Article citation information:

Medvecká-Beňová, S. Strength analysis of the

frame of a trailer. Scientific Journal of

Silesian University of Technology. Series Transport. 2017, 96, 105-113. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.96.10.

Silvia MEDVECKÁ-BEŇOVÁ[1]

STRENGTH ANALYSIS OF THE FRAME

OF A TRAILER

Summary. A

trailer for carrying a small boat or water scooters was designed for a private

sector company. It was a category O1 non-braked trailer with a gross weight up

to 750 kg and a height-adjustable traction device. The frame must be designed

and installed in such a way that, during its proposed lifetime, it will

withstand all the loads and influences that may occur during construction and

operation with an appropriate level of reliability. The designed frame of the

trailer is a welded galvanized structure. The article is devoted to the

problems related to the stress analysis of a trailer frame.

Keywords: trailer; frame; design; strength

analysis; finite element method

1. INTRODUCTION

The design of a frame structure is based on the

knowledge and experience that are commonly available at the time the design is

proposed [7-8, 10, 11]. The supporting structure (frame) must be designed and

installed in such a way that, during its proposed lifetime, it will withstand

all the loads and influences that may occur during construction and operation

with an appropriate level of reliability. Furthermore, the designed support

(frame) structure must meet the relevant user requirements specified for the

support structure or supporting element. The support (frame) structure must be

designed to have the appropriate durability and usability.

Possible damage to the steel structure (frame)

must be eliminated or prevented by the appropriate choice of measures [6]. These include ensuring the integrity of the load-bearing

structure and selecting a support structure that is considered to be capable of

carrying an unforeseen loss of an individual element or enduring acceptable

local damage.

It is also important to take appropriate

diagnostics during operationalization into account, for example, by

non-invasive methods [1-4, 9].

2. trailer

for transporting boats and personal watercraft

A trailer was designed for a private

sector company. It was a non-braked trailer (category O1, gross weight up to

750 kg) with a height-adjustable traction device for carrying small boat or

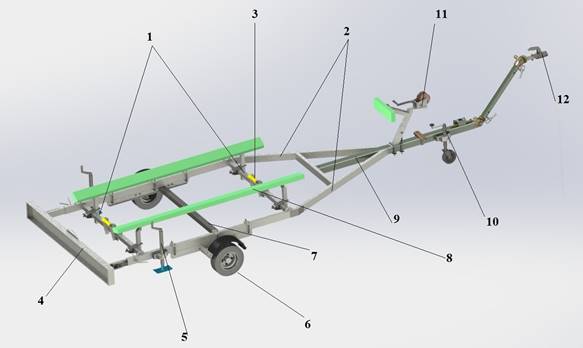

water scooters. The designed trailer and its accessories are shown in Fig. 1.

The support (frame) structure must

be designed to have the appropriate durability and usability.

Fig. 1. The designed trailer with

accessories

The descriptors for Fig. 1 are as

follows: 1) a cross beam; 2) longitudinal beam; 3) guide rollers; 4) a draw-out

light panel; 5) supporting leg with holder; 6) wheel; 7) axletree; 8) guide skis; 9) height-adjustable lift device; 10) supporting

wheel with holder; 11) height-adjustable reel; 12) connecting hinge.

The axle (position 7 in Fig. 1) is

mounted under the frame and fulfils the function of the intermediate transverse

beam. Between the axle (position 7 in Fig. 1) and the trailer frame are two

cross beams (position 1 in Fig. 1), which reduce stress and deformation on the

frame of the trailer. When loading and unloading a boat or water scooter, it is

necessary to immerse the trailer in the water. The trailer truck is designed to

have a total weight of not more than 750 kg. This means that the maximum

weight can be 450 kg because the weight of the separate trailer is 240 kg.

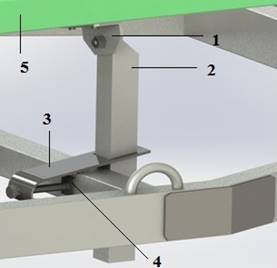

An important component is the boat

carrier for the transport of boats. It is attached to the frame by means of a

boulder clamp. The designed holder for the guide rail is shown in Fig. 2.

Position 1 is the top of the guide rail, which comprises 4 mm of thick sheet

metal. The centre holder of the cam chain guide is in

position 2. The bottom holder of the cam chain guide (position 3) also

comprises 4 mm of thick sheet metal. In position 4 is a screw with a washer, while a boat carrier is located in

position 5.

Fig. 2. The designed holder for the guide

rail

3. Design

of a trailer frame

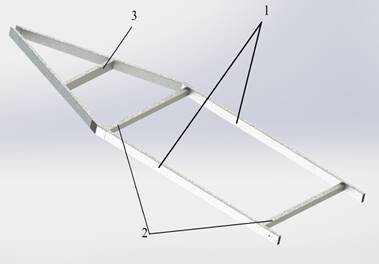

The designed frame of the trailer is

a welded galvanized structure. The frame consists of two longitudinal beams

(position 1), two cross beams (position 2) and one shorter cross beam (position

3), as shown in Fig. 3.

These elements are joined together

by welded joints. The overall frame dimensions are 5,200

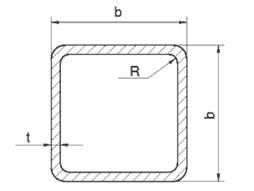

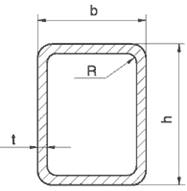

mm x 1,950mm. The longitudinal beams (position 1 of Fig. 3) are made of the profile 80 x 40 x 4 mm (h x b x t in Fig. 4).

The cross beams (position 2 of Fig. 3) are made of

the profile 50 x 50 x 4 mm (5 x b x t in Fig. 4) and the shorter cross

beam (position 3 of Fig. 3) is made of the profile 80 x

40 x 4 mm (h x b x t in Fig. 4).

All parts of

the frame are made of material W. Nr. 1.0039. This material has guaranteed

weldability.

Fig. 3. The frame of the designed

trailer

Fig. 4. The profile of the frame beams

4. Calculation

of fillet weld according to STN EN 1993-1-8

Welds are checked to connect the

cross beams (position 2 of Fig. 3) with the profile of the frame of the

trailer. The fillet weld is made around the circumference. The size of the filled weld is a = 2.1 mm (z = 3 mm). According

to STN EN 1993-1-8, the design resistance of the fillet weld is checked. Design

resistance to fillet welding is sufficient when conditions (1) and (2) are met.

![]() (1)

(1)

![]() (2)

(2)

where:

![]() – normal stress perpendicular to the plane of the weld [MPa]

– normal stress perpendicular to the plane of the weld [MPa]

![]() – shear stress (in the plane of welding) parallel to the

welding axis [MPa]

– shear stress (in the plane of welding) parallel to the

welding axis [MPa]

![]() – shear stress (in the plane of welding) perpendicular to the

welding axis [MPa]

– shear stress (in the plane of welding) perpendicular to the

welding axis [MPa]

![]() – nominal tensile

strength of the weaker of the joined parts [MPa]

– nominal tensile

strength of the weaker of the joined parts [MPa]

![]() – partial reliability factor [-]

– partial reliability factor [-]

![]() – relevant collector factor [-]

– relevant collector factor [-]

The

calculation follows:

![]()

![]()

Since the two conditions are met,

the weld is compliant.

To compare the results, this weld

was also checked using the standard calculation procedure according to the

following equation:

(3)

(3)

where:

![]() – result stress in the

weld [MPa]

– result stress in the

weld [MPa]

![]() – shear stress (in the plane of welding) parallel to the

welding axis [MPa]

– shear stress (in the plane of welding) parallel to the

welding axis [MPa]

![]() – shear stress (in the plane of welding) perpendicular to the

welding axis [MPa]

– shear stress (in the plane of welding) perpendicular to the

welding axis [MPa]

![]() – welding factor for the

given load direction [-]

– welding factor for the

given load direction [-]

![]() – welding factor for the given load direction

[-]

– welding factor for the given load direction

[-]

![]() – yield stress [MPa]

– yield stress [MPa]

![]() – coefficient of the thickness of the filled weld [-]

– coefficient of the thickness of the filled weld [-]

k – coefficient of security measure [-]

The

calculation follows:

![]()

Since the two conditions are met,

the weld is compliant.

5. Strength

analysis of the frame by FEM

Recently, given ever-faster evolving computer technology and the

available literature, we can encounter modern numerical methods, such as the

finite element method (FEM) [5, 13]. It is one of the most widely used numerical

mathematical methods for solving the problems of elasticity and strength, the

dynamics of pliable bodies, heat transfer, fluid flow, electromagnetism, and

many other problems in engineering.

An

important part is the definition of boundary conditions. The three-dimensional

model of the trailer was divided into four parts in order to create the

so-called nodule point. Nodule points serve as load points for load definition.

The second part of the longitudinal beam represents the start and end of the

axle of the trailer. At these two nodule points, binding was defined using the

“fixed geometry” function, which prevented movement in every direction. The cross beams were divided into three sections. The nodule

points on the cross beams make up the places where the guide skates are held.

At the nodule points of the cross beams, the binding was defined using the

“external loads” function, which represents the total load force applied to the

cross beams. The wearing force acting on the cross beams had to be calculated.

Load force is calculated from the weight of:

- the transported boat (450 kg)

- the cam chain guide (position 8 of Fig. 1)

- upper holder of the cam chain guide (position 1 of Fig.

2)

- centre holder of the cam chain guide (position 2 of Fig.

2)

- screw and self-locking nut

- bottom holder of the cam chain guide (position 2 of Fig.

2)

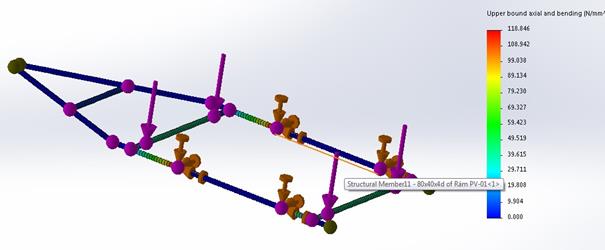

The total load on the frame is determined by the calculation FC =

4,645 N. Stress analysis by the FEM of the frame of the designed trailer is

shown in Fig. 5.

Fig. 5. Trailer frame stress

(reduced stress according to HMH strength theory)

The maximum stress is located in the points of

attachment of the axle to the trailer frame. The maximum stress achieved has a

value σmax = 118.8 MPa. The maximum stress value does not

exceed the permitted stress of σD = 210MPa. The results show

that the designed frame of the trailer meets the strength conditions.

6. FRAME DEFLECTION

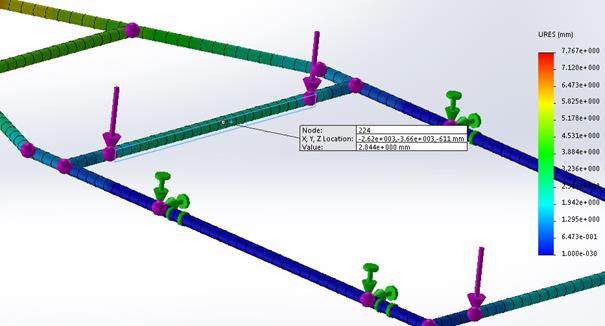

The deflection of the trailer frame by the FEM is

showed in Fig. 6. The maximum deflection occurred at the front of the trailer

frame; its size is 7.67 mm. In practice, the deflection is much smaller at this

point because the front part of the trailer is coupled with the trailer drawbar

by the welded joint.

Fig. 6. Deflection of the trailer

frame

After loading the boat or water scooter, most of the

cross beams are loaded. The deflection in the centre of the cross beams is 2.84

mm (Fig. 6). When designing similar types of trailers for the transport of

boats or water scooters, the greatest attention must be paid to the cross beam.

These elements carry most of the load.

7. CONCLUSION

The frame of the trailer must be designed to have the

appropriate durability and usability. The design of the frame is based on the

knowledge and experience that are commonly available at the time the design is

proposed. The designed trailer frame is designed as a welded structure. In our

case, all welds were by checked for strength according to STN EN 1993-1-8 [12].

Stress analysis of trailer frame was made using the FEM. When designing similar

types of trailers for the transport of boats or water scooters, the greatest

attention must be paid to the cross beam. These elements

carry most of the load. The results obtained show that the designed

trailer frame meets the strength and deformation conditions and can fulfil its

function.

Acknowledgements

This paper was written within the framework of the

VEGA grant project, “1/0473/17: Research and development of technology for

homogeneous charge self-ignition using compression in order to increase engine

efficiency and to reduce vehicle emissions”.

References

2.

Czech Piotr. 2012.

“Identification of leakages in the inlet system of an internal combustion

engine with the use of Wigner-Ville transform and RBF neural networks.” In:

Jerzy Mikulski, ed., 12th International

Conference on Transport Systems Telematics. Katowice Ustron, Poland. 10-13

October 2012. Telematics in the Transport

Environment. Book Series: Communications in Computer and Information Science

Vol. 329: 414-422. DOI: http://doi.org/10.1007/978-3-642-34050-5_47. ISSN:

1865-0929. ISBN: 978-3-642-34049-9.

3.

Figlus Tomasz,

Marcin Stańczyk. 2016. “A method for detecting damage to rolling bearings in

toothed gears of processing lines.” Metalurgija

55(1): 75-78. ISSN: 0543-5846.

4.

Figlus Tomasz,

Marcin Stańczyk. 2014. “Diagnosis of the wear of gears in the gearbox using the

wavelet packet transform.” Metalurgija 53(4): 673-676. ISSN: 0543-5846.

5.

Gąska Damian,

Tomasz Haniszewski, Jerzy Margielewicz. 2017. “I-beam girders dimensioning with

numerical modelling of local stresses in wheel-supporting flanges.” Mechanika 23(3): 347-352. ISSN 1392-1207.

6.

Kim Jung-Seok.

2006. “Fatigue assessment of tilting bogie frame

for Korean tilting train: analysis and static tests.” Engineering Failure Analysis 13(8): 1326-1537.

ISSN 1350-6307.

7.

Lotte Berghman, Roel Leus. 2015. “Practical solutions for a dock assignment problem with

trailer transportation.” European Journal

of Operational Research. 246(3):

787-799. ISSN 0377-2217. DOI: http://doi.org/10.1016/j.ejor.2015.05.057.

8.

Lučanin Vojkan J.,

Simić Goran Ž., Milković

Dragan D., Ćuprić Nenad, Golubović Snežana D. 2010. “Calculated

and experimental analysis of cause of the appearance of cracks in the running

bogie frame of diesel multiple units of Serbian railways.” Engineering Failure Analysis 17(1): 236-248. ISSN 1350-6307.

9.

Madej Henryk,

Czech Piotr. 2010. “Discrete wavelet transform and probabilistic neural network

in IC engine fault diagnosis.” Eksploatacja

i Niezawodnosc – Maintenance and Reliability 4(48): 47-54. ISSN 1507-2711.

10.

Manesis Stamatis.

1998. “Off-tracking elimination

in road trains of heavy duty trucks with multiple semi-trailers.” IFAC Proceedings Volumes 31(20):

355-359. DOI: http://doi.org/10.1016/S1474-6670(17)41820-9.

11. Mathissen Marcel, Scheer Volker, Kirchner Ulf, Vogt Rainer, Benter Thorsten. 2012. “Non-exhaust PM emission measurements of a light duty

vehicle with a mobile trailer.” Atmospheric

Environment 59: 232-242. ISSN 1352-2310.

12.

Standard STN EN

1993-1-8: Eurokód 3 Design of Steel Structures. Part 1-8: Design of Nodes.

Bratislava: STUN, 2007.

13.

Wittek Adam Marek,

Damian Gąska, Bogusław Łazarz, Tomasz Matyja. 2014. “Automotive stabilizer bar

– stabilizer bar strength calculations using FEM, ovalization of radial areas

of tubular stabilizer bars.” Mechanika

20(6): 535-542. ISSN 1392-1207.

Received 02.05.2017; accepted in revised form 30.07.2017

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License