Article citation information:

Juzek, M., Wojnar, G. Analysis of selected solutions and methods to limit the uneven load distribution on the tooth width. Scientific Journal of Silesian University of Technology. Series Transport. 2017, 96, 71-79. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.96.7.

Michał

JUZEK[1], Grzegorz WOJNAR[2]

ANALYSIS

OF SELECTED SOLUTIONS AND METHODS TO LIMIT THE UNEVEN LOAD DISTRIBUTION ON THE

TOOTH WIDTH

Summary.

This article is dedicated to the subject of gearboxes, with a specific focus on

the load distribution on the tooth. The aim of the study was to review the

selected solutions and methods that can contribute to aligning the load on the

width of the tooth. The structure and operation of each solution are described

in detail. The paper presents the possible benefits of using the described

solutions.

Keywords:

gear wheel; contact stress; load distribution

1. INTRODUCTION

Due to the

numerous advantages involved, gear transmissions are used in most current drive

systems. Gears can be used in a wide range of applications, such as land

vehicles, marine propulsion systems, aviation engines or machinery drives in

technological processes. Regardless of purpose, the gearboxes should be

characterized by high reliability and durability. A very important factor

influencing the previously mentioned characteristics of transmission is load

distribution over the tooth width, which occurs during the transmission

operation. Any unevenness of the load along the teeth contact line contributes

to a local increase in transmission load, which results in the deterioration of

its durability and carrying capacity. The article reviews the innovative

construction solutions aimed at counteracting the effects of an uneven load on

the tooth width [1, 2, 3, 5].

2. LOAD DISTRIBUTION ON THE WIDTH OF THE

TOOTH AND ITS IRREGULARITY

Under real operating conditions, the

load distribution along the teeth contact line is not even, while the

accompanying contact stresses are the main factors that determine the

durability of transmission. In order to equalize the load distribution on the

width of the meshing, a modification of the tooth trace direction can be used.

Unfortunately, there are also

numerous difficult-to-avoid factors that influence the load distribution along

the teeth contact line, resulting in increased contact stress and the uneven

distribution of load on the tooth width [1, 3, 4, 5, 8]. According to [3, 5],

the factors influencing the load distribution on the tooth’s width can be

classified as follows:

-

geometry

of meshing

-

meshing

deviations

-

deviations

of the buildings caused by deviations of the axle position

-

internal

bearing clearance

-

the

process of lapping the gear unit

-

misalignment

and parallelism of transmission shafts

-

stiffness

of the wheels (teeth and hub), shafts, bearings, transmission and its

foundation

-

compensating

structural means

-

additional

shaft load (e.g., pulley)

As a measure of the unevenness of

the load on the width of the meshing, the coefficient of unevenness of the load

distribution K can be defined. Factor

K is determined as the ratio of the

local maximum tooth load per unit length to the mean value of load, which is

calculated assuming an even load distribution. The value of the coefficient K can be calculated from the following

relation, as reported in [1]:

![]() (1)

(1)

where:

pmax – maximum load per unit of wheel

width

pm – average load per unit of wheel

width

fmax – maximal local deformation of the

tooth

fm – average tooth deformation on

wheel width

The main determinant of the

distribution of the load on the tooth width is the resulting deviation of the

teeth contact line in the plane of action Fβy.

Fβy deviation is

defined as the distance of the sides of the teeth that cooperate in the frontal

direction. Its measurement is made in the situation of entering into meshing of

cooperating pairs of teeth. The value of deviation Fβy can be determined on the basis of the relation

shown in [3]:

![]() (2)

(2)

where:

Fβx – initial contact line deviation

without taking lapping into account

yβ – a lapping value that decreases

the initial deviation of the contact line as a result of lapping teeth during

the operation

3. REVIEW AND ANALYSIS OF SELECTED

STRUCTURAL SOLUTIONS TO REDUCE THE IRREGULARITY OF LOAD DISTRIBUTION ON TOOTH

WIDTH

Appropriate

structural solutions may be used to reduce undesirable effects of uneven load

distribution on the width of the tooth. The following section presents and

describes innovative solutions for reducing the adverse effects of the uneven

distribution of load.

3.1. Divided satellite

gear wheels of planetary transmission

In planetary gearboxes, the satellite wheels work with

the sun gear and internally toothed wheel. Often the sun wheel and satellites

have a relative wide width, due to considerable surface pressures between the

cooperating teeth. For fixing satellites on the journal axes, two bearings

(ball or roller) are most commonly used. Such a way of settling the wheels and

their considerable wide width, despite the high degree of performance and

assembly of the transmission, contribute to the uneven load distribution on the

width of the tooth. In order to reduce this unevenness, an innovative design of

satellite wheels was proposed in [9]. These solutions consist of dividing one

wide satellite wheel in a plane perpendicular to its axis of rotation into a

few narrower separate wheels. The total width of the newly formed wheels is the

same as the width of a single wide wheel. In addition, one oscillating bearing

on each of the narrower wheels is used. Such bearing independence and the additional

possibility of tilting the wheel significantly increase its give and allow a

more favourable load distribution on the tooth width [7, 9].

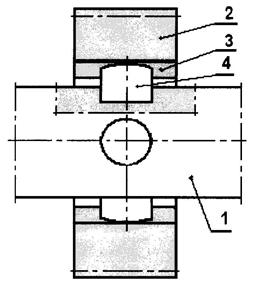

Fig. 1. Diagram of a portion of a satellite wheel with

bearing. Description of indications:

1) toothed ring of the classic wheel; 2-3) toothed rings of narrower wheels

formed;

4) bearings; 5) self-adjustable bearings; 6) journal of the satellite wheels

[7]

3.2. Oscillating wheel setting on the shaft using four

cylinders

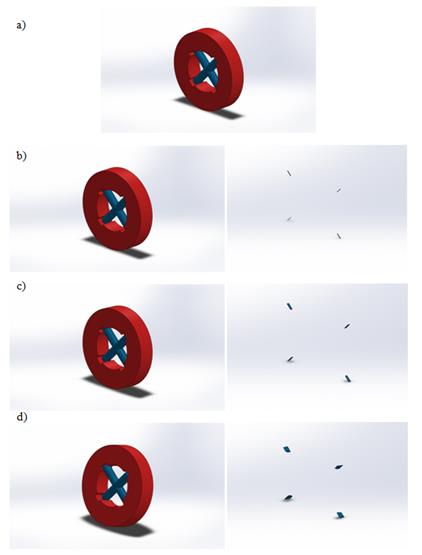

A solution to limit uneven load distribution on tooth widths can be found in the patent (PL 379605). This patent contains an application of a constructional solution consisting of a pivotally connected shaft journal with a hub. Four cylinders are arranged perpendicular to the axis of rotation of the shaft. They are placed in the holes on the surface of the journal at 90° intervals. The other end of each cylinder is located in the groove on the inner surface of the hub. The hub grooves have a rectangular cross section and are parallel to the axis of rotation. The surface of the cylinder face, which is in the hub groove, is rounded by a radius. The length of the radius corresponds to the distance from the bottom of the groove to the axis of rotation of the journal. The proposed construction solution is designed to allow the wheel hub to tilt at an angle to the shaft journal on which it is mounted. This will increase wheel susceptibility, which in turn will improve the load distribution on its width [10].

Fig. 2. Diagram of oscillating wheel setting on the

shaft, using four cylinders. Description of indications: 1) shaft’s journal; 2)

toothed gear; 3) groove with rectangular cross section;

4) cylinder [10]

For the above solution, a three-dimensional model has

been created. It shows the features of the analysed solution and simulates its

operation in different hub positions. For further consideration, an angle φ

was defined between the axes of the cross (obtained from the four cylinders

mentioned above) and their projection on the plane containing the shaft axis

and the gear axis. This plane is formed at a non-zero angle between the shaft

and gear axles.

It has been observed that, in the case of non-zero

angles between the axis of the shaft journal and the axis of the hub and the

non-zero values of the angle φ, there is overlapping of the side faces of

the rollers and the inner surface of the hub grooves. At a constant angle

between the shaft axis and the axis of the hub, this phenomenon reaches a

maximum value of φ = 45°. This phenomenon increases with the wheel hub

angle and is illustrated in Fig. 3. The presented situation can adversely

affect the durability of the joint and significantly accelerate the degradation

of the roll surfaces and hub grooves.

Fig. 3. Simulation of the hub oscillating operation:

a) three-dimensional model of the joint showing the main characteristics of the

analysed solution; b) the angle between the journal axis and the hub axis is

1°; c) the angle between the journal axis and the hub axis is 5°;

d) the angle between the journal axis and the hub axis is 15°

Figure 4 shows the overlapping volume of the side

rolls and the inner surface of the hub grooves Vk as a function of the angle

between the shaft rotation axis and the axis of the gear. In the illustrated

case, the diameter of the four-cross cylinder was 10 mm, the length of the two

cylinders was 60 mm and the diameter of the hole in hub was 52 mm.

Fig. 4. Overlapping

volume Vk diagram as a function of angle φ between the journal axis

and the hub axis

The

dimensionless coefficient of the overlapping volume Vk (Fig. 5) and the volume

of the crosspiece fragments, that is, the hub grooves Vf, were also proposed.

The Vk/Vf coefficients as a function of the angle between the axis of the shaft

journal and the axis of the hub φ are shown in Fig. 6.

Fig. 5. Fragments

of crosspieces in the hub grooves described as Vf

Fig. 6. Graph of

Vk/Vf ratio as a function of the angle of hub deflection φ

3.3. Eccentric setting of the shaft’s bearings

One method of limiting the uneven load distribution on

the tooth width, without interfering with wheel construction, is the eccentric

mounting of the shaft’s transmission bearings. Thanks to eccentric bearings, it

is possible to regulate the non-parallelism and misalignment of the

transmission axis, which also significantly affects the load distribution on

the width of the wheels mounted on the adjustable shafts. In addition, this

adjustability reduces the adverse impact of the elastic deformations of the

load-carrying elements and the deviations. The eccentric mounting of the shaft

bearings presented in [5] is particularly beneficial in the case of high-power

transmission with significant geometric dimensions. It is also worth

emphasizing that, compared to other solutions, this method does not

significantly increase the cost of transmission, but improves its strength

properties [5, 6].

3.4. Wheel construction with malleable elements

Patents US 2307129 [11] and US 307705 [12] illustrate

the construction of a gear, based on the separation of a cylindrical hub from a

toothed ring by use of an additional ring made of a malleable material. The

radius of the cylinder base was not accurately determined by the authors. The

ring can be one element or, as in the case of patent US 307705, two separate

and respectively narrower elements. The frictional force occurring on the

contact surface of the ring with the hub and the ratchet enables the transfer

of torque. In addition, in patent US 2307129, the authors applied two discs

attached to both side surfaces of the wheel by a screw connection. Discs are

designed to limit the excessive ring and wheel rim movements along the shaft

rotation axis. The use of a soft material in the toothed wheel structure allows

for a slight angular deviation in the rim, relative to the hub, which

translates into increased wheel give and can contribute to a more favourable

load distribution on its width.

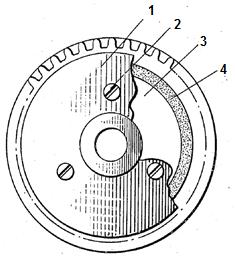

Fig. 7. Scheme of construction of wheel with a

malleable ring. Description of indications:

1) side discs; 2) screw connection; 3) wheel hub; 4) susceptible ring [11]

4. SUMMARY

Load distribution along the teeth

contact line occurring during the transmission operation is an important factor

affecting its durability. Due to the deviation in gear teeth manufacturing, the

transmission’s body and the elastic distortion of the shafts as a result of

inter-tooth force action, it is very difficult to obtain an even load

distribution under actual conditions. Any deviations cause an adverse increase

in contact stresses. The use of innovative gear designs or eccentric shaft

mounting, as described in the article, can contribute to a reduction in the

undesirable effects of uneven load distribution and significantly affect the

durability and reliability of the transmission. In addition, reducing the

unevenness of the load distribution on the width of the tooth also contribute

to a reduction in vibrations generated by the transmission and accompanying noise.

The article also presents an example of a structural

solution. Despite the relatively low cost of implementing this solution, which

is undoubtedly an important advantage, on the basis of the presented analysis,

it is stated that, in certain situations at work, there is a collision of

elements. For this reason, it is proposed to use this solution in terms of

relatively small values of uneven distribution of load on the width of the

meshing, rather than treat this solution, for example, as a method for equalizing

the load distribution when the transmission’s axes are non-parallel.

References

1.

Müller Ludwik.

1996. Przekładnie Zębate – Projektowanie.

[In Polish: Gears – Design.] Warsaw:

Wydawnictwa Naukowo-Techniczne. ISBN 83-204-1983-2.

2.

Müller Ludwik. 1986.

Przekładnie Zębate – Fynamika. [In

Polish: Gears – Dynamics.] Warsaw:

Wydawnictwa Naukowo-Techniczne. ISBN 83-204-0766-4.

3.

Łazarz Bogusław.

2001. Zidentyfikowany Model Dynamiczny

Przekładni Zębatej jako Podstawa Projektowania. [In Polish: Identified Dynamic Model of Toothed Gear as

the Design Basis.] Katowice-Radom: Wydawnictwo i Zakład Poligrafii

Instytutu Technologii Eksploatacji. ISBN 83-7204-249-7.

4.

Banaszek Jan,

Józef Jonak. 2008. Podstawy Konstrukcji

Maszyn – Wprowadzenie do Projektowania Przekładni Zębatych i Doboru Sprzęgieł

Mechanicznych. [In Polish: Fundamentals

of Machine Construction – An Introduction to the Design of Gears and the

Selection of Mechanical Couplings.] Lublin: Wydawnictwo Politechniki

Lubelskiej. ISBN 978-83-7497-042-6.

5.

Kochańczyk Marek.

2001. Metoda Wyrównania Rozkładu

Obciążenia kół Zębatych za Pomocą Mimośrodowego Psadzenia Łożysk. [In

Polish: Method of Equalizing the Load

Distribution of Gears by Eccentric Bearing Placement.] PhD thesis,

Katowice: Politechnika Śląska.

6.

Kochańczyk Marek,

Andrzej Wilk. 2002. “Wyrównanie

rozkładu obciążenia koła zębatego za pomocą mimośrodowego łożyskowania wału –

dobór cech geometrycznych.” [In Polish:

“Alignment of gear rack distribution by eccentric shaft bearings – selection of

geometric features”.] Szybkobieżne

Pojazdy Gąsienicowe 15(1): 1-7. ISSN 0860-8369.

7.

Filipowicz

Krzysztof. 2014. “Stanowisko badawcze do

wyznaczania wpływu dzielonych kół satelitów na obciążenie w zazębieniach

przekładni planetarnych”. [In Polish: “Research

station to determine the impact of split satellite wheels on planetary gear

engagement”.] Przegląd Mechaniczny

5: 29-34. ISSN 0033-2259.

8.

Zwolak Jan. 2012. “Wpływ nierównomiernego rozkładu obciążenia wzdłuż linii styku zębów na naprężenia kontaktowe.” [In

Polish: “Influence of uneven distribution of load along the tooth contact line

on contact stresses”.] Tribologia 5:

251-263. ISSN 0208-7774.

9.

PL 321717. Przekładnia Obiegowa. [In

Polish: Circulation Gear.] Kowal

Aleksander, Skoć Antoni, Spałek Jacek, Stachurski Jerzy, Suchoń Józef. 1 March

1999.

10.

PL 379605. Kształtowe Połączenie

Wahliwe Czopa z Piastą. [In Polish: Shaped

Swivel coupling Spindle with Hub.] Kowal Aleksander. 12 November 2007.

11.

US 2307129. Shockproof Gear. Barany Edmund, Hines

Earle G. 5 January 1943.

12.

US 307705. Stress Dissipation Gear and Method of Making

Same. P.J. Fenelon. 3 May 1994.

Received 09.05.2017; accepted in revised form 25.07.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License