicle coast-down method as a tool for calculating total resistance for the purposes of type-approval fuel consumption. Scientific Journal of Silesian University of Technology. Series Transport. 2018, 98, 161-172. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.98.15.

Branislav Šarkan[1],

Tomáš Skrúcaný[2],

Štefánia Semanová[3],

Radovan MADLEŇÁK[4],

Andrzej KURANC[5],

Marie SEJKOROVÁ[6],

Jacek CABAN[7]

VEHICLE

COAST-DOWN METHOD AS A TOOL FOR CALCULATING TOTAL RESISTANCE FOR THE PURPOSES

OF TYPE-APPROVAL FUEL CONSUMPTION

Summary. A coast-down test is carried out in cases when there is a need for the exact expression of the forces acting on a road vehicle during its coast-down. These forces act mainly against the vehicle’s movement due to air and tyre rolling resistance. Knowledge of the course of these forces throughout the vehicle’s movement range is also a requirement when measuring fuel consumption with a roller performance dynamometer. The reason is that this device has to load the rollers by force or performance corresponding to the given vehicle, while testing it during various driving cycles. For approval purposes, the requirements for this type of test are described in the applicable regulations, i.e., UNECE Regulations No. 83 and No. 101, or the newly developed Worldwide Harmonized Light Vehicles Test Procedure (WLTP). Slovak Technical Standard STN 30 0556 also contains detailed procedures for carrying out the test. The authors of this paper have taken into account both types of technical regulations in order to conduct coast-down tests on chosen vehicles. The results are usable in terms of measuring fuel consumption on a roller dynamometer. Furthermore, the vehicle’s economic performance in normal operation mode can be also assumed with these results.

Keywords: coast-down method, vehicle resistance, aerodynamic drag, tyre rolling resistance, fuel consumption

1. INTRODUCTION

A

coast-down test is applied to determine resistance under real conditions. This

is the test in which a vehicle running by its inertia is slowed down due to

driving resistances from the moment of shifting the neutral position of the

transmission until reaching zero speed. The test is carried out on a test

track. The driving resistances represent forces that act in opposition to the

movement of the vehicle running on a horizontal track. These include air

resistance and mechanical resistance. Air resistance is caused by the effect of

air flow as the vehicle passes through the air. Mechanical resistance

represents tyre rolling resistance and resistances in bearings and parts of the

transmission device [5 10,11,15,20].

2. measurement

methodology

The vehicle is driven on a straight

test track at constant speed under windless conditions; and, after shifting

into neutral, it moves further forward by inertia. The vehicle is thus

gradually slowed down due to rolling resistance, aerodynamic drag and friction

resistance in the transmission device until it completely stops. Changes in the

vehicle speed are continuously recorded. The vehicle movement is straight and

unevenly slowed during the coast-down. Driving resistances are calculated based

on the ascertained course of vehicle deceleration during the coast-down, as

well as geometric parameters of the test track and the known vehicle’s inertia

parameters. The coast-down characteristic of the vehicle is ascertained by

coast-down tests. Based on this characteristic, it is possible to assess the

mechanical condition of the vehicle, the chassis settings, the influence of

used tyres and the aerodynamic properties of the vehicle body [14,19].

Several requirements relating to a

vehicle, test track, test speed, atmospheric conditions and measuring equipment

must be met when carrying out coast-down tests. These requirements differ

depending on the type of regulation used. The requirements of the individual

regulations regarding a vehicle, test track, atmospheric conditions and accuracy

of the used measuring and recording equipment are listed in Table 1. The most

detailed description of such requirements is provided in the WLTP. The results

obtained in accordance with the WLTP are used for transferring the load of a

road vehicle in normal operation mode onto the rollers of a roller performance

dynamometer in order to determine the type-approval fuel consumption [25,30].

The methodology recommended by the

WLTP involves performing each coast-down measurement without interruption. However,

the division of the section is permitted if the data cannot be collected in a

continuous manner across the full speed range. When dividing the measurement

process, it is necessary to ensure that vehicle conditions remain as stable as

possible at each point of division [29].

Tab. 1

Different requirements for

carrying out the coast-down test [23,27,28,29]

|

Measurement requirements |

Available methodologies for the

coast-down |

||||

|

UNECE No. 101 |

UNECE No. 83 |

WLTP |

STN 30 0556 |

||

|

Test track parameters |

Longitudinal

slope |

±2% |

±1.5% |

±1% |

±1% |

|

Local

inclination |

±0.5% |

- |

±0.5% |

- |

|

|

Cross-sectional

slope |

Max. 1.5% |

- |

Max. 1.5% |

Max. 1.5% |

|

|

Atmospheric conditions |

Wind

speed (average) |

Max. 3 m·s-1 |

Max. 3 m·s-1 |

Max.

7 m·s-1 |

Max. 1.5 m·s-1 |

|

Wind

speed (gusts) |

Max. 5 m·s-1 |

Max. 5 m·s-1 |

Max. 10 m·s-1 |

- |

|

|

Wind

cross vector component |

Max. 2 m·s-1 |

Max. 2 m·s-1 |

Max.

4 m·s-1 |

- |

|

|

Area

of measurement above the surface |

0.7 m |

0.7 m |

- |

- |

|

|

Air

temperature |

5- 35°C |

- |

5-40°C |

5-25°C |

|

|

Air

pressure |

91-104 kPa |

- |

- |

97.33-101.25 kPa |

|

|

Relative

humidity |

Max. 95% |

- |

- |

- |

|

|

Vehicle |

Vehicle

run-in |

Min. 300 km |

Min. 3,000 km |

Min. 3,000 km |

- |

|

Tyre

run-in |

Min. 300 km |

- |

Min. 200 km |

Min. 1,000 km |

|

|

Tread

depth |

50-90% |

50-90% |

80-100% |

67% |

|

|

Time

recording (frequency) |

- |

- |

5 Hz |

- |

|

|

Measuring equipment |

Time

recording (accuracy) |

±0.1 s |

±0.1 s |

±0.01 s |

- |

|

Speed

record (accuracy) |

±0.5 km·h-1 |

±2% |

±0.5 km·h-1 |

- |

|

|

Wind

speed |

- |

- |

±0.3 m·s-1 |

- |

|

|

Wind

direction |

- |

- |

±3° |

- |

|

|

Air

temperature |

- |

- |

±1 K |

- |

|

|

Air

pressure |

- |

- |

±0.3 kPa |

- |

|

|

Vehicle

mass |

- |

- |

±10 kg |

- |

|

|

Tyre

pressure |

- |

- |

±5 kPa |

- |

|

The measurements of coast-down are

carried out in both directions repeatedly until at least three consecutive

measurement pairs meet the requirements for statistical accuracy p in percentage terms as shown below

(1).

![]() (1)

(1)

where ![]() represents the coefficient, which is

determined by the WLTP depending on the number of performed pairs of coast-down

measurements. For example, the coefficient 2.48 is used for n=3 and the

coefficient 1.6 is applied for n=4. The standard deviation expressed in seconds

is denoted as σ, while Δtj is the average time

of the coast-down at the reference speed in seconds.

represents the coefficient, which is

determined by the WLTP depending on the number of performed pairs of coast-down

measurements. For example, the coefficient 2.48 is used for n=3 and the

coefficient 1.6 is applied for n=4. The standard deviation expressed in seconds

is denoted as σ, while Δtj is the average time

of the coast-down at the reference speed in seconds.

The standard deviation is calculated according

to the following formula:

(2)

(2)

where Δtji

represents the harmonized average time of the coast-down of the i-th pair of measurements and is

calculated according to the following formula:

(3)

(3)

where Δtjai

and Δtjbi represent

the time of the coast-down for the i-th

measurement in each direction, respectively.

The calculated statistical accuracy of at least

three consecutive coast-down tests in each direction (three pairs of

measurements) should not exceed 3%, according to the WLTP [29].

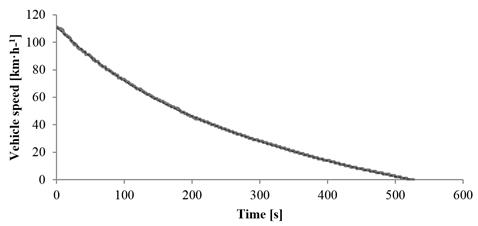

After meeting the accuracy of the

performed coast-down tests, coast-down curves are created based on the recorded

data (Figure 1), while vehicle resistances are determined in newtons for the

whole range of examined speed. To calculate these resistances, it is necessary

to divide the coast-down curve into individual vehicle speed intervals. The

WLTP recommends an interval width of 20 km·hod-1 for the coast-down

from the speed higher, rather than 60 km·hod-1. The durations are

assigned to the respective intervals of speed decreases, and thus the vehicle

resistances are determined or the dependence of vehicle resistance on speed is

ascertained.

Fig. 1. Coast-down curve

The resistance force for individual

speed intervals is calculated according to the formula shown below (4). In this

formula, mav represents

the vehicle mass while tested. This is the average vehicle mass before and

after carrying out the coast-down, while considering the consumed fuel.

Further, mr is the

equivalent effective mass of all the wheels and vehicle components rotating

with the wheels during the coast-down on the road. It should be measured or calculated

by an appropriate technique. Alternatively, mr

may be estimated to be equal to 3% of the unladen vehicle mass when increased

by 25 kg.

![]() (4)

(4)

If necessary, it is also possible to

determine resistance forces for individual directions of the vehicle

coast-down. This requires calculating the average times of the intervals for

the relevant direction; however, the formula is the same as the previous one.

![]() (5)

(5)

3. Measurement results

Three

vehicles were used for practical tests on the coast-down (Figure 2). The first

tested vehicle was that used in the laboratory of the Department of Road and

Urban Transport, namely, a Kia Ceed 1.6 CVVT, which is a vehicle with a

spark-ignition engine. The vehicle kerb weight is 1,163 kg, the air resistance

coefficient is 0.33 and the vehicle frontal area is 2.25 m2. The

second tested vehicle was a Ford Galaxy 2.0 Ghia, which has a diesel engine.

The vehicle kerb weight is 1,799 kg, the air resistance coefficient is 0.314

and the vehicle frontal area is 2.78 m2. The third tested vehicle

was a Hyundai i30 Wagon with a 1.6 CRDi diesel engine. The vehicle kerb weight

is 1,413 kg, the air resistance coefficient is 0.3 and the vehicle frontal area

is 2.136 m2. Before carrying out the coast-down tests, the vehicles

were subjected to tyre pressure control and the tyres were inflated as required

by the WLTP.

|

|

|

|

Fig. 2. Tested vehicles (Kia Ceed, Ford Galaxy,

Hyundai i30)

The

coast-down tests were carried out on the road connecting Water Dam Žilina with

the village of Mojš. The test track was 1.25 km long. The rest of the road

section was used for vehicle acceleration and turning the vehicle in opposite

direction. The road had an asphalted surface of sufficient quality. At the

beginning of the section, it was necessary to achieve the required vehicle

speed. The initial vehicle speed was 115 km·h-1 and the

coast-down was recorded from the speed of 110 km·h-1. As the test

track was not sufficiently long enough to carry out the whole coast-down, the

test was divided into two measurement parts (from 110 km·h-1 to 60

km·h-1, and from 65 km·h-1 to 0 km·h-1). The

test track is graphically illustrated in Figure 3.

Fig. 3. Test track [Google Maps]

During the

coast-down measurements, atmospheric conditions were controlled and recorded by

using a weather station with a thermometer, a moisture meter and an anemometer.

All atmospheric conditions complied with the required level for the

measurements. The wind speed was at the average level of 1.1 m·s-1

and air temperature was 14°C.

The

universal OBD2 diagnostics device, which was compatible with the diagnostic

interface equipped with the ELM327 chip and TouchScan software, was used to

record vehicle speed over time. This device allows for recording data at a

frequency of approximately 3 Hz. Before using the diagnostics device, it is

advisable to calibrate a speed indicator, e.g., by using a roller performance

dynamometer, which is also among the equipment available from the laboratory of

Department of Road and Urban Transport [3,9,17,19]. The record of vehicle speed

over time is saved in .txt format, meaning that it is possible to work with it

in Microsoft Excel.

After

processing the results of the coast-down for tested vehicles, the calculation

of accuracy was made according to the formulas mentioned previously in the

paper (see Chapter 2). In total, three coast-down tests in each direction of

the measuring section for each tested vehicle were carried out. Each measured

coast-down was divided into two measurement parts (from 110 km·h-1

to 60 km·h-1, and from 65 km·h-1 to 0 km·h-1)

due to the insufficient length of the test track. Based on Table 2 and Figure

4, it can be concluded that the duration of the coast-down in Direction 1 was

significantly shorter than the coast-down in Direction 2. This is caused by the

longitudinal slope of the measuring section. The value of this slope was 1.1%,

which slightly exceeds the required value according to the WLTP. Therefore, the

harmonized average time

of the coast-downs was applied to the calculations. In the case of first two

vehicles, the required statistical accuracy of not exceeding 3% was met.

However, the Ford Galaxy slightly exceeded this requirement. In the case of

using this information for determining the type-approval fuel consumption or

the official measurement of fuel consumption, it would have been necessary to

repeat the measurements with this vehicle until the statistical accuracy was

achieved at the required level.

Tab. 2

Calculation of statistical

accuracy of the coast-down for the tested vehicles

|

Vehicle |

Coast-down Direction 1 [s] |

Coast-down Direction 2 [s] |

Coast-down Direction 1 [s] |

Coast-down Direction 2 [s] |

Coast-down Direction 1 [s] |

Coast-down Direction 2 [s] |

Harmonized

average time Δtji [s] |

Average time of

the coast-down Δtj [s] |

STD |

Statistical

accuracy [%] |

||

|

Kia Ceed |

145.80 |

186.28 |

145.85 |

196.02 |

145.00 |

190.30 |

163.57 |

167.25 |

164.59 |

165.14 |

1.90 |

2.85 |

|

Hyundai i30 |

143.94 |

191.25 |

149.69 |

184.75 |

147.74 |

184.36 |

164.26 |

165.38 |

164.03 |

164.56 |

0.72 |

1.09 |

|

Ford Galaxy |

149.90 |

205.77 |

150.80 |

209.70 |

153.33 |

213.89 |

173.45 |

175.44 |

178.62 |

175.83 |

2.61 |

3.68 |

It is

possible to express the resistance force of the vehicle for each direction

separately. Mainly in the case of roads with a longitudinal slope near to the

tolerance limit, or in the case of wind direction in the longitudinal direction

of the measuring section, differences may occur in the values for individual

directions. For this

reason, the harmonized average time (∆tj)

of the alternating measurements of the coast-down must also be determined, so

that the average total vehicle resistance (Fj)

can be calculated. The processed results of the coast-down test for the Hyundai

i30 are presented in detail in Table 3.

The outcome

of this type of test is the determination of the total driving resistance of

the vehicle while driving at constant speed on a horizontal road. If necessary,

it is also possible to calculate the required performance (power) to overcome

this resistance. The resultant resistance force expressed in newtons is

multiplied by the actual vehicle speed in m·s-1, such that the calculated performance required to

overcome the resistance is expressed in watts. Using these types of

calculation, it is also possible to determine the performance needed to

overcome any speed or the maximum speed of the vehicle [7,8,10,11,14,32].

Fig. 4. Average times of the coast-down in the

“there” and “back” directions for

the Hyundai i30

Tab. 3

Processed results of the

coast-down for the Hyundai i30

|

Vehicle speed and

speed intervals [km·h-1] |

Time of the

coast-down for respective intervals for Direction 1 [s] |

∆tja |

Time of the

coast-down for respective intervals for Direction 2 [s] |

∆tjb |

Fja |

Fjb |

∆tj |

Fj |

|||||

|

105 |

<110;100) |

6.17 |

6.50 |

6.14 |

6.27 |

6.69 |

7.78 |

7.24 |

7.24 |

758.52 |

657.20 |

6.72 |

707.86 |

|

95 |

<100;90) |

6.62 |

7.99 |

7.79 |

7.47 |

9.01 |

8.77 |

8.31 |

8.70 |

636.96 |

546.87 |

8.03 |

591.91 |

|

85 |

<90;80) |

8.24 |

7.87 |

8.58 |

8.23 |

9.40 |

10.10 |

10.12 |

9.87 |

577.88 |

481.70 |

8.98 |

529.79 |

|

75 |

<80;70) |

8.50 |

9.84 |

9.95 |

9.43 |

11.31 |

11.92 |

11.79 |

11.67 |

504.34 |

407.42 |

10.43 |

455.88 |

|

65 |

<70;60) |

10.80 |

11.11 |

9.96 |

10.62 |

12.94 |

12.92 |

12.82 |

12.89 |

447.69 |

368.87 |

11.65 |

408.28 |

|

55 |

<60;50) |

12.45 |

13.54 |

13.20 |

13.06 |

16.14 |

16.18 |

16.33 |

16.22 |

364.07 |

293.28 |

14.47 |

328.67 |

|

45 |

<50;40) |

13.46 |

14.50 |

14.66 |

14.21 |

18.60 |

18.14 |

18.29 |

18.34 |

334.77 |

259.27 |

16.01 |

297.02 |

|

35 |

<40;30) |

15.00 |

16.10 |

15.81 |

15.64 |

19.47 |

19.85 |

19.65 |

19.66 |

304.15 |

241.95 |

17.42 |

273.05 |

|

25 |

<30;20) |

17.45 |

17.35 |

18.02 |

17.61 |

25.76 |

25.76 |

25.76 |

25.76 |

270.12 |

184.63 |

20.92 |

227.37 |

|

15 |

<20;10) |

20.03 |

19.59 |

20.39 |

20.00 |

29.18 |

22.72 |

23.96 |

25.29 |

237.76 |

188.08 |

22.34 |

212.92 |

|

5 |

<10;0> |

25.22 |

25.30 |

23.24 |

24.59 |

32.75 |

30.61 |

30.09 |

31.15 |

193.44 |

152.68 |

27.48 |

173.06 |

|

∑ |

143.94 |

149.69 |

147.74 |

147.12 |

191.25 |

184.75 |

184.36 |

186.79 |

- |

- |

- |

- |

|

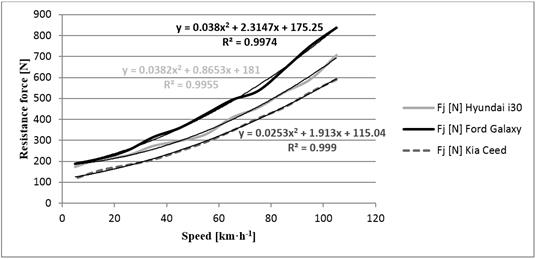

For

type-approval fuel consumption purposes, the final result of this kind of test

is the function of driving resistance curves. These curves are expressed as a

quadratic function of velocity. Individual parameters then become the basis for

transferring the load

of a particular vehicle to the rollers of a roller performance dynamometer.

Subsequently, this device is able to simulate respective driving resistances in

relation to the actual speed of a vehicle moving on the rollers.

Fig. 5. Comparison of the average driving

resistance of the tested vehicles

3. Conclusion

The issue of measuring vehicle

resistance is addressed by several methodologies. For the type-approval fuel

consumption purposes in 2018, it will be necessary to follow the methodology

presented in the WLTP [20,29], which insists on significant requirements to be

met relating not only to measuring equipment but also to the test track,

atmospheric conditions and the vehicle itself. This paper has analysed the

existing regulations for carrying out the coast-down test, as well as addressed

the difficulty in quantifying driving resistances by using practical

measurement examples involving three vehicles. The difficulty of the test lies

primarily in processing the results with statistical tools in such a way that

the resultant vehicle resistance corresponds to normal operation mode as

realistically as possible.

References

1.

Barta D. 2012. Kolesové vozidlá – autobusy. Žilina: Žilinská

univerzita. ISBN 978-80-554-0644-2 [In Slovak: Wheeled Vehicles – Buses. Žilina: University of Žilina.]

2.

Barta D., M.

Mruzek, M. Kendra, P. Kordos, L. Krzywonos. 2016. “Using of non-conventional

fuels in hybrid vehicle drives”. Advances

in Science and Technology Research Journal 10(32): 240-247. ISSN 2299-8624.

DOI: 10.12913/22998624/65108.

3.

Czaban J., D.

Szpica. 2013. “Drive test system to be used on roller dynamometer”. Mechanika 19(5): 600-605. DOI:

10.5755/j01.mech.19.5.5542.

4.

Czech P. 2013.

“Intelligent approach to valve clearance diagnostic in cars”. Activities of Transport Telematics. TST

2013. Communications in Computer and Information Science 395: 384-391. DOI:

https://doi.org/10.1007/978-3-642-41647-7_47.

5.

Czech P. 2017.

“Physically disabled pedestrians – road users in terms of road accidents”. Contemporary Challenges of Transport Systems

and Traffic Engineering. Lecture Note in Networks and Systems 2: 157-165.

DOI: https://doi.org/10.1007/978-3-319-43985-3_14.

6.

Czech P. 2017.

“Underage pedestrian road users in terms of road accidents”. Intelligent Transport Systems and Travel

Behaviour. Advances in Intelligent Systems and Computing 505: 33-44. DOI:

https://doi.org/10.1007/978-3-319-43991-4_4.

7.

Drozdziel P., H.

Komsta, L. Krzywonos. 2013. “Repair costs and the intensity of vehicle use”. Transport Problems 8(3): 131-138. ISSN

1896-0596.

8.

Drozdziel P., L.

Krzywonos. 2009. “The estimation of the reliability of the first daily diesel

engine start-up during its operation in the vehicle”. Eksploatacja i Niezawodnosc - Maintenance and Reliability 41(1):

4-10. ISSN 1507-2711.

9.

Fernandez-Yaneza

P., O. Armasa, S. Martinez-Martinez. 2016. “Impact of relative position

vehicle-wind blower in a roller test bench under climatic chamber”. Applied Thermal Engineering 106: 266.

DOI: 10.1016/j.applthermaleng.2016.06.021.

10.

Figlus T., M.

Stańczyk. 2016. “A method for detecting damage to rolling bearings in toothed

gears of processing lines”. Metalurgija

55(1): 75-78. ISSN 0543-5846.

11.

Figlus T., M.

Stańczyk. 2014. “Diagnosis of the wear of gears in the gearbox using the

wavelet packet transform”. Metalurgija

53(4): 673-676. ISSN: 0543-5846.

12.

Gnap J., A.

Kalašová, M. Gogola, J. Ondruš. 2010. “The Centre of Excellence for transport

service and control”. Communications

12(3): 116-120. ISSN 1335-4205.

13.

Hockicko P., B.

Trpišová, J. Ondruš. 2014. “Correcting students’ misconceptions about

automobile braking distances and video analysis using interactive program

tracker”. Journal of science education

and technology 23(6):763-776. ISSN 1059-0145.

14.

James, D.J.G.,

K.J. Burnham, M.J. Richardson, R.A. Williams. 1999. “Improving vehicle

performance using adaptive control techniques”. Artificial Life and Robotics 3(4): 236-241. DOI:

10.1007/BF02481187.

15.

Kalašová A., Ľ.

Černický, M. Hamar. 2012. “A new approach to road safety in Slovakia”. In Transport Systems Telematics: 12th

International Conference on Transport Systems Telematics: 388-395. 10-13

October 2012, Katowice-Ustroń, Poland. ISBN 978-3-642-34049-9. Available at:

http://link.springer.com/content/pdf/10.1007%2F978-3-642-34050-5_44.pdf.

16.

Knez M., B. Jereb,

M. Obrecht. 2014. “Factors influencing the purchasing decisions of low emission

cars: a study of Slovenia”. Transportation

Research Part D: Transport and Environment 30: 53-61. ISSN 1361-9309. DOI:

10.1016/j.trd.2014.05.007.

17.

Kubíková S., A.

Kalašová, Ľ. Černický. 2014. “Microscopic simulation of optimal use of

communication network”. In Telematics –

Support for Transport. TST 2014. Communications in Computer and Information

Science: 414-423. 22-25 October 2014, Katowice- Ustroń, Poland. ISBN

978-3-662-45316-2. DOI: https://doi.org/10.1007/978-3-662-45317-9_44.

18.

Kuranc A. 2015.

“Exhaust emission test performance with the use of the signal from air flow

meter”. Eksploatacja i Niezawodnosc –

Maintenance and Reliability 17(1): 69-74.

19.

Labuda R., A.

Kovalcik, J. Repka, V. Hlavna. 2012. “Simulation of a wheeled vehicle dynamic

regimes in laboratory conditions”. Communications

14(3): 5-9. ISSN 1335-4205.

20.

Moravčík Ľ., Š.

Liščák. 2012. “Zlepšovanie legislatívy pre schvaľovanie vozidiel”. [In Slovak:

“Improvement of legislation on vehicle approval”.] In CMDTUR: Sixth International Scientific Conference: 228-243. 19-20

April 2012, University of Žilina, Žilina, Slovak Republic. ISBN

978-80-554-0512-4.

21.

Nadolski R., K.

Ludwinek, J. Staszak, M. Jaśkiewicz. 2012. “Utilization of BLDC motor in

electrical vehicles”. Przegląd

Elektrotechniczny (Electrical Review) 2012 (4a). ISSN 0033-2097.

22.

Rievaj V, P.

Faith, A. Dávid. 2006. “Measurement by a cylinder test stand and tyre rolling

resistance”. Transport 21(1): 25-28.

ISSN 1648-4142. DOI: http://dx.doi.org/10.1080/16484142.2006.9638036.

23.

STN 30 0556. Cestné vozidlá. Rýchlostné vlastnosti.

Metódy skúšok. Bratislava: Úrad pre normalizáciu, metrológiu a skúšobníctvo

SR. [In Slovak: Road Vehicles. Speed

Characteristics. Test Methods. Bratislava: Slovak Office of Standards,

Metrology and Testing.]

24.

Šipuš D., B.

Abramović. 2017. “The possibility of using public transport in rural area”. In TRANSCOM 2017: International Scientific

Conference on Sustainable, Modern and Safe Transport. Book Series: Procedia Engineering 192: 788-793. DOI: 10.1016/j.proeng.2017.06.136.

25.

TNO Innovation for

Life. Road Load Determination of

Passenger Cars. Accessed: 2 November 2017. Available at: https://www.tno.nl/media/1971/road_load_determination_passenger_cars_tno_r10237.pdf.

26.

Tomasikova M., M.

Lukac, J. Caban, F. Brumercik. 2016. “Controllability and stability of a

vehicle”. LOGI – Scientific Journal on

Transport and Logistics 7(1): 136-142. ISSN 1804-3216.

27.

UNECE. Regulation

No. 101. Uniform Provisions Concerning the Approval of Passenger Cars Powered

by an Internal Combustion Engine Only, or Powered by a Hybrid Electric Power

Train with Regard to the Measurement of the Emission of Carbon Dioxide and Fuel

Consumption and/or the Measurement of Electric Energy Consumption and Electric

Range, and of Categories M1 and N1 Vehicles Powered by an Electric Power Train

Only with Regard to the Measurement of Electric Energy Consumption and Electric

Range. Accessed: 9 November 2017. Available at:

http://www.unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/2015/R101r3e.pdf.

28.

UNECE. Regulation

No. 83. Uniform Provisions Concerning the Approval of Vehicles with Regard to

the Emission of Pollutants According to Engine Fuel Requirements. Accessed: 9

November 2017. Available at:

https://www.unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/r083r4e.pdf.

29.

UNECE. Global

Technical Regulation No. 15. World Harmonized Light Vehicles Test Procedure.

Accessed: 9 November 2017. Available at:

https://www.unece.org/fileadmin/DAM/trans/main/wp29/wp29r-1998agr-rules/ECE-TRANS-180a15e.pdf.

30.

UNECE. World Forum

for the Harmonization of Vehicle Regulation (WP.29).. Available at:

https://www.unece.org/trans/main/welcwp29.html.

31.

Yanowitz J., M.S.

Graboski, L.B.A. Ryan, T.L. Alleman, R.L. McCormick. 1999. “Dynamometer study

of emissions from 21 in-use heavy-duty diesel vehicles”. Environmental Science Technology 33(2): 209-216. DOI:

10.1021/es980458p.

32.

Zbigniew M., M.

Jaśkiewicz, K. Ludwinek, Z. Gawęcki. 2015. “Special characteristics of

reliability for serial mechatronic systems”. In Selected Problems of Electrical Engineering and Electronics (WZEE).

The Kielce University of Technology and The Polish Society of Theoretical and

Applied Electrotechnics – Kielce Branch. 17-19 September 2015, Kielce, Poland.

ISBN 978-1-4673-9452-9.

Received 05.11.2017; accepted in revised form 12.02.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License