Article citation information:

Budzik, G., Mazurkow, A. Modelling and testing

of dynamic properties of C0-45 turbochargers. Scientific Journal of Silesian University of Technology. Series

Transport. 2017, 97, 17-25.

ISSN: 0209-3324. DOI:

https://doi.org/10.20858/sjsutst.2017.97.2.

Grzegorz BUDZIK[1],

Aleksander MAZURKOW[2]

MODELLING

AND TESTING OF DYNAMIC PROPERTIES OF C0-45 TURBOCHARGERS

Summary. The paper presents modelling process and results of the bench tests of

the C0-45, which is a turbocharger for heavy-duty diesel engines. For

turbochargers like this, it is necessary to measure the level of vibration. This paper presents the test results for 115

turbochargers. Rotor speed during the tests varied between 25,000 and 42,000

rpm. Rotor speed during the tests on a C0-45 turbocharger varied within three

ranges, i.e., Range I: n=25,000¸32,000 rpm and a=0.5g; Range II: n=33,000¸38,000 rpm and a=1.0g; Range III: n=39,000¸42,000 rpm and a=1.5g; (g=9.81m/s2). Measurement of

vibrations was realized by a sensor located on the body of the turbocharger.

Bench tests also included measurement of key charge parameters such as the

amount of mass trapped, mean flow velocities, turbulence level, gas pressure,

temperature and oil flow. The results are presented in the form of diagrams

showing the amplitude of the acceleration function with regard to the rotor’s

RPM. Research shows that using the correct parameters in construction and

technological processes of assembly are very important for the effective

functioning turbochargers.

Keywords: turbocharger; construction

parameters; dynamic properties; level of vibration; rotor speed

1. INTRODUCTION

Turbochargers are mainly used to

convert exhaust gases energy into compressed air energy. The air is pumped into

a fuel supply system in a combustion engine.

The basic operating parameters of a

turbocharger are: compression ratio, airflow, gas temperature, a maximum

rotating speed and a level of vibration. The operational accuracy of a rotating

set is tested with the use of an engine test stand.

2. TURBOCHARGER TEST STANDS

Each turbocharger is tested with the use of an engine

test stand (Fig. 1). This facility checks the assembly quality and cooperating

parts. Operational characteristics and the measurement of vibrations are also

determined.

The main elements of an engine test stand are:

-

turbocharger mounting brackets

-

combustion chamber with a fuel system

-

installation of air

-

lubrication system

-

measuring and control system

-

exhaust system

Fig. 1. Stand

test for C0-45 turbochargers and the vibration sensor

Measurement of vibrations is performed by a sensor

(Fig. 1), which estimates the level of acceleration of a rotating unit system

in a turbocharger. The sensor is located on the body of the turbocharger.

The level of vibrations is a basic requirement that

guarantees a proper operation and the usage of a turbocharger. Measurement is

performed during a set motion. Rotor speed for a C0-45 turbocharger varies

between 25,000 and 42,000 rpm. Commissioning requirements determine the values

of maximal acceptable accelerations, depending on the rotating speed of a

turbocharger rotor.

3. TEST STAND RESULTS

Operating parameters values for a C0-45 turbocharger

are:

-

compression ratio

2.8:1

-

airflow 31÷76 [m3/min]

-

gases temperature

700 [°C]

-

maximal rotating

speed nwmax=42,000 [rpm]

Values of acceptable vibrations during tests of

rotating speeds for a turbocharger C0-45 are varied across three ranges:

-

Range I: 25,000≤nw≤32,000

[rpm], adop≤0.5g

-

Range II:

33,000≤nw≤38,000 [rpm], adop≤1.0g

-

Range III:

39,000≤nw≤42,000 [rpm], adop≤1.5g

where g=9.81 m/s2 equates to gravitational acceleration.

Factory acceptance tests have demonstrated that a

large number of turbochargers, even when featuring suitable parameters

(consumption, compression ratio), is not able to work.

During acceptance testing of 115 turbochargers, it was

found that measured accelerations varied between 0.01 and 10.0 g. It should be

noted that maximal acceptable accelerations can reach up to 1.5 g.

The reason why turbochargers are not used concerns

excessive measured values of acceptable accelerations. Having tested all

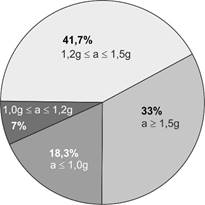

turbochargers, 33% of them do not meet the requirement concerning boundary

vibration values (Fig. 2).

Fig. 2. Percentage

of turbochargers according to vibration range level

Turbochargers that meet commissioning requirements can

be divided into two groups. The first group includes turbochargers that

work in upper ranges of vibrations (0.8g<adop≤1.5g) and the

second group includes turbochargers that work in lower ranges (adop≤0.8g).

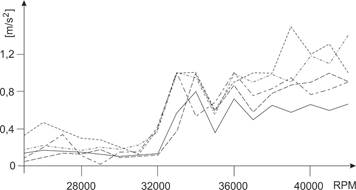

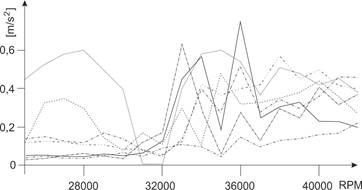

The diagram (Fig. 3) describes vibrations in an rpm function for the first

group of turbochargers, whereas the second group is presented in Fig. 4.

Fig. 3. Level of vibration of turbochargers (adop≤1.5g) during the rpm

function

Fig. 4. Level

of vibration of turbochargers (adop≤0.8g)

during the rpm function

Having examined vibration measurements for the first

group in the range 0≤nw≤42,000 rpm, we can note two resonant

zones. The first zone appears during the rotating speed nw=32,000 rpm, while

the second zone appears close to a speed equal to nw=38,000 rpm.

Ranges of resonant zones agree with the operating ranges of turbochargers.

The second group of turbochargers features small

vibrations values. In this case, there is only one resonant speed, which

appears at higher rotational speeds, i.e., nw=32,000÷37,000 rpm.

4. ANALYSIS OF TEST STAND RESULTS

Taking into account the testing results, we can see

that the right choice of construction and technological parameters of a

rotating set can guarantee the correct operating parameters of turbochargers.

Turbochargers with excessive acceptable vibrations

were disassembled in order to find reasons for this situation. Then, rotating

units were balanced again. The assembled turbochargers were tested once more.

It was not always possible to achieve the right

operating parameters of a turbocharger during another assembly because of

vibrations level. Therefore, these actions were repeated to achieve the proper

operating parameters.

5. THEORETICAL MODEL OF A ROTATING SET IN A

TURBOCHARGER

To assure the correct work of a turbocharger, it is

important to find sources of excessive vibrations and minimize them.

Theoretical bases for rotor construction and explanations for vibrations in

rotating sets are discussed in [1,4,7].

Test stand studies have shown that the main cause of

rotational motion disturbances in a rotating set within a turbocharger is

centrifugal fictitious forces, which appear because the axis of rotation does

not agree with the main axis of a rotating set. These different axis locations

are caused by the imbalance in rotating masses. The disequilibrium allows

centrifugal fictitious forces to appear. These forces constitute outer driving

forces and could lead to resonance.

It should also be mentioned that gravitational forces,

which act upon rotating parts, can be the source of vibrations.

Another cause of vibrations can be related to medium

resistance in the area where rotors are working.

The bearing mounting plays an essential part in rotor

operations. Slide bearings with an embedded rotor could be the reason for

hydrodynamic forces, which in turn contribute to self-activating vibrations in

the oil layer [2,3,4,5,6,8]. In the discussed turbocharger, a rotating unit is

supported in hydrodynamic bearings with a floating ring bearing.

The following reasons for vibrations have been

accepted by the author for the purposes of a design model:

-

imbalance in

turbocharger rotors

-

the mass of parts

in a rotating unit

-

floating ring

bearing masses

-

radial clearance

in a lateral slide bearing with floating ring.

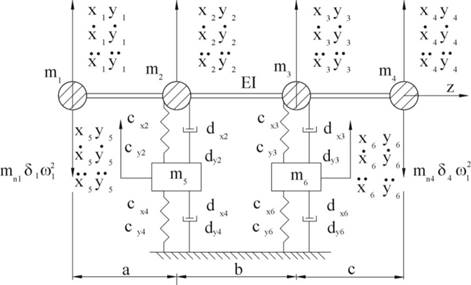

To explain these reasons shown above, the author has

designed a dynamic model for the rotating unit of a turbocharger (Fig. 5).

Rotors in a turbine and on the compressor side have different masses and

different unbalance values. In this model, each bearing has been modelled,

including a floating ring bearing mass. Moreover, attention has been paid to

rigidity and damping factors, as well as both oil films’ ability concerning

vibration damping. The motion of the

model is examined in two planes, i.e., 0XZ and 0YZ. The rigidity factors (cx,

cy) and damping factors (dx, dy) are treated

as coupled values.

Fig. 4. Model of a

rotating set

A mathematical version of the presented physics model

is constituted by motion equations, which are written according to the force

method for each mass of this model in planes OXZ and OYZ and can be expressed

thus:

![]()

![]() (1)

(1)

where matrixes take the form:

Values describing the work of a rotating

set are shown in Tab. 1. The influence of structural parameters on static and

dynamic characteristics is described in Tab. 2, while Table 3 presents

published results of the influence of unbalance on displacement amplitude in

knots of rotating sets.

Tab. 1

Given parameters for calculations of a rotating unit

|

Bearing loads [N] |

||||||

|

Fw=2=400-600 |

Fw=3=370-550 |

|||||

|

Rotational speed of a shaft [rpm]= |

||||||

|

n1=w1/2p=300-500 |

||||||

|

Concentrated masses in particular nodes [N∙s2/m] |

||||||

|

m1=5.0 |

m2=0.3 |

m3=0.25 |

m4=2.0 |

|||

|

Masses of floating ring bearings [N∙s2/m] |

||||||

|

m5=0.055-0.1176 |

m6=0.055-0.1176 |

|||||

|

Geometric parameters of rotating unit |

||||||

|

a=0.055 [m] |

b=0.075 [m] |

c=0.045 [m] |

Ix=0.15∙10-6

[m4] |

|||

|

Material constants |

||||||

|

E=1.915∙1011[N/m2] |

ISO VG 150 |

|||||

|

Unbalance of rotating masses [N∙s2] |

||||||

|

Nw1=0.18∙10-4,

0.88∙10-4 |

Nw4=0.5∙10-5 |

|||||

|

Geometry of bearings with a floating ring |

||||||

|

Slide bearings width [m] |

||||||

|

Bw1=0.017 |

Bw4=0.017 |

|||||

|

Radius of journal [m] |

||||||

|

(RJ1)w1=10.82-15.82∙10-3 |

(RJ1)w4=10.82-15.82∙10-3 |

|||||

|

Floating ring bearing thickness [m] |

||||||

|

(gp)w1=2.97-12.97∙10-3 |

(gp)w4=2.97-12.97∙10-3 |

|||||

|

Relative clearance of inner bearing [‰] |

||||||

|

(y1)w1=6.28-15.5 |

(y2)w4=2.8-12.4 |

|||||

Tab. 2

Influence of structural parameters

on the operating parameters of a rotating set

|

Characteristics |

|||

|

Static |

Dynamic |

||

|

h1,2,min ¯ |

T1,2 max ¯ |

p1,2max ¯ |

Ap(x5,

x6, y5, y6) ¯ |

|

yi ¯ |

yI ¯ |

yi |

yi ¯ |

|

C*R

¯ |

C*R

|

C*R

|

C*

¯ |

|

|

|

|

mp

|

|

B*

¯ |

B*

|

B*

|

B*

|

|

|

|

|

Nw¯ |

|

Tz

|

Tz

¯ |

Tz

¯ |

|

Tab. 3

The influence of unbalance on

displacement amplitude in knots of rotating sets

|

Unbalance of rotating masses |

Displacements amplitude in knots of rotating sets

[m] |

|||||

|

x1 |

x2 |

x3 |

x4 |

x5 |

x6 |

|

|

Task 1 Nw1=0.18∙10-4, Nw4=0.5∙10-5 |

2.267∙10-6 |

1.266∙10-6 |

1.162∙10-6 |

2.344∙10-6 |

0.2682∙10-6 |

0.2351∙10-6 |

|

Task 2 Nw1=0.88∙10-4, Nw4=0.5∙10-5 |

6.908∙10-6 |

6.19∙10-6 |

8.431∙10-6 |

13.16∙10-6 |

1.577∙10-6 |

2.076∙10-6 |

|

|

y1 |

y2 |

y3 |

y4 |

y5 |

y6 |

|

Task 1 Nw1=0.18∙10-4, Nw4=0.5∙10-5 |

3.641∙10-6 |

3.185∙10-6 |

2.971∙10-6 |

3.203∙10-6 |

0.5455∙10-6 |

0.3799∙10-6 |

|

Task 2 Nw1=0.88∙10-4, Nw4=0.5∙10-5 |

17.63∙10-6 |

22.04∙10-6 |

29.43∙10-6 |

34.82∙10-6 |

3.441∙10-6 |

4.067∙10-6 |

6. CONCLUSION

Table 2 shows that the influence of structural

parameters on static and dynamic characteristics can be, on the one hand,

contradictory (e.g., the feed oil temperature and the minimal height of a

lubricant gap) or, on the other hand, compatible (e.g., the feed oil

temperature and the oil film maximum temperature).

The

unbalance is an influence factor on displacement values (Table 3). In Task 1,

the unbalance was Nw1=0.18∙10-4

[N∙s2]; however, in Task 2, it was Nw1=0,88∙10-4

[N∙s2]. Having compared these two tasks, it can be seen that

in the Knot 4 displacements, the amplitude increases 11 times for the

coordinate y4. The smaller values of displacements appear in Task 1.

The professional literature and

published results show that vibrations appear during the construction stage,

particularly during parts formation or turbocharger assembly. Subsequent

research will deal with the misalignment of bearings on a turbine and the

compressor side or mistakes made to the shape of bearing bushes and their

influence on the level of vibrations in a rotating unit.

References

1.

Buluschek Bruno.

1980. Das Schwimmbüchsenlager bei stationärem Betrieb. Doctoral thesis. Zürich:

ETH. No. 6527,0000.

2.

Domes Bernd. 1980.

Amplituden der Unwucht - und

Selbsterregen Schwingungen Hochtouriger mit Rotierenden und nichtrotierenden

Schwimmenden Büchsen. [In German: Amplitudes

of Unbalance and Self-raising Vibrations at High Speed with Rotating and Non-rotating

floating cans.] Dissertation. Universität Karlsruhe.

3.

Fink Peter.A.

1970. Das Schwimmbüchsenlager unter

instationärer Belastung. [In German: The Floating Bush Bearing Under Transient Load.] Dissertation.

Zurich: ETH.

4.

Kiciński Jan.

2005. Dynamika wirników i łożysk

ślizgowych. [In Polish: Dynamics of

Rotors and Plain Bearings.] Gdańsk: Wydawnictwo Instytutu Maszyn

Przepływowych PAN. ISBN 8388237063.

5.

Krause Reinhold.

1987. Experimentelle Untersuchung eines

dynamisch beanspruchten Schwimmbüchsenlagers. [In German: Experimental Investigation of a Dynamically

Loaded Swimming Pool Bearing.] Dissertation. Zürich: ETH. DOI

10.3929/ethz-a-000403016.

6.

Chin-Hsiu Li, S.H.

Rohde 1980. “On steady state and dynamic performance characteristics of

floating ring bearings”. ASME Journal of

Lubrication Technology 103 (3): 389-397. DOI 10.1115/1.3251687.

7.

Muszyńska A. 1979.

“Modelowanie wirników”. [In Polish: “Rotor modelling”.] IV training course

from the Dynamics of Machines series, Jabłonna 5-10 Listopada 1979.

8.

Zhang W. “Dynamic

instability of multi-degree-of-freedom flexible rotor system due to full annular

rub”. In Vibrations Rotating Machinery,

International Conference, Heriat - Watt University, Edinburgh, 13-15 September

1988.

Received 20.08.2017; accepted in revised form 11.10.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License