Article citation information:

Margielewicz, J., Gšska,

D., Wojnar, G. Numerical modelling of toothed gear

dynamics. Scientific Journal of Silesian

University of Technology. Series Transport. 2017, 97, 105-115. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.97.10.

Jerzy

MARGIELEWICZ [1], Damian GĽSKA[2], Grzegorz WOJNAR[3]

NUMERICAL

MODELLING OF TOOTHED GEAR DYNAMICS

Summary.

This paper presents the results of computer simulations of a gear model, where

the variable stiffness of the meshing and backlash are considered. The outcome

of such assumptions is a non-linear mathematical model in which chaotic

phenomena can occur. During model studies, attention was paid to the

identification of areas limited by the physical parameters, for which the analysed

system behaved chaotically. To determine the ranges of irregular gear

behaviour, numerical procedures were used to plot the bifurcation diagram, the Lyapunov exponent, the amplitude-frequency distribution and

the Poincaré cross section.

Keywords:

dynamics; non-linear vibrations; chaos; toothed gear

1. INTRODUCTION

Heavy-duty machines, in particular

cranes, perform complex tasks with the result that heavy loads are transported

at close range. When transporting a load, it often happens that the operator is

forced to manoeuvre it to avoid collisions with surrounding obstacles. Making

safe manoeuvres is not possible without properly functioning enforcement

mechanisms. In every mechanism, there are toothed gears whose primary purpose

is to transform mechanical energy by reducing or multiplying angular speed.

Reducers used in crane hoisting mechanisms, whose ratios are in the range of 32÷100, are usually performed in three

stages. However, in the range of ratios from 112÷450, they are performed in four stages. Depending on the

manufacturer, two-speed gearboxes with gear ratios of 7÷50 are also used in the mechanisms. Such large gears allow for

lifting loads up to 500 t. The

typical range of crane-hoisting capacity ranges from 5÷50 t. The nominal torque at the gearbox output with gear ratios

from 7÷450 is in the range of 12÷660 kNm.

Single-stage gear units can also be used in low-level hoisting mechanisms.

The free meshing of the wheels is

ensured by the backlash and bottom clearance [17]. Their presence is one of the

main sources behind non-linearities appearing. Since

the mid-20th century there has been a growing interest among researchers in the

dynamics of non-linear systems [3,8,9]. Non-linearities

cause irregular intermittent forces in the gearboxes. It is believed that a

given phenomenon is chaotic if it is characterized by high irregularities.

Chaotic dynamics are evident when, in a two-run system, trajectories initially

located nearby expire exponentially over time [3]. Most commonly used in

computer simulations, gear models are based on non-linear differential

equations with variable coefficients. In gearing, the variation of coefficients

is mainly due to the stiffness of the meshing, which depends on the number of

pairs of teeth in the tooth contact. It is worth mentioning that the ratio of

stiffness of two-way and one-way meshing is usually in the range of 1.7 to 2 [16]. Its value depends, inter

alia, on the transmission ratio and the values of the shift coefficients [11,18,23].

The source of the excited vibrations of the cooperating pair of gear wheels is

also a deviation in the design and the position. Mostly, they are caused by

radial run-out and deviation in the tooth profile from the ideal position [15].

They are also often mapped via a function that is a superposition of several

harmonic components [7,22]. Mathematical models of toothed gears, in addition

to stiffness of the gearing, also take into account the susceptibility to

roller bearings on which the gears are mounted [25].

Studies of non-linear gear models

also deal with issues related to chaos. These analyses, inter alia, concern the

influence of individual parameters on the dynamics of the transmission [1,10,14,21].

In performed numerical experiments, the qualitative influence of the parameters

of the mathematical model characterizing single-stage gear on its dynamics was

investigated. To identify areas where chaos may have occurred, bifurcation

diagrams and charts of the maximum Lyapunov exponent

were created. It is believed that Lyapunovs maximum

exponent is one of the more reliable indicators for evaluating the chaotic

system, as its positive values indicate the irregular behaviour of the system

under study [2]. From a theoretical point of view, Lyapunov

exponents measure the sensitivity of the studied system towards initial

conditions and are interpreted as the average rate of dissipation along the

trajectory in the phase plane [4]. The bifurcation diagrams provide

quantitative and qualitative information on the doubling of the period, while

the qualitative properties are most conveniently investigated by fractal

geometry [19]. In this sense, it is worth mentioning that the term

bifurcation, within chaos theory, is understood as the division of the path

of solutions [13].

2. FORMULATION OF THE MATHEMATICAL

MODEL OF SINGLE-STAGE GEARING

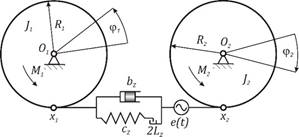

Gears with straight teeth were

modelled as a mechanical vibration system with two degrees of freedom. The

formulated model consists of two non-deformable discs with radii R1 and R2, whose inertial properties are mass moments of

inertia J1 and J2. The discs rotate relative

to the rigidly supported axis of rotation O1

and O2. The forces

generated in the engagement of the mating wheels are mapped in parallel onto

the joint of the spring cZ

element and dispersing element bZ. In addition, backlash 2LZ and the static error of the gearwheel cooperation e(t) have been considered. In model

studies, the gear wheel cooperation error is treated as a kinematic effect on

the cooperating teeth. The transmission is induced by the external torque M1, while the resistance

torque also affects the M2

gear. During the formulation of the phenomenological model, the influence of

errors caused by the positioning and the execution of the gears was omitted.

|

|

Fig. 1. Model of a toothed gear

Based on the phenomenological model,

differential equations of motion have been derived, which ultimately take on

the following form:

|

|

(1) |

It is more convenient to evaluate

the nature of the forces generated in meshing by using a reduced model with one

degree of freedom:

|

|

(2) |

where:

|

|

wZ = z1×wS - frequency of meshing, wS - angular velocity of the motor, and z1 - number of pinion teeth.

The variable stiffness of meshing

plays a significant influence on the value of the forces acting on the gear

teeth, but is not a source of non-linearity. The main cause of non-linearity,

which occurs in numerical gear models, is the backlash 2LZ. Its presence ensures that the meshing wheels

are free to mesh and demesh. Most often, it is

modelled using non-linear functions with a so-called dead zone [12,24]:

|

|

(3) |

The simplest and least laborious way

to identify stiffness in a tooth is to treat it as a fixed beam. This approach

provides imprecise results, but can be used to perform initial computer

simulations. This approach calculates the angular displacement of the gear

wheel caused by the force acting on the gear tooth [20]. With this information,

it is still possible to estimate the average rigidity of one- and two-way

meshes by the following relationships:

|

|

(4) |

where:

![]() - angular displacement of the wheel at one-way

mesh, and

- angular displacement of the wheel at one-way

mesh, and ![]() - angular displacement of the wheel at two-way

mesh.

- angular displacement of the wheel at two-way

mesh.

Based on the above, and using the Cai formula [5,6], the variable stiffness of time function

is obtained. Modelling dynamic systems, whose properties are described by

discontinuous functions, is cumbersome. Considering the improvement in numerical

calculations, variable meshing stiffness is reproduced through the harmonic

function:

|

|

(5) |

where:

c0 - medium

meshing stiffness, and c1

- amplitude of the dynamic component.

To more accurately reproduce

variable meshing stiffness in the computer simulation, the discontinuous

functions shown in Fig. 2 can be expanded into a Fourier series. In view of the

efficient and effective conduct of numerical experiments, the mathematical

model in (2) was written in dimensionless form:

|

|

(6) |

where:

|

|

The consequence of dimensionless

writing and the introduction of a new coordinate represents the change in the

dead zone range, which is currently in the range of -1 to 1. Transforming the

mathematical model of a toothed gear in (2) to form (6) significantly

accelerates numerical calculations. This formulated mathematical model is the

formal basis for quantitative and qualitative computer simulations.

3. MODEL TESTS OF A TOOTHED GEAR

Sample model tests were carried out,

based on numerical data specifying a single-stage gear (Table 1). Model studies

were conducted using the computer program Mathematica (version 11).

Tab. 1

Parameters

characterizing the analysed system

|

Name |

Symbol |

Value |

|

Module |

|

5 [mm] |

|

Number of wheels (1

tooth) |

z1 |

14 |

|

Number of wheels (2

teeth) |

z2 |

85 |

|

Rotor mass moment

of inertia |

JS |

2.7 [kg m2] |

|

Drum mass moment of

inertia |

JB |

5.3 [kg m2] |

|

Wheel 1: mass

moment of inertia |

J1 |

0.0011 [kg m2] |

|

Wheel 2: mass

moment of inertia |

J2 |

1.12 [kg m2] |

|

Medium meshing

stiffness |

c0 |

5.03×108 [Nm-1] |

|

Amplitude of the

dynamic component |

c1 |

3.27×107 [Nm-1] |

|

Error of the gearwheel cooperation |

e1 |

0.01 [mm] |

|

Rated power of the

drive motor |

P |

12 [kW] |

|

Nominal speed of

the drive motor |

nS |

1,450 [obr/min] |

When performing computer simulations

in the formulated phenomenological model (Fig. 1), the inertia of the

electric motor rotor JS

and the rope winch drum JB were

considered. The

obtained results of numerical calculations illustrating the influence of

particular parameters of the mathematical model on the dynamics of gears are

presented in the form of bifurcation diagrams, as well as the maximal Lyapunov exponent, the time waveform of generalized

coordinates, the amplitude-frequency spectra and the Poincaré

cross sections.

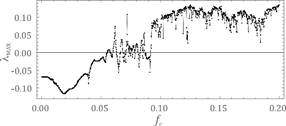

|

a) |

b) |

|

|

|

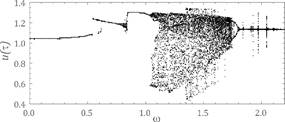

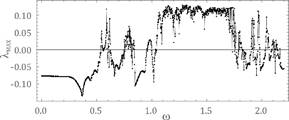

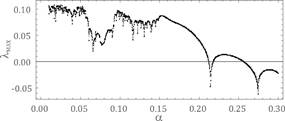

Fig. 2. Results of calculations showing the influence of frequency on

system dynamics obtained on the assumption of the following parameters: h=0.06, a=0.065, fr=0.044, fe=0,1 - a) bifurcation

diagram, b) maximal Lyapunov exponent

The time waveforms,

amplitude-frequency spectra and Poincaré cross

sections are further illustrated. However, it is limited to the illustration of

strange attractors arising on the phase plane, when the value of the

corresponding frequency of meshing is changed in the cooperating gear wheels.

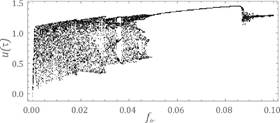

|

a) |

b) |

|

|

|

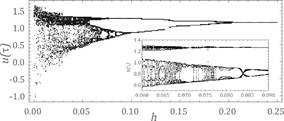

Fig. 3. Results of calculations showing the influence of frequency on

system dynamics obtained on the assumption of the following parameters: wť1.092, a=0.065, fr=0.044, fe=0.1 - a) bifurcation diagram, b) maximal Lyapunov

exponent

|

a) |

b) |

|

|

|

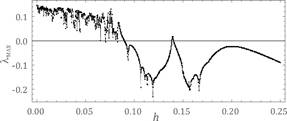

Fig. 4. Results of calculations showing the influence of frequency on

system dynamics obtained on the assumption of the following parameters: wť1.092, h=0.06, a=0.065, fr=0.044 - a) bifurcation diagram, b) maximal Lyapunov exponent

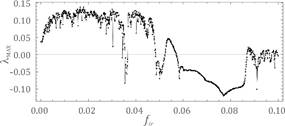

|

a) |

b) |

|

|

|

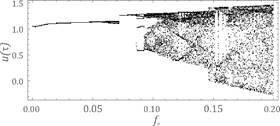

Fig. 5. Results of calculations showing the influence of frequency on

system dynamics obtained on the assumption of the following parameters: wť1.092, h=0.06, a=0.065, fe=0.1 - a) bifurcation diagram, b) maximal Lyapunov

exponent

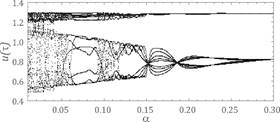

|

a) |

b) |

|

|

|

Fig. 6. Results of calculations showing the influence of frequency on

system dynamics obtained on the assumption of the following parameters: wť1.092, h=0.06, fr=0.044, fe=0.1 - a) bifurcation diagram, b) maximal Lyapunov

exponent

|

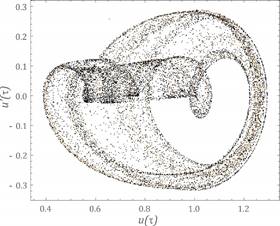

a) |

c) |

|

|

|

|

b) |

|

|

|

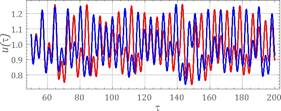

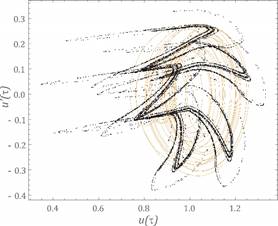

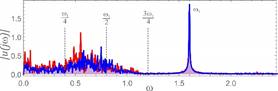

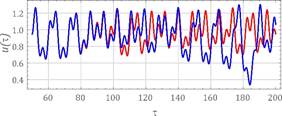

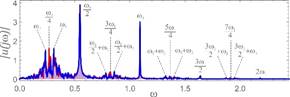

Fig. 7. Calculation results assuming the following parameters: w=1.6, h=0.06, k1=0.065, fr=0.044,

fe=0.1 - a) the time waveform, b)

amplitude-frequency spectra, c) Poincaré cross

section

|

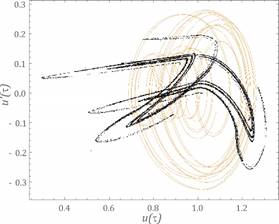

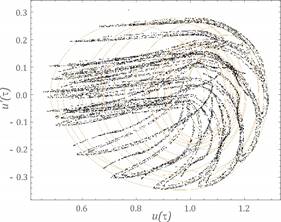

a) |

c) |

|

|

|

|

b) |

|

|

|

Fig. 8. Calculation results assuming the following parameters: w=1.5, h=0.06, k1=0.065, fr=0.044,

fe=0.1 - a) the time waveform, b)

amplitude-frequency spectra, c) Poincaré cross

section

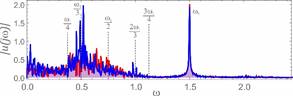

|

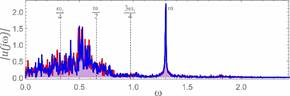

a) |

c) |

|

|

|

|

b) |

|

|

|

Fig. 9. Calculation results assuming the following parameters: w=1.3, h=0.06, k1=0.065, fr=0.044,

fe=0.1 - a) the time waveform, b)

amplitude-frequency spectra, c) Poincaré cross

section

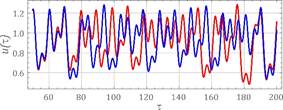

|

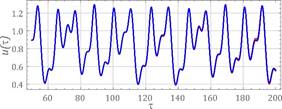

a) |

c) |

|

|

|

|

b) |

|

|

|

Fig. 10. Calculation results

assuming the following parameters: w=1.09246, h=0.06,

k1=0.065, fr=0.044, fe=0. 1 - a) the time waveform, b) amplitude-frequency spectra,

c) Poincaré cross section

Graphs showing time waveforms and

amplitude-frequency spectra also show the sensitivity of the system to the

initial conditions. They were prepared with the assumption that the difference

of initial displacements equalled e=0.0001. To identify strange attractors,

the Poincaré cross section was plotted against the

background of the phase portraits.

4. ANALYSIS OF RESULTS AND CONCLUSIONS

Based on the results obtained, it

was found that, when increasing the parameter fe, representing the

cooperation of the gears error, the maximum Lyapunov

exponent was positive (Fig. 4). Increasing stiffness a and damping h in the meshing reduces the phenomenon of chaos (Fig. 3

and Fig. 6). A similar effect on gear dynamics involved a parameter

that characterized the external forces acting on the gear units (Fig. 5).

Nevertheless, with their high values, chaotic phenomena can occur in the

transmission. In the case of the frequency parameter, the chaos dominates when

the meshing frequency is greater than the resonant frequency of the gear

(Fig. 2). In the considered dynamic gear model, the ratio of the meshing frequency

to the resonant frequency was about 1.092.

This value of parameter w did not show any noticeable sensitivity to the initial conditions (Fig.

10a). On the other hand, in the amplitude-frequency spectrum, harmonic

components, which are a combination of w1 and w2, dominate (Fig. 10b). On the basis

of computer simulations, it can be stated that strange attractors appear when

there are components in the amplitude-frequency spectrum corresponding to the

frequency of induction w = w1. In addition, the entire sequence of

components up to ¾w1 is excited. The shape of the

strange attractor is dependent on the dominance of harmonics located in the

range from ¼w1 to ½w1 (Figs. 7-9). The obtained results from the

model tests indicate that, when designing working machinery mechanisms,

particular attention should be paid to the proper selection of the drive motor.

From an operational point of view, the meshing frequency is one of the most

important parameters characterizing the dynamic properties of the drive system.

Its value significantly depends on the angular velocity of the impeller of the

drive motor and the number of teeth. Therefore, the rotational speed should be

chosen in such a way that the ratio of the meshing frequency to the resonant

frequency is outside the range where the behaviour of the system is chaotic.

References

1.

Al-Shyyab A., A. Kahraman. 2005.

Non-linear dynamic analysis of multi-mesh gear train using multi-term

harmonics balance method: sub-harmonic motion. Journal of Sound and Vibration 279: 417-451. ISSN 0022-460X.

2.

Awrejcewicz

Jan. 1995. Matematyczne metody mechaniki.

[In Polish: Mathematical

Methods of Mechanics.] Łód: Wydawnictwo

Politechniki Łódzkiej. ISBN

83-86453-42-7.

3.

Awrejcewicz

Jan. 1997. Tajemnice nieliniowej dynamiki.

[In Polish: Secrets

of Non-linear Dynamics.] Łód: Wydawnictwo Politechniki Łódzkiej. ISBN 83-87198-07-2.

4.

Baker Gregory, Gollub Jerry. P. 1998. Wstęp

do dynamiki układów chaotycznych. [In Polish: Introduction to the

Dynamics of Chaotic Systems.] Warsaw: PWN. ISBN: 8301126175

5.

Cai Y. 1995. Simulation on the

rotational vibration of helical gears in consideration of the tooth separation

phenomenon. Journal of Mechanical Design

117: 460-469. ISSN 1050-0472.

DOI:10.1115/1.2826701.

6.

Cai Y., T. Hayashi. 1994. The

linear approximated equation of vibration of a pair of spur gears. Journal of Mechanical Design 116:

558-564. ISSN 1050-0472. DOI: 10.1115/1.2919414.

7.

Ghosh S., G.

Chakraborty. 2016. On optimal tooth profile modification for reduction of

vibration and noise in spur gear pairs. Mechanism

and Machine Theory 105: 145-163. ISSN 0094-114X.

8.

Grega Robert, et al., 2017. Failure

analysis of driveshaft of truck body caused by vibrations. Engineering Failure Analysis 79:

208-215. ISSN 1350-6307.

9.

Grega Robert, et al. 2017.

Optimization of noisiness of mechanical system by using a pneumatic tuner

during a failure of piston machine. Engineering

Failure Analysis 79: 845-851. ISSN 1350-6307.

10.

Jingyue W., G. Lixin, W. Haotion. 2013.

Analysis of bifurcation and nonlinear control for chaos in gear transmission

system. Research Journal of Applied

Sciences, Engineering and Technology 6 (10): 1818-1824. ISSN 2040-7459.

11.

Jyoti D. Darbari,

Vernika Agarwal, Venkata

S.S. Yadavalli, Diego Galar,

Prakash C. 2017. A multi-objective fuzzy mathematical approach for sustainable

reverse supply chain configuration. Journal

of Transport and Supply Chain Management 11: 1-12. DOI:

10.4102/jtscm.v11i0.267.

12.

Kokare D. K., S.S. Patil. 2014. Numerical analysis of vibration in mesh

stiffness for spur gear pair with method of phasing. International Journal of Current Engineering and Technology,

Special Issue: 156-159. ISSN 2277 - 4106.

13.

Kozień M.S. 2000. Ćwiczenia laboratoryjne z miernictwa

dynamicznego. [In Polish: Laboratory Exercises with Dynamic

Measurement.] Cracow: Wydawnictwo Politechniki Krakowskiej.

14.

Litak G., M.I. Friswell.

2003. Vibration in gear system. Chaos,

Solution and Fractals 16: 795-800. ISSN 0960-0779

15.

Łuczko

Jan. 2008. Drgania regularne i chaotyczne

w nieliniowych układach mechanicznych. [In Polish: Regular and Chaotic

Vibrations in Non-linear Mechanical Systems.] Cracow: Wydawnictwo

Politechniki Krakowskiej.

ISBN 978-83-7242-492-1.

16.

Mężyk

Arkadiusz. 2002. Optymalizacja własnoci dynamicznych układów napędowych

maszyn. [In Polish: Optimization of dynamic properties of

machine drive systems.] Zeszyty Naukowe Politechniki lšskiej, Mechanika 139. ISSN: 0434-0817.

17.

Mężyk

Arkadiusz. 2002. Analiza i kształtowanie

cech dynamicznych napędów elektromechanicznych. [In Polish: Analysis and

Development of Dynamic Features of Electromechanical Drives.] Gliwice: Wydawnictwo Politechniki lšskiej. ISBN

83-7335-078-0.

18.

Müller

Ludwik. 1986. Przekładnie zębate -

dynamika. [In Polish: Toothed

Gears - Dynamics.] Warsaw: Wydawnictwa Naukowo-Techniczne. ISBN 83-204-0766-4.

19.

Peiting Heinz-Otto, Saupe Dietmar. 1996. Granice chaosu, fraktale. [In Polish: Limits of Chaos, Fractals.] Warsaw: PWN. ISBN 83-0111-784-2.

20.

Reszuta K., J. Drewniak.

2015. Komputerowo wspomagane modelowanie dynamiki przekładni dwudrożnej. [In Polish: Computer-aided modelling of two-way

transmission dynamics.] Mechanik

7: 715-724. ISBN 0025-6552.

21.

Shuang L., W. Jin-Jin,

L. Jin-Jie, L. Ya-Qian.

2015. Nonlinear parametrically excited vibration and active control of gear

pair system with time-varying characteristic. Chinese Physical Society 214 (10). DOI:

10.1088/1674-1056/24/10/104501.

22.

Wang J., J. Zheng,

Z. Yang. 2012. An analytical study of bifurcation and chaos in a spur gear

pair with sliding friction. In

International Conference on Advances in Computational Modeling

and Simulation, Procedia Engineering

31: 563-570.

23.

Wilk

Andrzej. 1981. Wpływ parametrów technologicznych i konstrukcyjnych na dynamikę

przekładni o zębach prostych. [In Polish: The

influence of technological and construction parameters on the dynamics of gears

with straight teeth.] Zeszyty Naukowe Politechniki lšskiej, Mechanika, z. 72. ISSN 0434-0817.

24.

Zhao X., C. Chen,

J. Liu, L. Zhang. 2015. Dynamics characteristics of a spur gear transmission

system for a wind turbine. In International

Conference on Automation, Mechanical Control and Computational Engineering:

1985-1990.

25.

Zhang Y., Z. Meng, Y. Sun. 2016. Dynamic modeling

and chaotic analysis of gear transmission system in a braiding machine with or

without random perturbation. Shock and

Vibration. Article ID 8457645. ISSN 1070-9622. DOI: 10.1155/2016/8457645.

Received 19.08.2017; accepted in revised form 07.11.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License