Article citation information:

Szala, G., Fajtanowski, R., Grygorkiewicz, P. Analysis of design concepts on the basis of selected designs for two-wheeled vehicles. Scientific Journal of Silesian University of Technology. Series Transport. 2018, 98, 149-159. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.98.14.

Grzegorz SZALA[1],

Romuald FAJTANOWSKI[2],

Piotr GRYGORKIEWICZ[3]

ANALYSIS

OF DESIGN CONCEPTS ON THE BASIS OF SELECTED DESIGNS FOR TWO-WHEELED VEHICLES

Summary. The paper explores the relationship between the design and construction process for technical objects and industrial design based on an analysis of selected examples of conceptual designs for two-wheeled vehicles. These examples have been taken from a collection of projects implemented by design students and graduates in the Faculty of Mechanical Engineering of the University of Science and Technology in Bydgoszcz. The paper presents didactic aspects of the issues connected with design and its relation to the design process for technical objects.

Keywords: industrial design, technical object design, bicycles

1. INTRODUCTION

The initial studies related to the

theory of engineering design were published by Janusz Dietrych in the 1970s

[1,2]. These works present the main stages in the evolution of a product

(design, construction, manufacturing and operation), including detailed

descriptions of the design and construction process, which is based on

conceptual work, leading to the creation of a concept for a technical object.

The criteria for evaluating the concept, as compared to other possible

solutions, play a key role in the above-mentioned analysis. There are many

groups of criteria including technical, manufacturing, operational, economic

and aesthetic ones. In Poland, the importance of the latter was emphasized by

Dietrych in the chapter entitled “The beauty of machines” (“Piękno maszyn”),

from Podstawy konstrukcji maszyn (Machine Construction Basics), which

points to the close relationship between industrial design and the construction

process.

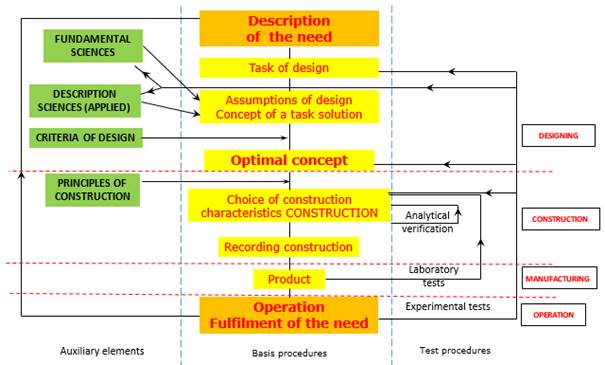

The problem of finding conceptual solutions and determining the criteria

for their evaluation is included in Chapter 2 of [6]. Figure 1 presents the

basic elements of the design and construction process connected with [6].

Industrial design is mostly included in the stage of design and involves

creating the most comprehensive set of design concepts, on the basis of which

criteria are chosen to obtain the best possible concept.

One of the most creative elements of

the design process is the creation of a set of concepts (the design process).

The effects of this process provide the basis for patent applications or

utility models. The most popular methods for identifying concepts are

heuristic, algorithmic, diagram, graph, spontaneous group thinking

(brainstorming) and analogy methods; these and other methods are described in

Section 2.3 of [6], entitled “Conception – conceptual design”, and [4].

Many universal utility products,

such as bicycles, are characterized by high aesthetic values and a high level

of performance, which often determine the choice of a product (aesthetics

criteria). Due to a high level of production capacity, globalization and major

competition in the market, aesthetics criteria are becoming increasingly

important.

Fig. 1. Elements of the design-construction process [6]

The aesthetic criteria are closely

related to the technical requirements that impose many restrictions. These

limitations include structural features (geometric, material and dynamic

features) and technological and operational requirements.

The connection between industrial

and other elements of design, construction, manufacturing and operation

processes is shown in Figure 1.

The problem of specialized design in

the field of industrial design is the subject of works by the Department of

Design in the Faculty of Mechanical Engineering at the University of Science

and Technology in Bydgoszcz, as well as specialist writings, such as [3,5,7].

The aim of this article is to

present selected analyses and conceptual studies, which were carried out by

students as part of their design and diploma work, supervised by the staff of

the Department of Design of the aforementioned faculty. All these solutions are

characterized by an original and innovative approach to the technical object,

in this case, the bicycle, as well as its functionality, ergonomics and aesthetics.

The projects presented in the study also took into account the changing

function and construction of the bicycle. There are various ways to approach

the theme of a bicycle, or rather a widely understood two-wheeled vehicle, for

which the bicycle was only a starting point.

2. SELECTED EXAMPLES OF CONCEPTUAL

PROJECTS

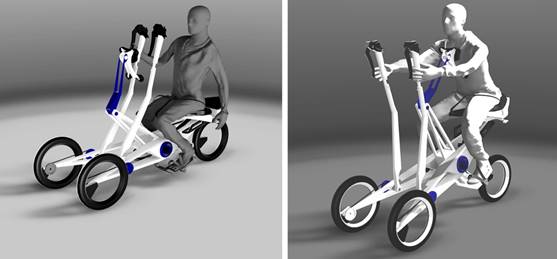

The first interesting example of the

implemented functional and structural solutions is the IVERC diploma project

from Daniel Sobieszyński (supervisor: Romuald Fajtanowski). The task undertaken

in this work involved designing a device that responds to the problem of

fatigue in the human body due to the exhausting body position resulting from

the form of the vehicle. The vehicle combines two main functions defined by

products that are currently available for sale. The first one is a

stepper/runner exercise bicycle (Figures 2 and 3).

Fig. 2. Visualizations of the designed bicycle (Daniel

Sobieszyński’s design)

The advantage of this type of device

is the lack of direct contact between the foot of the cyclist and the ground,

as well as the smooth movement of the leg, which eliminates the risk of injury.

According to this assumption, you can exercise the leg muscles and groups of

arm muscles depending on the position of the hands on the two-position handle

bars.

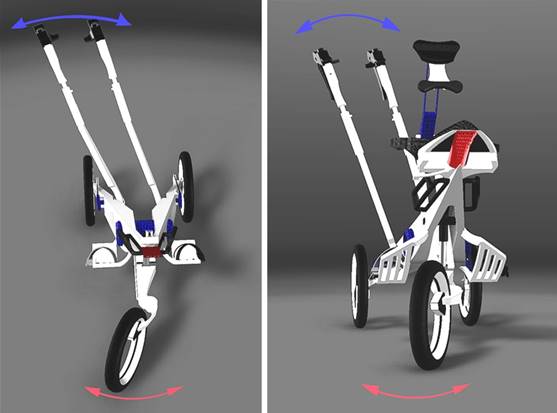

The distance between the axles is

108 cm and the angle of inclination of the frame is 69°, which is the optimum

parameter for stable driving. To turn the stepper into the horizontal position,

it is necessary to release the bicycle locks situated over the front wheel

fork, which are in the form of a quick-release gear, then slightly slide the

head out of the bearing seat and rotate the vehicle back 180°, and finally

secure the vertical position using the same locks.

The folded backrest, placed parallel

to the frame, should be straightened, unfolded and supported so as to provide a

predetermined angle of 125° (relative to the fixed seat). This angle is close

to the optimum (135°) for comfortable driving. It provides good visibility and

maintains the upright neck position, as close as possible to the natural

position. In order to adjust the distance between the pedals and the backrest,

the frame should be extended to reach a distance corresponding to the length of

a leg, reduced by 10%, so as to provide the user with comfort. The handle bars

should be inclined at an angle to make it comfortable for the driver.

When prepared as such, the

vehicle is designed for horizontal driving. In this case the front wheel is the

drive (formerly the rear wheel), with a torpedo-type brake (built into the hub,

which is popular in folding bicycles). The turning wheel situated behind the

rider (previously in front of him/her) is braked with a standard U-brake.

Fig. 3. Visualizations of the designed bicycle (Daniel Sobieszyński’s

project)

The horizontal position is a good

option for those who overestimate their endurance during training. It provides

easier riding with less leg loading in comparison to the standing position.

The 20-in wheels make it a typical city bicycle, which is also defined

by the location of the drive in the front (in a horizontal configuration). It

cannot accelerate to reach a speed comparable to the classic rear-wheel drive

and does not go up hills with the same ease, but it does manage to handle

distances that are slightly different in terms of altitude.

Another example of an interesting

approach to bicycle design, namely, in relation to its frame, is DROMEDAR from

Sławomir Tomasik (supervisor: Romuald Fajtanowski). The author focused on a classic bicycle frame based on two

triangles. Due to this “limitation”, the margin for manoeuvring is very

limited. Of course, you can bypass

this pattern by creating abstract forms; but, unfortunately, none of them will

match the system based on two triangles, in terms of endurance or riding

comfort (Figure 4).

Fig. 4. Designed bicycle frame (project by Sławomir Tomasik)

When designing a bicycle, it is important to note whether the material

from which the frame is built has a great influence on its structure. Steel is

the heaviest but most durable material, so you can use its thinnest profiles,

which may in turn greatly impact the overall design. Another major material

used in the production of bicycle frames is aluminium, which is relatively

cheap and extremely lightweight. It has only one defect: aluminium degrades

faster than steel and requires thicker profiles than steel to maintain the same

stiffness. The lightest material used in the construction of a two-wheel frame

is carbon. The interlaced carbon fibres form an extremely strong and rigid

structure. Mountain bicycles with full suspension have frames that are very

often made of more than one of the above-mentioned materials. Projects are

mostly created using two materials, for example, carbon and aluminium. This

project uses two materials: steel and carbon fibre. The combination of both

materials creates a unique form and makes the object extremely durable. When it

comes to the shape of the frame, it is designed primarily to provide all of the

assumed functions, which is an output resulting from the author’s creativity.

The third design,

which is presented in Figure 5, offers a number of improvements, which make the

bicycle easy to transport, handle and store. An additional advantage can be the

built-in protection, designed by the author of this work, and the wheels with

an innovative plait. The whole design is characterized by a geometry that is

suitable for mountain biking and subsystems that provide long and failure-free

operations, even under difficult conditions.

Fig. 5. Visualizations of the designed bicycle (project by Sławomir

Tomasik)

The student-designed KWADRON

bicycle, developed by Agnieszka Krzyżanowska and Adam Warszewski, presented in

Figure 6, was designed primarily for disabled people with leg dysfunction in

order to facilitate cycling. In this project, the cyclist can move with the

help of hands rather than legs. Riding involves manipulating two levers placed

in front of the bicycle. By pulling and pushing, the user drives the vehicle,

whereas, by moving the lever to the right or left, the user can change the

direction of travel. The drive levers are integrated with the rear swinging arm

with metal tie rods, thanks to which the movement of the lever (right-left)

causes a change in the rear swinging arm’s inclination angle.

Fig. 6. Visualization of the designed bicycle from the project by

Agnieszka Krzyżanowska and Adam Warszewski

The KWADRON bicycle has a hydraulic

cylinder system, which allows the shape of your bicycle to be changed from a

passive position, thus making it easier for a disabled person to assume a safe,

ergonomic, active position from a standard wheelchair, whose level is lower, as

would be the case with a fully functional two-wheeled vehicle.

The KWADRON bicycle user has the

possibility to adjust the height of the active position according to his/her

size and weight.

At the side of the bicycle, by the

saddle, there are two symmetrical handles, which enable the disabled person to

take up his/her position on the bicycle. Below, footrests are placed, along

with safety belts, which stabilize the feet. This prevents the legs from

slipping down and allows for safe riding on the bicycle. A similar function is

provided by a two-level adjustable chest support boom. This system is

facilitated by the manual operation of two levers, which can also adjust the

seat height. In addition, the system is integrated with the brakes, which

enable the gear ratio to be changed while driving (Figure 7).

The last example of a creative approach to bicycle design is Y COMPACT

from Nicholas Kościński (Figure 8). Here, the author presents a completely

different attitude towards the topic of folding; in fact, in this case, the

bicycle is almost dismantled. Most folding bicycles only have folding frames

with wheels permanently attached to them. For this project, the author offers

the opportunity to fold not only the frame but also the wheels, making the

bicycle more convenient for transport.

Fig. 7. Visualizations of the

designed bicycle from the project by Agnieszka Krzyżanowska and Adam Warszewski

The shape of the frame is similar to

a triangle, with slight differences. Two of its sides go beyond the base: they

“split” and turn into the shape of the front and rear forks. The bicycle frame

can be folded down with a single click of the button located under the saddle,

which releases the lock and allows it to be folded freely.

To fold the wheels, we remove the

tubeless tyres, while the rims, which are divided into three parts, must be

manually connected or disconnected with the use of two locking rims (Figure 9).

Fig. 8. Visualization of the designed bicycle from the project by

Nicholas Kościński

The power transmission works in a

similar way to that of a traditional bicycle, transmitting only the strength

(pressure) of the legs through two racks with a chain belt. The system is

located in front of the vehicle, making it easy to fold. The crank and pedal

rotate on independent axles and transfer the drive directly from the belt to

the wheel axle. The wheels have a standard adult bicycle diameter of 26 in.

The bike has been awarded the

innovative form and technical solution prize at the LINK 2012 international

competition.

3. SUMMARY

Examples of the designs described in

this article show different ways of implementing bicycle design, different

attempts to solve design dilemmas and different pathways that young designers

can follow. They also showcase uniquely innovative ideas, which reflect

thinking that is unfettered by any rigid schemes or fixed patterns.

Since implementing the didactic

programme of the Department of Design at the University of Technology and Life

Sciences in Bydgoszcz, students have been prepared for work in the broadly

recognized professional role of the designer. However, this type of training

can only produce satisfying results and prepare students for the design

profession if we look into the future, anticipate market needs, and fully take

into account the students’ further development prospects.

Therefore, the motivation that

prompted us to work on these projects was not only to take care of the

aesthetics side of design, but also to search for the best possible concepts,

functional qualities and material solutions, tailored to meet contemporary

needs.

In conclusion, it should not be

forgotten that a properly designed vehicle’s appearance also has a direct

impact on its technical parameters, for example, air resistance or combustion

level [8,9].

Fig. 9. The method of folding the bicycle from the project by Nicholas

Kościński

References

1.

Dietrych Janusz,

Stanisław Kocańda, Witold Korewa. 1974. Podstawy

konstrukcji maszyn. [In Polish: Machine

Construction Basics.] Warsaw: WNT.

2.

Dietrych Janusz.

1985. System i konstrukcja. [In

Polish: System and construction.]

Warsaw: WNT. ISBN 83-204-0660-9.

3.

Kroemer Karl,

Henrike Kroemer, Elbert Katrin Kroemer. 2000. Ergonomics. How to Design for Ease and Efficiency. New York:

Prentice Hall. ISBN 0-13-752478-1.

4.

Pahl G., W. Beitz.

1984. Nauka konstruowania. [In

Polish: Learning to Construct]

Warsaw: WNT. ISBN 83-204-0461-4.

5.

Pawłowska A. 1997.

O projektowaniu modeli idealnych,

problemy metodyki projektowania. [In Polish: On Designing Ideal Models: Problems of Design Methodology.] Warsaw:

PAN.

6.

Szala Józef. 1998.

Podstawowe problemy współczesnej techniki

i technologii. [In Polish: Basic

Problems of Modern Technology and Techniques.] Bydgoszcz: University

Publisher of the University of Technology and Agriculture.

7.

Tytyk Edwin. 2001.

Projektowanie ergonomiczne. [In

Polish: Ergonomic Design.]

Warsaw-Poznan: PWN. ISBN 83-01-13611-1.

8.

Fabian M., M.

Puskar, R. Boslai, M. Kopas, S. Kender, R. Hunady. 2018. “Design of

experimental vehicle specified for competition Shell Eco-marathon 2017

according to principles of car body digitisation based on views in 2D using the

intuitive tool Imagine&Shape CATIA V5”. Advances

in Engineering Software 115: 413-428. DOI:

10.1016/j.advengsoft.2017.10.006.

9.

Fabian M., M.

Puskar, M. Kopas, J. Kul’ka, R. Boslai, L. Gurbal, M. Masaryk, O. Sloboda,

P. Blistan. 2017. “Principles of car body digitisation based on geometry

extracted from views in 2D drawing documentation”. International Journal of Vehicle Design 74(1): 62-79. DOI:

10.1504/IJVD.2017.10005558.

Received 09.11.2017; accepted in revised form 24.02.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License