Article

citation information:

Droździel, P., Popovych, P., Vitenko,

T., Shevchuk, O., Zolotyi, R., Kononchuk, O. Prediction of transport

vehicles’ durability with consideration of corrosive surface cracks

propagation in structural elements. Scientific

Journal of Silesian University of Technology. Series Transport. 2018, 101, 47-57. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.101.5.

Paweł DROŹDZIEL[1],

Pavlo POPOVYCH[2],

Tetiana VITENKO[3],

Oksana SHEVCHUK4, Roman ZOLOTYI5, Oleksandr KONONCHUK6

PREDICTION OF

TRANSPORT VEHICLES’ DURABILITY WITH CONSIDERATION OF CORROSIVE SURFACE

CRACKS PROPAGATION IN STRUCTURAL ELEMENTS

Summary. Support frameworks of transport

vehicles operate under varying terrain conditions under the influence of

extreme climate and corrosive environments. When transporting cargo, dust is

deposited on the surface of metal structures. The combination of dust and

moisture creates an aggressive environment resulting in intense corrosion

damage. The damage is caused by the defects of corrosion pitting, which occur

on the surface and transform into corrosion cracks. Based on energy approaches,

with the application of well-known results for the mathematical description of

electrochemical reactions and the principles of fragile fracture mechanics, an

analytical model of durability is proposed for the first time. The model

determines the residual life of maximum loaded elements of undercarriages with

surface cracks under the action of dynamic loads and corrosive environments.

For this case, a set of mathematical relations in the form of a non-linear

differential equation was developed, as well as the initial and final

conditions for determining the life of vehicles’ structural elements with

corrosive surface cracks. The analytical model implementation is proven by

solving the problem of determining the residual life of a vehicle’s

element, i.e., a steel plate, weakened by a semi-elliptical surface crack,

which is under the action of dynamic loads in a 3% sodium chloride solution.

The insignificant increase in the crack’s initial size is proven to

greatly reduce the period of its subcritical growth. The developed model was

applied to define the residual life of thin-walled elements of structures with

surface cracks.

Keywords: elements of structures with surface cracks; kinetic diagram of

corrosion-fatigue crack propagation; period of subcritical growth of

corrosion-fatigue cracks; durability of vehicle

1. INTRODUCTION

Transport vehicles operate under

varying terrain conditions involving extreme climate and corrosive

environments. For this reason, their main bearing elements are mainly made of

steel. In most vehicular structures, the base unit is a frame that contains up

to 40% of the steel intensity of the vehicle and significantly affects its

life, with the key factor affecting durability being the damage to the frame

caused by cracks and corrosion [1]. Factoring in the volumes of fertilizers

transportation (about 2% of all cargo in Ukraine [18]), it is rational to

account for the influence of aggressive environments acting upon metal

materials of vehicles. When transporting fertilizers, poisonous chemicals and

other aggressive agrarian products, the dust of these substances is deposited

on the structure surface. The combination of dust and moisture creates an

aggressive environment, which, together with the operating loads (usually

cyclic), leads to intense corrosion damage, in particular, by propagating

surface corrosion-fatigue cracks in elements of vehicular structures [1-8, 14-22].

The corrosion processes rate is known to be a function of the aggressiveness

and duration of the environment effect, the air temperature, the metal surface

state (composition and structure of the protective film), the chemical

composition of the metal, the presence of mechanical stresses, structural

features (welds, bolt and rivet joints), and the combination of elements

creating cavities or cracks, in which moisture condenses. Contamination of

vehicles’ metal structure surfaces intensifies corrosion, while, in

combination with moisture, it can create an electrochemical environment that

causes more intensive corrosion processes. Corrosion is the most dangerous

phenomenon for parts operating under cyclic loads (springs, body springs, axes,

shafts etc.), whose lifetime is often reduced by 40-60% because of fatigue

failure [1,8,12,15,21]. Based on part failure analyses, fracture initiation

occurs due to the ulcers caused by corrosion and pitting, with the ulcers

transferring into surface corrosion cracks, which adversely affect vehicle

reliability [1,12,13,15,21].

2. MATERIAL AND METHODS

A three-dimensional body is

considered as an element of the vehicle metal structure. A flat surface crack

with a contour of a length L and an initial area S0 weakens the

body, which is loaded cyclically with the amplitude forces p. There is a corrosive-aggressive environment in the crack cavity

(Figure 1). Outer tensile loads are applied so that the stress-strain state in

this body is symmetrical, relative to the placement of a crack plane.

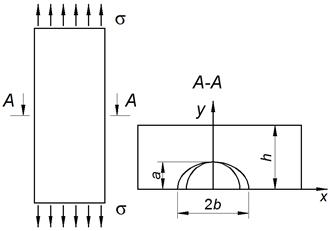

Fig. 1. Corrosion-fatigue cracks in

the vehicle frame, a classical body scheme of loading a body with a flat

surface crack

Hence, it is described in the

vicinity of its peak exclusively by the stress intensity factor of the first

kind ![]() . The task is to determine the

time or number of load cycles

. The task is to determine the

time or number of load cycles ![]() , in which the body, as an

element of the vehicle metal structure, will fracture.

, in which the body, as an

element of the vehicle metal structure, will fracture.

To solve this problem, a

mathematical model is developed: differential equations with initial and finite

conditions that describe this process. The assumption that the crack increases

continuously from the original area S = S0

to the final one S = S* is

correct, since it is well known that the real development of the

corrosion-fatigue crack is accompanied by jumps in the value ![]() in relatively large time intervals

in relatively large time intervals ![]() (

(![]() , where

, where ![]() is the number of load cycles

during an elementary jump of the crack and T

is the cycle period). Thus, the dependence for determining the growth rate of

the crack will be written approximately.

is the number of load cycles

during an elementary jump of the crack and T

is the cycle period). Thus, the dependence for determining the growth rate of

the crack will be written approximately.

![]() (1)

(1)

Similar to [8-11], the energy

balance equation for this non-equilibrium process is:

![]() (2)

(2)

where Q =

const is the value of thermal energy, A is the work of external forces, and

W is the energy of body deformation after the propagation of the crack

area by the value ![]() , written according to [8-11].

, written according to [8-11].

![]() (3)

(3)

where: ![]() is the elastic component W;

is the elastic component W; ![]() is a part of the work of plastic

deformations in the prefracture area, which depends exclusively on the area of

the crack l;

is a part of the work of plastic

deformations in the prefracture area, which depends exclusively on the area of

the crack l; ![]() is a part of the work of plastic

deformations caused by external forces, which is allocated at a constant crack

area during the incubation period of its jump preparation and depends only on

time t;

is a part of the work of plastic

deformations caused by external forces, which is allocated at a constant crack

area during the incubation period of its jump preparation and depends only on

time t; ![]() is the work of plastic deformations

during body unloading and compression of the prefracture area, which depends

exclusively on and generates by the body itself; Γ is the energy of body destruction, which depends on the

crack area, characteristics of the environment and t; Q is the released

thermal energy during body destruction, which is considered a relatively small

value and neglected in calculations; and K

is the kinetic energy, which in

this case is also considered a small value.

is the work of plastic deformations

during body unloading and compression of the prefracture area, which depends

exclusively on and generates by the body itself; Γ is the energy of body destruction, which depends on the

crack area, characteristics of the environment and t; Q is the released

thermal energy during body destruction, which is considered a relatively small

value and neglected in calculations; and K

is the kinetic energy, which in

this case is also considered a small value.

Considering the above and

differentiating the components of the energy balance equation (2) by the number

of load cycles N, an equation for the

velocities balance of the energy components change is deduced:

![]() (4)

(4)

The components of the dependence for

determining the energy of deformation are complex functions in S and N [9-10], while the area also implicitly depends on N. Thus, while substituting 3 for 4, the

following formula is developed:

![]() (5)

(5)

Based on (5), the rate value of the

crack area changes during its propagation:

![]() (6)

(6)

Based on [10, 11], (6) is written

thus:

![]() (7)

(7)

To complete this mathematical model,

in analogy with [10-11], respectively, the initial and final conditions are

added to 7:

![]() (8)

(8)

![]()

where the critical value of the crack area ![]() and

and ![]() are determined [10-11].

are determined [10-11].

![]() (9)

(9)

Thus, the kinetic equation (7) with

the conditions (8-10) is a mathematical model for the study of subcritical

growth in the corrosion-fatigue crack in the elements of vehicles’

structures on symmetrical loading.

The realization of the mathematical

problem (7-10) for specific cases is associated with significant mathematical

difficulties. Therefore, the problem solution is simplified in analogy with

[11]. Consequently, a half-space with a plane surface crack, into which the

corrosive environment enters, is stretched cyclically at endlessly distant

points, which are uniformly distributed by the amplitude σ and directed perpendicular to the plane of the crack

placement. According to the results [11-12], the growth rate V of the crack under consideration in

its straightforward propagation is related to the parameters of the

stress-strain state in the prefracture area by the ratios:

![]()

(10)

(10)

Similar to the [11-12], the case, in

which destruction occurs under the action of cyclic loads and a

corrosive-aggressive environment in one plane of a three-dimensional body, is

considered. Since the crack propagates along the normal to its periphery, the

movement in the time period ![]() of the arbitrary point M of the crack periphery runs towards

the normal (Figure 2).

of the arbitrary point M of the crack periphery runs towards

the normal (Figure 2).

![]()

Hence, the growth in the radius

vector ![]() of the polar system

of the polar system ![]() (Figure 2) is written thus:

(Figure 2) is written thus:

Fig. 2. Scheme for the local growth

of a flat corrosion-fatigue crack [11]

![]() (11)

(11)

where ![]() is the angle between the direction of the

radius vector

is the angle between the direction of the

radius vector ![]() and the normal to the crack periphery MM’. Based on the analysis of

geometric construction, in Figure 2, we get [11-12]:

and the normal to the crack periphery MM’. Based on the analysis of

geometric construction, in Figure 2, we get [11-12]:

(12)

(12)

Substituting 14 for 13 and moving to

the boundary at![]() , the velocity is:

, the velocity is:

(13)

(13)

In addition, based on 11 and 15, to

find an unknown function ![]() , the differential equation is

deduced:

, the differential equation is

deduced:

(14)

(14)

At initial and final terms:

(15)

(15)

In this case, Relations 16-17 define

the problem for determining the kinetics of propagation and the period ![]() of

subcritical growth in the surface crack under study (residual life) in the

metal structure element of the vehicle. To determine

of

subcritical growth in the surface crack under study (residual life) in the

metal structure element of the vehicle. To determine ![]() , the condition (Irwin’s

criterion [4]) is added:

, the condition (Irwin’s

criterion [4]) is added:

![]() (16)

(16)

To realize the mathematical model

(16-18), the following approximate approach [12-13] is proposed, according to

which the change in the area of a moving crack of the considered configuration

is approximately the same as for a semicircular crack of a radius ![]() of

a plane initial area. The rate of periphery propagation of such a crack is

defined by the constant in all its points for the maximum value

of

a plane initial area. The rate of periphery propagation of such a crack is

defined by the constant in all its points for the maximum value ![]() . Therefore, an error in the

resulting residual life

. Therefore, an error in the

resulting residual life![]() occurs in increasing the value

of the durability reserve, that is, 16 is simplified to:

occurs in increasing the value

of the durability reserve, that is, 16 is simplified to:

(17)

(17)

At initial and final terms:

(18)

(18)

where ![]() for a half-space with a surface

semicircular crack under tension is determined based on [13]:

for a half-space with a surface

semicircular crack under tension is determined based on [13]:

![]() (19)

(19)

By substituting 21 for 19 and

integrating it under the relevant conditions (20), to determine the period ![]() of subcritical growth in the

corrosion-fatigue crack of the initial area

of subcritical growth in the

corrosion-fatigue crack of the initial area ![]() in the half-space, the following

dependence is developed:

in the half-space, the following

dependence is developed:

(20)

(20)

where ![]()

3. RESULTS

To study

the implementation of the proposed model, the case associated with the case of

individual soils [14] is considered: the development of a surface corrosion

crack in a vehicle’s metal structure element made of steel (17G1C), in a

corrosive environment (3% solution of sodium chloride). The load frequency is

assumed to be 1 Hz, which is included in the asymmetry of the cycle ![]() with the loading amplitude

with the loading amplitude ![]() . The critical size of the crack in

this case is

. The critical size of the crack in

this case is ![]() , and the kinetic diagram of the

corrosion-fatigue crack growth is described by the ratio [10-11]:

, and the kinetic diagram of the

corrosion-fatigue crack growth is described by the ratio [10-11]:

(21)

(21)

Substituting the given data in 22 and integrating the sub-integral

integer numerically, the value![]() is derived

is derived

![]() cycles (22)

cycles (22)

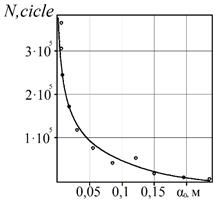

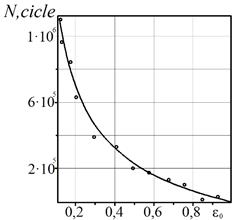

Based on the above (Figure 3), a dependency

graph of the period of subcritical growth in the corrosion-fatigue cracks on

the size of the crack ![]() is developed. Consequently, as

seen in Figure 3, the reduction of the crack size dramatically increases the

period of subcritical growth of the crack

is developed. Consequently, as

seen in Figure 3, the reduction of the crack size dramatically increases the

period of subcritical growth of the crack ![]() .

.

The residual life of the vehicle’s metal

structure element concerns a plate with a surface semi-elliptic crack. Let us

consider the steel plate 17G1C, with the thickness ![]() weakened by a surface

semi-elliptic crack, and a0

and bo (bo>ao) as the semi-axes, in which a 3% solution of sodium

chloride falls (Figure 4) [14]. It is assumed that the plate is stretched at

infinitely distant points perpendicular to the plane of crack propagation by

evenly distributed cyclic forces of the amplitude with a 1-Hz frequency and cycle

asymmetry

weakened by a surface

semi-elliptic crack, and a0

and bo (bo>ao) as the semi-axes, in which a 3% solution of sodium

chloride falls (Figure 4) [14]. It is assumed that the plate is stretched at

infinitely distant points perpendicular to the plane of crack propagation by

evenly distributed cyclic forces of the amplitude with a 1-Hz frequency and cycle

asymmetry![]() . The task is to determine the number of load cycles

. The task is to determine the number of load cycles ![]() , in which the corrosion-fatigue crack periphery will become tangent to its

opposite surface. Therefore, the kinetic diagram of the corrosion-fatigue crack

propagation in the plate material is described by analytic dependence (23).

, in which the corrosion-fatigue crack periphery will become tangent to its

opposite surface. Therefore, the kinetic diagram of the corrosion-fatigue crack

propagation in the plate material is described by analytic dependence (23).

Fig. 3. Dependence of

residual life ![]() on the initial size of a surface crack

on the initial size of a surface crack ![]()

Fig. 4.

Corrosion-fatigue crack of the vehicle’s carrier [23] and the scheme of

loading the plate with a surface semi-elliptic crack [15]

The solution is performed by

the method of equivalent areas [12-13]. According to this method, the change in

area, due to the corrosion-fatigue crack propagation of the considered

configuration, will be approximated as for a semicircular crack with a radius ![]() of

the same initial area. The propagation velocity of its periphery points is

assumed to be approximately the same. The crack periphery in a plate restricts

an area, which is equal to a semi-elliptical real crack, on account of a

semicircular radius

of

the same initial area. The propagation velocity of its periphery points is

assumed to be approximately the same. The crack periphery in a plate restricts

an area, which is equal to a semi-elliptical real crack, on account of a

semicircular radius ![]() .

Therefore, to replace this problem with a model, the maximum value of the SIF

along this chosen circular is [13]:

.

Therefore, to replace this problem with a model, the maximum value of the SIF

along this chosen circular is [13]:

![]() (23)

(23)

Substituting 25 for 23 in order to

determine the period ![]() , the following equation is deduced:

, the following equation is deduced:

(24)

(24)

At initial and final terms:

![]() ,

, ![]() ;

; ![]() ,

, ![]() .

.

To determine ![]() , (26)

integrates within the given initial and final conditions. As a result:

, (26)

integrates within the given initial and final conditions. As a result:

(25)

(25)

Numerical analysis of the expression

is performed at ![]() 0.04 m,

0.04 m, ![]() 70MPa. As a result, 27 is written as:

70MPa. As a result, 27 is written as:

(26)

(26)

Based on

28, the dependency graph of the residual life of the plate with a surface

corrosion-fatigue crack in the initial size ![]() (Figure 5) is developed.

Therefore, a small increase in the initial size

(Figure 5) is developed.

Therefore, a small increase in the initial size ![]() significantly reduces the period

of the surface corrosion-fatigue crack growth

significantly reduces the period

of the surface corrosion-fatigue crack growth![]() in the vehicle’s metal

structure.

in the vehicle’s metal

structure.

Fig. 5. Dependence of the period on ![]() of a surface corrosion-fatigue crack

growth in the initial size

of a surface corrosion-fatigue crack

growth in the initial size ![]()

4. CONCLUSIONS

For the case of the action of

variable loads in aggressive environments on vehicles’ structures with

corrosive surface cracks, a mathematical model is developed: the non-linear

differential equation in partial derivatives and the initial and final terms

for calculating the period of subcritical growth of corrosion-fatigue cracks in

these elements of vehicles. The effective method for an approximate solution of

this analytic problem is substantiated. The implementation of the mathematical

model is demonstrated using the example of calculating the durability of the

vehicle’s element as the residual life of a plate made of 17G1S steel,

which is weakened by a surface semi-elliptic crack under the action of cyclic

loads in a solution of sodium chloride. A slight increase in the initial sizes

of corrosive surface cracks is found to significantly reduce the durability of

vehicles’ structural elements.

References

1.

Severnyi А.Ye. 1993. Stability and corrosion protection of agricultural machinery.

Moscow: State Research and

Technological Institute.

2.

Pohmurskyi V.I., М.S. Khoma. 2008. Corrosive fatigue of metals and alloys. Lviv: Spolom.

3.

Romaniv О.N., S.Ya. Yarema, G.N. Nikiforchyn, N.А. Makhutov,

М.М. Stadnyk. 1990. Fatigue and cyclic crack resistance of structural materials. Kiev: Naukova

Dumka.

4.

Cherepanov G.P. 1974. Mechanics of brittle failure. Moscow:

Nauka.

5.

Dmytrah І.М., V.V. Panasiuk. 1999. Influence of corrosive media on local

destruction of metals near stress concentrators. Liviv: PMI NASU.

6.

Korneyenko S.V., О.М. Korbutiak. 2008. „Resources

of underground geological space of Ukraine”. Geology 43: 51-53.

7.

Korneyenko

S., О.M. Korbutiak. 2009.

„Problems of the influence of soil environment on corrosion of main gas

pipelines of Ukraine”. Geology

46: 42-43.

8.

Maltseva G. N. 2000. Corrosion and protection of equipment against corrosion. Penza.

9.

Andreykiv O.Ye., М.V. Кіt. 2006. Determination

of residual durability of thin-walled elements of structures at two-axis loads. Physical-Chemical Mechanics of Materials

1: 11-16.

10.

Andreykiv O.Ye., М.V.

Кіt. 2006. „Determination

of the period of subcritical growth of cracks in the elements of structures at

their two-frequency loads”. Machine Science 2: 3-9.

11.

Andreykiv O.Ye., N.B. Sas. 2008. “The

subcritical growth of a flat crack in a three-dimensional body at high

temperature creep”. Physical-Chemical Mechanics of Materials

2: 19-26.

12.

Andreykiv O.Ye., А.I. Darchuk. 1992. Fatigue failure and durability of structures.

Kiev: Naukova Dumka.

13.

Directory

of stress intensity coefficients. 1990. Mir: Murakami.

14.

Tsyrulnyk O.T., D.Yu. Petryna, M.I. Hredil. 2006.

“The fracture peculiarities of trunk pipeline steels after their long

term service”. Proceedings of the

international conference on Crack paths (CP 2006). Paper No 61. Parma,

Italy, 14th-16th September 2006.

15.

Shchurin К.V. 1994. Forecasting and increasing the fatigue life of the bearing systems of

agricultural tractor means. Dissertation of Doctor of Science

(Engineering). Orenburg.

16.

Figlus T. 2015. The

application of a continuous wavelet transform for diagnosing damage to the

timing chain tensioner in a motorcycle engine. Journal

of Vibroengineering17(3):

1286-1294. ISSN: 1392-8716.

17.

Koziol M., T. Figlus. 2017. Evaluation of

the failure progress in the static bending of GFRP laminates reinforced with a

classic plain-woven fabric and a 3d fabric, by means of the vibrations analysis.

Polymer Composites 38(6): 1070-1085.

DOI: 10.1002/pc.23670.

18.

Ukrayina u tsyfrakh. Statystychnyy

zbirnyk. Vidpovidal'nyy za vypusk O.A. Vyshnevs'ka. Za redaktsiyeyu: I.Ye. 2017.

Vernera. Kyyiv: Derzhavna sluzhba statystyky Ukrayiny. [In Ukrainian: Ukraine on numbers. Static zbirnik.

Edited by I.E. Werner. Kiyiv:

State Statistics Service].

19.

Kosicka

E., E. Kozłowski, D. Mazurkiewicz. 2015. „The use of stationary

tests for analysis of monitored residual processes”. Eksploatacja i Niezawodnosc – Maintenance and Reliability

17(4): 604-609. DOI: http://dx.doi.org/10.17531/ein.2015.4.17.

20.

Maruschak

Pavlo, Sergey Panin, Ilya Vlasov, Olegas Prentkovskis, Iryna Danyliuk. 2015.

„Structural levels of the nucleation and growth of fatigue crack in

17Mn1Si steel pipeline after long-term service”. Transport 30(1): 15-23.

21.

Maruschak

P., Poberezhny L., Pyrig T. 2013. “Fatigue and

brittle fracture of carbon steel of gas and oil pipelines”. Transport 28(3): 270-275.

22.

Figlus Tomasz, Marcin Stańczyk. 2014. “Diagnosis of the wear

of gears in the gearbox using the wavelet packet transform”. Metalurgija

53(4): 673-676. ISSN: 0543-5846.

Received 19.07.2018; accepted in revised form 11.10.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License