Article

citation information:

Szczucka-Lasota, B., Węgrzyn,

T. Filler

materials for MAG welding with microjet cooling for truck frame repairs. Scientific Journal of Silesian University of

Technology. Series Transport. 2018, 101,

215-226. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.101.19.

Bożena

SZCZUCKA-LASOTA[1], Tomasz WĘGRZYN[2]

FILLER MATERIALS

FOR MAG WELDING WITH MICROJET COOLING FOR TRUCK FRAME REPAIRS

Summary. The goal of this paper is to

analyse the mechanical properties of the weld steel structure of car body truck

frames following MAG welding repairs using various filler materials. The main

role of welding conditions is connected with filler materials, welding

technology, stress state and temperature. In the paper, the properties of steel

structures after MAG welding with microjet cooling are presented. Weld metal

deposits (WMDs) were prepared by using various welding wires with different

chemical compositions. A WMD with various nickel content was examined using

three different welding wires; simultaneously, a WMD with varied oxygen content

was examined using different gas mixtures for microjet cooling. In this study,

the metallographic structure and impact toughness of welded joints were

analysed in terms of welding parameters. The amount of acicular ferrite (AF) in

WMDs, with various amounts of nickel and oxygen after welding, was tested. The

various steel deposits were checked with the variable content of manganese and

silicon, as well as nickel. Gas mixtures of argon and carbon dioxide were used

for microjet cooling.

Keywords: MAG welding; cooling system; welded

construction; trucks, transport

1. INTRODUCTION

There is an increasing need for

sheet steels with high-impact toughness for automotive applications, in order

to reduce the body-in-white (BIW) weight. BIW refers to the stage in automobile

manufacturing in

which a car body’s sheet metal components have been welded together. This

is the stage before painting and before moving parts (doors, hoods and deck

lids as well as fenders), the engine, chassis subassemblies or trims (glass,

seats, upholstery, electronics etc.) have been assembled in the frame

structure. For this reason, a large part of current sheet steel research is

focused on the development of high-strength steels, by combining toughness,

which is highly tensile, with good elongation and good impact, and innovative

welding technologies [1-4].

The choice of alloying elements is

highly important due to their influence on the microstructure and impact

toughness. The largest contribution of the steel composition relates to the

effect of alloying elements on the microstructure, which determines most of the

mechanical properties of the final product. The influence of the chemical

composition of steel WMDs on Charpy V impact properties has been carefully

analysed over the last 15 years [8-10]. The influence of the steel alloying

elements classifies them into two groups: carbide-forming elements and elements

that do not form carbides. Generally, non-carbide-forming elements are

simultaneously austenite stabilizers (i.e., they expand the austenite zone),

while carbide formers are simultaneously ferrite stabilizers (i.e., they reduce

the austenite zone). Mn and Co are treated as carbide formers, which are

simultaneously austenite stabilizers. Ni, Cu are non-carbide formers, which are

simultaneously austenite stabilizers. On the other hand, Mo, Cr, V, W, Ti, Nb

and Zr are treated as carbide formers, which are simultaneously ferrite

stabilizers. Si, P and Al are non-carbide formers, which are also ferrite

stabilizers. An important role with regard to the tensile properties of WMDs is

also played by oxygen and nitrogen. According to current opinion, there is an

optimum percentage of some elements offering an optimal metallographic

structure and properties with the highest impact [4,10].

Nitrogen, chromium and vanadium

increase the strength of the joint, while at the same time having a negative

effect on its tensile WMD properties. Silicon and manganese can be treated as

neutrally acting elements on plastic properties of joints. The dominant view is

that there is a significant influence on the impact toughness of steel welds in

the case of such elements as nickel and oxygen. An amount in the range of about

1-2% nickel and 200-500 ppm for oxygen in the WMDs allows us to obtain

high-impact toughness for the steel joint; but the reasons for such dependences

are not definitively explained [10]. Nickel as the main non-carbide former and

austenite stabilizer inhibits the formation of larger-size ferrite at the grain

boundary, which favours the formation of much more beneficial AF. The effect of

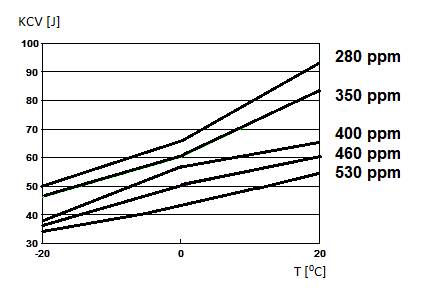

oxygen on good properties is most visible in the MMA welding process [4]; see

Figure 1.

On analysing Figure 1, it is easy to

deduce that the less oxygen there is in a WMD, the higher the impact toughness.

It can also be observed that second-class WMDs’ impact toughness (47 J at

-20°C) corresponds to a content of no more than 350

ppm of oxygen in the WMD. In other welding processes, these values

(optimal oxygen amount in a WMD) may be slightly different [4]. The oxygen

content in a WMD has an influence on the formation of inclusions that favour

the nucleation of AF. The special role of non-metallic inclusions, such as MnOAl2O3, TiO and TiN, on the AF formation

is strongly underlined [4,11].

Microjet cooling, immediately after

welding, offers a new opportunity to increase the amount of AF in the weld,

which consequently has an effect on the impact toughness of the weld [9-10].

Microjet cooling leads to significant ferrite grain disruption, which, in

connection with the optimal chemical composition, will give a perfect effect.

Microjet cooling can lead to a reduction in unfavourable MAC phases

(self-tempered martensite, retained austenite, carbide). Meanwhile, MAC phases

reduce the impact toughness of the weld and should not be higher than 5% in

WMDs [5,9].

Fig. 1. The influence of oxygen on the impact

toughness properties of the WMD [5]

2. EXPERIMENTAL PROCEDURE

The aim of the investigation presented below

was to observe the common effect of nickel and oxygen on some properties of the

MAG WMD, as well as assess the effect of nickel and oxygen on the mechanical

properties of deposited metals and welds made in gas shields, involving various

typical electrode welding wires used in automotive repairs (Table 1).

Table 1

The chemical compositions of various types of

electrode welding wires

|

Wire |

PN classification |

EN classification |

AWS classification |

Main chemical

composition |

|

A |

PN ISO 14341, 4Si1 |

EN ISO 14341, 4Si1 |

AWS A5.18, ER 70S-6 |

0.08% C; 0.6% Si; 1.3% Mn; 0.01% Ni |

|

B |

SPG1 |

EN 12536, OI |

AWS A 5.2, R45 |

0.08% C; 0.3% Si; 1.1% Mn; 0.1% Ni |

|

C |

PN-88/M-69420 SPG4N |

- |

- |

0.08% C; 0.3% Si; 1.1% Mn; 1% Ni |

The WMD was prepared by the MAG welding process

(shielding gas: Ar with 15% CO2) involving microjet cooling with

various gas mixtures of Ar and CO2. The main parameters of microjet

cooling were slightly varied:

–

Cooling

steam diameter was not varied (60 µm)

–

Gas

pressure was twice varied (0.5 and 0.6 MPa)

–

Microjet

gas mixtures were substituted (various gas mixtures of Ar and CO2)

The basic material being researched was

S355J2G3 steel (typical material for truck frames and car bodies). This typical

WMD had a rather similar chemical composition in all tested cases after MAG

welding using Wire A and staining various microjet cooling gas mixtures. The

parameters of the welding process in all tested cases (for Wires A, B and C)

are presented in Table 2.

Table 2

Parameters of the

welding process

|

Arc voltage |

28 V |

|

Current |

190 A |

|

Diameter of tested wires |

1.2 mm |

|

Shielding gas |

Ar with 15% CO2 |

|

Microjet gas pressure |

0.5 and 0.6 MPa |

|

Microjet diameter |

60 µm |

|

Microjet gas mixtures |

Ar Ar with 15% CO2 Ar with 30% CO2 |

In the main, welds produced via MAG

welding with microjet cooling with various microjet gas mixtures were tested

and compared. This typical WMD had various chemical compositions regarding

welding wire choice and microjet gas mixture (Tables 3-4).

Table 3

Chemical composition of the WMD

after MAG welding using Wire A

|

Element |

Amount |

|

C |

0.09% |

|

Mn |

1.37% |

|

Si |

0.52% |

|

P |

0.014% |

|

S |

0.017% |

|

O |

290-380 ppm |

|

N |

60 ppm |

|

Ni |

0.01% |

The use of microjet

cooling after MAG welding using Wire A noticeably affected the oxygen content

of the WMD (Table 4).

Table 4

Chemical composition of the WMD after MAG

welding using Wire A

|

Gas mixture in microjet cooling micro-k |

O amount, ppm |

|

Ar |

290 |

|

Ar with 15% CO2 |

330 |

|

Ar with 30% CO2 |

380 |

This typical WMD also

had a similar chemical composition in all tested cases after MAG welding using

Wire B and staining various microjet cooling gas mixtures (Table 5).

Table 5

Chemical composition of the WMD

after MAG welding using Wire B

|

Element |

Amount |

|

C |

0.09% |

|

Mn |

1.12% |

|

Si |

0.47% |

|

P |

0.012% |

|

S |

0.017% |

|

O |

280-370 ppm |

|

N |

60 ppm |

|

Ni |

0.1% Ni |

The chemical

composition of the tested deposits was similar (Tables 3 and 5). Both deposits

had low nickel content. The use of microjet cooling after MAG welding using

Wire B also clearly affected the oxygen content of the WMD (Table 6).

Table 6

Chemical composition of the WMD after MAG

welding using Wire A

|

Gas mixture in microjet cooling micro-k |

O amount, ppm |

|

Ar |

280 |

|

Ar with 15% CO2 |

330 |

|

Ar with 30% CO2 |

370 |

The typical WMD also

had a similar chemical composition in all tested cases after MAG welding using

Wire C and staining various microjet cooling gas mixtures (Table 7).

Table 7

Chemical composition of the WMD

after MAG welding using Wire C

|

Element |

Amount |

|

C |

0.07% |

|

Mn |

0.7% |

|

Si |

0.42% |

|

P |

0.019% |

|

S |

0.013% |

|

O |

300-390 ppm |

|

N |

60 ppm |

|

Ni |

1.04% |

The third

deposit’s (C’s) chemical composition differed from the other two

(A, B), mainly in nickel, whose content changed on a logarithmic scale (Wire A;

0.01% Ni; Wire B 0.1% Ni; Wire C 1% Ni). The use of microjet cooling after MAG

welding using Wire C also noticeably affected the oxygen content in the WMD

(Table 8).

Table 8

Chemical composition of the WMD after MAG

welding using Wire C

|

Gas mixture in microjet cooling micro-k |

O amount, ppm |

|

Ar |

300 |

|

Ar with 15% CO2 |

360 |

|

Ar with 30% CO2 |

390 |

The AF amount regarding the microjet

cooling parameters (gas mixture composition and gas pressure) was precisely

analysed. In all tested cases, MAC phases (self-tempered martensite, retained

austenite, carbide) were also observed. Examples of the results of the

metallographic structure analysis are shown in Tables 9-11.

Table 9

AF and MAC phases in the WMD after MAG welding

using Wire A regarding various microjet parameters

|

Wire (Table 1) |

Gas

mixture |

Microjet gas pressure [MPa] |

AF [%] |

MAC phases [%] |

|

A |

- |

- |

41 |

3 |

|

A |

Ar |

0.5 |

52 |

3 |

|

A |

Ar + 15% CO2 |

0.5 |

54 |

3 |

|

A |

Ar + 30% CO2 |

0.5 |

52 |

3 |

|

A |

Ar |

0.6 |

53 |

2 |

|

A |

Ar + 15% CO2 |

0.6 |

58 |

3 |

|

A |

Ar + 30% CO2 |

0.6 |

55 |

2 |

The WMD gained after welding with

microjet cooling did not guarantee a high content of ferrite AF, due to the

unfavourable chemical composition of Wire A (0.08% C; 0.6% Si; 1.3% Mn; 0.01%

Ni). Si as a ferrite stabilizer occurs with too much amount, while nickel, as

an austenite stabilizer, occurs only in a trace amount. Too high a content of

Si and Mn in WMDs creates larger non-metallic inclusions, which are not

beneficial to AF nucleation.

Table 10

AF and MAC phases in the WMD after MAG welding

using Wire A regarding various microjet parameters

|

Wire (Table 1) |

Gas

mixture |

Microjet gas pressure [MPa] |

AF [%] |

MAC phases [%] |

|

B |

- |

- |

45 |

3 |

|

B |

Ar |

0.5 |

57 |

3 |

|

B |

Ar + 15% CO2 |

0.5 |

61 |

2 |

|

B |

Ar + 30% CO2 |

0.5 |

53 |

3 |

|

B |

Ar |

0.6 |

63 |

2 |

|

B |

Ar + 15% CO2 |

0.6 |

68 |

2 |

|

B |

Ar + 30% CO2 |

0.6 |

62 |

2 |

The WMD gained after welding with

microjet cooling was able to guarantee a higher content of ferrite AF than in

the previous case, due to a more favourable chemical composition of Wire B

(0.08% C; 0.3% Si; 1.1% Mn; 0.1% Ni). Si as a ferrite stabilizer occurs at a

lower level, while nickel as an austenite stabilizer occurs at a higher level.

A lower content of Si and Mn in WMDs creates smaller non-metallic inclusions,

which are very conducive to the nucleation of AF.

Table 11

AF and MAC phases in the WMD after MAG welding

using Wire A regarding various microjet parameters

|

Wire (Table 1) |

Gas

mixture |

Microjet gas pressure [MPa] |

AF [%] |

MAC phases [%] |

|

C |

- |

- |

45 |

3 |

|

C |

Ar |

0.5 |

59 |

2 |

|

C |

Ar + 15% CO2 |

0.5 |

64 |

2 |

|

C |

Ar + 30% CO2 |

0.5 |

59 |

2 |

|

C |

Ar |

0.6 |

66 |

2 |

|

C |

Ar + 15% CO2 |

0.6 |

69 |

2 |

|

C |

Ar + 30% CO2 |

0.6 |

61 |

2 |

The presence of nickel in the weld

metal blocks the conversion of austenite into a coarse ferrite, which leads to

the granulation of the ferrite grain. On analysing Tables 9-11, it is possible

to deduce that MAG welding with microjet cooling could be treated as a strong

option in all tested cases, due to the elevation of the ferrite content. It is

also shown that microjet gas pressure after MAG welding, involving all tested

gas mixtures, should always be at the level of 0.6 MPa. AF with a percentage

above 60% was only achievable after microjet cooling in the case of Deposits B

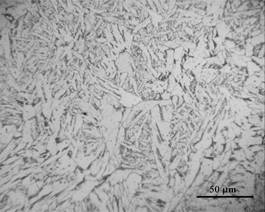

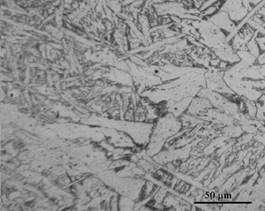

and C (Figure 2).

A WMD after

microjet cooling (65% AF) A WMD

without microjet cooling (45% AF)

Fig. 2. AF in various

deposits (45-65%)

In the last part of the research,

WMD impact strengths were tested at -20, 0 and 20°C and compared with the

values reported in the literature for the MMA process (Figure 1). Additionally,

it was decided to check the average size of non-metallic inclusions affecting

the nucleation of ferrite AF. Toughness was only tested in the case of

microjet-cooled deposits with a pressure of 0.6 MPa, because this parameter led

to a higher content of ferrite AF (Tables 12-14).

Table 12

Impact toughness for MAG welding

with varied microjet gases using Wire A

|

Microjet gas |

Temperature [°C] |

Impact toughness [KV, J] |

Rounded amount of non-metallic inclusions

sized 0.4-0.6 µm, % |

|

Without cooling |

- 20 |

below 47 |

15 |

|

Ar |

- 20 |

61 |

25 |

|

Ar + 15% CO2 |

- 20 |

63 |

35 |

|

Ar + 30% CO2 |

- 20 |

51 |

30 |

|

Without cooling |

0 |

54 |

15 |

|

Ar |

0 |

75 |

25 |

|

Ar + 15% CO2 |

0 |

81 |

35 |

|

Ar + 30% CO2 |

0 |

69 |

30 |

|

Without cooling |

+20 |

175 |

15 |

|

Ar |

+20 |

177 |

25 |

|

Ar + 15% CO2 |

+20 |

181 |

35 |

|

Ar + 30% CO2 |

+20 |

166 |

30 |

Microjet cooling clearly allows for

a second impact toughness class (i.e., a minimum value of 47 J at -20°C).

The highest content of smaller non-metallic inclusions corresponds to the

percentage of ferrite AF in a WMD. In addition to the positive cooling effect

of microjet cooling on the impact toughness of a WMD, the oxygen concentration in

the WMD plays an important role. The oxygen amount can be steered and precisely

controlled by the microjet process parameters.

Table 13

Impact toughness for MAG welding

with varied microjet gases using Wire B

|

Microjet gas |

Temperature [°C] |

Impact toughness [KV, J] |

Rounded amount of non-metallic inclusions

sized 0.4-0.6 µm, % |

|

Without cooling |

- 20 |

below 47 |

15 |

|

Ar |

- 20 |

67 |

25 |

|

Ar + 15% CO2 |

- 20 |

71 |

40 |

|

Ar + 30% CO2 |

- 20 |

58 |

35 |

|

Without cooling |

0 |

59 |

15 |

|

Ar |

0 |

77 |

25 |

|

Ar + 15% CO2 |

0 |

83 |

40 |

|

Ar + 30% CO2 |

0 |

77 |

35 |

|

Without cooling |

+20 |

176 |

15 |

|

Ar |

+20 |

179 |

25 |

|

Ar + 15% CO2 |

+20 |

185 |

40 |

|

Ar + 30% CO2 |

+20 |

168 |

35 |

Microjet cooling makes it even

easier to obtain a second impact toughness class (i.e., a minimum value of 47 J

at -20°C) in this case. An even higher content of small inclusions was

observed compared to the previous case (Wire A). A higher content of small

non-metallic inclusions corresponds directly to the respectively higher

percentage of ferrite AF within a WMD. Furthermore, in this case, the positive

cooling effect of microjet cooling on the impact toughness of a WMD with oxygen

concentration in the WMD was observed. This part of the investigation also

confirmed that the oxygen amount can be steered and precisely controlled by the

microjet process parameters.

Table 14

Impact toughness for MAG welding

with varied microjet gases using Wire A

|

Microjet gas |

Temperature [°C] |

Impact toughness [KV, J] |

Rounded amount of non-metallic inclusions

sized 0.4-0.6 µm, % |

|

Without cooling |

- 20 |

52 |

25 |

|

Ar |

- 20 |

71 |

40 |

|

Ar + 15% CO2 |

- 20 |

86 |

45 |

|

Ar + 30% CO2 |

- 20 |

73 |

40 |

|

Without cooling |

0 |

62 |

25 |

|

Ar |

0 |

74 |

40 |

|

Ar + 15% CO2 |

0 |

92 |

45 |

|

Ar + 30% CO2 |

0 |

75 |

40 |

|

Without cooling |

+20 |

171 |

25 |

|

Ar |

+20 |

172 |

40 |

|

Ar + 15% CO2 |

+20 |

175 |

45 |

|

Ar + 30% CO2 |

+20 |

169 |

40 |

Microjet cooling makes it even

easier to obtain a second impact toughness class (i.e., a minimum value of

47 J at -20°C) in this case. An even higher content of small inclusions was

observed, compared to the previous case (Wires A-B). The highest content of

small non-metallic inclusions (compared with A and B) corresponds directly to

the respective percentage of ferrite AF in the WMD. Furthermore, in this case,

the positive cooling effect of microjet cooling on the impact toughness of a

WMD with oxygen concentration in the WMD was observed. This part of the

investigation also confirmed that the oxygen amount can be steered and

precisely controlled by the microjet process parameters. A significant role for

nickel in terms of the plastic properties of the joint was noted. The WMD had a

second class of impact resistance, even without microjet cooling, while the

best results were obtained with the use of Wire C and microjet cooling in

comparison with the A and B deposits.

It is possible to

deduce that impact toughness in the case of a negative temperature for the WMD

is apparently affected by the type of microjet gas mixture in the cooling

injector. A gas mixture of Ar + 15% CO2 could be considered as

optimal.

3. CONCLUSIONS

The connection between processes such as MAG

welding and microjet cooling was tested with various filler materials. It was

noticed that the chemical composition of the wire and the chemical composition

of the gas mixture used for microjet cooling have an influence on WMD structure

and impact toughness. The preliminary

results validate the theoretical assumptions and indicate that it will be

possible to apply this technology in the automotive industry.

On the basis of the investigation, we

may deduce that:

–

microjet

cooling could be treated as an important element in the MAG welding process

–

microjet

cooling after welding could provide an amount of AF that is the most beneficial

phase in low-alloy steel WMDs

–

a

high amount of AF could guarantee, in relative terms, good impact toughness

properties

–

by

using microjet cooling after welding, it may be possible to steer the

metallographic structure (percentage of AF and MAC phases)

–

only

argon or helium should be used for microjet cooling after laser welding

–

a

gas mixture of Ar + 15% CO2 could be considered as optimal

References

1.

Hadryś D. 2016. “Mechanical Properties of Plug Welds After Micro-jet Cooling”.

Archives of Metallurgy and Materials 61:

1771-1775.

2.

Hadryś D. 2015. “Impact Load of Welds After Micro-jet

Cooling”. Archives of Metallurgy

and Materials 60(4): 2525-2528.

3.

Stanik Z. 2014. “Mechatronic Systems, Mechanics and

Materials”. Solid State Phenomena

210: 58-64.

4.

Evans G.M. 1994. “Microstructure and Properties of Ferritic Steel

Welds Containing Al and Ti”. Oerlikon-Schweissmitt

130: 21-39.

5.

Fornalczyk A., J. Willner, J. Cebulski, D. Pasek, M. Saternus, P. Czech.

2016. “Structure and Surface State of Different Catalytic Converters

Applied in Cars”. Fifth International

Lower Silesia-Saxony Conference “Advanced Metal Forming Processes in the

Automotive Industry (Autometform 2016)”: 327-333. 28-29 June 2016.

Wroclaw, Poland.

6.

Fornalczyk A., M. Saternus, J. Willner, M.

Fafiński, H. Kania, P. Czech. 2016. “The Results of Platinum Recovery from Metal Substrate

Catalytic Converters by Using Magneto-hydro-dynamic Pump”. 25th Anniversary International Conference on

Metallurgy and Materials “METAL 2016”: 1382-1387. 25-27 May

2016. Brno, Czech Republic. ISBN: 978-80-87294-67-3.

7.

Burdzik R., L. Konieczny, Z. Stanik, P. Folęga,

A. Smalcerz, A. Lisiecki. 2014. “Analysis of Impact of Chosen Parameters on the Wear of

Camshaft”. Archives of Metallurgy

and Materials 59(3): 957-963.

8.

Kasuya T., Y. Hashiba, S. Ohkita, M. Fuji. 2001. “Hydrogen

Distribution in Multipass Submerged Arc Weld Metals”. Science and Technology of Welding &

Joining 6(4): 261-266. DOI: 10.1179/136217101101538767.

9.

Lukaszkowicz K., L. Dobrzański, G. Kokot, P.

Ostachowski. 2012.

“Characterization and Properties of PVD Coatings Applied to Extrusion

Dies”. Vacuum 86: 2082-2088.

10.

Evans G.M. 1992. “The Effect of Micro-alloying Elements on the

Microstructure and Properties of Ferritic All-weld Metal Deposits”. IIW Doc II-A-855-92: 1-20.

11.

Mazurkiewicz D. 2010. “Tests of extendability

and strength of adhesive-sealed joints in the context of developing a computer

system for monitoring the condition of belt joints during conveyor operation”.

Eksploatacja i Niezawodnosc - Maintenance

and Reliability 3: 34-39.

12.

Krneta M., I. Samardžić, Ž. Ivandić,

D. Marić. 2018. “Joining materials by metalock repair method”.

Metalurgija 57(1-2): 142-144.

Received 14.07.2018; accepted in revised form 30.10.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License