Article citation information:

Vojtková, J.

Determining and verifying the geometric characteristics of helical

grooves in the worm in planetary toroidal drives in a more effective way. Scientific

Journal of Silesian University of Technology. Series Transport. 2017, 96, 197-204. ISSN: 0209-3324. DOI:

https://doi.org/10.20858/sjsutst.2017.96.18.

Jarmila VOJTKOVÁ[1]

Determining

and verifying the geometric characteristics of helical grooves in the worm in planetary

toroidal drives in a more effective way

Summary. In

the toroidal drive, a screw-shaped groove is cut into the globoid worm. There

is contact with the rolling element in this groove. This helix can be described

by parametric equations. When calculating the values of the first and second

curvature of the curve, as well as the radius of curvature, we must calculate

the individual derivations. A new, more effective way is to determine the

values already mentioned by using NX software only. When using Siemens PLM NX

software, it is not necessary to determine individual derivations and their

values, although the NX software determines the radii of the first and second

curvature, based on the defined helix curve.

Keywords: groove in the globoid worm; helix;

curvature; parametric equations

1. INTRODUCTION

In practice, different types of rolling

transmissions are used. The helical grooves in which the rolling elements are

rolled can be described by equations. These grooves correspond to the teeth in

the toothed gears. The values of the radii of curvature of the groove and the

rolling elements influence the contact pressures in the transmission. The

article deals with the values of the first and second curvature and the radii

of curvature of the helical grooves that are on a non-cylindrical surface.

Helical grooves can also be cut into a globoid or toroidal surface, mostly in

special rolling transmissions. An example is a toroidal planetary drive. So

far, the above-mentioned values, that is, the first and second curvature and

the radii of curvatures, have been solved only by mathematical methodology,

i.e., by calculating the individual partial derivations and then calculating

the radii of curvature. Siemens PLM NX10 software provides the option to

determine these required characteristics in a more efficient, simpler way,

without calculating derivations. The aim of this article is to propose a new

method, which is very effective on globoid and toroidal surfaces. On such

surfaces, the values of the radii of the first and second curvatures are

variable in their entirety.

After the design process, various types of

checks are performed (e.g., by FEM [1, 2]). Then, it is necessary to be mindful

of the diagnostics during the operation of the element (e.g., by non-invasive

methods [3-7]).

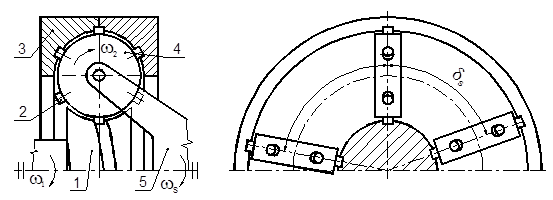

2. DRIVE Members

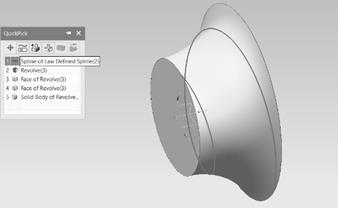

Mechanical planetary toroidal drives

consist of the following basic members (Fig. 1): 1) globoid worm, which is the

driving member, 2) rollers, 3) divided stator, 4) planet and 5) carrier. [8,

9]. Turning the worm into motion is provided by means of the rolling body in

the planet. Without a stator, the planet would only rotate around its own axis.

The carrier is activated by the grooves cut in the stator, which is the output

of the transmission. Such a drive can be classified as transmissions with very

low clearance and good efficiency [8].

Fig. 1. Planetary

toroidal roller drive

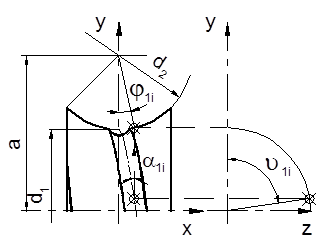

3. Screw

grooves in the globoid worm

There is a

screw-shaped groove in the globoid worm. In Fig. 2, there is a defined

general point of the helix before cutting the shape itself, which takes into

account whether the rolling elements are rollers or balls. For defining this

helix, which is the basis for the groove modelling, equations are used. When

describing parametric equations, the parameter used here is an angle, which is

a general parameter. In Siemens PLM NX software, the main parameters are first

determined by the command EXPRESSIONS,

namely, the number of grooves z1,

the number of rolling bodies in the planet z2,

the diameter of the worm d1

and the diameter of the planet d2

in the middle section. One groove in the worm is considered in the article,

i.e., z1 = 1. In

parametric equations, the angle parameter j1 is defined by the

vertical axis. The variance of the angle j1 is defined by the

parameter t, which takes values from

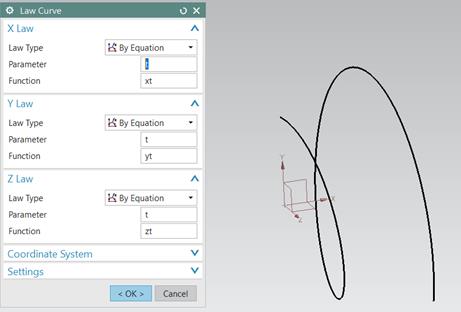

0 to 1 with a step. The helix is created as a LAW CURVE using coordinates xt,

yt, zt (Fig. 3). In Fig. 3, z1

= 1, z2 = 8, j1 = 60⁰.

Fig. 2. Helical

groove in the worm

Fig. 3. Law

Curve: helix on the globoid surface of half of the worm

The worm diameter at the general point (Fig. 2)

is:

![]() (1)

(1)

where d1

is the worm diameter in the middle section, d2 is the planet

diameter,

and j1is the

rotation of the planet from the vertical axis.

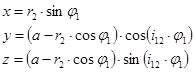

The helical groove

parametric equations are:

(2)

(2)

where:

x, y, z – Cartesian

coordinates of the helix point

a – internal axial

distance

r2 –

planet radius

i12

– gear ratio between rolling bodies and worm

For writing in the NX software, you need to define a variable angle

using the parameter t:

![]() (3)

(3)

where t is

a variable parameter from 0 to 1, and fi1 is maximum angle j1.

For the lead angle:

![]() (4)

(4)

where v is the circumferential

speed, and w is the

angular velocity.

For the

pitch:

![]() (5)

(5)

The screw groove in the worm is characterized by a constant pitch

(Equation 5), defined by the number of grooves in the worm and the number of

rolling bodies in the planet. The pitch of the helix varies, depending on the

diameter of the worm.

A helix with a radius of 50 mm and a pitch of 50 mm was used to verify

the software. For a cylindrical helix, the values of the first and second

curvatures are constant, but the values are different. The CURCE ANALYSIS command determines the value of the first radius of

curvature as a variable with a minimum of 50.6067 mm and a maximum of 51.6097

mm for 200 points on the helix. The calculation is the radius of 51.2665 mm.

The second curvature (torsion) is possibly found in More CURVE ANALYSIS Info.

The value of a standard helix with the above parameters is a minimum of

3.015375e-03 mm-1 and a

maximum of 3.145,624e-03 mm- 1,

as specified by the software. The second curvature (torsion) is calculated as

3.104,462e-03 mm- 1. As we can see, the accuracy levels are

very high.

Fig.

4. Helix on the surface of the worm for z2=8

For the globoid worm, the first and

second curvatures are not constant, but they vary depending on the ratio

between the worm and the planet i12,

as well as the ratio between the planet diameter and worm diameter.

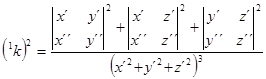

The first curvature of curve-squared

(for the general parameter φ):

(6)

(6)

where

the partial derivations are:

![]()

![]()

![]() (7)

(7)

For the radius of the first curvature of the

worm:

![]() (8)

(8)

For the second curvature of the

helix:

(9)

(9)

Tab. 1

Cartesian

coordinates of the helix in the worm,

worm diameter and lead angle for

d1= 90 mm, d2= 85 mm, z1=1, z2=6

|

j1 (⁰) |

Point (mm) |

d1 (mm) |

α1 (⁰) |

|

|

0 |

x |

0.000 |

90.000 |

8.945382 |

|

y |

45.000 |

|||

|

z |

0.000 |

|||

|

30 |

x |

21.250 |

101.388 |

7.954295 |

|

y |

-50.694 |

|||

|

z |

0.000 |

|||

|

60 |

x |

36.806 |

132.500 |

6.102780 |

|

y |

66.250 |

|||

|

z |

0.000 |

|||

In

Table 1, only three helix points are selected and their coordinates are calculated,

along with the value of the diameter d1i

and the angle α1. In

the calculation, the rounding of the coordinates to six decimal places in mm

and angles to eight decimal places in degrees was considered. Table 2 presents

the first curvature of the helix and its reciprocal value of the radius of

curvature. In the next column, the NX software defines the radius of curvature.

The difference between the radius of curvature is determined by the

calculation, with the rounding considered; the software value is small and

represents a variation of about 0.3%. In turn, it is possible to determine the

first and second curvature of the curve, as well as the radii of curvatures

using the NX software.

Tab.

2

The first and

second curvature of the helix, their radii of curvatures, as per the

calculation,

and the software NX for d1= 90 mm, d2= 85 mm, z1=1,

z2=6

|

j1 (⁰) |

1k calculation (mm-1) |

r1k calculation (mm) |

r1k NX (mm) |

2k calculation (mm-1) |

2k NX (mm-1) |

r2k calculation (mm) |

|

0 |

2.1116e-02 |

47.357 |

47.225 |

3.1321e-03 |

3.1131e-03 |

319.277 |

|

30 |

1.9105e-02 |

52.344 |

52.213 |

2.2494e-03 |

2.2173e-03 |

444.570 |

|

60 |

1.4986e-02 |

66.730 |

66.526 |

0.8252e-03 |

0.8256e-03 |

1,211.254 |

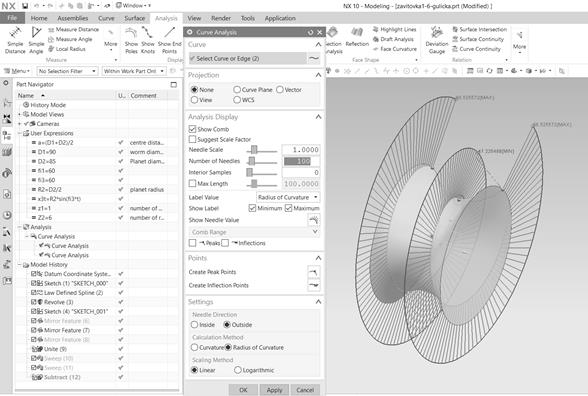

NX10 software allows you to

determine and display the values of the radius of curvature or the first

curvature at individual points, while their number can be determined as needed.

NX also allows you to specify minimum and maximum values, as well as other

data. Fig. 5 presents a graphic view of helix curve analysis with a scale and

extreme values of the radii of curvature. For the determination of the contact

pressure, it is necessary to determine the second curvature of the helix. The

second curvature of the curve (torsion) can be determined by listing the

individual values as needed. The software determines the points on the curve

according to parameter t, which

adjusts according to the number of points in which the data are to be detected.

The accuracy of the values varies slightly depending on the number of points.

Fig. 5 The radius of curvature of the helix in

the scale of NX software

4. CONCLUSION

In those transmissions where the rolling elements are in the screw

grooves on globoid and toroidal surfaces, it is necessary to determine the

radii of both curvatures of curves. Only certain software packages allow you to

determine both curvatures of curves. NX software lists, in addition to the

coordinates, the radius of the first curvature, or the first curvature of

curve, as well as the torsion, i.e., the second curvature of curve.

Furthermore, the curve values can be determined by using NX software, even

without calculating individual derivations, which appears to be a more

effective and faster method for determining both radii of curves. The accuracy

of the values is high. To determine values at specific points, it is better to

specify the point precisely because the software modifies the parameter t in its own way. This method can also

be used for other transmissions containing helices.

Acknowledgements

This paper was written in the

framework of the VEGA grant, “1/0473/17 Research and development of technology

for homogeneous charge self-ignition using compression in order to increase

engine efficiency and to reduce vehicle emissions”.

References

1.

Gąska

Damian, Tomasz Haniszewski, Jerzy Margielewicz. 2017. “I-beam girders dimensioning with numerical modelling of local

stresses in wheel-supporting flanges.” Mechanika

23(3): 347-352. ISSN 1392-1207.

2.

Wittek

Adam Marek, Damian Gąska, Bogusław Łazarz, Tomasz Matyja. 2014. “Automotive stabilizer bar – stabilizer bar

strength calculations using FEM, ovalization of radial areas of tubular

stabilizer bars.” Mechanika 20(6):

535-542. ISSN 1392-1207.

3.

Czech Piotr. 2012.

“Diagnosis of industrial gearboxes condition by vibration and

time-frequency, scale-frequency, frequency-frequency Analysis.” Metalurgija 51(4): 521-524. ISSN: 0543-5846.

4.

Czech Piotr. 2012.

“Identification of leakages in the inlet system of an internal combustion engine

with the use of Wigner-Ville transform and RBF neural networks.” In: Jerzy

Mikulski , ed., 12th International

Conference on Transport Systems Telematics. Katowice Ustron, Poland. 10-13

October 2012. Telematics in the Transport Environment. Book Series: Communications in Computer and Information

Science Vol. 329: 414-422. DOI:

http://doi.org/10.1007/978-3-642-34050-5_47. ISSN: 1865-0929. ISBN:

978-3-642-34049-9.

5.

Czech Piotr,

Henryk Madej. 2011. “Application of cepstrum and spectrum histograms of

vibration engine body for setting up the clearance model of the piston-cylinder

assembly for RBF neural classifier.” Eksploatacja i Niezawodnosc –

Maintenance and Reliability 4(52): 15-20. ISSN: 1507-2711.

6.

Figlus Tomasz,

Marcin Stańczyk. 2016. “A method for detecting damage to rolling bearings in

toothed gears of processing lines.” Metalurgija

55(1): 75-78. ISSN: 0543-5846.

7.

Figlus Tomasz,

Marcin Stańczyk. 2014. “Diagnosis of the wear of gears in the gearbox using the

wavelet packet transform.” Metalurgija 53(4): 673-676. ISSN: 0543-5846.

8.

Kuehnle M.R., H.

Peeken, Chr. Troeder, S. Ciernak, 1981. “The toroidal drive.” Mechanical Engineering 32(2): 32-39.

9.

Lizhong Xu, Fu

Linping. 2015. “Toroidal with half stator.” Advance

in Mechanical Engineering 7(6): 1-8. Available at:

http://journals.sagepub.com/doi/pdf/10.1177/1687814015589270.

Received 21.04.2017; accepted in revised form 25.07.2017

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under

a Creative Commons Attribution 4.0 International License