Article

citation information:

Pil’a, J., Ojciec, M., Balcerzak,

T. Investigation

into the production flaws in thin solid carbon laminates by using the

ultrasonic phased array method. Scientific

Journal of Silesian University of Technology. Series Transport. 2018, 101, 141-148. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.101.13.

Jan PIL’A[1], Mateusz OJCIEC[2], Tomasz BALCERZAK[3]

INVESTIGATION INTO

THE PRODUCTION FLAWS IN THIN SOLID CARBON LAMINATES BY USING THE ULTRASONIC

PHASED ARRAY METHOD

Summary.

Composites

are used in a wide variety of markets, including the aerospace, architecture,

automotive and military sectors. Along with the increased use of composites,

multiple non-destructive testing (NDT) methods have been further developed specifically

for inspecting them. Among them, one can single out ultrasonic phased arrays.

Research described in this article focuses on the use of ultrasonic PAs for

production flaw investigations into an aileron. The examined part was made of

up to 16 layers of BAER 3068 epoxy carbon prepreg. The investigation was

carried out by using the tap test, conventional ultrasonic measurement and

phased array methods. The phased array method allowed us to thoroughly check

the affected specimen and confirm the presence of a production flaw in the form

of epoxy resin build-up. The results show how effective this method can be and

emphasize its advantages over traditional ultrasonic inspections.

Keywords:

carbon;

composites; CFRP; non-destructive testing; ultrasonic phased array

1.

INTRODUCTION

Composite

materials are made by combining two or more base materials with significantly

different properties, which, after being combined, have unique properties

different to those of base components. Despite being connected, when looking

closely at the composite structure, one can still see the different materials

as they do not blend or dissolve together. The new material may be preferred

for reasons such as higher strength, lighter weight or lower cost when compared

to traditional materials. Composites are used in a wide variety of markets,

including the aerospace, architecture, automotive, military and household goods

sectors. [1]. Along with the increased use of composites, multiple NDT methods

have been further developed specifically for examining them. These inspections

can range from the manufacturing process and continue with routine and

non-routine inspections throughout the components’ life [2]. Except for

visual checks, which are commonly used in all industries, many other methods

such as thermography, acoustic emission, eddy current and ultrasonic testing

have been investigated and used for inspecting composites. The selection of

investigation method can be dependent on multiple factors such as the physical

properties of the reviewed specimen (size, shape etc.) or the

manufacturer’s instructions (for example, NDT manuals in aviation, which

differ for each type of aircraft) [3-4]. Ultrasonic testing (UT) is

a well-established technique based on the vibration of materials. It can

be used for both composite and metal structures. The inspection of carbon fibre

reinforced polymer (CFRP) components with UT is subject to strict requirements

in terms of ensuring reliable and time efficient NDT. Examining composites

carries some major technical challenges such as the attenuation, scattering and

absorption of the signal and the shadowing effect of multiple damage can have

an influence on the received results. The majority of these difficulties can be

overcome by using phased array ultrasonic testing (PAUT), involving signal

processing and correction with advanced algorithms, such as the threshold

modified S-transform (TSMT), combined with multiple pulser-receiver elements

working together [5-7,12]. Research described in this article has been done in

order to determine whether visible irregularity in the composite skin structure

of an aileron is a production flaw or another kind of defect. In order to do

this, several methods have been used, as described in the following chapters.

2.

BASICS OF ULTRASONIC PHASED ARRAY NDT METHOD AND EQUIPMENT

Traditional

ultrasonic transducers used for non-destructive testing consist of a single

active element or a pair of elements. Meanwhile, an UT phased array transducer

consists of between 16 and 256 individual elements, which can be pulsed

separately from each other. These elements are coordinated by a complex

computer-based instrument, which is integrated into the array. This instrument

is capable of driving the multi-element probe, receiving echoes and converting

them into a digital format, as well as mapping the echoes in a variety of

formats [8].

Phased

array systems work, based on the wave physics law of phasing, which changes the

time between a range of outgoing ultrasonic pulses. This is done in such a

way that the separate wave fronts produced by elements in the array merge

together, in turn increasing or decreasing the total energy in a desired way,

which allows for the effective guidance of the sound beam. In order to realize

such a situation, each of the individual probe elements is pulsed at different

times. A focal law calculator calculates each group’s firing time delays

to achieve the desired beam shape. The beam shape is dependent on probe

characteristics as well as the geometry and acoustical properties of the

inspected element. The pulsing sequence is chosen by the instrument’s

operating software and introduces several wave fronts in the test material.

Once inside, the wave fronts merge together and pass via the material to reflect

off the back walls (back wall echo), as well as discontinuities, cracks and

other boundaries, such as delaminations [9]. Measurements can be presented in

A-scan, B-scan, C-scan and S-scan modes. The A-scan represents the

amplitude and time of an ultrasonic signal. Additionally, the A-scan waveform

denotes reflections from a single sound beam position in the tested

material. The S-scan denotes a two-dimensional (2D) cross-sectional

view obtained from a range of A-scans, which are mapped in accordance with the

refracted angle and time delay. B-scan imaging examines the material

with a sound beam moving along the preferred axis. A C-scan is a 2D presentation of data, which appears as a top view of a

test piece [5].

3.

DESCRIPTION OF EXPERIMENT

During

the redelivery process of an Airbus A319, one of the technical representatives

indicates his suspicion that two delaminated spots are present on the outboard

edge of an aileron. To prove that these are not delaminated areas but

production flaws, it is decided to probe them by using a tap test, conventional

ultrasonic measurement and the phased array method. These methods are selected

because they are approved by Airbus and the preferred methods for testing

composite structures in NDT manuals. In the thickest area, the inspected

component is made of 16 layers of epoxy prepreg carbon fabric (5H satin weave).

This type of prepreg contains 45% epoxy resin and, during manufacture, is cured

at 180°C. This material meets the requirements given in the BAER 3068 specification.

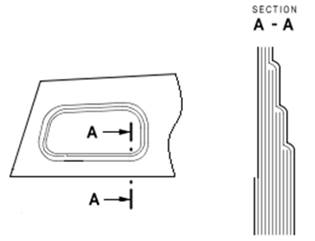

Figure 1 depicts the section of the aileron that was inspected. The closer to

the centre, the fewer the cloth layers present, thus the element thickness is

reduced.

Fig. 1.

Drawing of the aileron segment with a sectional view of carbon layers

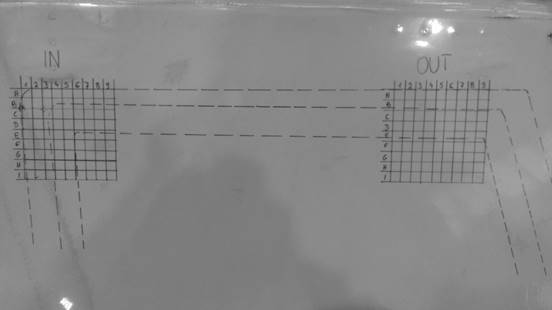

In order

to perform the examination, a plies layout is drawn on the aileron, along with

10x10 [mm] grid mapping over the areas where the production flaw is suspected.

The first phase of this investigation is done by the tap test method [10] using

a certified Airbus tap test tool. It is possible to notice a slight change in

sound during the test; however, it is not typical and, as a result, it is

insufficient proof to come to a conclusion. As such, further testing is

required.

Fig. 2.

Aileron segment with the drawn thickness change layout

and a grid over the suspected area

The

next step requires the use of the PAUT method. Olympus Omniscan SX is used

together with an Olympus RollerFORM-5L64-5 probe. In order to overcome the lack

of calibration block, the equipment is manually set to the speed of sound in

carbon (approximately 3,000 ![]() ) [11]. The

remaining settings, such as gain, frequency and range, are set according to

Chapter 51-10-06 of the Airbus

Non-Destructive Testing Manual for phased array inspections of carbon

monolithic components. The company where the experiment is performed does not

have a proper calibration block for CFRP testing. However, in the case of this

particular experiment, obtaining an exact thickness value is not of the highest

importance; thus, an approximate value is satisfying. Water is used as a

couplant. The alarm gate value is set at 1.5 and 3 mm. Arranging the gate

values in this way causes the received image to clearly indicate any possible

defects. Setting the gate values in a given manner is possible as it is not

necessary to satisfy any requirements regarding minimum material thickness. The

results of this investigation can be seen in Figures 3 and 4 below. After the

PAUT measurements are finished, UT measurement of the previously prepared grid

mapping is also been performed. The results of this measurement can be found in

Table 1. Equipment for this measurement is calibrated using the same NTM

chapter; however, the instructions are specific to the conventional UT of carbon

composite monolithic structures.

) [11]. The

remaining settings, such as gain, frequency and range, are set according to

Chapter 51-10-06 of the Airbus

Non-Destructive Testing Manual for phased array inspections of carbon

monolithic components. The company where the experiment is performed does not

have a proper calibration block for CFRP testing. However, in the case of this

particular experiment, obtaining an exact thickness value is not of the highest

importance; thus, an approximate value is satisfying. Water is used as a

couplant. The alarm gate value is set at 1.5 and 3 mm. Arranging the gate

values in this way causes the received image to clearly indicate any possible

defects. Setting the gate values in a given manner is possible as it is not

necessary to satisfy any requirements regarding minimum material thickness. The

results of this investigation can be seen in Figures 3 and 4 below. After the

PAUT measurements are finished, UT measurement of the previously prepared grid

mapping is also been performed. The results of this measurement can be found in

Table 1. Equipment for this measurement is calibrated using the same NTM

chapter; however, the instructions are specific to the conventional UT of carbon

composite monolithic structures.

4.

ANALYSIS OF RESULTS

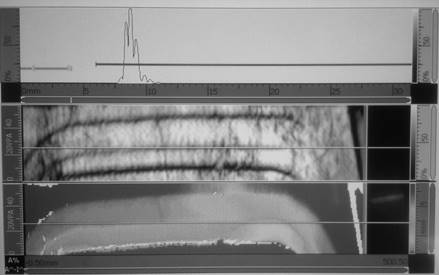

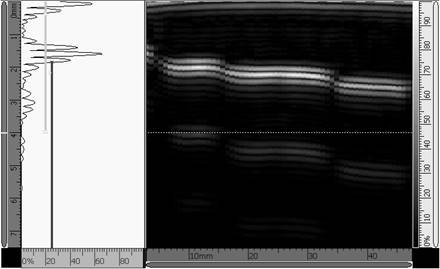

Figures

3 and 4 are screenshots taken directly from the Olympus scanner. Based on these

figures, as well as Table 1, it can be easily determined that no damage is

present at the inboard corner of the suspected area. There is no visible change

in material thickness, which would indicate delamination or other damage both

on the UT measurement and PAUT scans. In terms of the outboard edge, it can be

seen that there is an irregularity (slightly brighter colour on the C-scan

image in Figure 3). This irregularity has also been detected by traditional UT

measurement (cells E3-E6, F3-F5 and G3-G5, as seen in Table 1). It can be

noticed that thickness values within these cells are around 0.05-0.12 [mm]

lower than in the surrounding area. For further investigation purposes, it is

necessary to refer to the A-S-scan image (Figure 4). In this picture, one can

see that the composite layers are intact, as a good back wall echo has been

received on the entire scan length. In turn, it is possible to confirm that no

structural damage is present on the examined segment of the aileron. The final

question that needs to be answered concerns why there is a change in thickness

indicated on the outboard corner. In the middle C-scan image, as seen in Figure

3, one can notice a white area in the spot where we have observed a thickness

change. This means that there was a lower dampening of ultrasonic signal,

probably caused by a larger amount of resin. This accumulation of resin might

have occurred during the manufacture of the aileron as it was made of epoxy

prepreg material. Thus, it can be called a production flaw.

Fig. 3.

A-C-C-scan views of the inspected sample

Fig. 4.

A-S-scan images of the examined part of the aileron

In

order to have the opportunity to compare the results received through PAUT,

additional measurements were made with a traditional UT probe CLF-4 and Olympus

Panametric 35DL meter. The instrument has been calibrated as a given in the

aircraft’s NDT manual, with the speed of sound propagation in CFRP

structures manually selected. Again, as in the case of PAUT, measurement

reference standards were not available to check the calibration. However,

thickness values read during the measurement matched the ones obtained during

the phased array scan. This measurement was done using 10x10 [mm] grid mapping.

The results of this measurement are presented in the table below. This table

contains thickness values measured in the grid, as seen in Figure 2. These values

represent the depth at which the back-wall echo has been received. If the value

is lower than in the surrounding cells of the same material thickness, this can

be interpreted as a flaw or defect in the inspected component. Such dependence

can be seen in cells E3-E6, F3-F5 and G3-G5 of the outboard grid.

Table

1.

Results

of UT measurement involving 10x10mm grid mapping over areas of the suspected

production flaw

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

A |

2.54 |

2.51 |

2.56 |

2.55 |

2.54 |

2.56 |

2.53 |

2.53 |

2.54 |

|

B |

2.56 |

2.56 |

2.57 |

2.59 |

2.57 |

2.49 |

2.52 |

2.52 |

2.57 |

|

C |

2.56 |

2.57 |

2.57 |

2.48 |

2.41 |

2.29 |

2.29 |

2.29 |

2.27 |

|

D |

2.56 |

2.57 |

2.45 |

2.24 |

2.30 |

2.29 |

2.27 |

2.27 |

2.17 |

|

E |

2.57 |

2.40 |

2.27 |

2.30 |

2.23 |

1.98 |

2.03 |

2.03 |

1.95 |

|

F |

2.42 |

2.28 |

2.21 |

1.98 |

1.94 |

1.37 |

1.35 |

1.35 |

1.38 |

|

G |

2.30 |

2.21 |

1.94 |

1.62 |

1.17 |

1.23 |

1.18 |

1.18 |

1.34 |

|

H |

2.26 |

2.01 |

1.62 |

1.48 |

1.27 |

1.25 |

1.22 |

1.22 |

1.34 |

|

I |

2.10 |

1.91 |

1.52 |

1.47 |

1.42 |

1.50 |

1.39 |

1.39 |

1.42 |

|

|

|||||||||

|

OUTBD |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

A |

2.40 |

2.44 |

2.42 |

2.45 |

2.48 |

2.52 |

2.54 |

2.57 |

2.57 |

|

B |

2.61 |

2.41 |

2.40 |

2.42 |

2.48 |

2.50 |

2.56 |

2.52 |

2.58 |

|

C |

2.02 |

2.05 |

2.06 |

2.09 |

2.13 |

2.14 |

2.28 |

2.50 |

2.57 |

|

D |

2.06 |

2.01 |

2.02 |

2.01 |

2.06 |

2.16 |

2.22 |

2.25 |

2.54 |

|

E |

1.92 |

1.83 |

1.77 |

1.75 |

1.74 |

1.81 |

1.93 |

2.20 |

2.25 |

|

F |

1.43 |

1.39 |

1.31 |

1.27 |

1.33 |

1.88 |

1.96 |

2.01 |

2.28 |

|

G |

1.43 |

1.39 |

1.35 |

1.33 |

1.37 |

1.42 |

1.46 |

2.21 |

2.05 |

|

H |

1.42 |

1.41 |

1.42 |

1.42 |

1.43 |

1.47 |

1.50 |

1.53 |

2.17 |

|

I |

1.46 |

1.47 |

1.46 |

1.49 |

1.51 |

1.53 |

1.54 |

1.54 |

1.55 |

|

Note: all dimensions in [mm] |

|||||||||

5.

CONCLUSIONS

The

phased array method allowed us to thoroughly check the affected specimen and

confirm the presence of a production flaw in the form of epoxy resin build-up.

The major advantage of this method over traditional UT testing is that the

array covers a much larger area. The software facilitates grid mapping over the

scanned image and automatically fills it with measured thickness values. Thus,

this inspection is much quicker and easier to perform. Additionally, PAUT

equipment is capable of performing all four types of scans and saving the

images, which makes analysis of the results a lot easier. Additionally, it

is possible to transfer an entire scan file into a PC or a laptop and work with

it in the same way as on the scanner. The presentation of results is clearer

and does not require drawing grids on inspected components. By using a range of

colours, PAUT equipment makes it easier to spot irregularities compared to

tables with thickness values. In the case of this investigation, it is much

easier to spot the production flaw in the A-C-C-scan image (Figure 3) than to

find it based on material thickness values, as given in Table 1. It is possible

to view the measured thickness of any point within the scan range by manually

selecting the focus point. This is very useful when measurements are made in

close proximity to thickness steps, as was the case in this experiment. The

PAUT method produced the clearest indication of all the methods used to

investigate whether the defect was a production flaw.

The

PAUT method can be used in a variety of situations and on different materials

such as aluminium alloys, CFRP, GFRP and GLARE. Additionally, this method can

be used on both monolithic composites and honeycomb structures (depending on

their thickness). Most of the major aircraft manufacturers, such as Airbus or

Boeing, approve this method for aircraft maintenance. While the equipment and

training of personnel can be quite costly, this method is much more

time-efficient than traditional UT measurements and capable of lowering NDT man

hours required for aircraft maintenance. Phased array measurement, as described

in this article, took approximately 15 min, including the hardware set-up. The

ability to use water as a couplant makes the phased array method more universal

(as water is widely available) compared to conventional ultrasonic

measurements, which often require the use of gels or pastes for coupling

purposes.

Last,

but not least, PAUT examinations of composite structures are going to be used

more widely in the very near future, as new aircraft, such as the Boeing 787

and the Airbus A350, use many more composites compared to the previous

generation of airplanes. Indeed, both the Boeing 787 and the Airbus A350 have

bonded skin stiffeners and solid carbon laminate fuselages, which can be easily

inspected for possible damage by using this method.

References

1.

Kappatos

V. 2016. “Theoretical Assessment of Different Ultrasonic Configurations

for Delamination Defects Detection in Composite Components”. Proceedings of the Fifth

International Conference in Through-life Engineering Services: 29-34. Cranfield: Cranfield University.

2.

Armstrong K.B., R.T. Barrett. 1998. Care and Repair

of Advanced Composites. Warrendale, PA: Society of Automotive Engineers,

Inc.

3.

Hsu, D.K. “Nondestructive Evaluation of Damage

in Composite Structures”. Proceedings

of the 21st Technical Conference of the American Society for Composites:

1-14. Dearborn, MI.

4.

Buynak C.F., C.F.

Moran. 1987. “Characterization of Impact Damage in Composites”. Review of Progress in Quantitative NDE

6B: 1203-1211. New York, NY: Plenum Press.

5.

Holmes C., B.W. Drinkwater, P.D. Wilcox.

2008. “Advanced

Post-processing for Scanned Ultrasonic Arrays: Application to Defect Detection

and Classification in Non-destructive Evaluation”. Ultrasonics 48(6-7): 636-642.

6.

Senyurek V.Y., A. Baghalian, S. Tashakori.

2018. “Localization of Multiple Defects Using the Compact Phased Array

(CPA) Method”. Journal of Sound and

Vibration 413: 383-394.

7.

Abdessalem B., S. Redouane. 2015.

“Enhancement of Phased Array Ultrasonic Signal in Composite Materials

Using TMST Algorithm. Proceedings of the

2015 ICU International Congress on Ultrasonics. 70: 488-491. Metz, France.

8.

Chatillon S., G. Cattiaux, M. Serre. 2000.

“Ultrasonic Non-destructive Testing of Pieces of Complex Geometry with a

Flexible Phased Array”. Ultrasonics

38(1-8): 131-134.

9.

Kumar S., H. Furuhashi. 2018. “Characteristics of an

Ultrasonic Phased Array Transmitter in Medium Range”. Ultrasonics 82: 331-335.

10.

Hsu D.K., D.J. Barnard, J.J. Peters. 2000.

“Physical Basis for Tap Test as a Quantitative Imaging Tool for Composite

Structures on Aircraft”. Review of

Progress in Quantitative Nondestructive Evaluation 19: 1857-1864. Ames, IA.

11.

Jalili M.M., S.Y. Mousavi, A.S. Pirayeshfar. 2014. “Investigating

the Acoustical Properties of Carbon Fiber-, Glass Fiber-, and Hemp

Fiber-reinforced Polyester Composites”. Polymer Composites 35(12): 2103-2111.

12.

Rimkeviciene J., V. Ostasevicius, V. Jurenas,

R Gaidys. 2009. “Experiments and simulations of ultrasonically assisted

turning tool”. Mechanika 1:

42-46.

Received 16.07.2018; accepted in revised form 04.11.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License