Article

citation information:

Oeljeklaus, M., Pešík,

L. Control system for slow running bearings. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 100, 157-164.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.100.13.

Michael OELJEKLAUS [1],

Lubomír PEŠÍK [2]

CONTROL SYSTEM FOR

SLOW RUNNING BEARINGS

Summary. The subject of this

paper is the design of a control system for slow running bearings including a

strength analysis and load capacity measurement. The intention here is to apply

the results to the manufacturing operation of chain conveyors in paint shops.

Keywords: slow running bearing;

diagnostics of bearing; vibrodiagnostics; paint shop.

1. INTRODUCTION

The design of a control system for slow running bearings is highly

desirable across a wide range of industrial sectors. Especially for transport,

technologies are necessary to identify damaged bearings before production

failure and large economic losses occur.

Chain conveyors are used in the bodywork painting process, with chain

wheels mounted on the shaft, which is in turn mounted on two roller bearings.

Shaft speed is relatively slow in terms of rpm. There is no doubt that the

reliability of this construction has a major influence on the volume of production,

especially since the paint shop is the bottleneck of the whole production

process of cars.

The diagnostics of high-speed bearings are based on vibration

measurement, which has been reliably used for many years. For the diagnostics

of slow running bearings, there is no appropriate physical method able to

identify the bearing damage.

2. USED METHODS

The design of a control system for slow running roller bearings is based

on the analysis of the current state. The basis is to determine a load under

all manufacturing conditions and the force of the chain in the most exposed

position. With knowledge of the manufacturing operation force of the chain, it

is possible to calculate the load of shaft and roller bearings. The results may

be used for FEM analysis, calculation stresses and deformations in each part of

the current state as the basis of a design solution.

The design solution for a system of diagnostics for slow running roller

bearings can be based on the principle of rolling resistance or vibration

measurement. However, effective vibration detection depends on a sufficient

level of measured acceleration, which cannot be achieved in slow rotational

movements. This means, for the current state, dismounting the chain and then

measuring the rolling resistance, or increasing the rpm by external power and

measuring the vibration.

Pursuant to the demand for reliable chain conveyors and mounting for

shafts and chain wheels, we designed a system consisting of two pairs of roller

bearings: shaft and frame. These are connected to each other by the so-called

reference part, which is a freely rotatable part. This solution allows us to

identify the bearing damage with the two methods. The first method is dependent

on changes in rolling resistance during the forced rotation of reference part.

The other method uses vibration measurement by increasing the rpm with properly

connected external power. This innovative solution is protected by patent.

A kinematic link between the shaft and reference part allows for the distribution

of the dynamic load between the shaft and frame bearings, which is convenient

for manufacturing operational matters. Based on this kinematic link, the shaft

and reference part are in forced rotation. Due to the kinematic link of the

shaft, reference part and frame, the design solution leads to the integration

of a planetary mechanism with spur or bevel cogwheels. This solution is

protected by patent as well.

After the strength analysis of the designed solution, the prototype was

made with the intention to experimentally measure deformation using the nominal

and maximum load value. The fatigue test has already been prepared.

2. DESCRIPTION OF CURRENT STATE

The current state of the shaft mounting of the conveyor chain wheel is

made up of two spherical roller bearings mounted to the frame by bearing units.

The chain wheel is connected to the free end of the shaft and separated by the

frame’s front plate, which is connected to the frame of the paint shop

production line.

Fig. 1. Current state of

the shaft mounting of the chain wheel

The

advantage of the current shaft mounting of the conveyor chain wheel is its

relative simplicity. Significant disadvantage is complicated by the dismounting

and changing of the bearings. As a result, the bearings are subjected to

vibrodiagnostics using the latest technologies. Low-frequency vibration sensors

are used for the identification of damaged bearings. The difficulty relates to

the insufficient intensity in the vibrations of slow running bearings, whose value

merges with the vibrational background of the paint shop production line. The

reliability of the identification of damaged bearings is insufficient.

3. DESIGN SOLUTION FOR

THE DIAGNOSTIC SYSTEM

The reliable design of a control system for slow running bearings can be

based on the identification of changes in the rolling resistance of the

bearings or their vibrations in the case of sufficient rpm. Both these methods

are difficult to be realized during the manufacturing operation. A change in

rolling resistance can only be identified with increased power load, which is

usually too late. The sufficient rpm value of the bearing can only occur if the

standard, low-speed operation is off.

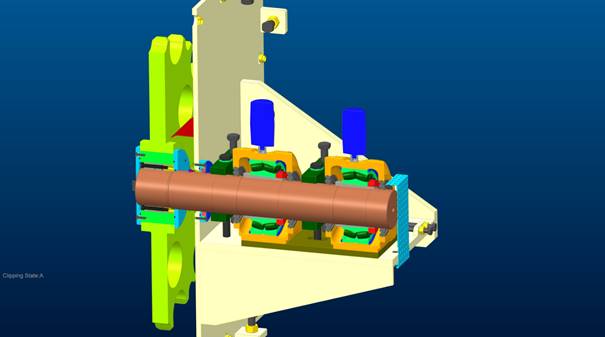

The design solution for a control system for slow running bearings, which

is the topic of this paper, comes from the idea that, if one ring of the roller

bearing is forced into a low speed, the second ring of the roller bearing is

freely rotatable. This diagnostic solution allows for the identification in the

change in the rolling resistance of the shaft bearing or a sufficient rpm

increase in its freely rotatable ring, which enables the damage to the bearings

to be determined using known vibrodiagnostics methods. The freely rotatable

ring of the shaft bearing is rotatably mounted to the frame using the frame

bearing. The reference part is mounted between the shaft and the frame bearing

(Figure 2).

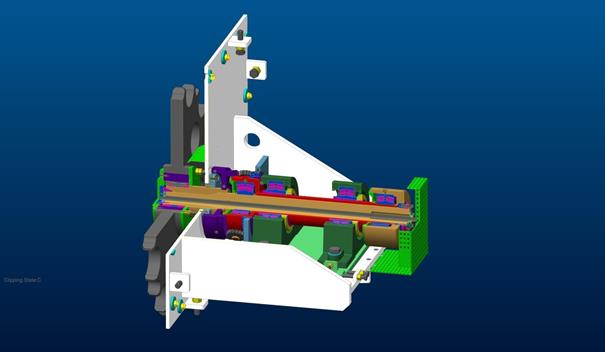

Fig. 2.

Drafted solution of the chain wheel shaft mounting

Changing the bearings is quite a difficult operation and, because of

that, the shaft is divided between the chain wheel and the bearing. This design

allows us to repair or change the bearing outside of the paint shop production

line.

This solution provides a number of design variants, one of which is

chosen as optimal and analysed.

4. STRENGTH ANALYSIS

Strength analysis is an important element of every design solution.

Fig. 3.

Equivalent stress (von Mises test) of the designed solution

With this shaft mounting solution, strength analysis is mainly focused

on stress and deformation calculations. In all cases, Ansys software for FEM

analysis was used.

Fig. 4.

Deformation in the z-axis direction of the designed solution

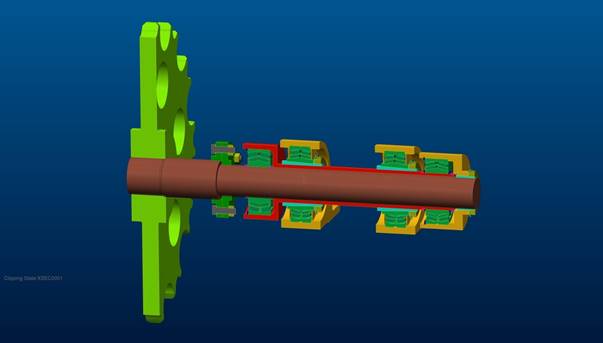

5. DAMAGE IDENTIFICATION SYSTEM

The identification of the damaged shaft or frame bearing can be made

based on the change in rolling resistance. For this purpose, the kinematic and

moment link in the shaft, reference part and frame, consisting of a planetary

gear with simple planets and bevel cogwheels, was designed. The shaft cogwheel

with the main axis of rotation is tightly connected to the shaft. The frame

cogwheel with the main axis of rotation is connected to the frame by an

adjustable frictional moment. The link between these cogwheels is made by

satellites mounted on the pins of the reference part.

The motion of the reference part is determined by a kinematic and moment

link of the planetary gear. If the rolling resistance of the shaft bearing

increases beyond the load capacity limit, the frictional moment between the

frame cogwheel and frame is exceeded. The frame cogwheel then starts to rotate

in the same shaft direction.

If the rolling resistance of the frame bearing increases beyond the load

capacity limit, the frictional moment between the frame cogwheel and the frame

is exceeded. The frame cogwheel then starts to rotate in the countershaft

direction.

Both rotations of the frame cogwheel against the frame can be easily

identified by a connected sensor (Figure 5).

Fig. 5.

Designed solution of shaft mounting of chain wheel

5. CONCLUSION

The paper is focused on the actual issue of the diagnostics of slow

running roller bearings. The designed solution uses a reference part between

the shaft and the frame bearing. A change in rolling resistance, which leads to

bearing damage, can be identified using the reference part. This can be

realized during the manufacturing operation. The designed diagnostic system

consists of a planetary gear with bevel cogwheels. Considering this is an

original solution, two patent applications have been filed, one of which has

been granted.

References

1.

Altschuller G.S. 1984. Erfinden.

Wege zur Lösung technischer Probleme. [In German: Inventing. Ways to Solve Technical Problems.] Berlin: Verlag

Technik.

2.

Bachman W. 1992. Signalanalyse. [From

German: Signal Analysis.]

Braunschweig/Wiesbaden: Vieweg Publishing Company.

3.

Bearing Damage. Damage Detection and Inspection off Used Rolling

Bearings. Schaeffler Technologies AG & Co. KG, 2013.

4.

Broch J.T. 1984. Mechanicel

Vibration and Shock Measurements. Nærum: Brüel&Kjær.

5.

Czech Piotr, Jerzy Mikulski. 2014.

“Application of Bayes Classifier and Entropy of Vibration Signals to

Diagnose Damage of Head Gasket in Internal Combustion Engine of a Car”.

In Telematics - Support for Transport. Book

Series: Communications in Computer and

Information Science 471: 225-232. Springer-Verlag Berlin Heidelberg ISSN:

1865-0929. ISBN: 978-3-662-45316-2.

6.

Dresig Hans. 2006. Schwingungen

mechanischer Antriebsysteme. [In German: Vibrations of Mechanical Drive Systems.] Berlin: Springer. ISBN-13

978-3-540-26024-0.

7.

Figlus Tomasz, Jozef Gnap, Tomas Skrucany, Branislav Sarkan, Jozef

Stoklosa. 2016. “The use of denoising and analysis of the acoustic signal

entropy in diagnosing engine valve clearance”. Entropy 18(7): article number 253.

8.

Figlus Tomasz, Marcin Stańczyk. 2016.

“A method for detecting damage to rolling bearings in toothed gears of

processing lines”. Metalurgija

55(1): 75-78. ISSN: 0543-5846.

9.

Figlus Tomasz, Marcin Stańczyk. 2014.

“Diagnosis of the wear of gears in the gearbox using the wavelet packet

transform”. Metalurgija 53(4):

673-676. ISSN: 0543-5846.

10.

Goreczka, Stefan, Jens Strackeljan. 2010. “Automatic parameter

setting for the signal processing in rolling bearing CM”. In Seventh International Conference on

Condition Monitoring and Machinery Failure Prevention-CM2010.

11.

Hauptmann Peter. 1991. Sensoren.

Prinzipien und Anwendungen. [In German: Sensors.

Principles and Applications.] Munich and Vienna: Verlag C. Hanser.

12.

Herold H. 1993. Sensortechnik.

[In German: Sensor Technology.]

Heidelberg: Verlag Hüthigure.

13.

Jedliński Ł. 2016. “A new

design of gearboxes with reduced vibration and noise levels”. Diagnostyka 17(4): 93-98.

14.

Kolerus J. 1995. Zustandsüberwachung

von Maschinen. [In German: Condition

Monitoring of Machines.] Renningen: Verlag Expert.

15.

Kosicka E., Kozłowski E., Mazurkiewicz

D. 2015. “The use of stationary tests for analysis of

monitored residual processes”. Eksploatacja

i Niezawodnosc - Maintenance and Reliability 17(4): 604-609. DOI: http://dx.doi.org/10.17531/ein.2015.4.17.

16.

Lahdelma Sulo. Esko Juuso, Jens Strackeljan. 2008. “Vibration

analysis with generalised norms in condition monitoring”. In Proceedings of the Seventh Aachen Colloquium

for Maintenance, Diagnosis and Plant Monitoring. Aachen.

17.

Liscak Stefan, Tomasz Figlus. 2014. “Assessment of the

vibroactivity level of SI engines in stationary and non-stationary operating

conditions”. Journal of

Vibroengineering 16(3): 1349-1359.

18.

Randall Robert. 1987. Frequency

Analysis. Nærum: Brüel&Kjær.

19.

Schoppnies E. 1992. Lexikon der

Sensortechnik. [In German: Lexicon of

Sensor Technology.] Berlin and Offenbach: Verlag VDE.

20.

Seeliger A., P. Burgwinkel. 2008. Aachener

Schriften zur Rohstoff und Entsorgungstechnik, Vol. 70. [In German: Aachen Writings on Raw Material and Disposal

Technology, Vol. 70.] R. Zillekens.

21.

Sturm Adolf, Rudolf Förster. 1990. Einführung in die Theorie der Technischen Diagnostik. [From

German: Introduction to the Theory of

Technical Diagnostics.] Berlin: Springer Verlag.

22.

Tomeh E. 2007. Diagnostics

Methodology of Rolling Element and Journal Bearings. Liberec:

Technická univerzita v Liberci. ISBN 978-80-7372-278-4.

23.

Töpfer H. 1989. Grundlagen

der Automatisierungstechnik. [In German: Basics of Automation Technology.] Berlin: Verlag Technik.

24.

Mazurkiewicz D. 2014.

“Computer-aided maintenance and reliability management systems for

conveyor belts”. Eksploatacja i

Niezawodnosc - Maintenance and Reliability 16(3): 377-382.

25.

Mazurkiewicz D. 2010. “Tests of

extendibility and strength of adhesive-sealed joints in the context of

developing a computer system for monitoring the condition of belt joints during

conveyor operation”. Eksploatacja i

Niezawodnosc - Maintenance and Reliability 3: 34-39.

26.

Wittek Adam Marek, Damian Gąska,

Bogusław Łazarz, Tomasz Matyja. 2014. “Automotive

stabilizer bar - stabilizer bar strength calculations using FEM, novelization

of radial areas of tubular stabilizer bars”. Mechanika 20(6): 535-542. ISSN 1392-1207.

Received 05.03.2018; accepted in revised form 11.08.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License