Article citation information:

Faltinová, E., Mantič, M., Kuľka, J., Kopas, M. Reliability analysis of crane lifting mechanism. Scientific Journal of Silesian University of Technology. Series Transport. 2018, 98, 15-26. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.98.2.

Eva FALTINOVÁ[1],

Martin MANTIČ[2],

Jozef KUĽKA[3],

Melichar KOPAS[4]

RELIABILITY

ANALYSIS OF CRANE LIFTING MECHANISM

Summary. This paper focuses on a reliability analysis of various structural variants of a crane lifting mechanism. The reliability of such a mechanism is a basic requisite for the safe operation of the crane as a whole. The article analyses and jointly evaluates structural solutions for the lifting mechanism in a bridge crane, in order to emphasize the technical aspects of system reliability in this context.

Keywords: lifting mechanism, crane, reliability, technical system, reliability indicators, block diagram

1. INTRODUCTION

In the area

of transport and handling machines or machinery, there are many devices with a

high potential of danger or technical risk. The lifting mechanism of cranes,

which are used, for example, in the transport of hazardous substances, is

representative in this regard. It is possible to improve the reliability of

such devices by taking various measures, e.g., by slowing the process of

deterioration, eliminating the source of deterioration, following the

procedures for operation and maintenance, and using alternate components.

A growing number of components in

complex technical systems, however, has increased the probability of failure.

Given that it is usually possible to improve the indicators of system

reliability by carrying out several appropriate measures, finding a structural

solution is very important too.

To perform a quantitative analysis

of technical system reliability by using reliability indicators, mathematical

methods of probability and statistical probability are applied. The most

relevant methods used for the evaluation of structural reliability, including

the theoretical basis of these methods, are described in [1,2,3]. A specific

approach to reliability is presented in [4], whose authors derive the value of

reliability from the scheduling of an activity with a random duration, such as

travel under congested conditions, concerning questions related to transport.

The ability to forecast machinery failure is vital in order to reduce

maintenance costs, operation downtime and safety hazards. A novel approach to

incorporating information on population characteristics and suspended condition

trending data on historical units into prognoses is presented in [5,6]. A

comprehensive, up-to-date description of all the important methods for the

design, development, manufacture and maintenance of reliable engineering

products and systems can be found in [7,8,9]. Another important aspect of

machine reliability is the reliable maintenance or influence of maintenance on

the reliability of machines and machinery [26,27,28,29,30,31,32].

Reliability-centred maintenance is a method for maintenance planning developed

within the aircraft industry and later adapted to several other industries and

military branches. This method is demonstrated in [10,11].

The reliability aspects of dynamic

systems relating to engineering production plants are described in [12], while

a reliability analysis of technical systems, which considers working

environment parameters, is presented in [13].

A special approach to the questions

of reliability is required in the case of driving systems equipped with piston

combustion engines. Typical examples illustrating this investigation area can

be found in [14,15].

The most important mechanism in

every crane is the lifting mechanism. The motion of a crane lifting mechanism

is considered in [16,17]. A special example of the crane lifting mechanism,

which is installed in a quay container crane, is modelled in [18]. Questions

concerning the bridge crane load spectrum and load distribution are analysed in

[19,20]. An intelligent anti-swing control for the bridge crane is introduced in

[21,22].

This article analyses and evaluates

the technical system reliability relevant to the standard variants of a crane

lifting mechanism, which is typically installed in bridge cranes.

2. METHODS USED FOR CALCULATING RELIABILITY

INDICATORS IN TECHNICAL SYSTEMS

A system refers to a device, which

consists of multiple parts, known as system components. It is important to

understand its structure and the nature of its work to such an extent that we

are able to determine whether or not the failure of a particular component will

cause the entire system to fail. The system of our inquiry, which consists of n components, can be divided into

series, parallel and combined configurations.

The reliability of a technical

system that consists of components can be conveyed numerically by using the

following indicators of system reliability, [23,24]:

F(t) – failure

probability (unreliability

R(t) – failure-free

probability (reliability)

f(t) – failure

probability density

λ(t) – failure

intensity

In order to calculate the

reliability indicators of a technical system, it is necessary:

Ø To know the probability of a failure-free operation

for ri(t), for i = 1, 2, ..., n components.

Ø To draw a reliability block diagram.

A reliability block diagram illustrates how the components are

interconnected in terms of reliability analysis and calculation.

Ø To assume that the individual parts are independent.

This means that the failure, or rather the survival, of a particular system

component does not affect the failure, or rather the survival, of other system

components. Based on this simplification, we can determine the reliability of

fundamental component interconnections.

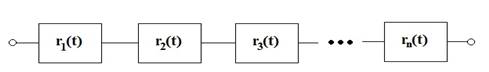

2.1. Series systems

Series interconnection is a configuration of components in

a reliability block diagram, in which a system failure occurs when at least one

component fails. A reliability block diagram for a series system is shown in

Figure 1.

Fig. 1. Reliability

block diagram of series interconnection

Reliability indicators for

series systems are calculated by using the following formulas:

Probability of a failure-free operation in

series systems

![]() (1)

(1)

Probability of failure in series systems

![]() (2)

(2)

Failure probability density in series systems

![]()

Each element is expanded by quantity

![]() , for i = 1, 2, ..., n. Then:

, for i = 1, 2, ..., n. Then:

(3)

(3)

Failure intensity in series system

(4)

(4)

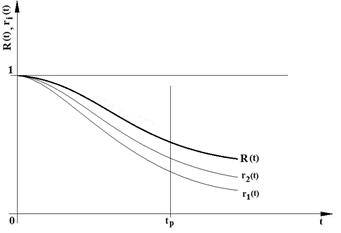

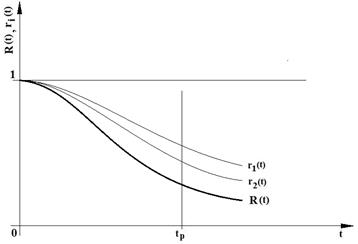

The resulting reliability of the

series system is always less value than the reliability of the most unreliable

component from the given system (Figure 2).

Fig. 2. Time behaviour

of the reliability of the system and components in the case of series

interconnection

2.2. Parallel systems

Parallel interconnection is a configuration of components in

the reliability block diagram, in which a system failure occurs when all

components fail. A reliability block diagram for parallel systems is shown in

Figure 3. Reliability indicators for parallel systems are calculated by using the

following formulas:

Probability of failure in parallel systems

![]() (5)

(5)

Probability of a failure-free operation in

parallel systems

![]() (6)

(6)

Failure probability density in parallel systems

Each element is expanded by quantity ![]() , for i = 1, 2, ..., n. Then:

, for i = 1, 2, ..., n. Then:

(7)

(7)

Failure intensity in parallel systems

![]() (8)

(8)

The resulting reliability of the

parallel system is always higher than the reliability of the most reliable

component from the given system (Figure 4).

|

|

|

|

Fig. 3. Reliability block

diagram of parallel interconnection |

Fig. 4. Time

behaviour of the reliability of the system and components in the case of

parallel interconnection |

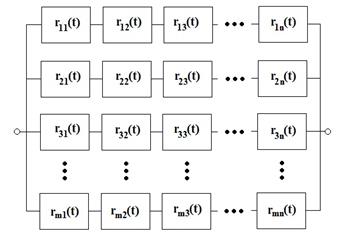

2.3. Combined systems

Combined systems merge series and parallel subsystems

into a single system. A combined interconnection diagram is shown in

Figure 5.

Fig. 5. Reliability block diagram of a combined

interconnection

Reliability indicators for

combined systems are calculated by using the following formulas:

Probability of a failure-free operation in

combined systems

(9)

(9)

where: i

= 1, 2, ..., m (number of branches in the system); and j = 1, 2, ..., n (number of components in the branches of the

system).

Probability of failure in combined systems

![]() (10)

(10)

Failure probability density in combined systems

![]() (11)

(11)

Failure intensity in combined systems

![]() (12)

(12)

3. RESULTS OF RELIABILITY EVALUATION FOR THE

MAIN STRUCTURAL VARIANTS OF A LIFTING MECHANISM

This chapter presents

a reliability analysis of five solution variants for lifting mechanisms in

bridge cranes.

|

Fig. 6.

Examples of crane lifting mechanism (Demag Cranes) |

Fig. 7. Scheme of crane lifting mechanism |

The first variant (ZM A) represents

the most complex configuration of the lifting mechanisms, whose modification

through structural simplifications creates the other four variants (ZM B to ZM

E).

Figure 6 illustrates typical structural solutions for

lifting mechanisms in bridge cranes. Figure 7 shows a scheme for

a lifting mechanism in its most complex structural configuration (ZM A).

Table 1 presents an overview of structural solutions

for all five variants of lifting mechanisms, i.e., from ZM A to ZM E.

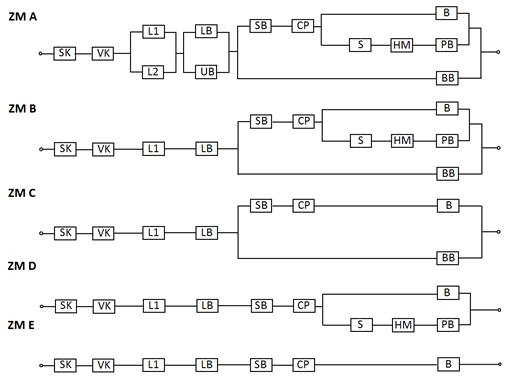

The next section presents the

results of an investigation into the extent to which the probability of

a load drop event can be affected by structural simplifications. For this

purpose, it is necessary to configure reliability block diagrams for each

variant of the lifting mechanism. (Figure 8).

Table 1. Overview of

design differences among the individual variants from

ZM A to ZM E

|

Variant ZM |

Description |

|

ZM A |

Lifting mechanism matches the illustration in

Figure 7 |

|

ZM B |

Like ZM A, but without a support drum

fitting, and with a single rope |

|

ZM C |

Like ZM B, but without an auxiliary brake |

|

ZM D |

Like ZM B, but without a safety brake |

|

ZM E |

Like ZM C, but without a safety brake |

Fig. 8. Reliability

block diagrams of lifting mechanism variants

The designated symbols in the

reliability block diagrams for the individual components of the lifting

mechanism refer to the following:

|

SK –

sheave block with a lifting hook L – rope VK –

balancing block LB – rope

drum including support fitting UB –

support drum fitting SB – drum

clutch |

CP – front

gearbox S – clutch HM – motor

shaft including support fitting BB –

safety brake PB –

auxiliary brake B –

operational brake |

A load drop event, i.e.,

lifting mechanism failure, does not occur if:

o

The

sheave block (SK) or the balancing block does not incur damage (VK)

o

One

of the two ropes is intact

o

The

rope drum, including its support fitting or the support fitting (UB), is intact

o

The

rope drum remains locked

The rope drum remains locked if the

safety brake (BB) is functional, or if the drum clutch (SB) and the gearbox

(CP) transmit the braking torque from the drive. Weibull distribution, in its

following analytical form, was used to describe the failure of the components

in the analysed lifting mechanisms:

![]() (13)

(13)

It is characterized by parameters a (scale parameter), b (shape parameter) and ![]() .

.

The specified distribution is

a suitable failure-free time or life model for machines or equipment that

are affected by fatigue damage. To calculate the probability of failure ![]() according to Weibull distribution,

it is necessary to know the values of its parameters. The parameters were

identified during life tests for the lifting mechanism shafts and their values

were derived from [25]:

according to Weibull distribution,

it is necessary to know the values of its parameters. The parameters were

identified during life tests for the lifting mechanism shafts and their values

were derived from [25]:

![]() = 1,905,802 (number of loading

cycles)

= 1,905,802 (number of loading

cycles)

a =

4,567,187 (number of loading cycles)

b = 0.725

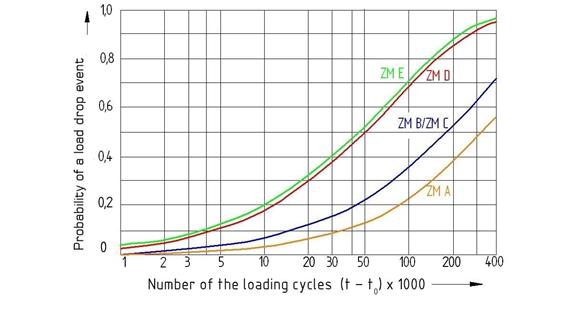

The F(t) function, which conveys the probability of failure, or

alternatively, the probability of a load drop event for each of the five

variants of lifting mechanisms (ZM A to ZM E), is shown in its dynamic

graphical representation in Figure 9.

The calculation and drawing of the

dynamic outcomes were acquired by using ASMBOOL, the software product

specifically designed for this purpose.

Fig. 9. Probability of

a load drop event for the individual variants of lifting mechanisms, i.e., ZM A

to ZM E

4. DISCUSSION

This article presents the findings of our

investigation into the reliability of technical systems (more specifically,

lifting mechanisms in bridge cranes) by calculating the probability of system

failure, i.e., the probability of a load drop event for five variant designs of

the analysed mechanisms.

Figure 9 illustrates three groups of dynamic

curves for the probability of a load drop event, namely, ZM E/D, ZM C/B and ZM

A, which differ in the gradient of the increasing values of probability.

The ZM A variant appears to best suit the

criteria of reliability and safety, since the probability of a load drop event

in this case developed at the slowest rate, and reached the lowest values for

all other outcomes. In the real world, this would be caused by the fact that

the ZM A mechanism features the most alternate safety components, i.e., brakes.

The dynamic outcomes for ZM B and ZM C overlap.

This conjunction can be explained by the fact that a safety brake reduces the

probability of a load drop event in both variants. The parallel configuration

of an auxiliary brake, coupled with a motor shaft and a clutch, in comparison

with the auxiliary brake, seems to have practically no effect on the

probability of a load drop event.

The difference between the ZM A variant and the

ZM B/C variants has ensued from using an extra rope and a support drum fitting

in the former.

The most dramatic increase in the probability

values of a load drop event is evident in the ZM D and ZM E variants. These

configurations are therefore the least desirable to use. The minor difference

between the two variants follows from using the safety brake feature in the ZM

D configuration.

Acknowledgements

This paper

was elaborated within the framework of the VEGA 1/0110/18 research and

development projects in the area of reverse engineering and rapid prototyping,

with a focus on the innovation of constructional parts designed for

experimental vehicles and transport equipment.

References

1. Ditlevsen O., H.O Madsen. 1996. Structural Reliability Methods. Chichester:

John Wiley & Sons Ltd. ISBN 0 471 96086 1.

2. Bigoš

Peter, Ján Pidany. 1987. Prevádzková

spoľahlivosť. [In Slovak: Operational

Reliability.] Bratislava: Alfa. ISBN 80-05-000-97-8.

3. Bukoveczky

Juraj.1982. Prevádzková spoľahlivosť

a životnosť stavebných strojov. [In Slovak: Operational Reliability and Durability of Building Machines.]

Bratislava: ES SVŠT, Alfa. ISBN 80-05-001-59-4.

4. Fosgerau Mogens, Anders Karlström. 2010.

“The value of reliability”. Transportation

Research Part B Methodological 44(1): 38-49. ISSN 0191-2615. DOI:

10.1016/j.trb.2009.05.002.

5. Heng Aiwina, Andy C.C. Tan, Joseph Mathew,

Neil Montgomery, Dragan Banjevic, Andrew K.S. Jardine. 2009. “Intelligent

condition-based prediction of machinery reliability”. Mechanical Systems and Signal Processing 3(5): 1600-1614. ISSN

0888-3270. DOI: 10.1016/j.ymssp.2008.12.006.

6. Pai Ping-Feng. 2006. “System reliability

forecasting by support vector machines with genetic algorithms”. Mathematical and Computer Modelling

43(3-4): 262-274. ISSN: 0895-7177. DOI: 10.1016/j.mcm.2005.02.008.

7. O’Conor Patrick P., Andre Kleyner. 2012. Practical Reliability

Engineering. New Delhi: John Wiley & Sons Ltd. ISBN

978-0-470-97982-2.

8. Fabian

Stanislav, Ľuboslav Straka. 2007. Teória

spoľahlivosti výrobkov a systémov v aplikačných príkladoch. [In

Slovak: Theory of Reliability of Products

and Systems in Application Examples.] Košice: FVT TU. ISBN

978-80-553-1670-4.

9. Starý

Ivan, Libor Obruča.1991. Teorie spolehlivosti.

[In Slovak: Theory of Reliability.]

Prague: ES ČVUT. ISBN 978-80-564-1677-5.

10. Atiq

Waliullah Siddiqui, Mohamed Ben-Daya. 2009. “Reliability centered maintenance”.

In M. Ben-Daya,

S.O. Duffuaa,

A. Raouf,

J. Knezevic, D. Ait-Kadi,

eds., Handbook of Maintenance Management and Engineering: 397-415. London: Springer. ISBN

978-1-84-882-471-3.

11. Smith David. 2005. Reliability, Maintainability

and Risk. Amsterdam: Elsevier. ISBN 9780750666947.

12. Herczner Peter, Alena Pauliková. 2011.

“Koncepcia hodnotenia strojárskych prevádzok”. [In Slovak: “Engineering concept

assessment”.] Strojárstvo 15, (11):

111-112, ISSN 1335-2938.

13. Pauliková Alena. 2007. “Dynamical systems with

parameters of working environment”. In Environmentálne

inžinierstvo a manažérstvo, 215-218. Košice: Faculty of Mechanical

Engineering TUKE. ISBN 978-8-080-73894-5.

14. Baran Peter, Robert Grega. 2015. “Comparison

of dynamic properties of dual mass flywheel.” Diagnostyka 16 (1): 29-33. ISSN 1641-6414

15. Grega, Robert, Jozef Krajňák, Lucia Žuľová,

Gabriel Fedorko, Vieroslav Molnár. 2017. “Failure analysis of driveshaft of

truck body caused by vibrations”. Engineering

Failure Analysis 79 (1): 208-215. ISSN: 1350-6307.

16. Cveticanin L. 1995. “Dynamic behaviour of the

lifting crane mechanism”. Mechanism and

Machine Theory 30 (1): 141-151. ISSN 0094-114X. DOI:

10.1016/0094-114X(94)00045-M.

17. Olearczyk J., A. Bouferguène, M.

Al-Hussein, U. Hermann. 2014. “Automating motion trajectory of crane-lifted

loads”. Automation in Construction

45: 178-186. ISSN: 0926-5805. DOI: 10.1016/j.autcon.2014.06.001.

18. Pan Yang, Chengji Liang, Lei Liu. 2011. “The

modeling of main hoist mechanism of quay container crane”. In Fourth International Conference on

Information Management, Innovation Management and Industrial Engineering

(ICIII): 377-381. Shenzhen, China. 26-27 November 2011. ISBN:

978-1-61284-450-3.

19. Wang Ai Hong, Ge Ning Xu , You Shan Gao, Ping

Yang. 2010. “Bridge crane load spectrum distribution good-of-fit testing”. Applied Mechanics and

Materials 20-23:

512-517. ISSN 1662-7482. DOI: 10.4028/www.scientific.net/AMM.20-23.512.

20. Wang Ai Hong, Ge Ning Xu , You Shan Gao. 2011.

“Bridge crane load distribution fitting and test”. Jixie Qiangdu/Journal of Mechanical Strength 33: 105-112. ISSN:

1001-9669.

21. Zhi-mei Chen, Meng Meng Wen-jun, Zhang Jing-Gang.

2012. “Intelligent anti-swing control for bridge crane”. Journal of Central South University 19 (10): 2774-2781. ISSN 2095-2899. DOI: 10.1007/s11771-012-1341-6.

22. Dietrich von Berg. 1989. Krane und Kranbahnen. [In German: Cranes and Crane Runways.] Stuttgart: B.G. Teubner. ISBN

978-3-322-96767-1.

23. Bigoš

Peter. 1987. Dynamická pevnosť a

životnosť. [In Slovak: Dynamical

Strength and Durability.] Bratislava: Alfa. ISBN 978-80-553-0623-7.

24. Bigoš Peter, Eva Faltinová.

2011. Spoľahlivosť technických systémov.

[In Slovak: Reliability of Technical

Systems.] Košice: Edícia vedeckej a odbornej literatúry, TU Košice. ISBN

978-80-553-0802-9.

25. Kitschke Erwin. 1983. Wahrscheinlichkeits Theoretische Methoden

zur Ermittlung der Zuverlässigkeits Kenngrossen von Mechanischer Systeme auf

der Grundlage der statistischen Beschreibung des Ausfallverhaltens von

Komponenten. [In German: Probability

Theoretical Methods for the Determination of the Reliability Characteristics of

Mechanical Systems on the Basis of the Statistical Description of the Failure

Behaviour of Components.] Bochum: RUHR-Universität. ISBN 978-80-334-0705-5.

26. Izrael Gregor, Ladislav Gulan. 2014. “Vplyv

pracovného zaťaženia na životnosť nakladača”. [In Slovak: “Effect of workload

on loader lifespan”.] Stavební technika 13:

24-26. ISSN: 1214-6188.

27. Izrael, Gregor, Juraj Bukoveczky, Ladislav

Gulan. 2011. “Influence of nonstandard loads onto life of chosen modules of

mobile working machines”. Machine Design

3: 13-16. ISSN: 1821-1259.

28. Gąska Damian, Tomasz Haniszewski, Jerzy

Margielewicz. 2017. “I-beam girders dimensioning with numerical modelling of

local stresses in wheel-supporting flanges”. Mechanika 23(3): 347-352. ISSN

1392-1207.

29. Gąska Damian, Czesław Pypno. 2011. “Strength

and elastic stability of cranes in aspect of new and old design standards”.

Mechanika 17(3): 226-231. ISSN 1392-1207.

30. Wittek Adam Marek, Damian Gąska, Bogusław

Łazarz, Tomasz Matyja. 2014. “Automotive stabilizer bar – stabilizer bar

strength calculations using FEM, ovalization of radial areas of tubular

stabilizer bars”. Mechanika 20(6): 535-542. ISSN 1392-1207.

31. Kosicka E.,

E. Kozlowski, D. Mazurkiewicz. 2015. „The use of stationary tests for analysis

of monitored residual pro cesses”. Eksploatacja

I Niezawodnosc-Maintenance And Reliability 17(4): 604-609. ISSN 1507-2711.

32. Mazurkiewicz D. 2014. „Computer-aided

maintenance and reliability management systems for conveyor belts”. Eksploatacja I Niezawodnosc-Maintenance And

Reliability 16(3): 377-382. ISSN 1507-2711.

Received 18.11.2017; accepted in revised form 25.02.2018

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License