Article citation information:

Redo, W. Selected aspects of the quality of parameter measurements saved by on-board recorders. Scientific Journal of Silesian University of Technology. Series Transport. 2018, 98, 119-131. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.98.12.

Wojciech REDO[1]

SELECTED

ASPECTS OF THE QUALITY OF PARAMETER MEASUREMENTS SAVED BY ON-BOARD RECORDERS

Summary. This article highlights the specifics of on-board recorders among the various systems found on aircraft. Attention is drawn to the legal and technical compliance requirements concerning modern on-board recorders. Reference is also made to certain aspects of recording methods and data security. Furthermore, the paper especially focuses on the process of measuring a parameter, indicating the basic criteria regarding the accuracy of the measurement. In addition, the role of two essential elements in the measuring chain is discussed: the feeder as a parameter measurer and the transformation system, i.e., AC converter.

Keywords: flight data recorder, registration system, feeder, accuracy of parameter measurement

1. INTRODUCTION

On-board flight recorders belong to a group of devices

of aircraft equipment that are subject to stringent requirements. The

specificity of these devices stems from their destination and purpose for which

they are built on aircraft, compared with how other aircraft systems

operationalize these functions. The basic functions of on-board recorders

involve recording significant operating parameters of systems and on-board

installations of the aircraft, as well as the parameters of the spatial

position and their memorization and protection.

Today’s on-board recorders are technologically advanced devices in terms of

design and data processing. In practice, on-board recorders are used to record

up to a hundred different types of parameters. As such, the number of currently

registered parameters is no longer problematic; but, accuracy remains an issue,

from the time of measuring the parameter values, through all the phases of

conversion and encoding, to the restoration of their physical values in the

registered entries.

2. DIVISION AND THE STANDARDS FOR ON-BOARD

RECORDERS

Considering the types of data recorded by

on-board recorders, four main groups of recorders can be identified:

1.

Flight data recorders (FDRs)

2.

Recorders of conversations and sounds in the cockpit, i.e., cockpit voice

recorders (CVRs)

3.

Recorders of board images, i.e., airborne image recorders (AIRs)

4.

Recorders of digital data links, i.e., data link recorders (DLRs)

The first

two types may exist either as two separate

devices or as single integrated units. Registration systems for the flight are

now standard equipment on all civilian and state aircraft. These systems should

not be equated with other aircraft systems, as they play quite a different

role. The distinguishing feature of such systems is that they play out the role

of “controller” concerning the given airship

parameters and database for the course of the flight. Thus, bearing in mind the

specificity of the system, there is an obvious need to meet the requirements

set by them. It should be mentioned that all formal and legal issues (including

the requirements) regarding the operation of civil aviation is governed by the International

Civil Aviation Organization (ICAO), established under the Convention on

International Civil Aviation (also known as the Chicago Convention), which is

an international agreement regulating issues in the field of aviation law,

signed in Chicago on 7 December 1944.

Detailed requirements on recording

equipment are included in Annex 6 to the Chicago Convention [1], which covers

the operation of aircraft. These requirements mainly concern:

–

The definition of recorder working time (in relation to the readiness to turn

off)

–

Parameters that must be registered

–

Types of recorders and systems of flight data recording

–

Construction and assembly

Meanwhile, detailed expectations for

military aviation recording equipment are found in Decision No. NO-16-A200

entitled the “Defensive Standard on Military Aircraft: On-board Catastrophic

Recorders – Requirements and Tests”[2].

The standard specifies the

requirements and functional characteristics of on-board catastrophic recorders

installed on military aircraft, as well as include a list of recorded

parameters and test methods concerning the impact resistance of recorders in

relation to factors present at the time of the crash of the aircraft. The

standard also defines the specifications of flight data and disposable signals

recorded by on-board catastrophic recorders on military aircraft and a list of

authorized uses for certain types of sensors that measure parameters found on

multi-engine airplanes (transport), fighters, attack aircraft, trainer aircraft,

helicopters and airplanes capable of vertical or short take-offs and landings

[6].

Given the above requirements and the previously

mentioned features of the registration system, one should not relate its

functionality to the role of the autonomous recorder. This is because an

on-board recorder system realizes not only the parameter registration process,

but also the measurement of parameters and their transformations. Modern

registration systems for flights charge selected data from on-board databases

and specialized sensors (feeders). Thus, by understanding the organization of

the processes carried out by different types of recorders, one can define the

purpose of registration systems as systems for recording and protecting

specific groups of data:

1.

Parameters of the flight

2. The

parameters of the powertrain

3.

Location of aircraft controls

4.

Status of individual devices and installations

There is also a need to assess:

1.

Flight safety

2.

Techniques of piloting,

3.

Technical state of the exploited aircraft

In other words, as a “record”, we refer to an

ordered stream of change (ARINC code) in the data (events) as a function of

time. In turn, the “protection” of the recording is realized through the

technical protection of data collected by the recording element, located in the

construction (casing) line of the catastrophic recorder, against the

effects of exceptionally extreme

external factors.

Given the aviation tasks, maintenance as well

as cases of unforeseen air events, it is necessary to adjust the recorder

design for quick access to stored data. This type of requirement is provided by

the practical application of the on-board recorder for wireless data

transmission, mobile operating cartridges or other storage media (e.g., in line

with Personal Computer Memory Card

International Association standards). Portable cassette supplies are

often referred to as quick access recorders (QARs). A QAR is used as a double

of a catastrophic recorder and contains the same recording data as a

catastrophic recorder. For the catastrophic recorder system, there is an

opportunity to join up with a portable QAR. Such an option involves BUR and

TESTER recorders.

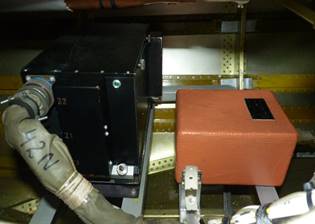

Figure 1 shows two types of QAR produced by

ATM. The ATM-QR4 recorder was the successor of the unproduced

ATM-QAR and came into production in 1996. Compared to the previous model, all

the technical parameters were improved, so that it was possible to use modern

memory cassettes in the MC5 series with a large capacity. The only elements

that did not change were the external dimensions and the connector connecting

the recorder with the on-board installation of the aircraft, meaning that

interchangeability was retained with the old model. An important solution by

which the QAR differed from the QR4 concerned the modular design, which allowed

the configuration of the recorder to change, even during operations [8].

|

|

|

|

Fig. 1. Quick access recorders: ATM-QAR and

ATM-QR4 Source: WSOSP LKL; ATM |

|

However, for the security of recorded data,

safety record cassettes are used to protect the data on the permanent memories

(flash), magnetic media and photosensitive materials. Building the safety

cassette system (catastrophic) into the rear part of the fuselage increases the

chances for users to save data under the most extreme conditions. It should be

added that the structure of the same catastrophic cartridge and its

functionality must meet the requirements of the NO-16-A200 standard. Currently

used recorders must have the capacity for saving:

–

2 h of flight information in the case of CVRs

–

25 h of flight information in the case of FDRs

The number of recorded analogue and discrete

parameters depends on the type of aircraft and can reaches up to 1,000.

Catastrophic recorders have to survive a crash,

which means there are certain minimum criteria to be met by protective tape in

order to for undamaged records to be recovered. The main criteria are:

– Immersion in consumables liquids (aviation fuel,

oils, hydraulic fluid) for 48 h

– Hydrostatic pressure of seawater at a depth of 6,000

m for 30 days,

– Testing of fire temperature to 1,100°C for 30 min

– “Oven” testing at a temperature of 260°C for 10 h

– G-force overload to 3,400 units with a duration of

6.5 ms

– Direct impact of 226 kg of weight falling from a

height of 3 m onto the surface of the protective cartridge, along with a

ball-shaped blade with a diameter of 6 mm

Underwater locator beacons are built into

today’s protective cassettes systems, which act as transmitters sending signals

to confirm their location (time to send a signal: up to 30 days). The

protective cassettes are installed as sources of electricity (batteries) used

to maintain the contents of flash memory for up to 10 years.

For the above-described design solutions for

on-board recorders, collected data can be stored on two types of cassettes,

which differ in terms of their ability to survive under extreme conditions:

namely, operational cassettes (in QARs) and catastrophic cassettes. A flight

data recorder stores the same information on a protective cartridge or a quick

access cartridge (operational).

Data stored on a protective cartridge are used

to analyse the causes of air events, while data from a quick access cassette

are mainly used for the analysis of the mission carried out by the crew of the

aircraft.

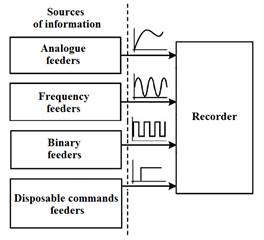

To summarize, a flight data recorder is

generally designed for recording analogue signals, digital signals, and

frequency and disposable (binary) signals originating from feeders and onboard

equipment on cassettes, as well as identification data entered by the crew

before the flight or automatically.

|

|

|

|

Fig. 2. Installation of an S23ai

recorder on Source: LKL WSOSP |

Fig. 3. Installation of an S23A

recorder on an SW-4 Source: LKL WSOSP |

3. MEASUREMENT OF PARAMETERS

3.1. Sources of

information

As

mentioned above, the operation of all aircraft systems and, in principle, the

operation of each on-board device are not technical problems concerning how to

register the status represented by a parameter or a specific group of

parameters. Ensuring the proper functionality of recorders comes down to:

– Defining the scope (number) of measured and recorded

parameters

– Determining the type and extent of the measured

parameter

– Selecting the appropriate kind (type) of feeder

(transducer)

– Correcting (according to technical guidelines and

the laws of physics) the installation of the feeder (transducer) on board the

aircraft (design requirements)

– Executing (according to technical guidelines) the

recorder connection

– Scaling the measuring channels (feeders)

– Checking the proper operation during the flight

Defining the element that directly measures a

parameter with the word czujnik (sensor) is mainly due to the fact that this element is referred

to in English as “sensor”. However, mainly because of the many years of

operation in domestic aviation involving Russian-produced recorders, it is

defined within the context of technical nomenclature by the word

“датчик”, which literally means feeder

(giver, provider or

supplier). Defining the element for

measuring the feeder clearly reflects the meaning of the principle of operation

of this element: to measure the parameter and pass the information, in this

case, to the on-board recorder. This qualification implemented by the function

of this element basically requires it to be

called a transmitter. When determining the measuring element as a czujnik

or sensor in the future, the property

of “passing on” should also be borne in mind, which means we can then use these

terms interchangeably: feeder and transmitter.

The system of collecting information

about the status of the aircraft is based on data obtained

from a specific location (the system) of aircraft by using a sensor (feeder)

that can adequately measure the parameter. While sensors are deployed in

different parts of the aircraft, they are mostly located in points that have a

critical impact on the course of all phases of the flight (propulsion,

hydraulic, control, chassis system etc.). Their number depends on the size of

the aircraft structure, the drive type and the destination. Furthermore, they

simply communicate all data to a collective information unit (or

flight data acquisition unit), which acts as their “eyes and ears”.

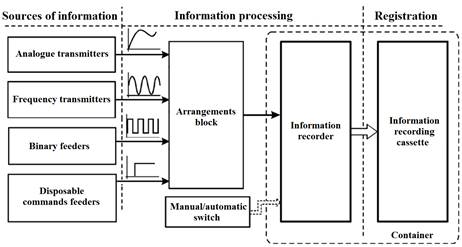

Fig. 4. Sources of information and

types of recorded signals

3.2. Classification of

measuring sensors

Concerning today’s on-board

recorders, we have to deal with different types of feeders

used by manufacturers. In terms of the number of recorded parameters and their

individual types (analogue, digital, frequency, single), analogue parameters

constitute the vast majority. A sample juxtaposition

of recorded parameters of the aircraft with respect to the type of feeder is presented in Table 1.

Tabl. 1

Examples of feeders for measuring

parameters (variant)

|

Parameter name |

Type of feeder |

Kind of feeder |

|

Airspeed |

MDD-Tje-0-1,5 |

A |

|

Amount

of barometers |

MDD

Tje-1-780 |

A |

|

Rudder

angle |

MU-614 |

A |

|

DSS

position |

MU-614 |

A |

|

Current

fuel residue |

TRW-2 |

A |

|

Engine

speed |

DTE-1 |

B |

|

Name of command |

Type of feeder |

Kind of feeder |

|

Deflection

of the left flap |

W-311 |

E |

|

Temperature

controlling |

RT-12-3M |

E |

|

Pressing

combat button |

MP-5 |

E |

|

A:

analogue, B: frequency, C: binary, E: disposable commands |

||

One of the most popular feeders with

which to measure analogue parameters is the MU-615 angular displacements

feeder. The design of this type of feeder is that of a typical potentiometer

with a wire line resistor with an (adjustable) zero point of the slider at the

mid-length point of the resistor. The basic parameters that describe the

resistance feeder are the resistance range and the range of the angular

displacement of the slider. Under the influence of the control (e.g., the

movement of the rudder) and the feeder mounted on it, along with a

potentiometer with a resistance of R=700 Ω (for MU-615A), the rotary brush

of the potentiometer moves to a distance proportional to the angle change of

the rudder.

|

|

|

Fig. 5. MU-615 angular displacements feeder

The circuit for measuring analogue

values is one of the fundamental problems arising from the selection of the

right sensor and its adaptation to the on-board recorder installation. Even if

it only includes a resistive sensor and a system for data acquisition,

obtaining accurate measurements requires many complex issues to be taken into

account.

The types of measuring sensors for

flight parameters operating in FDR systems on military aircraft is determined

by the NO-16-A200 standard, as follows:

1.

Disposable commands sensors

2.

Strain torque gauges

3. AC

sensors (differential)

4. DC

sensors (differential)

5.

Synchros

6. Digital

signal sensors

7.

Magnets (synchro with permanent magnets)

8.

Tachometric generators

9. AC

frequency sensors

10.

Thermocouples

11. Resolvers

12.

Accelerometers [6]

3.3. The essence of

parameter measurements

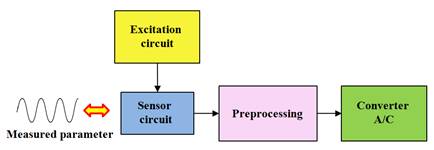

Figure 6 presents a classic work

(measuring) system containing a resistor in a sensor circuit as the measuring element. Although the block diagrams of all

analogue signal strings look similar, the parameters of each block depend on

many factors, of which the most important are the change in resistance of the

sensor per unit change of the measured value (and

thus the change in voltage), the distance from the sensor to the measurement

system (i.e., measurement error due to the resistance of wires), the type of

disturbance and the required accuracy.

Fig. 6. A general diagram of an

analogue measuring system

The measuring transmitter can process the non-electric signal (N) in relation to the

size of the electrical (E) value, in two ways:

1) Directly, by a single

elementary transducer of non-electrical value for either electrical (N/E) or non-electrical

(N/N) values. Such a transducer serves as a sensor. For example, the sensor

function directly corresponds to the thermocouple with two different metals,

joined at one end. The thermoelectric power is generated between the free ends,

caused by the temperature difference of the measurement weld and the free ends

(N/E processing).

2) Indirectly, as a result of

preprocessing by the elementary converter N/N, which measures the

non-electrical value for other non-electric values.

This is easily measurable for the purposes of further processing by the N/E

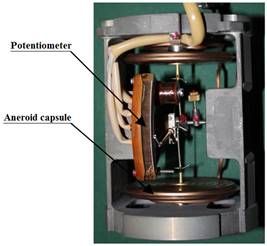

transmitter in order to obtain a measurement result. An example of this is a

pressure transducer with a steel membrane (Figure 7).

Fig. 7. DAS speed feeder (indirect converter)

The difference in measured pressure is first processed by a resilient mechanical

transducer in relation to other non-electric signal deformations of the

membrane, and then converted to the relative resistance change. The

potentiometer does not respond directly to the measurand value (differential

pressure), but to the deformation of the membrane. In this case, the measuring pressure transducer comprises two elementary converters: N/N and N/E.

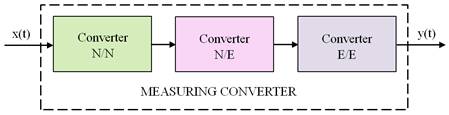

Fig. 8. Block diagram of the measuring converter of non-electrical value

(N: non-electrical value, E: electric value)

Source: [2]

Except for the

N/N and N/E converters, E/E elementary transducers are often used as measuring converters (Figure 8) in order to implement the

basic functions of the measuring transducer or the matching electrical output

signal of the N/E sensor and the parameters of the rest of the measurement path

[3]. The above-mentioned parameters determine:

– The type of excitation

– How to enable the sensor in relation to the measurement

path

– The required value of the gain factor for the

recorder acquisition circuit and the analogue-digital converter (ADC)

– The resolution and range of the input of the ADC

– The type of protection against disturbance (filter)

– The setting of the threshold for cut-off noise

The proper selection of a feeder for

parameter measurements and execution in accordance with technical

guidelines for network connections between the feeder and recorder

increases the accuracy of the measurement path on the feeder line, i.e., the

recorder arrangements block. The fulfilment of this condition greatly limits

the possibility of occurrence of the measurement

error for the parameter machining process. It is very important that the

falsified information entered into the system by the feeder can turn during the

operation of the aircraft in the case of a systematic error whose consequences

can be catastrophic. An example of an incorrect “matching” feeder and the

measuring track is the application of conductors,

which is inconsistent with the requirements of the manufacturer’s resistivity

in a system for measuring the exhaust gas temperature (thermocouple). An

example of the wrong configuration of the measurement path is the use of an

incorrect feeder in the channel in terms of height or speed. The application of

a feeder with the wrong range of a potentiometer reduces the measurement

sensitivity. However, the fundamental issue concerns the properties of the

aneroid, which controls the potentiometer brush. The “sensitivity” box and

range of measured values for the physical parameter are determined by the

dimensions. In the first case, we are dealing with the accuracy of a measuring

point, and in the second with the risk of possible damage (blowing) if the

acceptable range is exceeded. The differences in external dimensions, and in

turn the size of the aneroid cans, are shown in Figure 9.

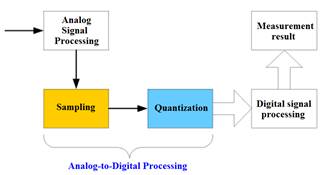

Regardless of the type of measuring transducer (Figure 8), there is always an analogue signal at its output. Taking into consideration such issues as compression, transmission and storage of data, the analogue signal in subsequent stages is subject to digital processing [5].

The signal from the feeder is passed

to the acquisition block of the recorder, and then undergoes transformation into

digital form. Transforming is performed in the recorder arrangements block

through an ADC. To assess the risk of error at this stage of signal processing,

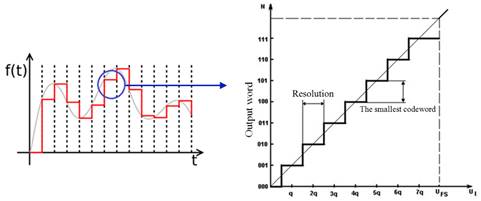

one should carry out an overall analysis of the operation of the transmitter. The operation of an ADC is shown the figure 11.

Fig. 9. Comparison of speed feeders: Mdd-Te 0-1.5 and DAS

Fig. 10. Block diagram of the

recorder system

Fig. 11. The process of signal

processing

The process of analogue-digital

conversion consists of three basic operations: sampling, quantization and

coding. Sampling involves collecting (definite and uniform) time samples of an

analogue signal and recording the instantaneous values of the samples taken.

Quantization involves dividing a continuous set of values of the signal into a

finite number of well-defined, adjacent compartments and determining the so-called quantization levels, or

specific values of each compartment representing all values in this range [7];

each sample is assigned to the corresponding (closest) level of quantization,

while, in the encoding process, it is attributed its coded number. Thus, each

sample of the analogue signal corresponds to the code word constituting the

digital, usually binary, record of a certain level of quantization (Figures 12-13):

Fig. 12. The theoretical (ideal)

action of the analogue converter

Fig. 13. The practical (real) action

of an ADC

One of the major mistakes in the

processing of the analogue signal into a digital one is the quantization error,

also known as the resolution mistake. It is a systematic error, which amounts

to ±ULSB/2, which is equal to half of the input voltage variation, which causes

a change in the lowest number position. This error can be treated as an

additional interfering signal and is often called quantization noise.

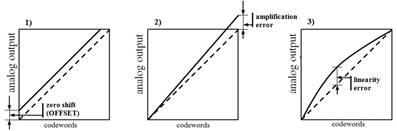

The ideal characteristics of ADCs

can be represented as a stepped line assigning individual compartments of a

processed input voltage-specified digital signal (code word). Actual converters

deviate from the ideal characteristics. In practice, we have to deal with three

types that may occur as a result of the transformation of the AC transducer

signal: zero offset error, amplification error and non-linearity error (Figure

14). The reasons for the error are mostly the ageing of components and

temperature variations.

Fig. 14. Illustration

of the definitions: 1) zero error, 2) amplification error,

3) linearity error of the total

4. CONCLUSION

The use of on-board recorders in both state and civil aviation is becoming more common. On the one hand, safety considerations and the possibility of using these devices in other areas of aviation, as support for flight training and prevention in the operation of the aircraft, have meant that they have become, in a sense, universal. The ability to capture virtually any parameter of the aircraft allows for the most accurate way to describe the status and situation of the aircraft during a flight. However, it is not the number of recorded parameters, but the accuracy of their measurement that allows us to get closer to the actual (physical) conditions in the air. Maintaining the required accuracy of parameter measurements consists of many factors, occurring at different stages of operating on-board recorders. Across the entire spectrum of recorded parameters, only single commands offer overall measurement accuracy. For this group of signals, the total measurement accuracy is based on zero-one architecture. It is quite different in the case of the accuracy of measurement parameters, where the accuracy of the measurement should be understood in the overall context, i.e., from the moment of measuring the phenomenon to the reading of the measured physical value. All elements included in the measurement path (measurement, processing and registration) must meet specific performance requirements. The record from the completed SP flight is not only material for analysis in the field of the quality of the task in the air, but also an important component with which to assess the technical condition of the aircraft and thus must be taken into account in terms of accident prevention. The aircraft, as a complex system [4], imposes quantitative requirements on the FRD (the number of recorded parameters), as well as requires the use of measuring tracks that ensure the objective measurement of the phenomenon.

Examples of factors that may cause the registration of

false information have been cited in this article, indicating that errors in

the measurement circuit result from a level of accuracy limited by technological

devices. Maintaining the proper standards, in accordance with the technical

requirements of the FDR system’s operation, imposes certain criteria that

should be met by the personnel operating the FDR, as well as the personnel

performing the reading and parameter analysis.

References

1. ICAO. 2008. Annex 6 (Operation of Aircraft).

2. Gawędzki W. 2010. Electrical Measurements of Non-electrical Quantities. Cracow: AGH.

3. Kester W. 2012. Analog-digital Conversion. Legionowo: BTC.

4. Lewitowicz J. 2006. The Basics of Aircraft Operation. Warsaw: ITWL.

5. Marwen C., G. Ewers. 1999. Outline of Digital Signal Processing. Warsaw: WKŁ.

6.

Defensive

Standard No. NO-16-A200 (Military Aircraft: On-board Catastrophic Recorders –

Requirements and Tests). Official Journal of the MON

4, Pos. 63.

7.

Tumański

S. 2007. Measurement Technology.

Warsaw: WNT.

8.

ATM

Production Company Sp. z o.o. Available at:

http://www.atmavio.pl/lotnictwo/wyroby-dla-lotnictwa-cywilnego/rejestratory-szybkiego.

Received 16.10.2017; accepted in revised form 24.01.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License