Article citation information:

Irlik, M. Linear positioning of railway objects.

Scientific Journal of Silesian University

of Technology. Series Transport. 2016, 95,

49-57. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.96.5.

Maciej IRLIK[1]

LINEAR POSITIONING OF RAILWAY

OBJECTS

Summary. The

article provides an explanation of the issue related to the linear positioning

of railway objects in the context of preparing site data for automatic train

protection systems, such as the European Rail Traffic Management

System/European Train Control System (ERTMS/ETCS). This paper identifies and

compares current approaches for an object’s position based on a line chainage

for orientation and documentation purposes, as well as the object’s position

based on a track axis for the calculation of real world distances, along with

providing examples of measurement systems and presenting conclusions from test

runs for ERTMS/ETCS Level 2 purposes.

Keywords: railway; ERTMS; ETCS; line mileage;

safety systems; railway signalling; measurement

1. INTRODUCTION

Safety

is one of the essential requirements related to railway systems. To increase

safety on railway lines, different automatic train protection (ATP) and

automatic train operation (ATO) systems are used, depending on the

architecture. These provide drivers with lineside information related to the

authorization to move, enabling them to carry out safe operations in the case

of human failure (ATP) or automated operations on trains (ATO). Today, in the

European railway network, a unified ERTMS/ETCS can be found, which meets the

European ATP standard. The common element found in most safety-related systems

(especially ERMTS/ETCS) is granting authorization to trains to move, using

lineside information and trackside descriptions about the length of

authorization, gradients and other information related to the track. Above all,

it is essential that site data introduced to the specific application of the

system will based on trusted and real data about the trackside.

2. ERTMS/ETCS REQUIRES TRUSTED AND REAL SITE

DATA

In an ERTMS/ETCS system, a radio

block centre (RBC) or balise grants specific trains authorization based on

information from the lineside. For an RBC, this is based on interlocking

information about the locked route or the kind of authorization; for a balise,

this is based on information from a lineside electronic unit encoder about a

signal aspect or the state of relay contacts. A system based on this

information and site data, as specified in an RBC-specific application (Level 2

or 3) or a balise telegram (in Level 1), sends information about the authorized

distance (distance to the end of authority in line with the last relevant

balise group passed by the train). This means that the system is based on routing

from element to element. Additionally, this information contains additional

track descriptions, such as static speed profiles, speed limitations, gradient

profiles or track conditions, axle load speed profiles, and the change in

adhesion factor [7-8].

Based on this information, an

onboard ETCS system, based on its odometry information, can calculate and

supervise the braking curve to the end of authority or speed limitation.

Above all, it is essential that site

data used for preparing specific ERTMS/ETCS applications must be trusted and

based on:

- the real-world length for each track

and route

- the list of passable tracks

- navigability between tracks

3. AXIS: TWO CONCEPTS

3.1. Line axis: traditional approach

Currently, in a railway

transportation system, for orientation and documentation purposes, the railway

object’s (e.g., signals, points) position provide linear position information

represented by a metric value based on a line chainage. The line chainage is a

linear referencing system with a non-normed origin. Mostly, this is based on

the instructions and regulations of the competent railway administration. In

Poland, within the PKP Polskie Linie Kolejowe infrastructure, instruction Id-12

sets out the rules for line mileage and includes a list of all railway lines in

the network. Similar rules are in force with regard to other railway

administrations in the EU [1-4].

The line chainage is based on a line

axis, which is traditionally used for positioning objects on one or more

parallel tracks on the line or at a station. The mileage in this context is not

able to reflect real distances travelled by a train because it cannot assume

different distances on two or more tracks involving curves and connectors

between tracks (see Fig. 1).

Fig. 1. Line chainage vs. real

distance reflecting differences in route length

Moreover, in some cases on the line,

when tracks have different longitudinal or plan profiles, chainage gaps or

chainage overlengths are used (see Fig. 2).

Fig. 2. Chainage gaps in the case of

different plan profiles involving two tracks on one railway line

This approach is appropriate for

driver orientation purposes, e.g., in the case of respective speed limitations.

Information about line mileage is presented to the driver by mileage indicators.

Other important information is also delivered to the driver by trackside

indicators (e.g., about speed limitations, sections with lower pantograph). For

documentation purposes and schematic plans with a track layout, this approach

is sufficient.

3.2. Track axis: system distance

The track axis approach is based on

a model that defines the topology for a network of railway tracks (node-edge

model).

In this model, the node connects two

or more adjacent edges. The node could be a signal, point or other

infrastructure trackside object. Each edge defines its own linear referencing

system used for linear positioning or railway objects related to the edge they

belong to (see Fig. 3).

Fig. 3. Edge position of railway

objects

As the measurement along the edge is

based on the track axis (centre line of a pair of rails), this means that it is

able to reflect the real distance travelled by a train. Based on this, it is

possible to easily calculate the relative distance between neighbouring

objects. For the ETCS, it could be used directly or after the calculation of

the track-based distance for each track or route, which is understood as:

![]() length of each track segment (edge)

length of each track segment (edge)

4. METHODOLOGY OF

MEASUREMENT TRACK AXIS

4.1. Measurement tool and process

For the measurement of the real

distance between a neighbouring object on the track, systems are used, which

can be installed on the locomotive and measure different data from different

sources [5-6], namely:

- tachometer

- GPS/GNSS

- video data from high-resolution

cameras installed on front and back of the locomotive

- accelerometer

Equipment

is installed on the locomotive on a draisine (see Figs. 4 and 5)

Fig. 4. Measurement tool schema

Fig. 5. Equipment installation on an

EM120z draisine during a test run

This kind of system can collect a

wide range of relevant information, such as track-related distances between

infrastructure elements based on two independent sources, gradients, geographic

position, and video data used in data processing.

Data are collected during a run on

the line. Each edge between two nodes (points) must be travelled at least once.

These recorded data are used for

data processing, which consists of three stages, as shown in Fig. 6.

Fig. 6. Data process

Analysed data are treated as the

source. It is also necessary to have track layout plans or topology in place

with a list of measured objects.

Rules defining the requirements of

analysis data for safety critical systems are found in [2-9]. These rules may mean that,

during analysis, two independent persons are required, with analysis of the

video data carried out from two sides (one from the travel direction during the

measurement run and one from the opposite side).

During analysis, the measured and

synchronized data are compared with the track layout plans and the list of

objects being considered (these could be signals, points, balises, track

joints, axle counters, indicators etc.). Additionally, when balises for the

ERTMS/ETCS system are installed, it is possible to synchronize video data about

the real position of balises with information recorded on the onboard Juridical

Recorder for the ETCS concerning the content of particular balise (ID) in order

to assess the installation and programming of particular balises.

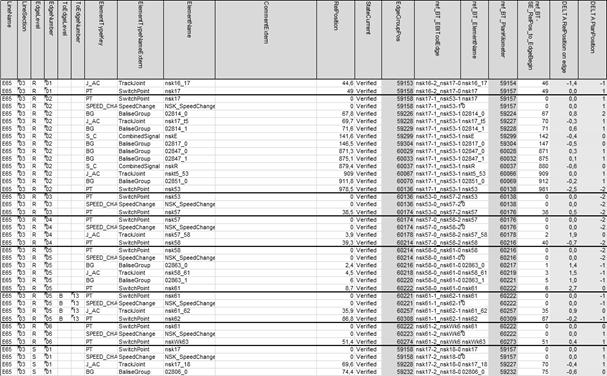

The output report from the analysis contains at

least a table with specific data, as shown in Table 1.

Tab. 1

Element list

|

Content |

Description |

|

Basic structure |

Track topology |

|

Elements |

E.g., switch, signal, train detection (axle

counter, isolating joint), platform (begin/end), indicator |

|

Attributes |

|

|

Measurement data |

|

Data can be provided in Excel format

(see Fig. 7) or in one of the XML formats (e.g., RailML format) for further

action.

Fig. 7. Example of an element list

format

Processing is divided into two

stages: measurement and validation

The

measurement stage is mostly dedicated to the existing line and without good

quality documentation (line book) for collecting the necessary data for design

purposes. It can be skipped when the line is new and the geodesists’

documentation is of good quality.

The

validation stage is the final verification step after the installation of the

trackside equipment (such as balises). In this stage, data from the design

documentation are compared while being measured, with any deviations analysed.

These measured data can be directly used in the specific application of a

system (e.g., as an input in an electronic XML format).

5. SUMMARY

The author

participated in the test run, as described in Chapter 4, involving the

measurement tool and the review of the reports following analysis. The test was

carried out in January 2017 in the Nasielsk area on the E65 line between the

Warszawa Praga Towarowa and Świercze stations.

Due to the

existing installation of balises and current design documentation for

ERTMS/ETCS Level 2 purposes, the test was based on the validation stage and

carried out with an EM120z draisine, equipped with an onboard ERTMS/ETCS.

Measurement

of this particular area was carried out over three days.

The

collected data were related to distances, gradients and the validation of the

balise telegram. During the test run, some intentional bugs were inserted

during the balises’ installation in order to check whether the tool and the

process were able to find them; this part of test was executed with a positive

result.

Deviations

between plans and measured data mainly occurred if one edge on two parallel

tracks involved a curve. Depending on the curve, the difference was about 10-20

m in distance between the objects located on two tracks.

The above

results allow us to conclude that, for specific purposes such as collecting

site data for an ERTMS/ETCS Level 2 system, track axis data ensure that we have

data that are relevant to the real distance travelled by the train in question.

References

1.

UNISIG-SUBSET-026

version 2.3.0. 2008. Available at: http://www.era.europa.eu.

2.

PN-EN 50126:2002. Zastosowania Kolejowe: Specyfikacja Niezawodności,

Dostępności, Podatności Utrzymaniowej i Bezpieczeństwa. Warszawa: Polski Komitet Normalizacyjny. [In Polish: PN-EN 50126-1:1999. Railway Applications: The Specification and Demonstration of

Reliability, Availability, Maintainability and Safety. Warsaw: Polish

Committee of Standardization.]

3.

PN-EN 50128:2011. Zastosowania Kolejowe: Systemy Łączności,

Przetwarzania Danych i Sterowania Ruchem – Oprogramowanie Kolejowych

Systemów Sterowania i Zabezpieczenia. Warszawa: Polski Komitet Normalizacyjny. [In Polish: PN-EN 50128:2011. Railway Applications: Communication, Signalling and Processing Systems

– Software for Railway Control and Protection Systems. Warsaw: Polish

Committee of Standardization.]

4.

PN-EN 50129:2007. Zastosowania kolejowe: Systemy Łączności,

Przetwarzania Danych i Sterowania Ruchem – Elektroniczne Systemy

Sterowania Ruchem Związane z Bezpieczeństwem. Warszawa: Polski Komitet Normalizacyjny. [In Polish: PN-EN 50129:2003. Railway Applications: Communication, Signalling and Processing Systems

– Safety-related Electronic Systems for Signalling. Warsaw: Polish

Committee of Standardization.]

5.

Oz MA,

Kaymakcı OT, Koyun A. 2017. “A safety related perspective for the power

supply systems in railway industry.” Eksploatacja

i Niezawodnosc – Maintenance and Reliability 19(1): 114-120. DOI:

http://dx.doi.org/10.17531/ein.2017.1.16.

6.

Wang Y., L. Bi, S.

Wang, S. Lin, W. Xiang. 2017. “The application of dynamic Bayesian network to

reliability assessment of EMU traction system.” Eksploatacja i Niezawodnosc – Maintenance and Reliability 19(3):

349-357. DOI: http://dx.doi.org/10.17531/ein.2017.3.5.

7.

Hans W. Ittmann.

2017. “Private-public partnerships: a mechanism for freight transport

infrastructure delivery?” Journal of

Transport and Supply Chain Management 11: 1-13.

DOI: http://dx.doi.org/10.4102/jtscm.v11i0.262. ISSN: 2310-8789.

8.

Fanny Saruchera.

2017. “Rail freight transportation concerns of developing economies:

a Namibian perspective.” Journal of

Transport and Supply Chain Management 11: 1-9. DOI:

http://dx.doi.org/10.4102/jtscm.v11i0.288. ISSN: 2310-8789.

9.

Vivek Singhal, Sukhvir Singh Jain. “Road driver behaviour evaluation

at unmanned railway level crossings.” 2017. European

Transport/Transporti Europei 65: 1-25. ISSN: 1825-3997.

Received 09.06.2017; accepted in revised form 27.08.2017

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License