Article citation information:

Melnychuk, S., Vitiuk, I., Bovsunivskyi, I., Beherskyi,

D., Kubrak, Y. Vehicle suspension system modelling and simulation in the

SolidWorks software environment with motion analysis applications. Scientific Journal of Silesian University of

Technology. Series Transport. 2017, 97,

117-130. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.97.11.

Serhiy MELNYCHUK[1],

Ivan VITIUK[2],

Ihor BOVSUNIVSKYI[3],

Dmytro BEHERSKYI[4],

Yuriy KUBRAK[5]

VEHICLE

SUSPENSION SYSTEM MODELLING AND SIMULATION IN THE SOLIDWORKS SOFTWARE

ENVIRONMENT WITH MOTION ANALYSIS APPLICATIONS

Summary. An

N1 vehicle model is created, which allows for changing suspension parameters

and conditions of experimental performance. A methodology of computer

testing performance for vehicle ride comfort and stability service properties’

characterization in a virtual environment is proposed. Vehicle suspension

system modelling and simulation are performed. The results of the N1 vehicle

suspension system from full-scale laboratory and road tests are given.

Keywords: stability; ride comfort; testing

methodology; vehicle suspension; cushioning; roll; vibration frequency

1. INTRODUCTION

Given that, in the process of building

mathematical models of vehicle motion or its suspension systems, designers and

engineers face difficulties in relation to copious factors, simplifications are

often applied. In the majority of cases, introducing simplifications can

significantly affect a product. Taking into an account this fact, along with

modern scientific progress, computer technological development, advances in

powerful engineering software products for difficult mechanical systems and

process descriptions, computer modelling and simulation are used for new

machines and assembly engineering.

Computer modelling and simulation significantly

speed up manufacturing processes at the planning stage, allow for tests to be

performed with the possibility to change a design and provide test conditions

that increase the quality of a product, promotes its implementation and reduces

its price.

Even at the planning stage, modern methods of

vehicle development allow for researching and developing cushioning and

vibrodamping systems, while estimating such characteristics as ride comfort,

stability and carrier system load by means of computer modelling and simulation

[3]. Methods of computer modelling and simulation can account for a majority of

suspension parameters that influence vehicle operation and its motion safety.

Modelling task priority lies in the definition

of system work parameters and the explanation of processes, which regulate

recognition and definition.

2. LITERATURE REVIEW AND PROBLEM STATEMENT

The analysis of recent publications

confirms that computer modelling and simulation are important parts in the

study of systems’ technological processes.

The modern market proposes a wide

range of computer-aided design (CAD) software products. Therefore, one of the

most critical tasks involves the choice of the software environment that will satisfy

the needs of designers, engineers and executives.

Software must ensure a project’s

design execution speed, a great source of software, a wide range of parametric

characteristics, the quality of the work performed, simplicity and ease of

professional service, work reliability, an easy mastering process, and constant

improvement. The most popular CAD systems in engineering were studied, with

their possibilities analysed and software packages compared, including their

features and functional peculiarities. In turn, the most appropriate system to

meet modern demands for software products created for home engineering

enterprises was defined.

Nowadays, the most popular CAD

systems include SolidWorks, T-Flex and

Компас, all of which satisfy appropriate

needs and requirements and are more often used in engineering.

SolidWorks CAD software,

manufactured by the SW Corporation, offers 3D design solutions of parts and

assemblies with possibilities to perform analyses of different types and create

design documentation.

In [6,7,8,9,11], a wide range of CAD

usage possibilities are presented in order to model and simulate assemblies’

interaction processes, as well as define basic development and existing

simulation models’ improvement streamlines. On the ADAMS/Car platform, a module

to analyse vehicle motion stability has been developed. The software allows for

changing suspension stiffness and damping parameters, the centre of mass etc.

It enables software users to input values of parameters for different types of

vehicle. But the software has many disadvantages as well, including the

simplification of many processes, which significantly affects the end result.

Notwithstanding a large amount of

the literature dedicated to the vehicle and its components modelling and simulation,

the issue of defining dependence of parameters of vehicle ride comfort and

stability on the quality of the work of its suspension system needs further

investigation. Moreover, existing models partly reflect processes in the

suspension systems.

3. AIM AND OBJECTIVES OF THE STUDY

The aim of

this paper is to forecast parameters of N1 vehicle ride comfort and stability

by means of computer modelling and simulation in the process of suspension

system design. The research objectives in this study are listed as follows:

–

To develop a computer model of N1 vehicle motion,

which allows for investigating ride comfort and stability and accounting for

design parameters of the suspension system.

–

To perform laboratory and road tests of the N1

vehicle suspension system.

–

To create a computer model and simulation of the N1

vehicle suspension system under conditions similar to the performed full-scale

tests and to compare results in order to state the adequacy of the computer

model.

–

To use the developed computer model in order to

investigate the designed suspension system on the basis of a four-bar linkage

assembly.

4. MATERIALS AND METHODS OF THE STUDY OF

OPERATIONAL PARAMETERS OF AN N1 VEHICLE: RIDE COMFORT AND STABILITY

A vehicle was chosen as a simulation

model on the basis that it is widely used in cities due to its mobility and

versatility. The cargo and passenger vehicle peculiarity involves significant

pressure difference in the sprung mass, which mostly occurs in the rear axle

(loaded-unloaded), while its operation in cities includes a turn, a three-point

turn and road positioning. Therefore, there are high expectations of ride

comfort and stability provision under different operational conditions with

such a vehicle.

For the purposes of the study, a

full-size simulation model of the experimental N1 vehicle was developed with

all its operational qualities. The Izh 2715 was chosen as an experimental

vehicle. All the necessary parameters and dimensions for developing a

simulation model were measured on this vehicle

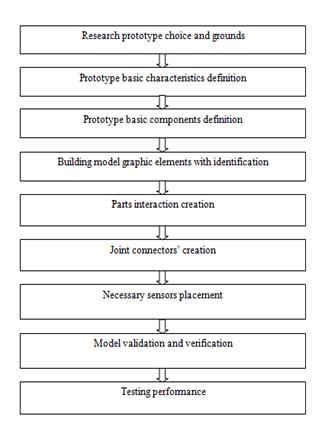

The structural scheme represents

simulation model components in Fig. 1.

The analysis of modern scientific works on N1 vehicle

simulation model development and modelling and simulating mechanical systems

interaction has shown that, among a large number of CAD products, the

SolidWorks CAD software, manufactured by the SW Corporation, is one of the most

powerful and polyfunctional products.

SolidWorks software is developed for designing parts

and assembles, creating drawings, and testing performance to obtain different

types of data. The main advantage of this system is that the most powerful

manufacturers in the world have chosen it as standard. With powerful SolidWorks

solutions, modern machines and transfer lines are designed and produced within

automobile manufacturing enterprises. Unification reduces service and logistics

costs, while raising product quality.

To model and simulate vehicle motion kinematics

parameters, the Motion Analysis application was used, which is intended for

modelling and simulating dynamic systems in the SolidWorks software environment

and for assemblies’ motion simulation with allowance for kinematics and force

factors. The application is fully integrated with SolidWorks and creates a

geometric model, while calculation parameters and results notation are also

carried out in the SolidWorks model.

Fig. 1. The structural scheme of the vehicle

simulation model components

The data input procedure that was defined in order to

create a model is shown in Fig. 2.

Next, the SolidWorks assembly was analysed by means of

the Motion Analysis application, while its conversion to a nominal model was

performed with the parts’ mass-inertia characteristics taken into account. The

inertia parameters were taken from the SolidWorks parts geometry, with the

density parameter set for each element separately, irrespective of the

geometric form. Then, a motion differential equation set was proposed, which

was later solved by means of a difference scheme. Subsequently, the software

displayed the processed numerical results in a form suitable for

representation. At this point, the system again interacted with real geometry.

The computational kinematics model representation (in the form of thumbnails)

and results were performed in the SolidWorks graphics window on the background

of the SolidWorks assembly.

Fig. 2. The model building procedure

5. RESULTS

5.1. The study of N1 vehicle stability using a

simulation model

The study of N1 vehicle stability was performed on the

basis of the developed computer model.

From the laboratory measurements [2], the vehicle

suspension system’s basic characteristics were obtained, which were used for

the main virtual model of an experimental vehicle in SolidWorks Motion, along

with the basic suspension system and the suspension system, on the basis of the

four-bar linkage assembly.

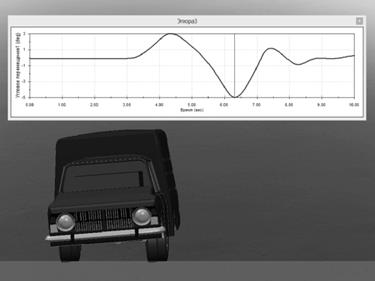

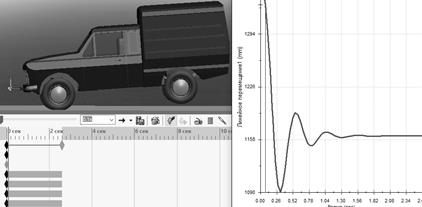

These models (Fig. 3) include the vehicle and its

elements, along with all the mass-geometric parameters, inertia forces,

friction in the levers, damping elements, friction of a tyre with a bearing

surface, gravitational forces and other parameters.

Fig. 3. N1 vehicle computer model developed to

study ride comfort and stability parameters

The simulation model was developed in such a way that,

at the beginning of the research, the vehicle moved parallel to the X-axis,

which was directed along a road. The N1 vehicle motion was studied at the time

interval t=10 s until the vehicle came to a complete stop. As a result of

numerical modelling by means of SolidWorks Motion, we obtained data on the

vehicle body position at any time with an interval part of 0.04 s at the 10-s

interval [10].

We performed the research on the vehicle dynamic model

with visualization, which allows for representing a model’s characteristic

movement along the designed part of the road in accordance with the applied

kinematics and force constraints and limitations.

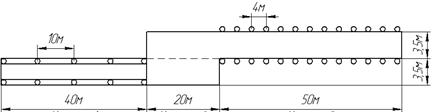

The methodology was developed on the basis of GOST

52302-2004 in order to perform computer testing of a “20-m sharp lane change”

(Fig. 4). According to the proposed methodology, the vehicle gained the

necessary fixed speed and performed the “20-m sharp lane change” manoeuvre

without braking and speeding-up over a 20-m road distance, with a 7-m road

width.

Fig. 4. The testing performance

scheme for the “20-m sharp lane change”

The developed methodology allowed us to perform

testing at different speeds with different vehicle workloads. The testing of a

“20-m sharp lane change” by the vehicle model was performed at a speed of 20-50

km/h with a speed part of 5 km/h (Fig. 5).

In the process of testing, a virtual angular movement sensor, which was

placed on the vehicle model body and operated relative to the bearing surface,

was used for the vehicle body roll registration.

Fig. 5. The testing performance: the

vehicle body rolled with the factory-made suspension system in the process of

the “20-m sharp lane change” manoeuvre performance

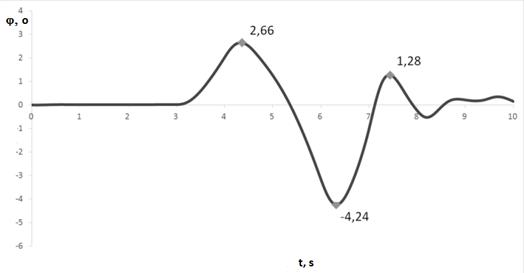

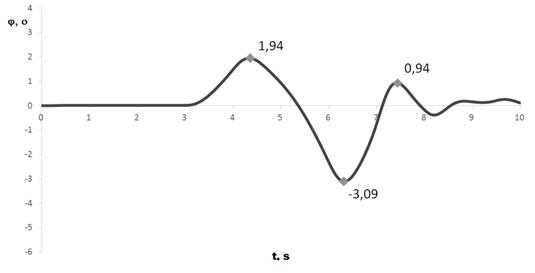

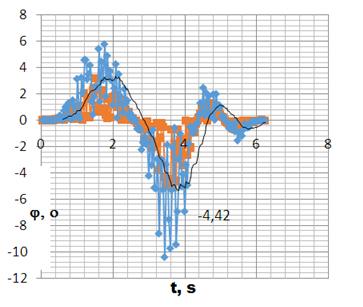

Comparative graphs were created according to the

performed computer and road testing (Figs. 6-7). In the process of the “20-m

sharp lane change” manoeuvre performance at the speed of 50 km/h, the vehicle

body roll with the factory-made suspension system added up to 4.24°, while that

involving a suspension system on the basis of a four-bar linkage assembly

amounted to 3.09° under the same conditions in the process of the manoeuvre

performance.

Fig. 6. The vehicle body roll with

the factory-made suspension system in the process of the “20-m sharp lane

change” manoeuvre performance

Fig. 7. The vehicle body roll with

the suspension system on the basis of the four-bar linkage assembly in the

process of the “20-m sharp lane change” manoeuvre performance

5.2. The study of N1 vehicle ride

comfort using a simulation model

Using the developed computer simulation model, we

investigated N1 vehicle ride comfort by means of a drop test method (Fig. 8).

Fig. 8. The test performance: the

drop test

To perform the computer simulation testing, the

following vehicle computer research procedure by means of the drop test method

was used [1,2]:

- The

vehicle model was set on the virtual flat horizontal plane.

- The front

wheels were fixed and did not turn.

- The front

suspension system was fixed and did not vibrate.

- The

virtual movement sensors were set.

- It was

essential for the rear wheels’ height to comprise 55-65 mm relative to the

measurement plane.

- The

vehicle model was dropped, and the sprung and unsprung mass vibration process

was fixed.

- The tests

were repeated with a model load of 25, 50 and 75, and 100% of the vehicle load

carrying capacity.

- Vibration

process parameters were reported by means of the movement sensor embedded into

the Motion module.

The testing was performed for both the vehicle with

the factory-made suspension system (Fig. 9) and the one with the suspension

system on the basis of the four-bar linkage assembly (Fig. 10).

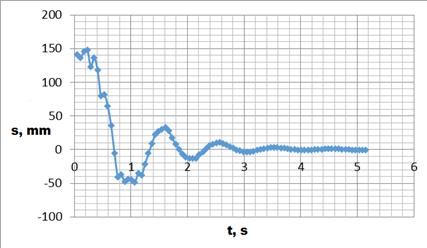

Fig. 9. The

dependence of the vertical vibration displacement, which took place in the

process of free vibrations of the sprung mass of the vehicle with the

factory-made suspension system

Fig. 10. The

dependence of the vertical vibration displacement, which took place in the

process of free vibrations of the sprung mass of the vehicle with the

suspension system, on the basis of the four-bar linkage assembly

For the vehicle with the factory-made suspension

system, the free vibrations frequency of the sprung mass changed in the range

from 1.33 to 1.8 Hz, according to the quantity of the vehicle body load. The

value of 1.33 Hz referred to the entirely loaded vehicle, and the value of 1.8

Hz referred to the unloaded vehicle, which corresponded to the actual values of

the free vibrations frequency of N1 vehicles with the factory-made spring

suspension system.

For the vehicle with the suspension system, on the basis

of the four-bar linkage assembly, the values of the free vibrations frequency

changed in the range from 0.8 to 1.05 Hz under the same conditions.

The obtained data on the computer modelling and

simulation of the vehicle model with different types of suspension systems

pointed to the proposed model adequacy and the fact that, even under the

limited conditions of the computer research, the suspension system, on the

basis of the four-bar linkage assembly, operated in the expected frequency

range.

5.3. The road testing of N1 vehicle stability

To validate and verify the available theoretical

computer and mathematical stability studies, we decided to perform a full-scale

testing of the factory-made suspension system of the experimental vehicle. For

this purpose, we developed a methodology for the road testing of the “20-m

sharp lane change” manoeuvre on the basis of GOST 52302-2004.

According to the proposed methodology, in a similar

manner to the computer testing, the vehicle gained the necessary fixed speed on

the hard bituminous concrete surface and performed the “20-meter sharp lane

change” manoeuvre without braking and speeding-up over a 20-m road distance,

with a 7-m road width, as previously indicated in the scheme (Fig. 4).

For recording vehicle motion speed, a reed sensor was

used, which was placed on the vehicle drum and sent signals to the computer by

means of an analogue-to-digital converter. For recording the vehicle body roll

change, a gyro sensor was used, which was placed in the vehicle body above the

rear axle. The testing was performed at a speed of 20-50 km/h with a speed part

of 5 km/h. The vehicle body load was created by sacks containing 25 kg of sand.

To improve accuracy, we repeated the testing four to five times under the same

conditions. For the purposes of visual control and analysis, we also recorded

the experiment with a high-speed camcorder with a frequency of 60

frames/second. We obtained the results in the form of graphs (Fig. 11).

The graph shows that, in the process of road testing,

the vehicle body roll amounted to 4.42° at a speed of 50 km/h under conditions

similar to those of the computer testing.

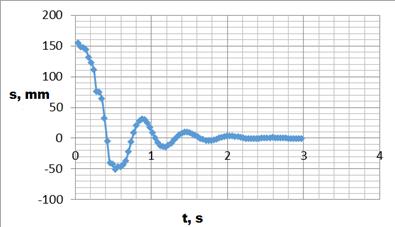

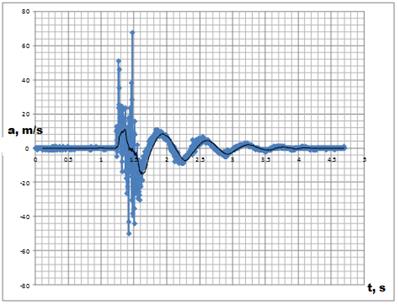

5.4. Full-scale laboratory testing of N1

vehicle ride comfort

To validate and verify the computer modelling and

simulation by means of the drop test, we decided to carry out laboratory

testing on the experimental vehicle using the same test.

For this purpose, we developed a procedure similar to

computer testing, which included the vehicle rear axle dropping on the hard

horizontal surface. The front axle was preliminarily fixed and did not turn or

vibrate (in order to avoid swinging and obtain free vibrations of the vehicle

rear axle). It was also necessary to fix an accurate ballast placement directly

and evenly above the rear axle. For recording free vibrations, a high-accuracy

accelerometer was used, which was placed in the middle of the body above the

rear axle. To process a signal, the accelerometer data were sent to a special

board, which communicated the signal to a personal computer. The data of the

vertical vibration acceleration of the vehicle rear axle appeared on the

personal computer by means of the special program (Fig 12).

Fig. 11. The road

testing: the vehicle body roll with the factory-made suspension system in the

process of the “20-m sharp lane change” manoeuvre performance

Fig. 12. The

laboratory testing by means of the drop test: the vibration acceleration of the

rear axle of the vehicle with the factory-made suspension system

The obtained experimental data validated both the

theoretical calculations and the results of the computer modelling and

simulation. Under the same conditions, the factory-made suspension system

operated in the range of 1.33 to 1.67 Hz, while the proposed system, on the

basis of the four-bar linkage assembly, operated in the range of 0.91 to 1.17

Hz. In comparison with the computer model, the regularity of distribution of

the operating frequencies, at which the suspension systems being studied

operated, remained. This validated the chosen procedure and validated the

necessary evidence resulting from the performed research.

6. DISCUSSION OF THE RESEARCH RESULTS OF N1

VEHICLE RIDE COMFORT AND STABILITY

Using the developed simulation model, testing was

performed to define the vehicle service properties. We managed to improve ride

comfort and stability by means of changing the vehicle’s factory-made spring

suspension system into one on the basis of a four-bar linkage assembly.

In the process of “20-m sharp lane change” experiment,

at a speed of 50 km/h, the maximum roll angle of the vehicle with the

factory-made suspension system amounted to 4.24°; in the process of testing the

suspension system on the basis of the four-bar linkage assembly, the roll angle

added up to 3.09°. Furthermore, the critical speed of the manoeuvre performance

was defined: the critical speed with the factory-made suspension system

amounted to 60 km/h, while the one with the suspension system on the basis of

the four-bar linkage assembly added up to 65 km/h. Thus, the testing results

proved that, under the same conditions, the vehicle performed the manoeuvre

with more stability using the suspension system being studied.

Having analysed the obtained value of the sprung mass

vibrations frequency reported in the modelling and simulation results (Figs.

9-10), it may be concluded that the sprung mass vibrations frequency for the

factory-made suspension system added up to 1.33 Hz with the entire load (sprung

mass of 520 kg), while the one for the suspension system on the basis of the

four-bar linkage assembly amounted to 0.8 Hz [5].

The results of the performed research pointed to the

fact that using the new suspension system significantly improves the vehicle’s

ride comfort and stability parameters. Thus, the proposed N1 vehicle suspension

system is both practical and expedient in terms of usage.

7. CONCLUSIONS

A virtual model of the vehicle was developed in order

to perform computer testing of the ride comfort and stability parameters. The

proposed model allowed for the fast changing of such parameters as vehicle

weight, height of the centre of mass and suspension system types. Besides, the

model can easily adapt to different research conditions. Thus, the proposed

model is suitable for performing research on the vehicle ride comfort parameter

by means of such methods as the drop test, a head-on crash and driving on

setts, and the vehicle stability parameter by means of a sharp lane change, a

turn or a moose test.

The standard research procedures of the ride comfort

and stability parameters, by means of the drop test and the sharp lane change,

were adapted for use in the proposed vehicle computer model.

Research on the stability parameters of the vehicle

with the factory-made suspension system and with the suspension system on the

basis of the four-bar linkage assembly was performed. The vehicle with the

suspension system on the basis of the four-bar linkage assembly demonstrated a

60% decrease in the free vibrations frequency of the sprung mass, compared with

the vehicle with the factory-made suspension system. Research on the ride

comfort of the vehicle with the factory-made suspension system and with the

suspension system on the basis of the four-bar linkage assembly was also

performed. The vehicle with the suspension system on the basis of the four-bar

linkage assembly demonstrated a decrease in the roll angle of 37%, compared

with the vehicle with the factory-made suspension system, and a decrease in the

critical speed under the condition of an 8.3% stability loss.

References

1.

Мельничук

С.В., Ю.О.

Подчашинський,

І.В. Вітюк, І.А.

Бовсунівський.

2010. “Визначення

параметрів плавності

ходу моделі

підвіски на

основі чотириланкового

важільного

механізму”. Вісник

ЖДТУ 55 (4): 25-28. [In Ukrainian: Melnychuk

S., Y. Podchashynskyi, I. Vitiuk, I. Bovsunivskyi. 2010. “Determination of the

parameters of smoothness of the pendant model on the basis of a quadrilateral

lever mechanism”. Visnyk ZhDTU 55

(4): 25-28.]

2.

Мельничук

С.В., І.В. Вітюк,

І.А.

Бовсунівський.

2014. “До питання

підвищення

показників

плавності

ходу

автомобіля

категорії М1.

Програмно-апаратний

комплекс для проведення

натурного

дослідження

підвіски”. Сучасний

технології в

машинобудуванні

та

транспорті.

Науковий

журнал 1: 73-80. [In Ukrainian:

Melnychuk S., I. Vitiuk, I. Bovsunivskyi. 2014. “On the issue of increasing the

speed of the car category M1. Software and hardware complex for conducting a

full-time study of a suspension bracket”. Modern

Technology in Mechanical Engineering and Transport. Scientific Journal 1:

73-80.

3.

Бугаєв А.В.,

В.О. Занора, Р.В.

Юринець. 2008.

“Аналіз

сучасних

САПР і їх

порівняльна

характеристика”.

Вісник

ЧДТУ 1: 96-99. [In Ukrainian: Buhaiev A., V.

Zanora, R. Yurynets. 2008. “An analysis of modern spares and their comparative

characteristics”. Bulletin of the ChSTU

1: 96-99.]

4.

Tang A.H., O.

Jian, G. Hong Deng. 2010. “Modeling and kinematics characteristic analysis of

twist beam rear suspension using ADAMS/Car”. Advanced

Materials Research 139: 1056-1059. Trans Tech Publications.

5.

Shim T., P.C.

Velusamy. 2006. “Influence of

suspension properties on vehicle roll stability (No. 2006-01-1950)”. SAE

Technical Paper. DOI: https://doi.org/10.4271/2006-01-1950.

6.

Chen J., M. Qin,

Y. Jiang, L. Jin, Y.P. Chang. 2015. “Modeling, analysis and optimization of the twist beam

suspension system”. SAE International Journal of Commercial Vehicles

8 (2015-01-0623): 38-44.

DOI: https://doi.org/10.4271/2015-01-0623

7.

Волохов

О.С. 2008. “Моделирование

динамики

легкового

автомобиля с

учетом

взаимовлияния

продольных и

поперечных

сил в пятне

контакта

колес”. Вісник

Східноукраїнського

національного

університету

імені

Володимира

Даля 125 (7): 176-179. [In Russian: Volokhov O.S. 2008. “Modeling of passenger car dynamics, taking into

account the mutual influence of longitudinal and transverse forces in the

contact spot of wheels”. Bulletin of

the Volodymyr Dahl East-Ukrainian National University 125 (7): 176-179.]

8.

Гацько

В.І., М.А.

Подригало,

А.І. Коробко. 2010. “Підвищення

точності

вимірювання

параметрів

руху

автомобілів

у процесі

динамічних

випробувань”. Метрологія

та прилади.

Науково-виробничий

журнал 3: 49-52. [In Ukrainian:

Gatsko V.I., M.A. Podrygalo, A.I. Korobko. 2010. “Improvement in the accuracy

of the measurement of automobile movement parameters in the process of dynamic

testing”. Metrology and Devices.

Scientific and Production Journal 3: 49-52.]

9.

Артюшенко

А.Д., О.Г.

Суярков. 2013. “Дослідження

впливу

характеристик

підвіски

автомобіля

малого класу

на плавність ходу

та її

модернізація”. Вісник

НТУ«ХПІ».

Серія:

Транспортне

машинобудування.

Харків:

НТУ«ХПІ», 1004 (31): 21-27. [In Ukrainian:

Artyushenko A.D., O.G. Suyarkov. 2013. “Investigation of the influence of

characteristics of the suspension of a car of a small class on smooth running

and its modernization”. Bulletin of the

NTU “KhPI”. Series: Transport Engineering 1004 (31): 21-27. Kharkiv, NTU

“KhPI”.]

10.

Макаров

В.А., А.Є.

Бондаренко,

О.С. Волохов,

А.В. Куплінов.

2012. “До питання

визначення

похибок при

проведенні

експериментального

дослідження

курсової

стійкості

руху

автомобіля”. Вісник

Східноукраїнського

національного

університету

імені

Володимира

Даля 180 (9)

Частина 1: 131-136.

Луганськ. [In Ukrainian: Makarov

V.A., A.E. Bondarenko, O.S. Volokhov, A.V. Kuplinov. 2012. “On the issue of

determining the errors in conducting an experimental study of the exchange rate

stability of the car”. Bulletin of the

Volodymyr Dahl East-Ukrainian National University 180 (9) Part 1: 131-136.

Lugansk.

11.

Corman, F.,

D’Ariano, A., Pacciarelli, D. 2010. „Centralized versus distributed systems to

reschedule trains in two dispatching areas”. Public Transport 2(3): 219-247.

https://doi.org/10.1007/s12469-010-0032-7.

Received 10.08.2017; accepted in revised form 11.11.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License