Article citation information:

Bisták, M., Brumerčík, F., Lukáč, M. Weighing

systems in traffic. Scientific Journal of

Silesian University of Technology. Series Transport. 2017, 97, 5-15. ISSN: 0209-3324.

DOI: https://doi.org/10.20858/sjsutst.2017.97.1.

Marek BISTÁK[1],

František BRUMERČÍK[2],

Michal LUKÁČ[3]

WEIGHING

SYSTEMS IN TRAFFIC

Summary. This article presents a brief overview of

weighing systems and devices designed to facilitate fluent and safe road

traffic. The number of vehicles on roads is perpetually on the rise, resulting

in increased wear of road surfaces. This is why weight check gates have widely

been implemented to check the speed and weight of a vehicle against what is

permitted by law. A cheaper, albeit more time-consuming, traffic weighing

alternative would involve weighing points using weighbridges or mobile axle

scales. The second part of this article examines the development of an axle

scale. The design and calculation works were performed with the use of the Creo

Parametric CAD system and the ANSYS Workbench FEM system.

Keywords: dynamic weighing system axle scale;

load cell vehicle

1. INTRODUCTION

The primary expectation of transport

infrastructure is the assurance of traffic safety and fluency [10,11,12]. To be

able to meet this requirement, motorways, roads, bridges and other traffic

structures must have their pavement in an appropriate technical condition. The

growing number of vehicles increases the load on roads and their speed of their

deterioration, resulting in an impaired road pavement quality. In order to

maintain roads in a good condition, in addition to ensuring regular road

maintenance and repair, it is necessary to exclude, or impose limitations on,

the traffic of unfit categories of vehicles. Such vehicle categories could

include those failing to meet technical requirements (in terms of dimensions,

weight etc.), as well as overloaded trucks exceeding the permitted total mass.

To achieve this, statutory weight

limits have been established by law for each vehicle category. The

implementation of the new legislation has been accompanied by the development

of technical devices to check compliance with the limits. Since it is not

feasible to have all vehicles stopped and weighed at a single point, it has

been necessary to develop a system that will be able to determine the weight of

a vehicle, within a reasonable range of accuracy, while the vehicle is in

motion. Vehicles suspected of non-compliance with the weight limitation

regulations will thus be identified and can be safely stopped, with their mass

checked by means of a mobile axle weighing system or a weighbridge in a

suitable place.

2. VEHICLE WEIGHING SYSTEMS AND

DEVICES

Two weighing methods are recognized: dynamic

weighing and static weighing.

Static method

The static method requires the

vehicle to be in a static state on the scale; more specifically, where a

weighbridge or a small mobile scale is employed, either the whole vehicle or

the measured wheel, respectively, must be motionless. What is measured is the total

mass transmitted from all axles to the wheels over a 15-s time span. The

measured impulse is then processed and evaluated by the control electronics.

The weight reading is visible on a display or an external monitor.

Dynamic method

This method is used in high-speed

weight-in-motion (HS-WIM) systems and low-speed weight-in-motion (LS-WIM)

systems (more often referred to as axle weighing systems). With a HS-WIM

system, the vehicle is weighed as it passes over two or three sensors sunk in

the road pavement; the weighing is performed at speeds up to 250 km/h

(intervals of 1 s) without the driver noticing what happens. The measured

signal is processed within 0.5 s and the result that is obtained is either the

total mass or the load on each axle of the vehicle.

In the latter case, a number of axle

scales corresponding to the number of vehicle axles is set on a firm floor. The

measurement is performed as the wheels of each axle of the vehicle pass over

the axle scales at a speed of 10 to 15 km/h at intervals of 30 or 60 s. The

resulting weight of the vehicle (or weight per wheel or per axle) is calculated

from the acquired time course records.

2.1. High-speed weight-in-motion

system

The system is used on motorways and

expressways for the purposes of control monitoring the vehicle traffic flow.

The system checks compliance with the statutory speed and weight limits.

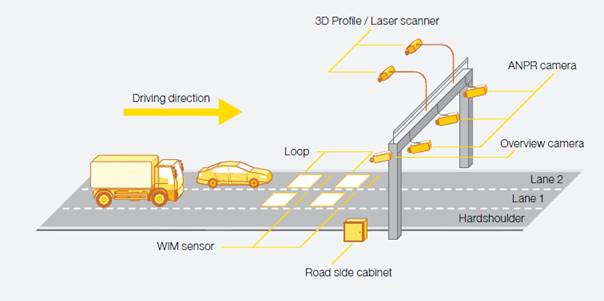

A WIM system is composed of a gate

with ANPR cameras, laser scanners and, possibly, other electronics to improve

the accuracy of the control cycle.

Fig. 1. High-speed weight-in-motion

system

Two to three piezoelectric sensors

(of the Kistler Lineas quartz type)

are installed in the pavement to weigh, with a high accuracy, a vehicle in

motion at up to 250 km/h. The control unit with evaluation electronics is

installed in a cabinet in a safeguarded location near to the check gate.

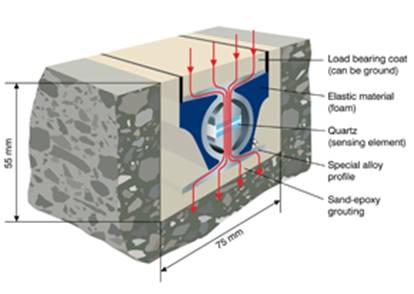

Kistler Lineas quartz sensor

The sensor consists of a weighbridge

mounted onto an aluminium alloy section. Two quartz plates are placed in the

middle of the section to generate an electric impulse when loaded (based on the

piezoelectric principle), with the signal directly proportional to the

gravitational force of the wheel. The sensor is isolated from lateral forces by

means of a special flexible material.

The load measurement accuracy is

neither influenced by the tyre type, tread pattern or pressure, nor the number

of tyres. In the case of dual tyres, the sensor generates a single signal,

which is expressed as a single-wheel load, equivalent to the sum of the two-wheel

loads.

The sensor is inserted in a slot in

the pavement and fixed by a grouting compound (supplied by the manufacturer)

made of an epoxy material and sand. The surface is then ground to a level [3,5].

Fig. 2. Kistler Lineas quartz sensor

design

Table 1. Technical parameters of the

Kistler Lineas 9195E sensor

|

Technical parameter |

Value |

|

Accuracy class [%] |

2 |

|

Range wheel load [kN] |

0-150 |

|

Load-bearing capacity on the

sensor surface [N/mm2] |

6 |

|

Operating temperature range

[ºC] |

-40÷70 |

|

Temperature coefficient

(sensitivity) [%/ºC] |

-0.02 |

|

Sensor length [m] |

1.5/1.75/2.00 |

|

Sensor length [m] |

40/100 |

|

Degree of protection |

IP 68 |

|

Position |

Stationary |

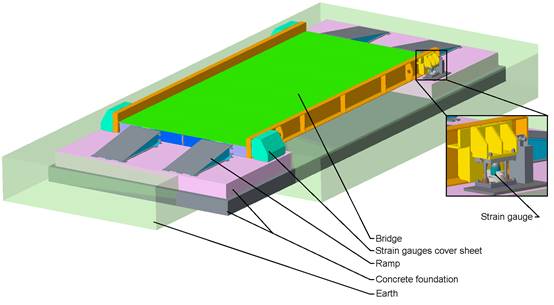

2.2. Weighbridge

A weighbridge is a device designed

to measure the weight of a passenger car, a truck, or a truck and trailer

combination. There are two basic design types: an above-ground version and a

pit version.

An above-ground weighbridge

comprises load cells, evaluation electronics, a weighbridge, an approach ramp

and a departure ramp. It is usually designed as a steel structure with a

weighing capacity between 1 and 80 t and a length ranging between 5 and 20 m.

The scale may be positioned on either a paved ground or a concrete road surface

that has a sufficient load-bearing capacity and is appropriately level. Where

the device is to be installed on a concrete road, concrete bases are usually

provided for the load cells. The design must reasonably provide for the

approach of a vehicle.

Fig. 3. Above-ground weighbridge

A pit-mounted road weighbridge does

not pose any obstacle and is, therefore, usually installed in locations where

the available space is limited by adjacent structures. The installation depends

on the prefabricated pit, the location layout and the slope of the road.

Lengths vary within the range of 8 to 24 m. The bridge may be designed as

either a steel structure with a load-bearing capacity of 60 t or a steel shell

filled with high-performance concrete with a load-bearing capacity of up to 120

t.

Fig. 4. Pit weighbridge

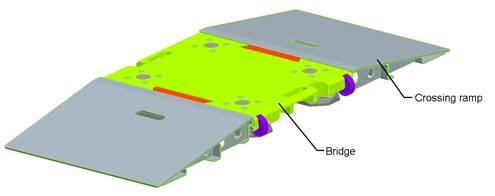

2.3. Axle measurement system

An axle measurement system comprises

a control and evaluation unit and an even number of axle scales (two scales for

each vehicle axle to be weighed).

An axle scale is made of an

aluminium weighbridge, which is set on four, six or eight load cells. The

measurement range is up to 3, 6, 10, 12 or 20 t. Smooth passage over the bridge

is facilitated by approach and departure ramps with a structure made of steel

or a hardened material [1].

The evaluation unit is enclosed in a

protective case made of a strong, but flexible, impact resistant copolymer to

ensure safety. During the measurement (using a static method, or a dynamic

method for LS-WIM systems), the unit processes the electric signal generated by

the scales, which is transmitted via 15-m cables or Wi-Fi. The resulting weight

reading is shown on the display or printed in a paper-based measurement report.

Fig. 5. Axle measurement system

3. AXLE SCALE DEVELOPMENT

The customer who initiated the

project requested six mobile scales to be developed for an existing control and

evaluation unit. The system was required to be able to weigh any vehicle with a

mass of up to 40 t and no more than three axles in any place with a paved

surface.

3.1. Requirements for the axle scale

development

Requirements for the axle scale

development are:

- Axle scale measuring range: up

to 10 t/wheel

- Maximum dimensions of a scale

with ramps: (WxLxH): 500x11,000x60 [mm]

- Scale capacity: vehicles with

two or three axles up to 40 t in weight

- Manufacturability within the

company’s own capacities

- Mobility and simple handling

- Reasonable project costs

3.2. Design of the chosen axle scale

alternative

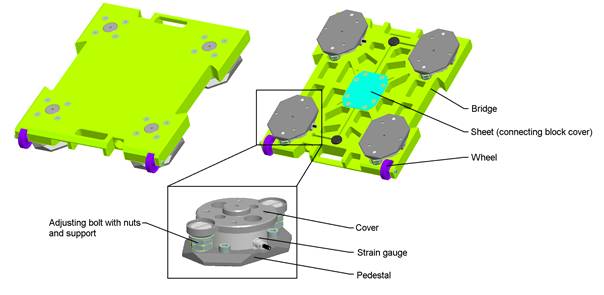

The axle scale system incorporates a

weighbridge and load cell units. The weighbridge is designed as an aluminium

alloy plate deck with weight reduction slots, two handles and sliding locks to

secure the passage ramps against movement. Two wheels are provided on the

right-hand side to facilitate the handling. The scale electronics is mounted on

the bottom side of the deck in a steel enclosure. The enclosure partially

enhances the rigidity of the deck. Four load cell units are screw-mounted to

the deck.

A load cell unit contains a HBM C9C

load cell, which is mounted in a slot of the unit base. Three screws are

provided on the base, turned by 120º to secure the sensor against movement

in the x-axis and y-axis directions (offset). A steel roller is fitted between

the top cover and the measurement surface of a tension meter to provide the

single-point force transmission. The top cover is fixed to the base by two screw

rods, each with two nuts [4,6].

Fig. 6. Axle scale

Fig. 7. Axle scale with a load cell

unit

Table 2. Technical parameters of the

designed axle scale

|

Description |

Unit/characteristics |

|

Weighing capacity [kg] |

10,000 |

|

Readability - scale division [kg] |

5 |

|

Nominal sensitivity [mV/ V] |

2±0.2% |

|

Function |

Weighing (static/dynamic) |

|

Weighing speed [s] |

≤10 |

|

Deck dimensions (WxL) [mm] |

500x400 |

|

Dimensions of the scale with ramps: (Wx LxH)

[mm] |

500x1,100x60 |

|

Scale weight [kg] |

35 |

|

Structure material |

Steel/aluminium |

|

Standard operating temperature [°C] |

-10÷40 |

|

Operating temperature limit [°C] |

-40÷70 |

|

Data transmission |

Cable |

|

Position |

Mobile |

|

Protection class |

IP 68 |

3.3. Simulation

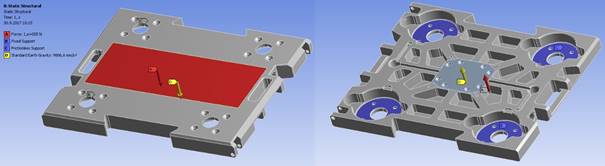

The proposed axle scale design was

subjected to an FEM-based strength analysis in the Static Structural module of

the Ansys Workbench software. The static weighing of a truck was simulated. The

simplified simulation model incorporated a weighbridge (material: aluminium

alloy) and a cabling enclosure (material: steel). The contact surface between

the deck and the truck wheel was modelled using an FEM mesh of 23,278 elements

with 43,209 nods. The contact surface was loaded with a force (F) of 100,000 N (the gravity transmitted

by a wheel from the axle). The seats of the load cell units were fitted by

means of a fixed support and a frictionless support. The model also provides

for the gravity of the weighbridge itself (gravitational acceleration (g) of 9.8066 m/s; see Fig. 8).

Fig. 8. Scale simulation model

3.4. Results

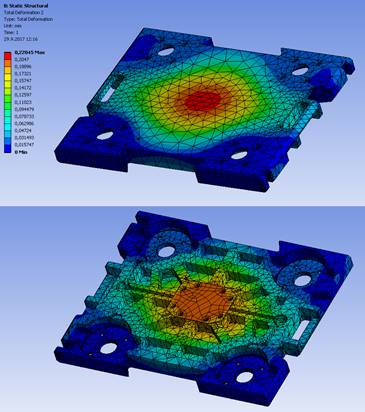

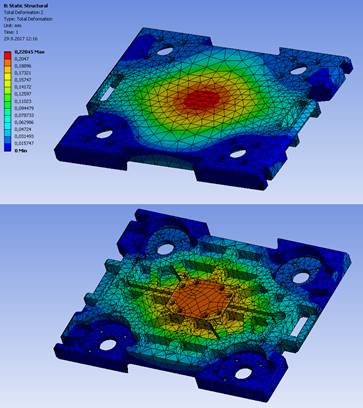

The outcome of the FEM simulation is

the maximum plate deflection of 0.221 mm and tensions ranging from 25 to 100

MPa, which occur in the centre of the bottom side of the scale (Figs. 9-10).

The agreed yield strength of the chosen aluminium alloy material is Remin=260 MPa and ultimate

tensile strength is Rm=675

MPa. The agreed yield strength of the chosen steel material is Remin=180 MPa and ultimate

tensile strength is Rm=380

MPa. The former implies that the proposed axle scale design meets the strength

requirements.

Fig. 9. FEM simulation result

Fig. 10. FEM simulation result

4. DISCUSSION

The FEM simulation in ANSYS

Workbench demonstrated that the proposed axle scale design meets the strength

requirements based on the anticipated loads. The FEM analysis results are

consistent with the strength calculations performed at the device development

stage. Hence, one pair of test prototypes was fabricated and tested in

practice. The test prototypes passed the tests successfully [2].

5. CONCLUSION

The first part of this article

provided a brief overview and description of weighing systems and devices

currently used in traffic applications. The second part of the article

described the development of an axle scale that meets all the requirements of

the customer. As a particular advantage, the scale features a mobile design,

easy installation and a favourable cost. The scale is able to weigh trucks with

two or three axles and a total mass of up to 40 t.

References

1.

Skrucany Tomas, Kendra Martin, Skorupa Milan,

Figlus Tomasz. 2017. “Comparison of chosen

environmental aspects in individual road transport and railway passenger

transport”. Procedia

Engineering 192: 806-811. DOI:

https://doi.org/10.1016/j.proeng.2017.06.139.

2.

Skrucany Tomas, Sarkan Branislav, Figlus

Tomasz, et al. 2017. “Measuring of noise

emitted by moving vehicles”. MATEC Web of

Conferences 107: 00072. ISBN:

978-1-5108-4114-7. DOI: https://doi.org/10.1051/matecconf/201710700072.

3.

IRD. “Lineas Quartz WIM Sensor by Kistler”. Available at:

http://www.irdinc.com/pcategory/wim-scales--sensors/lineas-quartz-wim-sensor-by-kistler.html.

4.

HBM. “C9C”. Available at:

http://www.hbm.cz/produkty/snimace-sily/c9c/

5.

Weighing Review. “Kapsch presents new weigh in motion

solution at ITS Europe”. Available at:

http://www.weighingreview.com/2013/12/kapsch-presents-new-weigh-in-motion.html.

6.

Walzscale. “Axle scale wheel weighers”. Available at:

https://www.walzscale.com/portable-wheel-axle-load-weighers.

7.

Samociuk W., Z.

Krzysiak, M. Szmigielski, J. Zarajczyk, Z. Stropek, K. Gołacki,

G. Bartnik, A. Skic, A. Nieoczym. 2016. “Modernization of the

control system to reduce a risk of severe accidents during non-pressurized

ammonia storage”. Przemysł Chemiczny

95 (5): 1032-1035. ISSN 0033-2496. DOI: https://doi.org/10.15199/62.2016.5.29.

8.

Samociuk W. Z.

Krzysiak, G. Bartnik, A. Skic, S. Kocira, B. Rachwał, H. Bąkowski,

S. Wierzbicki, L. Krzywonos. “Analysis of explosion hazard on propane-butane liquid

gas distribution stations during self tankage of vehicles”. Przemysł Chemiczny. 96 (4): 874-875.

ISSN 0033-2496. DOI: https://doi.org/10.15199/62.2016.5.29.

9.

Faturik L., Trsko L.,

Hrcek S., Bokuvka O. 2014. “Comparison of structural design in

high and ultra-high cycle fatigue regions”. Transactions

of FAMENA. 38 (4): 1-12. ISSN 1333-1124.

10.

Droździel Paweł,

Monika Wińska, Radovan Madleňák, Paweł Szumski. 2017. “Optimization of the position

of the local distribution centre of the regional post logistics network”. Transport Problems 12 (3): 42-74. ISSN

1896-0596. DOI: https://doi.org/10.20858/tp.2017.102.3.4.

11.

Droździel Paweł,

Iwona Rybicka, Radovan Madleňák, Aleksandra Andrusiuk, Dariusz Siłuch. 2017. “The engine set

damage assessment in the public transport vehicles”. Advances in science and technology Research Journal Vol. 10 (1):

117-127. ISSN 2299-8624. DOI: https://doi.org/10.12913/22998624/66502.

12.

Niels van Oort, Rob van Nes. 2017. ”Regularity analysis for optimizing

urban transit network design”. Public

Transport 1(2): 155-168. https://doi.org/10.1007/s12469-009-0012-y.

Received 11.09.2017; accepted in revised form 02.11.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License