Article citation information:

Staniek, M. Detection of cracks in asphalt

pavement during road inspection processes. Scientific

Journal of Silesian University of Technology. Series Transport. 2017, 96,

175-184. ISSN:

0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.96.16.

Marcin STANIEK[1]

DETECTION OF CRACKS IN ASPHALT

PAVEMENT DURING ROAD INSPECTION PROCESSES

Summary.

Road inspection is one of key processes of a pavement management system, whose

function is to examine and describe the road infrastructure condition. When

thoroughly performed, it provides the information required to implement an

adequate road infrastructure maintenance policy and plan ad hoc repairs or

refurbishments. This article discusses a solution for automatic asphalt pavement

cracking detection, based on image-processing technology. This solution makes

it possible to identify different crack types, i.e., transverse, longitudinal,

alligator-type and technological cracks. The detection process is based on the

application of various methods, including statistical difference identification

for pre-assumed image analysis directions, i.e., in and opposite to the test

vehicle running direction. The purpose of the morphological and filtering

operations applied was to reduce the image noise level. The solution proposed

was verified using video material in the form of a sequence of images recorded

using the test vehicle.

Keywords:

microlinear asphalt pavement distresses; crack mapping; line detection; crack

pavement

1. INTRODUCTION

Every day around the world, there

are road accidents. Traffic participant faults, transport breakdowns and poor

road infrastructure contribute to their creation. It is most difficult to

eliminate the first mentioned causes [1, 2]. Appropriate diagnostics of the

means of transport (for example, by non-invasive methods [3, 4]) can reduce

their cause in road accidents. The last element is road infrastructure,

including the state of the roads.

Road pavement crack detection is one

of elements of the road inspection process. It comprises problems of crack

analysis [5, 6], crack classification [7], crack depth estimation [8, 9] and

crack sealing [10]. The most popular solutions used as asphalt pavement crack

detection tools are based on the analysis of dependent variables in the pixel

intensity function. A threshold value established by

the application of statistical measures of the image intensity function

determines whether pixels should be assigned to a crack or to its vicinity [11].

In the studies described

in [12, 13], the wavelet transform of an image was used to detect road pavement

cracks. A comprehensive analysis of multi-resolution was proposed, where the

determination of texture characteristic curves was based on the Haar,

Daubechies, Coiflet, ridgelet and curvelet transformations. A critical

assessment of multi-resolution analysis and statistical thresholding methods,

as well as edge detection and wavelet transforms, is provided in [14].

Machine learning-based

solutions for the detection of road pavement cracks are described in [15],

which reports on a study in which the graph cut segmentation technique [16, 17]

was applied to find crack and background regions in the image. For

classification purposes of cracks, specific characteristics were defined to describe

factors on which defects depended. The identified cracks were classified

according to individual sets: transverse cracking, longitudinal cracking, block

cracking or alligator-type cracking. The solution described in [18] is based on

a similar concept, the only major difference being that images are recorded

using vehicle windshield-mounted cameras. The sequence of images recorded shows

the road infrastructure, vehicles, pedestrians and buildings. Using simple

linear iterative clustering [19], the road pavement surface is extracted for

further calculations, while dependent variables of the intensity and texture

function are used to identify image descriptors. Analogically to the study

described in [15], characteristic curves describing the dependences

conditioning the occurrence of cracks were defined for the support vector

machine. Problems of crack detection have also been addressed in [20, 21, 22].

2. ASPHALT PAVEMENT CRACK DETECTION METHOD

The method proposed in this paper

for asphalt pavement crack detection is based on the analysis of differences

between dependent variables in the function of intensity of successive pixels

in an image line, with the mean dependent variable of the intensity function

calculated in the given image area. It takes into consideration the dependent

variable in the intensity function for the pixels, subject to analysis in the

detection process, such that specific objects, i.e., defects of another type

which do not belong to the pavement crack group, are cut off in the image. The determined threshold values make it possible to

unambiguously assign pixels of the image to the existing asphalt pavement

cracks. They are calculated for large image fragments, which increases the

probability of the adequate estimation of the threshold value in statistical

terms.

The proposed asphalt

pavement crack detection method comprises the following consecutive actions:

-

Road

image acquisition

-

Image

noise filtering

-

Image

breakdown into fragments

-

Determination

of mean dependent variables of the intensity function for preset image

fragments

-

Determination

of deviation values for a preset estimation window

-

Determination

of thresholding parameter levels

-

Identification

of pixels belonging to a crack group

-

Image

morphology operations

-

Segmentation

of image objects/crack identification

-

Creating

records of identified cracks

A sequence of asphalt pavement

images recorded by means of a CCD camera is used in the detection process. The

acquired image designated as I is

1,024 x 768 pixels in dimensions and features an 8 bit colour depth. The images are subject to low-pass filtering given by the

following formula:

![]() (1)

(1)

where:

p – cut-off threshold level estimated depending

on the illumination conditions during image acquisition

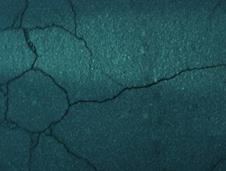

Once the filtering procedure is

completed, images are divided into fragments (Fig. 1) and the mean dependent

variable of the range intensity function is established. The proposed breakdown

results from the necessity to eliminate the non-uniformity of illumination, as

well as image distortions in the optoelectronic system which affect the

analysis of pixels and crack detection.

Fig. 1. Breakdown of a sample road

image into fragments

The assumed breakdown of image I into fragments of 64 x 64 pixels in

size constitutes a complete horizontal and vertical division of the image into

16 and 12 fragments, respectively. For the image

fragments subject to analysis, the mean dependent variable of the intensity

function is calculated according to the following formula:

![]() (2)

(2)

where G is the set of coordinates (i, j) of image I used to determine the mean dependent

variable of intensity function F with

indices (m, n), as given by the

following formula:

![]() (3)

(3)

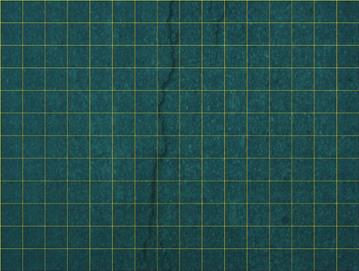

The next step in the detection

method consists of determining the value of deviation D for the given estimation window M, which has been defined as the n set of successive pixels in the given line or column of image I. A graphical interpretation of

estimation window M is provided in

Fig. 2.

Fig. 2. Graphical interpretation of

estimation window M for the value of

deviation D

On account of the assumed crack

detection methods, the procedure for determining the value of deviation D for the given estimation window M is performed twice, independently for

all lines (4) and all columns (8) of image I

under analysis, i.e., in the direction of the running test vehicle and in

the opposite direction.

(4)

(4)

where Mr

is the window for the estimation of deviation D in the dependent variables of the intensity function, given by a

set of coordinates (i’, j’), as

per Formula (5);

m is the horizontal index for the range of

the mean dependent variable of intensity function F, given by the following formula: ![]() ; and n

is the vertical index for the range of the mean dependent variable of intensity

function F, given by the following

formula:

; and n

is the vertical index for the range of the mean dependent variable of intensity

function F, given by the following

formula: ![]() .

.

![]() (5)

(5)

where pr

is the number of pixels analysed in a line to the left and to the right of the

base pixel with coordinates (i, j)

in image I.

The procedure for

determining the values of deviation Dc

for each preset estimation Mc

for all columns of image I under

analysis is conducted according to Formula (6):

(6)

(6)

where Mc

is the window for the estimation of deviation Dc in the dependent variables of the intensity function,

given by a set of coordinates (i’, j’),

as per Formula (7),

![]() (7)

(7)

where pc

is the number of pixels analysed in a column above and below the base pixel

with coordinates (i, j) in image

I.

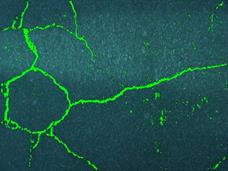

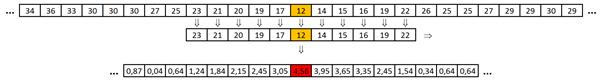

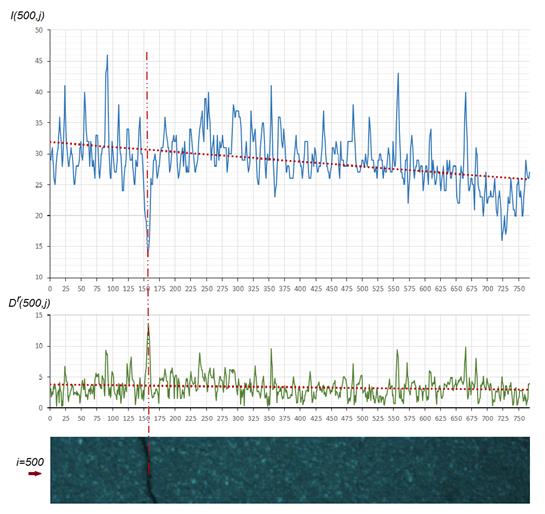

Fig. 3 presents an example of the

identification of pixels belonging to a specific group of asphalt pavement

cracks. It compares a graph of dependent variables in the intensity function

for image I in the given column (the

data of which are taken into consideration in the identification process), with

a graph of deviations Dr determined

for the pre-assumed estimation window of Mr. It additionally shows an image fraction with the analysed

line marked.

In the interests of the

automatic identification of cracks, for the initially determined values of

deviations Dr and Dc of all pixels in image I, two criteria were defined to allow

for the assignment of pixels depending on the analysis type: in lines (8) or in

columns (9).

(8)

(8)

(9)

(9)

where t1c, t2c

are the threshold values of column c analysed

in image I, chosen with reference to

a linear regression model developed by the application of the least-squares

method; and t1r, t2r

are the threshold values of line r analysed

in image I, chosen with reference to

a linear regression model developed by the application of the least-squares

method.

If one of the foregoing criteria

points at the analysed pixel meets with coordinates (i, j) in image I, then

it is a road pavement crack; otherwise, it is regarded as the background, i.e.,

the road image. In this way, a new road image of I’ is created with the locations of

cracks marked.

To enable the successful

identification and recording of cracks in image I’, one should perform a typical morphological operation, which

consists of closing objects. This constitutes a combination of the operations

of dilation and erosion, with the target object being 3 x 3 pixels in size [23].

What follows is an object segmentation procedure conducted with the application

of the region growing method [24].

Fig. 3. Graphical

representation of the crack pixels identification method

3. VERIFICATION OF THE PROPOSED SOLUTION

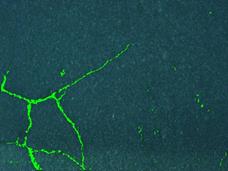

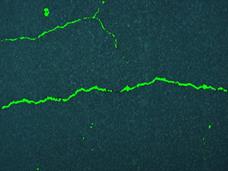

The asphalt pavement

crack detection method was verified using test material, recorded as a sequence

of images, which was taken by means of a stereo vision set installed on the

test vehicle. The studies were performed on local roads whose overall test road

section length came to about 1.6 km. Cracks were identified and recorded

for 1,281 images in video sequences, which corresponded to about 0.983 km of

the test road section. The cracks identified as a result of

the measurements were of the longitudinal, transverse and alligator types.

No technological cracks in the road pavement were found in the sections subject

to tests. Fig. 3 shows selected cracks identified in the asphalt pavement being

examined.

|

|

|

a) Longitudinal-type

crack |

|

|

|

|

|

b) Alligator-type

crack |

|

|

|

|

|

c)Transverse-type

crack |

|

|

|

|

|

d)Alligator-type

crack |

|

Fig. 4. Examples of identified

asphalt pavement cracks

4. CONCLUSION

The paper provides a discussion

concerning an automatic method of asphalt pavement crack detection, based on

the application of image-processing technologies and the statistical analysis

of the image intensity function. The studies addressed in the article provide

grounds for an assumption that, once it has been implemented, the method in

question enables crack detection at the level of 92% of all existing cracks

identified by manual visual inspection (i.e., by an expert conducting road

inspections). The solution assumed for this application makes it possible to

identify longitudinal, transverse and alligator-type cracks. Meanwhile, owing

to the segmentation operation, one can perform crack surface dimensioning and

establish both the type and the scope of the necessary repairs.

The follow-up research endeavours

involved in extending the detection method, as proposed in this paper, will

cover the identification of cracks where chipping of the asphalt pavement grain

can be observed. Further studies will also be undertaken to devise a method for

the detection of patches and potholes, with the aim of developing a

comprehensive tool for the identification of surface defects on asphalt road

pavements.

References

1.

Czech Piotr. 2017. “Physically disabled pedestrians -

road users in terms of road accidents.” In: E. Macioszek, G. Sierpiński, ed.,

Contemporary challenges of transport systems and traffic engineering. Lecture Notes in Network Systems, Vol.

2: 157-165. Springer. ISSN: 2367-3370. DOI:

https://doi.org/10.1007/978-3-319-43985-3_14.

2.

Czech Piotr. 2017. “Underage pedestrian road users in

terms of road accidents.” In: G. Sierpiński, ed., Intelligent

Transport Systems and Travel Behaviour.

Advances in Intelligent Systems and Computing, Vol. 505: 75-85. Springer.

ISSN: 2194-5357. DOI: https://doi.org/10.1007/978-3-319-43991-4_4.

3.

Czech Piotr. 2012.

“Diagnosis of industrial gearboxes condition by vibration and time-frequency,

scale-frequency, frequency-frequency analysis.” Metalurgija 51(4): 521-524. ISSN: 0543-5846.

4.

Madej Henryk,

Czech Piotr. 2010. “Discrete wavelet transform and probabilistic neural network

in IC engine fault diagnosis.” Eksploatacja

i Niezawodnosc – Maintenance and Reliability 4(48): 47-54. ISSN 1507-2711.

5.

Wang

Kelvin C., Weiguo Gong. 2005. “Real-time automated survey system of pavement

cracking in parallel environment.” Journal of Infrastructure Systems

11(3): 154-64. DOI: http://doi.org/10.1061/ASCE1076-0342200511:3154.

6.

Yaxiong

Huang, Bugao Xu. 2006. “Automatic inspection of pavement cracking distress.” Journal

of Electronic Imaging 15(1): 013017. DOI: http://doi.org/10.1117/1.2177650.

7.

Yukin

Sun, Ezzatollah Salari, Ellie Chou. 2009. “Automated pavement distress

detection using advanced image processing techniques.” In: Proceedings of

2009 IEEE International Conference on Electro/Information Technology, EIT 2009:

373-77. DOI: http://doi.org/10.1109/EIT.2009.5189645.

8.

Saha Arpita, Bhupendra Singh, Subhadip Biswas. 2017. “Effect of

nano-materials on asphalt concrete mixes; a case study.” European Transport/Transporti Europei

65: 1-12. ISSN 1825-3997.

9.

Saumya

Amarasiri, Manjriker Gunaratne, Sudeep Sarkar. 2010. “Modeling of crack depths in digital

images of concrete pavements using optical reflection properties.” Journal

of Transportation Engineering 136(6): 489-99.

DOI: http://doi.org/10.1061/(ASCE)TE.1943-5436.0000095.

10.

Haas

Carl. 1996. “Evolution of an automated crack sealer: a study in construction

technology development.” Automation in Construction 4(4): 293-305.

DOI: http://doi.org/10.1016/0926-5805(95)00010-0.

11.

Kim

Young S., Hyun S. Yoo, Jeong H. Lee, Seung W. Han. 2009. “Chronological

development history of X-Y table based pavement crack sealers and research

findings for practical use in the field.” Automation in Construction

18(5): 513-524. DOI: http://doi.org/10.1016/j.autcon.2009.02.007.

12.

Nejad

Moghadas, Fereidoon, Hamzeh Zakeri. 2011. “A comparison of multi-resolution

methods for detection and isolation of pavement distress.” Expert Systems

with Applications 38(3): 2857-2872. DOI: http://doi.org/10.1016/j.eswa.2010.08.079.

13.

Starck

Jean-Luc, Fionn Murtagh, Emmanuel J. Candès, David L. Donoho. 2003.

“Gray and color image contrast enhancement by the curvelet transform.” IEEE

Transactions on Image Processing 12(6): 706-717. DOI: http://doi.org/10.1109/TIP.2003.813140.

14.

Tsai

Yi-Chang, Kaul Vivek, Russell M Mersereau. 2010. “Critical assessment of

pavement distress segmentation methods.” Journal of Transportation

Engineering 136(1): 11-19. DOI:

http://doi.org/10.1061/(ASCE)TE.1943-5436.0000051.

15.

Moussa

Ghada, Hussain Khaled. 2011. “A new technique for automatic detection and

parameters estimation of pavement crack.” In: Fourth International

Multi-conference on Engineering Technology Innovation, IMETI. DOI:

http://doi.org/10.13140/2.1.3191.2001.

16.

Boykov

Yuri Y., Marie-Pierre Jolly. 2001. “Interactive graph cuts for optimal boundary

& region segmentation of objects in ND images.” In: Proceedings Eighth

IEEE International Conference on Computer Vision. ICCV 20011:105-112.

DOI: http://doi.org/10.1109/ICCV.2001.937505.

17.

Yin

Li, Jian Sun, Chi-Keung Tang, Heung-Yeung Shum. 2004. “Lazy snapping.” ACM

Transactions on Graphics 23(3): 303-308.

DOI: http://doi.org/10.1145/1015706.1015719.

18.

Achanta

Radhakrishna, Appu Shaji, Kevin Smith, Aurelien Lucchi, Pascal Fua, Sabine

Susstrunk 2010. “SLIC superpixels.” EPFL Technical Report 149300.

DOI: http://doi.org/10.1109/TPAMI.2012.120.

19.

Varadharajan

Srivatsan, Jose Sobhagya, Sharma Karan, Lars Wander, Christoph Mertz. 2014.

“Vision for road inspection.” In: 2014 IEEE Winter Conference on

Applications of Computer Vision: 115-122. DOI:

http://doi.org/10.1109/WACV.2014.6836111.

20.

Žuraulis

Vidas, Loreta Levulytė, Edgar Sokolovskij. 2014. “The impact of road

roughness on the duration of contact between a vehicle wheel and road surface.”

Transport 29(4): 431-439. DOI:

http://doi.org/10.3846/16484142.2014.984330.

21.

Byrne

Matthew, Tony Parry, Ricardo Isola, Andrew Dawson. 2013. “Identifying road

defect information from smartphones.” Road and Transport Research 22(1):

39-50.

22.

Kodippily

Sachi, Irina Holleran, Erik Glynn. 2016. “Characterising bitumen binders for

pavements in the Auckland region.” Road & Transport Research: A Journal of Australian and

New Zealand Research and Practice 25(4):

27-38. ISSN: 1037-5783.

23.

Cyganek,

Boguslaw, J. Paul Siebert. 2009. An Introduction to 3D Computer Vision Techniques and Algorithms.

Chichester, UK: John Wiley & Sons.

DOI: http://doi.org/10.1002/9780470699720.

24.

Bowyer,

Kevin, Narendra Ahuja. 1996. Advances in Image Understanding: A Festschrift

for Azriel Rosenfeld. Los Alamitos, USA: Wiley-IEEE Computer Society Press.

ISBN: 978-0-8186-7644-4.

Received 01.05.2017; accepted in revised form 25.07.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License