Article

citation information:

Brumercik, F., Lukac, M., Majchrak,

M., Krzysiak, Z., Krzywonos, L. Teeth geometry and contact pressure calculation of

external cycloidal gears. Scientific

Journal of Silesian University of Technology. Series Transport. 2018, 101, 27-35. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.101.3.

Frantisek

BRUMERCIK[1], Michal LUKAC[2], Maros MAJCHRAK[3], Zbigniew KRZYSIAK[4], Leszek KRZYWONOS[5]

TEETH GEOMETRY AND

CONTACT PRESSURE CALCULATION OF EXTERNAL CYCLOIDAL GEARS

Summary.

Cycloidal (also called epicyclical or convex-concave) gears are used less often

than common involute gears, which are very easy to manufacture and can be

modified by corrections to the gear profile. Cycloidal gears are very sensitive

to the proper axial distance between the pinion and the gear. The main

advantage of convex-concave gears is the lowering of the contact pressure due

to teeth flanks meshing and also the lowering of the slide ratios compared to

involute gears. The calculation of the selected geometrical parameters and the

contact pressure between the teeth flanks of the cycloidal gearing is described

in the presented article.

Keywords: gear; cycloidal; convex-concave;

geometry; contact pressure

1. INTRODUCTION

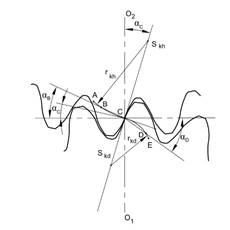

The mathematical model of convex-concave

gearing is the basis of the geometry model calculation and as described in

detail in [1]. The determination of the geometric parameters in the

gear’s teeth flanks is based on the equations evaluated from the shape of

the path of contact. The general path of contact starting at point A and ending

at point E for this type of gearing is presented in Figure 1.

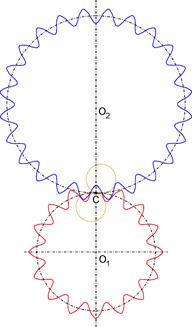

Fig.

1. Path of contact of convex-concave gearing

The arcs of the path of contact are

circular arcs defined by their radii rkh for the upper one and rkd

for the lower one. The centres of the arcs Skh and Skd,

which lie on the common link passing through the contact inflection point C,

are defined by the coordinates xSkh, ySkh and xSkd,

ySkd in the coordinate system with the origin located in contact

point C.

Points A and

E are limiting points of the teeth gear mesh. Their position can also be

projected onto the teeth flanks’ cycloidal curves in both meshing gears,

which limits the working area of the teeth flanks [2, 3].

2. GEOMETRY OF THE

TEETH FLANKS

The

cycloidal teeth can generally be understood as any teeth whose tooth flank

forms a curve with a convex and a concave part. Such teeth are present when the

contact path is a so-called S-curve, as defined above [4]. Deriving the form of

the correctly mating profiles of a cycloidal gearing can be done using basic

knowledge of differential geometry and the direct application of the

fundamental law of gearing [5]. The main goal of this method is to determine

the relation between the

pressure angle at various points of the path of contact α and the angle of the gear

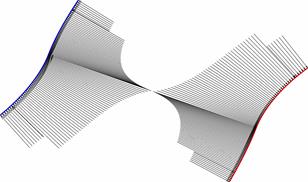

rotation between pressure angles of two arbitrary points φr (α) (Figure 2).

Fig.

2. Relation between the angles α

and φr:

1)

path of contact; 2) tooth flank profile; 3) tooth flank profile evolute

The relation is defined by Equation 1:

, (1)

, (1)

where:

α -

the pressure angle at various points of the path of contact

φr (α) - the angle of

the gear rotation between pressure angles of two arbitrary points

and the signs are

defined as positive for the upper part and negative for the lower part of the

path of contact.

The parametric

equations of the gear tooth flank profiles, obtained by the coordinates’

transformation of the path of contact’s compound of two circular arcs,

are defined by the Equation 1.

![]() , (2)

, (2)

![]() . (3)

. (3)

The x and y coordinates are defined for the coordination system with the

origin aligned to the point of rotation of the pinion O1 and the

gear O2. The upper signs in the equations stand for the upper part

of the path of contact (indexed with h) and the lower signs in the equations

stand for the lower part of the path of contact (indexed with d).

The division of the

contact path into an upper and a lower part requires the division of all geometric

and other cycloidal gear pair parameters into analogous parts, which will be

defined according to the corresponding parts of the contact path curve [6].

It is suitable to

derive Equations 2 and 3 into a form that defines the addendum (indexed with a)

and the dedendum (indexed with f) of the gear teeth separately.

2.1. Pinion

The

coordinates of the pinion 1 addendum flank curve are based on the upper part of

the contact path arc dimension, according to the following equations:

![]() , (4)

, (4)

![]() . (5)

. (5)

The coordinates of the pinion 1 dedendum flank curve

is based on the lower part of the contact path arc dimension, according to the

following equations:

![]() , (6)

, (6)

![]() . (7)

. (7)

2.2. External gear

The tooth flank profile coordinates of the external

gear 2 can be derived from the equations defined for the pinion 1 considering

the gear ratio between them, which is defined as:

![]() . (8)

. (8)

The coordinates of the external gear addendum flank

curve are based on the lower part of the contact path arc dimension, according

to the following equations:

![]() , (9)

, (9)

![]() . (10)

. (10)

The coordinates of the external gear dedendum flank

curve is based on the upper part of the contact path arc dimension, according

to the following equations:

![]() , (11)

, (11)

![]() . (12)

. (12)

3. SINGLE MESH POINTS

The coordinates of the single mesh

points B and D are obtained by solving Equation 1, while considering the angle turns φrAD and φrEB

to be equal to the angle defined by the pinion tooth pitch [1].

![]() , (13)

, (13)

![]() . (14)

. (14)

The pressure angles αB and αD in the single mesh points B and D are

calculated using the following transcendental equations:

, (15)

, (15)

. (16)

. (16)

The single mesh points are important for the

definition of the normal force value, which is divided between two pairs of

meshing teeth at the path of contact curves AB and CD (Figure 1).

4. CONTACT PRESSURES

The contact pressure

calculation is based on Hertz contact theory [3,7], which is also defined for

the upper as well as the lower parts of the path of contact by the following

equations:

![]() , (17)

, (17)

![]() . (18)

. (18)

The normal forces at

the contact points A to C (F1h)

and at C to E (F1d) are

calculated at the pinion 1, loaded by the input torque Mk1, as follows:

![]() (19)

(19)

![]() (20)

(20)

The reduced Young’s modulus of the

pinion and gear material is a part of the material coefficient ZE, which is calculated by

Equation 8 [9].

, (21)

, (21)

where:

μ1, 2 - Poisson’s

ratios of the contact pair materials,

E1, 2 - Young’s moduli

of the contact pair materials.

The

reduced radius of curvature ρred

is calculated according to these equations:

![]() , (22)

, (22)

![]() . (23)

. (23)

The

radii of curvature of the pinion 1 addendum (a) and dedendum (f) are defined

as:

![]() , (24)

, (24)

![]() . (25)

. (25)

The

radii of curvature of the gear 2 addendum and dedendum are defined as:

![]() , (26)

, (26)

![]() . (27)

. (27)

5. CALCULATION OF SELECTED GEAR PAIR VALUES

The selected

gear pair with the module m = 4 mm

and the teeth number z1 =

16 and z2 = 24 will

represent the application of all derived equations into a model of cycloidal

gear pair geometry and the distribution of contact pressure by meshing of the

gear teeth.

The geometry

is influenced by the module m, the

number of teeth z, the radii of the

contact path arcs rkh and rkd, and the pressure angle

at the point C αC. The

convex-concave condition is satisfied, if there is a valid inequation [1].

![]() . (28)

. (28)

The radii of

the contact path arcs in the symmetric arrangement within the selected gear

pair were defined as rkh =

rkd = 8 mm and the

pressure angle in the point C as αC

= 20°, which satisfies the inequation (28). The geometry of the selected

gear pair is presented in Figure 3.

The contact

pressure between the pinion and the gear at the tooth flanks is calculated by

the unit values of the torque Mk1,

the speed w1 and the gear

tooth flank width l, all of which are

defined as being equal to 1. The gears are considered from steel with

Poisson’s ratios μ1

= μ2 = 0.3 and

Young’s moduli E1 = E2 = 210000 MPa. The Hertz

pressure distribution, as projected onto the pinion and gear teeth flanks, is

presented in (Figure 4).

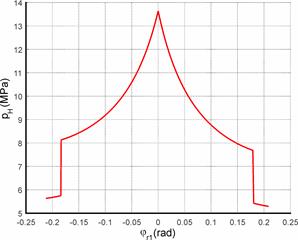

The contact

Hertz pressure pH between the pinion and

the gear, up to the angle of the pinion rotation between the pressure angles of

two arbitrary points φr1 (α), is shown in Figure 5.

Fig.

3. Geometrical model of the gear pair with cycloidal teeth flanks

Fig.

4. Hertz pressure distribution projected onto the gear (left) and pinion

(right) teeth flanks

Fig.

5. Hertz’s pressure pH

up to angle φr1

6. CONCLUSION

The article

presents a possible approach for modelling cycloidal gear teeth flanks based on

the path of contact curves. The calculation of the maximum contact pressure at

various points of the gear pair teeth flanks is also defined. The calculation

of a selected gear pair is performed by the unit values of the torque, speed

and tooth flank width. The obtained model is fully parametric and allows us to

calculate the Hertz pressures for various combinations of the characteristic

gear pair values, such as the module, the teeth numbers, the pressure angle in

the contact point C and the radii of the path of contact curve. The change in

the characteristic gear pair values enables us to pursue further research on

their influence on Hertz pressure values [9,10,12].

Acknowledgement

The research

is supported by the Cultural and Educational Grant Agency of the Ministry of

Education, Science, Research and Sport of the Slovak Republic under Project No.

046ŽU-4/2018.

References

1.

Veres Miroslav,

Miroslav Bosansky, Jan Gadus. 2006. Theory

of convex-concave and plane cylindrical gearing. Bratislava: Slovak

university of technology. ISBN 80-250227-2451-3.

2.

Puškár

M., M. Fabian, T. Tomko. 2018. „Application of multidimensional

statistical model for evaluation of measured data obtained from testing of the

HCCI engine prototype”. Diagnostyka

19(1): 19-24. DOI: http://dx.doi.org/10.29354/diag/78349.

3.

Sarkan B., O. Stopka, Ch. Li. 2017. “The issues of measuring the

exterior and interior noise of road vehicles”. Komunikacie 2: 50-55.

4.

Glowacz Adam, Zygfryd Glowacz. 2017. „Diagnosis of the three-phase

induction motor using thermal imaging”. Infrared physics & technology 81: 7-16. ISSN 1350-4495. DOI:

https://doi.org/10.1016/j.infrared.2016.12.003.

5.

Glowacz Adam, Zygfryd Glowacz. 2017.

„Diagnosis of stator faults of the single-phase induction motor using

acoustic signals”. Applied Acoustic

117A: 20-27. ISSN 0003-682X. DOI: https://doi.org/10.1016/j.apacoust.2016.10.012.

6.

Figlus Tomasz, Mateusz

Koziol. 2016. „Diagnosis of

early-stage damage to polymer - glass fibre composites using non-contact

measurement of vibration signals”. Journal of Mechanical Science and Technology 30(8): 3567:3576. ISSN 1738-494X. DOI: 10.1007/s12206-016-0717-1.

7.

Skrucany Tomas, Branislav Sarkan, Tomasz Figlus, et al.

2017. „Measuring of noise emitted by moving

vehicles”. MATEC

Web of Conferences 107: 00072. ISBN:

978-1-5108-4114-7. DOI: https://doi.org/10.1051/matecconf/201710700072

8.

Kohar Robert,

Slavomir Hrcek. 2014. „Dynamic Analysis of a Rolling Bearing Cage with

Respect to the Elastic Properties of the Cage for the Axial and Radial Load

Cases”. Communications –

Scientific Letters of the University of Zilina 16 (3A): 74-81. ISSN

1335-4205.

9.

Faturik Lukas, Libor Trsko, Slavomir Hrcek,

Otakar Bokuvka. 2014. „Comparison

of structural design in high and ultra-high cycle fatigue regions”. Transactions of FAMENA 38 (4): 1-12.

ISSN 1333-1124.

10.

Nieoczym

Aleksander. 2005. „Application of a transportation flux for determining

qualitative indices”. Communications

– Scientific Letters of the University of Zilina 7(1): 47-48. ISSN

1333-1124.

11.

Figlus Tomasz,

Marcin Stańczyk. 2016. “A method for detecting damage to rolling

bearings in toothed gears of processing lines”. Metalurgija 55(1): 75-78. ISSN: 0543-5846.

12.

Chepil R., V.

Vira, Y. Kharchenko, V. Kulyk, Z. Duriagina. 2018. The peculiarities of fatigue

process zone formation of structural materials. Diagnostyka 19(4): 27-32. DOI: 10.29354/diag/94754.

Received 05.09.2018; accepted in revised form 20.11.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License