Article citation information:

Urbanský, M. Harmonic analysis of torsional vibration force

excitation. Scientific Journal of

Silesian University of Technology. Series Transport. 2017, 97, 181-187. ISSN: 0209-3324. DOI:

https://doi.org/10.20858/sjsutst.2017.97.16.

Matej URBANSKÝ[1]

HARMONIC

ANALYSIS OF TORSIONAL VIBRATION FORCE EXCITATION

Summary. In

our department, we deal with various methods for the continuous tuning of

torsional oscillating mechanical systems during their operation, mainly in

terms of torsional vibration magnitude. Therefore, in order to carry out

necessary experimental research, we need torsional oscillation exciters, which

operate on various principles. The objective of this paper is to conduct a

harmonic analysis of a torsional oscillation force excitation mechanism, in

order to identify the possibilities of its application.

Keywords: torsional vibration; force

excitation; harmonic analysis

1. INTRODUCTION

In the laboratory of our workplace (namely, the

Department of Construction, Automotive and Transport Engineering), we are

involved in the measuring and tuning of torsional oscillation in torsional

oscillating mechanical systems (TOMSs).

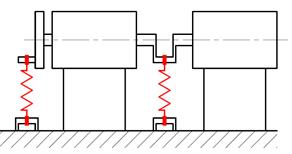

In terms of dynamics, it is possible to define

a TOMS (Fig. 1) as a mass disk system. These disks are connected together with

flexible bonds, wherein rotary power transmission occurs, with torsional beats

and vibration arising during operation [1-6,8-10,12]. Their intensity depends

on the dynamic terms of the respective mechanical system (mainly on natural

frequency and torsional excitation source).

Fig. 1. Torsional

oscillating mechanical system

The most dangerous torsional vibration is

caused by devices that are working with time-variable periodic torque, e.g.,

[1,2,5-10,13,15,16]:

·

Piston

machines (combustion engines, compressors)

·

Gear

transmissions and cam mechanisms

·

Propellers

(of ships, fans etc.)

The system reaches the most critical torsional

vibration values in the resonance area when the mechanical system’s natural

frequency is equal to the excitation frequency. The resonance is much higher

when loading the mechanical system’s parts.

In our department, we deal with the continuous

tuning of TOMSs during their operation (see [8-10,12]). This continuous tuning

mainly concerns the magnitude of torsional vibrations (but also the magnitude

of rectilinear vibrations or noise arising from torsional vibrations). For this

continuous tuning, we use pneumatic flexible shaft couplings (pneumatic

torsional vibration tuners) developed by our department (see [11,14]).

The torsional stiffness of the given pneumatic

tuners, and in turn the natural frequencies of the torsional systems, can be

changed by adjusting the gaseous media (most commonly, air) pressure in their

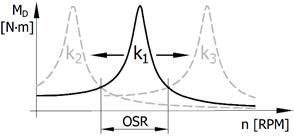

pneumatic flexible elements. With a suitable value of torsional stiffness k (k2

< k1 < k3), resonances from

individual harmonic components of excitation (Fig. 2) can be moved from the

operational speed (n) range (OSR) of

the mechanical system, and herewith the value of dynamic component MD of the

transmitted load torque can be reduced, i.e., [6,8-10,12,15].

Fig. 2. Mechanical

system’s tuning principle

In our laboratory, in order to carry out our

complex research practice, we need torsional oscillation exciters, which

operate on various principles, in addition to torsional oscillation tuners. The

objective of this paper is to perform a harmonic analysis of a special

torsional oscillation force excitation mechanism, in order to identify the

possibilities of its application.

2. force

torsional oscillation excitation mechanism

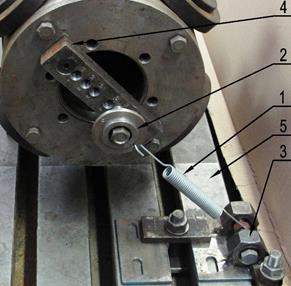

The

mechanism for force torsional oscillation excitation, as shown in Figure 3,

produces, during its operation, the load torque of an alternating character.

The force of the extended tension spring (1) and arm depends on the turn angle

of the rotary flange, on which the excentre is (4) mounted. To avoid damage to

the spring eyes during operation of the mechanism (as a consequence of

frictional wear), it is necessary to use bearings in places (2) and (3). It is

possible to adjust the spring preload by a spring extension fixed to the base

plate (5). As we can see in Figure 3b, this mechanism can be mounted:

·

to

the frontal surface of the driving or driven machine flange

·

to

the crank of the crankshaft situated in the drive chain of a mechanical system

|

|

|

|

a) |

b) |

Fig. 3. Force torsional oscillation

excitation mechanism: a) construction example and b) application

scheme

3. Derivation

of mathematic formulas for force excitation

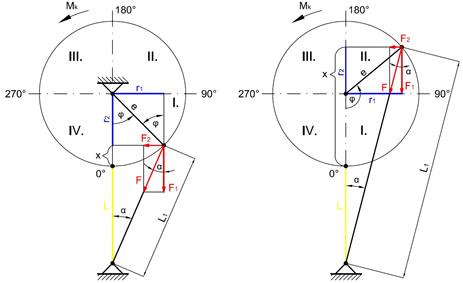

In Figure 4, a schematic drawing of

the given mechanism with force terms is presented.

Fig. 4. Mechanism scheme

with force terms

Consequently, as shown in Table 1,

formulas are derived for torque Mk

from Figure 4, where: Mk - torque,

which it is necessary to expend on rotation in the direction of rotation angle φ, which increases

counterclockwise; F - spring force, which is

decomposed to components F1

and F2; L - distance of the axes of the

spring grip pins in the bottom dead centre.

Tab. 1

Derived formulas for torque Mk

|

All

quadrants |

Quadrant

III |

Quadrant

II |

|

|

|

|

|

Quadrant

IV |

Quadrant

I |

|

|

|

|

4. HARMONIC

ANALYSIS OF the EXCITATION

In Table 2, the amplitude values of

the first, second and third harmonic components (HCs) and the various

eccentricity values of the phase angle without a spring preload are computed.

The amplitudes of higher HCs have only a negligible size (less than 1% of the

first HC amplitude).

Tab. 2

Computed values of harmonic components without

spring preload

|

Eccentricity [% of L] |

1st HC amplitude MA1 [N.m] |

(MA2/MA1).100 [%] |

(MA3/MA1).100 [%] |

2nd HC phase

angle shifting ψ2

[°] |

3rd HC phase

angle shifting ψ3

[°] |

L [m] |

|

1 |

0.040.x |

49.443 |

0.367 |

180.5 |

181 |

Constant |

|

5 |

x |

47.324 |

1.700 |

180.5 |

181 |

Constant |

|

10 |

4.019.x |

44.896 |

3.060 |

181 |

Constant |

|

|

15 |

9.076.x |

42.686 |

4.171 |

180.5 |

181 |

Constant |

|

20 |

16.187.x |

40.668 |

5.075 |

180.5 |

181 |

Constant |

|

25 |

23.359.x |

38.817 |

5.808 |

180.5 |

181 |

Constant |

|

50 |

102.238.x |

31.503 |

7.818 |

180.5 |

181 |

Constant |

In Table 3, the amplitude values of

the first, second and third harmonic component (HCs) involving various spring

preloads with a constant eccentricity value of 10% of L are computed. The value of ψ2,

in all cases, is 180.5°, while the value of ψ3,

in all cases, is 181°.

Tab. 3

Computed values of harmonic components with spring

preload

|

Eccentricity [% of L] |

1st HC amplitude MA1 [N.m] |

(MA2/MA1).100 [%] |

(MA3/MA1).100 [%] |

Spring preload [stretched % of L] |

L [m] |

|

10 |

x |

44.896 |

3.060 |

0 |

Constant |

|

10 |

1.494.x |

28.541 |

1.945 |

5 |

Constant |

|

10 |

1.990.x |

20.318 |

1.385 |

10 |

Constant |

|

10 |

2.483.x |

15.369 |

1.047 |

15 |

Constant |

|

10 |

2.977.x |

12.063 |

0.822 |

20 |

Constant |

|

10 |

3.472.x |

9.699 |

0.661 |

25 |

Constant |

|

10 |

3.966.x |

7.924 |

0.540 |

30 |

Constant |

|

10 |

4.461.x |

6.542 |

0.446 |

35 |

Constant |

|

10 |

4.955.x |

5.437 |

0.370 |

40 |

Constant |

It

is possible to describe the dependence of load torque Mk, which arises during the operation of the given

mechanism, on rotation angle φ

using the following formula:

Mk = MA1.sin φ + MA2 sin (2.φ + ψ2) + MA3 sin (3.φ + ψ3),

where:

MA1, MA2, MA3

- amplitudes of the first, second and third HCs of excitation; Ψ2 and Ψ3 - phase angle

shifting of these second and third HCs towards the first HC.

5. CONCLUSION

From the

values stated in Tables 2 and 3, it is possible to say that:

·

Without a spring preload, but with a linearly

increasing eccentricity percentage value, the first HC amplitude value

increases quadratically, the second HC amplitude percentage decreases and the third HC percentage

increases.

·

With a suitable spring preload, we can increase the

first HC amplitude value, substantially reduce the second HC amplitude value and minimize the

third HC amplitude value to a negligible size (less than 1% of the first HC

amplitude).

These

facts relate to the property of the given mechanism (not its deficiency). Among

general advantages of the mechanism, it is possible to mention:

·

Negligible small friction resistances while

operational

·

Simplicity of its construction and therefore low

manufacturing costs

·

Simple and accurate calculation of load torque

dependence

The main

disadvantage of the given mechanism is the rise of relatively high radial

loading in the system at the point of the excentre in relation to the rotary

part mounting, which should be provided at the shafts, and the dimension of the

bearings.

References

1.

Czech P., J. Mikulski. 2014.

“Application of Bayes Classifier and Entropy of Vibration Signals to Diagnose

Damage of Head Gasket in Internal Combustion Engine of a Car”. In: J. Mikulski

(ed.). 14th International Conference on Transport Systems Telematics. Katowice

Ustron, Poland. 22-25 October 2014. Telematics - Support for Transport. Book

series: Communications in Computer and Information Science, Vol. 471: 225-232.

2.

Czech

P. 2013. “Intelligent approach to valve clearance diagnostic in cars”. In:

J. Mikulski (ed.). 13th International Conference on Transport Systems

Telematics. Katowice Ustron, Poland. 23-26 October 2013. Activities of

Transport Telematics. Book series: Communications in Computer and Information

Science, Vol. 395: 384-391.

3.

Figlus Tomasz, Marcin Stańczyk.

2016. “A method for detecting damage to rolling bearings in toothed gears of

processing lines”. Metalurgija 55(1): 75-78. ISSN: 0543-5846.

4.

Figlus Tomasz, Marcin Stańczyk.

2014. “Diagnosis of the wear of gears in the gearbox using the wavelet packet

transform”. Metalurgija 53(4): 673-676. ISSN: 0543-5846.

5.

Folega

Piotr, Grzegorz Wojnar, Rafał Burdzik, Łukasz Konieczny. 2014. “Dynamic

model of a harmonic drive in a toothed gear transmission system”. Journal of Vibroengineering 16 (6):

3096-3104. ISSN 1392-8716.

6.

Fraunhofer L.B.F. 2015. Gesteigerter Yacht-Genuss: Aktive Kupplung

mindert Schwingungen in Schiffsantrieben. [In German: Increased Yacht Enjoyment: Active Clutch

Reduces Vibration in Ship Propulsion Systems.] Available at:

http://www.lbf.fraunhofer.de.

7.

Gąska Damian, Tomasz Haniszewski,

Jerzy Margielewicz. 2017. “I-beam girders dimensioning with numerical modelling

of local stresses in wheel-supporting flanges”. Mechanika 23(3): 347-352. ISSN

1392-1207.

8.

Homišin Jaroslav. 2002. Nové typy pružných hriadeľových spojok:

Vývoj-Výskum-Aplikácia. [In Slovak: New

Types of Flexible Shaft Couplings: Development-Research-Application.]

Košice: Vienala. ISBN 80-7099-834-2.

9.

Homišin Jaroslav. 2006. “Tuning methods of mechanical systems

by means of torsional oscillation tuner application”. Pneumatyka 61 (6): 32-35. ISSN 1426-6644.

10.

Homišin Jaroslav, Peter Kaššay.

2014. “Experimental

verification of the possibility using pneumatic flexible shaft couplings for

the extremal control of torsional oscillating mechanical system”. Diagnostyka 15 (2): 7-12. ISSN

1641-6414.

11.

Kaššay Peter. 2017. Pneumatická pružná hriadeľová spojka s

hadicovým pružným elementom. [In Slovak: Pneumatic Flexible Shaft Coupling with Hose-resilient Element.]

Utility pattern SK 7708 Y1. Banská Bystrica: ÚPV SR 2017.

12.

Lacko Pavol. 1988. “Die kontinuierliche Änderung

dynamischer Parameter von Schwingungssystemen im Betriebszustand”. [In German:

“The continuous change of dynamic parameters of vibration systems in the

operating state.”] Maschinenbautechnik

6: 274-277.

13.

Mario De Luca. 2017. ”A comparison

between prediction power of artificial neural networks and multivariate

analysis in road safety management”. Transport

32(4): 379-385. ISSN: 1648-4142. DOI:

https://doi.org/10.3846/16484142.2014.995702.

14.

Patent

PL 216901 B1. Układ mechaniczny strojony

w sposób płynny. [In Polish: Mechanical

System Tuned in a Smooth Way.] Homišin J., 2014.

15.

Sapieta

M., A. Sapietová, V. Dekýš. 2017. “Comparison of the thermoelastic

phenomenon expressions in stainless steels during cyclic loading”. Metalurgija 56 (1-2): 203-206. ISSN

0543-5846.

16.

Wittek

Adam Marek, Damian Gąska, Bogusław Łazarz, Tomasz Matyja. 2014. “Automotive stabilizer bar – stabilizer bar strength calculations

using FEM, ovalization of radial areas of tubular stabilizer bars”. Mechanika

20(6): 535-542. ISSN 1392-1207.

This paper was written within the

framework of the KEGA 041TUKE-4/2017 grant project entitled, Implementation of

New Technologies Specified for Solving Questions Concerning the Emissions of

Vehicles and Their Transformation in Educational Processes in Order to Improve

the Quality of Education.

This article was created with

support from the PhD students and young researchers project entitled, Solution

of a Control System Element for Mechanical Systems’ Continuous Tuning.

Received 19.08.2017; accepted in revised form 01.11.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License