Article

citation information:

Radziewicz, K. Garbala, K.,

Cegłowski, M. Homologation tests of single-stage R02 reducer. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 101, 149-157.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.101.14.

Katarzyna RADZIEWICZ[1], Krzysztof GARBALA2,

Michał CEGŁOWSKI3

HOMOLOGATION TESTS

OF SINGLE-STAGE R02 REDUCER

Summary. This article presents the results

of homologation tests of an LPG reducer. Due to the material requirements of

the LPG reducer in this case, the R02 reducer, designed by the joint-stock

company AC Spółka Akcyjna, is used. Test procedures, which must be

carried out, are also presented and generally explained with specified

conditions for conducting the processes. The advantages

of using the R02 are also presented. The properties of aluminium alloy 226, which is

the body of the reducer, are characterized and are divided into four groups:

technological features/qualitative indications, physical properties, mechanical

features and chemical composition. The whole article is

summarized with appropriate conclusions.

Keywords: LPG reducer; aluminium alloy 226; test

procedures; R02 reducer

1. INTRODUCTION

Rising oil prices and the

instability of oil supplies have directed the attention of vehicle

manufacturers and users towards substitute fuels. This term should be

understood as fuels other than the previously used classical options, e.g.,

petrol and diesel. The justifications for such actions arise from the following

premises [2,4,5,6,7,12]:

·

Economic

- searching for cheaper fuels and reducing car operations

·

Ecological

- searching for solutions in the field of environmental protection

The mentioned factors

contribute to the increased interest in fuelling cars with LPG gas. In accordance

with Polish law, certain rules are in force to ensure an adequate level of

safety in the use of cars, including those equipped with gas supply systems.

Strict requirements for the

use of an LPG reducer as a widespread product for everyday use match those set by the competent standardization

committee, but also provide the highest quality of service. Test procedures

help to determinate the utility of the equipment and also provide information

about safe usage. The texture of a reducer must also meet appropriate technical

requirements.

2. R02 REDUCER

The R02

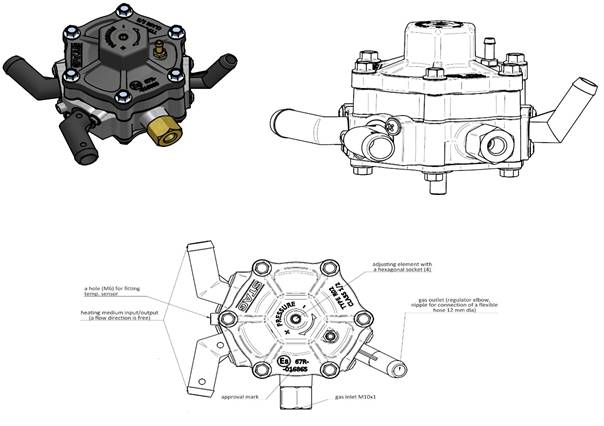

single-stage reducer (Figure 1) is designed by AC Spółka Akcyjna

for car sequential injection systems. The device is responsible for converting

the LPG state from its liquid phase into a gaseous one (vaporization), reducing

tension in the LPG vapour to the required value and keeping the pressure level

in the regulator output in a strictly determined range [13].

Figure 1

presents the LPG reducer in three ways: a three-dimensional model in colour, a

side view in black and white and the view from the top, also in black and

white.

It is

equipped with a thermal insulation system, a pressure stabilizing system and a

universal mounting system.

The technical data for the R02

(Table 1) emphasize the advantages of using it, which include:

- small dimensions

- excellent thermal efficiency

- resistance to LPG contamination

- stable feeding, independent of gas

cylinder inlet pressure

- low pressure drops at high loads

- stable adjustments

- elbow connector system

- mounting with a single, centrally located

bolt

Table 1

Technical data on the R02

|

Material |

Two aluminium castings and a cover

made of hard and resistant plastic material |

|

Weight |

Reducer - 850 g Complete kit – 1,156 g |

|

Dimensions [mm] |

125x122x89 |

|

Maximum inlet

pressure |

3 MPa |

|

Outlet pressure |

Adjustable, 0.9-1.5 bar |

|

Voltage electrovalve |

12 VDC |

|

Coil power |

11 W |

|

Electrovalve

connector |

Amp Superseal socket |

|

Gas inlet diameter

[mm] |

Ø 6.0 MI0x1 |

|

Gas outlet diameter

[mm] |

Ø12 |

|

Water connector

diameter [mm] |

Ø16 |

|

Maximum engine power |

100 kW/136 km |

|

Type approval number |

E8-67R-01 6865 |

|

Compensation pressure input [mm] |

Ø4 |

3. TEST PROCEDURES FOR THE LPG REDUCER

The LPG reducer, as an appliance in

everyday use, is susceptible to wear. To verify whether it is efficient, test

procedures are conducted according to standards established by the competent

standardization committee [8,9,10].

Test procedures are executed in the

two different parts of the reducer, which are referred to as

‘classes’:

- Class 1 - a part of the regulator being in

contact with the liquid LPG

- Class 2 - a part of the regulator

contained the vaporized LPG

Table 2 presents the actual test

procedures conducted at the lab, which apply both to Class 1 and Class 2.

Fig. 1. The R02 reducer

Table 2

Test procedures for the LPG reducer

|

|

Test

pressure/time (Class 1) |

Comments |

Test

pressure/time (Class 2) |

Comments |

|

Overpressure test under

hydraulic conditions |

6,750 kPa /min |

Rupture and permanent distortion are tested |

1,015 kPa /min |

Rupture and permanent distortion are tested |

|

External leakage test |

0 to 4,500 kPa/min |

- |

0 to 675 kPa /min |

- |

|

High temperature test |

4,500 kPa /min |

8 h of tempering |

675 kPa /min |

8 h of tempering |

|

Low temperature test |

4,500 kPa /min |

8 h of tempering |

675 kPa /min |

8 hours of tempering |

|

Endurance |

- |

- |

- |

- |

|

LPG compatibility

test for synthetic materials |

- |

Maximum change in volume and

change in mass, after air tempering, are

tested |

- |

Maximum change in volume and

change in mass, after air tempering, are tested |

|

Resistance to dry heat |

- |

Allowable change in tensile

strength and allowable change in ultimate elongation are tested |

- |

Allowable change in tensile

strength and allowable change in ultimate elongation are tested |

|

Ozone ageing |

- |

Cracking of test piece is tested |

- |

Cracking of test piece is tested |

|

Corrosion resistance |

- |

- |

- |

- |

|

Compatibility with heat exchange

fluid |

- |

Maximum change in volume, change

of mass after air tempering, allowable change in tensile strength and

allowable change in ultimate elongation are tested |

- |

Maximum change in volume, change

of mass after air tempering, allowable change in tensile strength and

allowable change in ultimate elongation are tested |

It is required that the leakage

cannot be greater than 15 cm3/h.

3.1. External leakage test

The

external leakage test is conducted at:

- Room temperature (+20°C)

- Low temperature (-20°C)

- High temperature (+120°C)

3.2. Endurance test

The endurance test (Table 3) is

conducted at a rate of six cycles/min. The total number of cycles during the

test is 50,000. The testing medium is air [1]. Subsequently, the external

leakage test is conducted after every endurance test.

Table 3

Endurance test parameters

|

|

Number of cycles |

Test pressure |

External leakage test pressure |

|

Room temperature

cycling - part 1 (+20°C) |

47,500 |

700 kPa |

0 to 700 kPa over 1 min |

|

Room temperature

cycling - part 2 (+20°C) |

500 |

From 700 kPa to 350 kPa |

0 to 700 kPa over 1 min |

|

High temperature

cycling - part 1 (+120°C) |

500 |

700 kPa |

0 to 700 kPa over 1 min |

|

High temperature

cycling - part 2 (+120°C) |

500 |

From 700 kPa to 350 kPa |

0 to 700 kPa over 1 min |

|

Low temperature

cycling - part 1 (-20°C) |

500 |

350 kPa |

0 to 350 kPa over 1 min |

|

Low temperature cycling - part 2 (-20°C) |

500 |

From 350 kPa to 175 kPa |

0 to 350 kPa over 1 min |

It is required that the leakage

cannot be greater than 15 cm3/h.

- The general external leakage test is

conducted again after the endurance test is finished.

3.3. LPG compatibility test for synthetic

materials

The following is required:

- Maximum change in volume of a sample: 20%

- The change in mass after air tempering

must be greater than -5%

3.4. Resistance to dry heat

The following is required:

- Allowable change in tensile strength

cannot be greater than 25%

- Allowable change in ultimate elongation

from -30% to +10%.

3.5. Corrosion resistance

One sample is tested according to

ISO 9227 over 144 h under salt spray. The second is tested according to ISO

6957 by immersion in ammonia for 24 h.

After the corrosion resistance test,

the previous tests are carried out again, namely:

- Overpressure hydrostatic test

- External leakage test

- High temperature test

- Low temperature test

3.6. Compatibility with heat exchange fluid

The following is required:

- Maximum change in volume of a sample: 20%

- Change in mass after air tempering must be

greater than -5%

- Allowable change in tensile strength

cannot be greater than 25%

- Allowable change in ultimate elongation:

from -30% to +10%

4. MATERIAL USED AS A REDUCER BODY: ALUMINIUM

ALLOY (DIN 226)

The material used as reducer body

must provide excellent thermal insulation and resistance to LPG contamination [3,11].

Table 4 presents the properties of

aluminium alloy 226, which are divided into four groups

(technological features/qualitative indications,

physical properties, mechanical features and chemical composition) as shown

below.

Table 4

Properties of aluminium alloy 226

|

Technological features/qualitative

indications |

Strength at elevated temperature (to

200°C) |

GOOD |

|

|

General resistance to corrosion |

LOW |

||

|

Machinability |

GOOD |

||

|

Castability |

GOOD |

||

|

Polishing |

MEDIUM |

||

|

Resistance to hot tearing |

GOOD |

||

|

Pressure tightness |

MEDIUM |

||

|

Weldability |

NOT RECOMMENDED |

||

|

Decorative anodizing |

INSUFFICIENT |

||

|

Shock resistance |

LOW |

||

|

Physical properties |

Density |

kg/dm3 |

2.76 |

|

Specific heat |

J/g*K |

0.88 |

|

|

Linear shrinkage at high pressure |

% |

0.4-0.6 |

|

|

Electric conductivity |

MS/m |

13-17 |

|

|

Modulus of elasticity |

kg/mm2 |

7,500 |

|

|

Thermal conductivity at 20°C |

W/m*K |

110-120 |

|

|

Linear thermal expansion from 20°C to

100°C |

1/K |

21x10-6 |

|

|

Suggested casting temperature in pressure die |

°C |

630-710 |

|

|

Mechanical features |

Tensile strength |

N/mm2 |

240-310 |

|

Yield strength |

N/mm2 |

140-240 |

|

|

Elongation |

% |

0.5-3 |

|

|

Brinell hardness |

HB |

80-120 |

|

|

Chemical composition |

Si |

% |

8.0-11.0 |

|

Fe |

Max. 1.0 |

||

|

Cu |

2.00-3.50 |

||

|

Mn |

0.10-0.5 |

||

|

Mg |

0.10-0.50 |

||

|

Cr |

Max. 0.10 |

||

|

Ni |

Max. 0.30 |

||

|

Zn |

Max. 1.20 |

||

|

Pb |

Max. 0.20 |

||

|

Sn |

Max. 0.10 |

||

|

Ti |

Max. 0.15 |

||

|

Individual impurities |

Max. 0.05 |

||

|

Global impurities |

Max. 0.25 |

||

5. CONCLUSIONS

Based on the analysis of

the test results, the following final conclusions can be formulated:

- The LPG reducer is

subject to high technical requirements.

- Elements of

the gas installation must be highly durable and safe.

- The reducer

should be resistant to large temperature fluctuations when operational.

- The reducer

retains its performance and strength properties in the temperature range

from -20 °C to + 120 °C.

- The

installation should be tight and the maximum leak should not exceed 15 cm3/h.

- The material

used for the production of the reducer body has natural anti-corrosion

properties.

- The aluminium

body provides excellent thermal insulation and resistance to LPG

contamination. Good thermal conductivity means that lower temperatures

have a positive effect on the internal parts of the reducer and provide

greater durability.

- The material used to

cast the reducer body was selected in such a way that the highest

endurance parameters were obtained at the lowest cost.

References

1.

Beal R.E. 1999.

“Methods and Equipment for Engine Coolant Testing”. Engine

Coolant Testing 4: 319-326. West Conshohocken, PA: ASTM International. ISBN

978-0-803-12610-7.

2.

Ćurčija D., I. Mamuzić, M. Buršak,

J. Kliber. 2012. “Effects of cross-roughness on cold rolling process with

greases”. Goriva i maziva

51(2): 135-147.

3.

GRAFEN. “EN

AC-46000 AC-ALSI9CU3(FE)”. Available at:

http://info.grafen.ippt.pan.pl/bazy/bazy-materialowe/aluminium/aluminium-i-jego-stopy/odlewnicze-stopy-aluminium/itemlist/category/431-en-ac-46000-ac-alsi9cu3-fe.html?limitstart=0.

4.

Jacyna M., J. Merkisz. 2014. “Proecological

approach to modelling traffic organization in national transport system”.

Archives of Transport 2(30): 43-56.

5.

Jacyna-Golda I., M. Wasiak, M. Izdebski, K. Lewczuk,

R. Jachimowski, D. Pyza. 2016. „The Evaluation of the Efficiency of

Supply Chain Configuration”. In: Proceedings

of the 20th International Scientific Conference “Transport Means 2016”.

P.: 953-957. Juodkrante, Lithuania, Oct 05-07, 2016. ISSN: 1822-296X.

6.

Luft S. 2007. Dwupaliwowy silnik o zapłonie samoczynnym z wtryskiem

ciekłego LPG do kolektora dolotowego. [In Polish: Dual-fuel,

Self-ignition Engine with Liquid LPG Injection for Intake Manifold.] Monograph No. 103. Printing Works of the Radom

Polytechnic. ISSN 1642-5278.

7.

Mikulski M., S. Wierzbicki, M. Smieja, J. Matijosius.

2015. „Effect of CNG in a fuel dose on the combustion process of a

compression-ignition engine”. Transport

30(2): 162-171.

8.

PN-EN

60068-2-11:2002. Badania środowiskowe - Część 2-11:

Próby. Próba Ka:

Mgła solna. [In Polish: PN-EN

60068-2-11:2002. Environmental Research - Part 2-11: Trial. Ka’s

Attempt: Salt Spray.] Warsaw: Polish Committee of Standardization.

9.

PN-EN

ISO 9227:2206. Badania korozyjne w sztucznych atmosferach. Badania w rozpylonej solance. [In Polish: PN-EN ISO 9227. Corrosion Tests in

Artificial Atmospheres. Research on Salt Spray.] Warsaw: Polish Committee

of Standardization.

10.

PN-ISO

6957:1997. Miedź i stopy miedzi - próba amoniakalna odporności

na korozję naprężeniową stopów miedzi. [In Polish:

PN-ISO 6957:1997. Copper Alloys - Ammonia Test for Stress Corrosion

Resistance.] Warsaw: Polish Committee of Standardization.

11.

RAFFMETAL.

“EN AB-46000”. Available at:

http://www.raffmetal.com/web_eng/prodotti.asp?q=1.

12.

Romaniszyn K.M. 2007. Alternatywne zasilanie samochodów

benzyną oraz gazami LPG i CNG. Badania

porównawcze dynamiki rozpędzania i emisji spalin. [In Polish: Alternative

Fuel Supply for Cars with Gasoline and LPG and CNG Gases. Comparative Studies

on Acceleration and Emission Dynamics.]

Warsaw: Scientific and Technical Publishers. ISBN 978-83-204-3308-1.

13.

Schwartz S.A.

1999. “Silicate Stabilization Studies in Propylene Glycol”. Engine

Coolant Testing 4: 327-351. West Conshohocken, PA: ASTM International. ISSN

0066-0558.

Received 22.07.2018; accepted in revised form 11.11.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License