Article citation information:

Sala, D., Motylewski, J., Mróz, A., Pawłowski,

P. Vibroacoustic system

for measurement of the touchdown of a light aircraft. Scientific Journal of Silesian University of Technology. Series

Transport. 2017, 97, 147-156.

ISSN: 0209-3324. DOI:

https://doi.org/10.20858/sjsutst.2017.97.13.

Damian SALA[1], Jerzy MOTYLEWSKI[2], Arkadiusz MRÓZ[3], Piotr PAWŁOWSKI[4]

VIBROACOUSTIC

SYSTEM FOR MEASUREMENT OF THE TOUCHDOWN OF A LIGHT AIRCRAFT

Summary.

Aircraft touchdown is one of the most difficult and dangerous phases of a

flight. The paper presents an aerial light aircraft, prepared and produced by

vibroacoustic tests, using an aircraft landing and landing monitoring system

(AVI). The concept is based on the use of an ultrasonic transceiver head and

vibration transducer, together with an appropriate signal processing and

analysis system. The system measures the touchdown speed and altitude of the

aircraft in the final phase of the flight and determines the level of load

transmitted to the aircraft during the landing. Thanks to data archiving, it

allows for better estimation of the wear rate of the structure, which is

important in determining the causes of possible malfunction. It can be used

with light and ultralight aircraft and, after adaptation, in unmanned aircraft.

It can also be used to evaluate the art of piloting during landing.

Keywords:

aircraft landing; landing monitoring system; ultrasonic measures

1. AVI SYSTEM

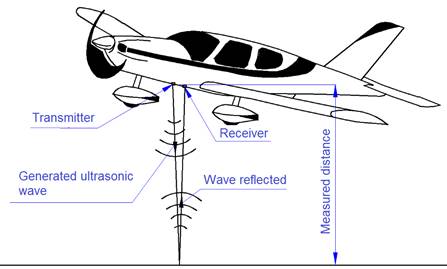

The ultrasonic measuring system

consists of a transmitter head, receiver head, signal processing circuitry and

controller.

The method of measurement is based

on the detection of wave propagation time along the path from the transmitting

head, through the ground surface, to the receiving head. This time depends on

the distance of the aircraft from the landing. A schematic view of the AVI

system operating principle is shown in Fig 1. Working in the 40-kHz band, the

interfering signal generated by the aircraft when in flight can be

significantly reduced

Fig. 1. Schematic view of the AVI system

operating principle

An ultrasonic pulse is formed by the

transmitter and sent periodically with repetition time T. The generated wave

after reflection from the landing plane returns to the receiver head after Tri,

(Fig. 2). The distance between the sensor and the reflection plane Hi

is equal to the product of the half-wave propagation time and propagation

velocity in the medium:

Hi=½ c TRi (1)

where TRi

is the ultrasonic wave propagation time; and c is the propagation velocity (for

air 343 m / s at 20°C). The vertical component of the landing velocity can be

determined using differential methods (Fig. 3).

Fig. 2. Ultrasonic signal in the time domain

Fig. 3. Speed determination scheme

The

measured velocity is described with the relationship:

![]() (2)

(2)

or more

accurately:

![]() (3)

(3)

where

Vi is the measured speed; L i and Li-1 are the

consecutive distances; and T is the repetition time.

The distributed pole

effectiveness of the directional transmitting head diagram is shown in Fig. 4.

Fig. 4. Distributed pole effectiveness of the

directional transmitting head

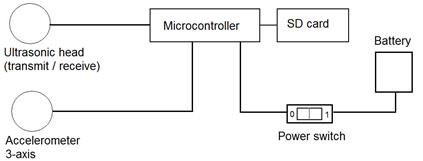

A modified AVI velocity identification and acceleration (AVI-a) system

has been developed and implemented, which measures the height of the aircraft,

the vertical velocity of the touchdown in the final phase of landing, and the

vibration amplitude of selected aircraft components. Fig. 5 shows a block

diagram and Fig. 6 shows a general view of the AVI-a system.

Fig. 5. Block diagram of the AVI-a system

Fig. 6. General view of the AVI-a system

The vibration acceleration measurement allows us to determine the loads

to be delivered to the aircraft during the landing and gives a better estimate

of the wear rate of the structure, which is important for determining the cause

of any landing failures. The system can be used to evaluate the art of piloting

(quantitative identification of pilot skills).

2. AVI-A SYSTEM TESTS WITH CZAJKA AIRCRAFT

BALLAST

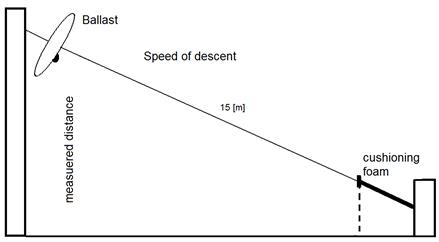

The purpose of this AVI research was to verify the assumptions about the

system’s suitability in aviation applications.

The methodology for the study consisted of the simultaneous measurement

of distance and acceleration in the course of the falling of the ballast and

the impact on the protective barrier, which was supposed to simulate the moment

of plane touchdown. The measurement station diagram is shown in Fig. 7.

Handles were mounted on the ballast, with which it was suspended on the

ropes. The hitch was at a height of 7 m, while their other end was mounted at a

height of about 1 m.

![]()

![]()

Fig. 7. The scheme of the AVI-a system for

testing

An ultrasonic transceiver head and an accelerometer measuring

acceleration in three mutually perpendicular directions, x, y, z, was placed on

the ballast. The view of the ballast with sensors and the accelerometer is

shown in Fig. 8.

Fig. 8. View of the

ballast during tests with the AVI-a system

There were two types of tests on the station. The first was a free throw

of the ballast, while the second was a throw-in with a controlled braking

force. Simultaneously with the height measurement, the vibration of the ballast

was measured.

An example of the elevation change as a function of time for free

discharge is given in Fig. 9, while Fig. 10 shows the acceleration waveforms

for the three directions recorded during the discharge.

Fig. 9. The waveform of

height change as a function of time for a freefall

Fig. 10. Waveforms of the vibration acceleration

of three directions as recorded during discharge

In addition, tests were carried out on a

high-speed object (up to 140 km/h) to verify the operation of the ultrasound

head. The tests confirmed the possibility of using the above head during

high-speed measurements.

3. AVI

SYSTEM TEST ON SKYLEADER 600 AIRCRAFT

The AVI system was also tested under

operational conditions on the Skyleader 600 aircraft (Fig. 11).

Fig. 11. View of the

Skyleader 600 aircraft

AVI system tests were carried out at airports with different runway

surfaces: on a grass runway (Rybnik) and on a concrete runway (Kaniów).

The block diagram of the applied system is given in Fig. 12, and the

system view with ultrasonic heads is shown in in Fig. 13.

Fig. 12. Block diagram of the AVI system

Fig. 13. View of the AVI system with ultrasonic

heads

A view of the AVI system mounted on the Skyleader 600 aircraft is shown

in Fig. 14. The heads were placed under the wing at a height of about 66 cm.

Head Head Receiver Transmitter

Fig. 14. Location of

transmitter and receiver head

4. TESTS RESULTS

During the measurement session, many landings were conducted under the

same weather conditions with the same pilot. It can be observed that each

landing had a different character.

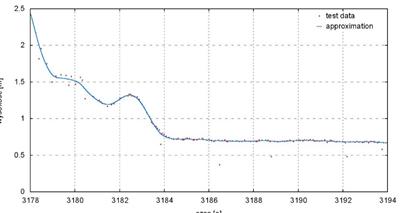

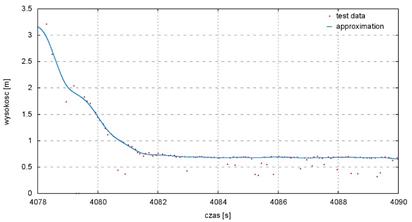

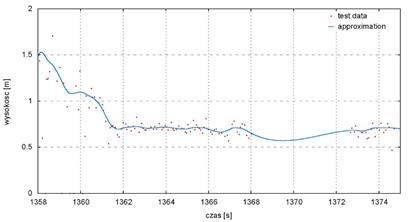

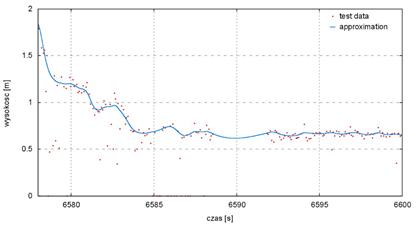

Below are graphs showing the individual touchdown processes on the

concrete runway (Figs. 15 and 16) and on the grass runway (Figs. 17 and 18).

Time [s]![]()

![]()

Fig. 15. Touchdown: concrete runway (Test 3)

Time [s]![]()

Fig. 16. Touchdown: concrete runway (Test 5)

Time [s]

![]()

Fig. 17. Touchdown: grass runway (Test 8)

Time [s]

![]()

Fig. 18. Touchdown: grass runway (Test 12)

The above charts can be read for

different types of landing, i.e., slowly (Fig. 15) or faster (Fig. 16). For the

grassland runway, the measurement noise was greater than for the concrete

runway.

5.

CONCLUSION

The system can be used to assess pilotage during the landing phase in

terms of quantifying the pilot’s skills and assessing the impact of the landing

on the construction of the aircraft, as well as determining the wear rate of

the structure, which is important for establishing the cause of any landing

failure. All data for height, the vertical velocity component and the vibration

acceleration amplitude of the test element are recorded on a micro SD card,

allowing for historical data recovery and subsequent analysis.

The system can be used to:

1. Determine

the kinetic energy of the touchdown for optimal adjustment of the energy

absorber (e.g., in an adaptive pneumatic landing gear).

2. Quantitatively

evaluate the touchdown manoeuvre as a training aid for pilots.

3. Measure

the position and speed in small planes and helicopters equipped with an

adaptive chassis.

4. Track

the course of landings during training flights.

Thanks to data archiving, the AVI system allows for better estimation of

the wear rate of the structure, which is important for determining the causes

of possible failures. It can be used in light and ultralight aircraft and,

after adaptation, in unmanned aircraft. It can also be used to evaluate the art

of piloting during landing.

In the case of unmanned aircraft, it is possible to use such signals in

automatic control systems at the moment of touchdown.

References

1.

Dong X.M., G.W. Xiong. 2013. “Vibration attenuation of

magnetorheological landing gear system with human simulated intelligent

control”. Mathematical Problems in

Engineering, Article ID 242476. DOI: 10.1155/2013/242476.

2.

Mikułowski G., Ł. Jankowski. 2009. “Adaptive landing gear: optimum

control strategy and potential for improvement”. Shock and Vibration 16(2): 175-194.

3.

Mikułowski G., J. Holnicki-Szulc. 2007. “Adaptive landing gear concept-feedback control

validation”. Smart Materials and

Structures 16(6): 2146-2158.

4.

Sekula K., C. Graczykowski, J.

Holnicki-Szulc. 2013.

“On-line impact load identification”. Shock

and Vibration 20: 123-141.

Received 20.08.2017; accepted in revised form 18.10.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License