Article citation information:

Brodzik, R. The influence of thermal loads on modern road concrete

pavements in Poland. Scientific Journal

of Silesian University of Technology. Series Transport. 2017, 95, 27-37. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.95.3.

Robert BRODZIK[1]

THE INFLUENCE OF THERMAL LOADS

ON MODERN ROAD CONCRETE PAVEMENTS IN POLAND

Summary. This article presents the

opportunities for the development of road concrete pavements in Poland. The

analysis of the prospects for evolving a new type of concrete pavement, based

on continuous reinforcement, has been performed. The advantages and

disadvantages, in terms of functionality, strength and economy, have been

analysed. The evaluation of stress and displacements in the analysed

continuously reinforced concrete slabs, involving the use of the finite element

method (FEM), has been performed on selected temperature distributions derived

from thermal loads. Based on the analysis of adopted decompositions, the use of

the FEM to assess the effectiveness of the continuously reinforced pavements

has been proposed.

Keywords: continuously reinforced concrete pavement; numerical

modelling; thermal loads; concrete slab; temperature.

1.

INTRODUCTION

The Programme

for National Road Construction 2014-2023 (with a View to 2025) is a

document that defines the objectives regarding the development of road

infrastructure. It includes a schedule for the realization of investments,

aimed at their accomplishment and highlighting funding sources and the amount

of planned expenditures. The main aim of the programme is to build a consistent

and modern system of roads in the country, which will provide the effective

functioning of road passenger and cargo transport. The programme costs, which

are estimated at PLN 107 billion, will be used to build about 3,900 km of

highways and expressways, as well as 57 ring roads. Furthermore, PLN 51.8

billion will be allocated to the maintenance and modernization of existing

roads. In order to achieve the above goals, missing parts of expressways and highways

will be completed, while selected parts of national roads will be refurbished

and ring roads constructed, which will improve the traffic flow in the urban

centres that are the most affected by loaded transit traffic. The crucial aim

of the above programme is to build, by 2023, over 880 km of concrete roads in

the national road system [3,7,10].

On the new financial horizon, it is assumed that

approximately three quarters of new roads will be built using traditional

bitumen technology, whereas approximately one quarter will use concrete

pavements. In 2016, upon the completion of parts of concretized expressways and

highways, as well as making them available for use, their total length will be

less than 580 km, which will only constitute 6% of all highways.

2. DEVELOPMENT OF

CONCRETE PAVEMENTS IN POLAND

Concrete pavements date back to ancient times, when

the Romans started using cement to bond the layers that roads were made of. The

first contemporary concrete pavements were created at the beginning of the 20th

century in the US, with the first concrete pavement comprising a concrete slab,

which was 0.175 m thick, 1 mi long and 4.5 m wide, and had stretching gaps with

wooden inserts positioned every 7.5 m. The first concrete highways appeared in

1939 in Germany, while Poland developed a new technology for constructing road

surfaces for the first time in 1912 in Cracow [6,13].

Since the early 20th century, concrete pavements

have gone through a period of significant evolution and technological

revolution, including a reduction in the distance between transverse gaps up to

5 m, the implementation of a road foundation of concrete slabs, the obligatory

use of aeration admixtures of concrete, and the careful use of fresh concrete.

The advantages of concrete pavements have been

recognized by many countries, mainly in Western Europe. Germany is the country

with the longest and the most significant tradition in Europe regarding the

creation of concrete pavements. Currently, Germany has 12,000 km of highways,

with as much as 40% of such a grade of roads made with the use of concrete

technology. In the context of European countries, Belgium should also be

mentioned, where concrete pavements constitute nearly 90% of the main road

system. The main advantages of concrete pavements can be divided into three

categories: technical (long-term endurance of pavements), economic (a lower

overall cost of creation and maintenance) and social (the majority of the

materials used are produced in the country).

There are additional advantages of concrete

pavements, which were taken into account while planning future road investments

in Poland:

-

Resistance to

deformation, especially rutting: it is planned to build concrete roads where

heavy traffic load occurs, in particular, where the ratio of passenger traffic

is similar to truck traffic (truck traffic equates to approximately 5,000

vehicles per day)

-

A much longer

period of using concrete pavements (over 30 years) compared to asphalt

pavements (about 20 years of use)

-

Concrete pavements after

applying surface treatment do not require additional funding, even over a

period of up to 20 years (or up to nine years in the case of asphalt pavements)

-

Increasing the

number of contractors, both domestic and international, with experience

regarding the possibility of realizing new tasks using concrete technology

Currently, concrete pavements compete with asphalt

ones at the executive stage, as the former are poorer in terms of endurance.

While comparing other aspects of both types of the surface, concrete pavements

are characterized by greater durability over a long period of their use (they

do not require repairs or replacements for up to 50 years). Concrete pavements

are appreciated by drivers, as they are properly designed and textured, as well

as lesser deformation (lack of rutting), thus guaranteeing greater safety,

driving comfort and decreased fuel need. In turn, brighter-coloured concrete

pavements and increased reflexivity improve visibility, especially at night.

Regarding concrete mixtures used for surfaces, industrial by-products and waste

products can be used (cement with fly ash, open-hearth slag), which not only

eliminate the need for their storage, but also reduce the need for new

materials, thereby saving natural resources [5,13,14].

According to the Board of the Generalna Dyrekcja

Dróg Krajowych i Autostrad (GDDKiA), or the General Directorate for National

Roads and Motorways, once the Programme

for National Road Construction has been implemented after 2023, there will

be over 22,000 km of roads in total, including 4,611 km of highways and

expressways. Regarding the national road system, there will be 20,660 km of

asphalt roads (94%) and 1,350 km of concrete roads (over 6%) (Fig. 1). The

decision of the GDDKiA regarding the construction of 810 km of roads using

concrete technology is surprising in the context of historical data; within the

last 20 years, only 600 km of roads of this type have been built. The current

change in attitude is the result of observing experienced road managers in

other countries and the similarity of costs in the construction of both

concrete and asphalt roads. Meanwhile, the development of concrete roads

involves searching for new and improved construction techniques, implementing

new technologies, and conducting related research.

Fig. 1. Expressways and highways to be built with

the use of concrete surface technology. S6: Tri-city metropolis ring road, 32.7 km; S5

sections: Aleksandrowo junction (Bydgoszcz-North), Bydgoszcz-Szubin, 37.9 km;

S7 sections: Mazovian/Mazurian border-Warmia Provinces-Płońsk-Warsaw, 128.3 km;

S2: POW (Puławska junction-Lubelska junction), 18.5 km; S7: Warsaw-Grójec

and the border of Świetokrzyskie/Lesser Province of Widoma-Cracow, 84.6 km

3. CONTINOUSLY

REINFORCED CONCRETE PAVEMENTS

After more than century of experience regarding the

use of road concrete pavements, the following types of pavements are available:

-

Unreinforced and

non-interconnected pavements

-

Unreinforced

interconnected surface and anchored pavements

-

Reinforced pavements

with interconnected gaps

-

Prestressed

concrete pavements

-

Prefabricated

pavements

-

Complex pavements

(mixed): concrete foundation upon which a thin layer of a mineral is placed;

asphalt mixture or a concrete layer placed on existing asphalt pavement (white topping)

-

Continuously

reinforced pavements without transverse gaps [13,14]

In the context of construction technology at a

global level, the practical use of concrete pavements concerns the following

types: dowel and anchored, unreinforced and non-interconnected, complex

pavements (mixed) and continuously reinforced. The latter type is undoubtedly

the most popular in the US and EU countries (namely, England, Belgium and

France). The main disadvantage of this method is the higher cost of construction

(about 5 to 8%), which has been a significant barrier to its use in Poland. In

terms of road concrete pavements in Poland, however, it can be observed that

continuously reinforced pavements include the following advantages:

-

High levels of

driving comfort: a lack of dilatation means that there is no prevalence of

curling

-

Lower maintenance

and operation costs in relation to other types of pavements, with regard to the

limitation of dilatation gaps

-

The lack of the

adverse phenomenon known as so-called “pumping water in gaps” (penetration of

water into the subsoil does not occur)

-

The significantly

long period of their usage

The general rules for constructing continuously

reinforced pavements are based on the transverse reinforcement disposed at

between 0.1 and up to 0.23 m, situated in the middle of the concrete slabs’

thickness. Reinforcement bars are usually placed on props (Fig. 2) or by means

of specialized machines designed for this purpose. During the operation,

capillary fractures appear, which are 0.2 mm wide, reaching to a depth of 1 to

2 cm from the surface of the concrete. According to repair technology, it is

assumed that such pavements may be covered with a thin layer of a new

bituminous surface in the future (in approximately 30 years’ time) without the

need to incur expenses for its repair.

One of the first experimental parts of a

continuously reinforced road concrete pavement was constructed at the section

of the A4 highway near Kąty Wrocławskie. The contractor was a consortium

comprising Joint Venture Kirchner/Bogl/Berger, which is the main contractor of

the A4 highway, and the GDDKiA department in Wrocław. While testing a new

pavement, a new continuously reinforced section, which was 1 km long and 11 m

wide, with only two oblong gaps, was made. This section was built as a “testing

ground” before a more comprehensive implementation of a new type of surface in

Poland [4].

Fig. 2. The works conducted during the construction of a continuously

reinforced concrete highway

4. THERMAL LOADS OF CONTINUOUSLY REIFORCED

CONRETE PAVEMENTS

Concrete pavements are affected,

apart from the external forces caused by movement on them, by internal forces

generated in the pavements themselves, due to changes in atmospheric

temperature referred to as thermal forces. Apart from stresses coming from

wheels, thermal stresses, caused by a change in temperature on the pavement and

the bottom of a concrete slab, can be distinguished. There are several methods

for calculating the rigid surface, in which the criterion may be, for instance,

allowable deflection, allowable deformation of the subsoil or an allowable load

of the subsoil [1]. The theoretical studies on concrete pavements are mainly

based on the Westergaard method. The following point is an attempt to present

the possibilities of supporting classical methods for designing modern concrete

pavements with the use of numerical methods. Such support can be used to verify

the main construction parameters of a pavement, e.g., the thickness of a

pavement, the type and grade of the used concrete, the types of gaps, or the

type of road foundation. On the basis of the knowledge about temperature

distribution in concrete pavements, an idea has been proposed whereby it is

used in calculating the strength of the continuously reinforced concrete

pavements by taking a numerical approach.

The values of stresses in

continuously reinforced concrete pavements, caused by a change in temperatures,

should be maintained with such limitations in order to avoid uncontrolled

cracking of concrete slabs. Searching for optimal solutions for a proper

functioning of concrete pavements is a difficult task to perform, due to the

fact that fulfilling all the criteria must involve a compromise between

economy, durability and safety. Below, an example is given in terms of how

reinforced slabs, which are thermally loaded, can be tested (modelled) in such

a way where all the decisive factors affecting surface durability can be

properly selected.

Due to a large number of factors

affecting the durability of concrete constructions, it is necessary to develop

a numerical model with the most optimal assumptions and solutions related to

the actual ones. Previous strength analyses of concrete pavements were based on

the assumptions, whereby a concrete slab rests on an elastic foundation with

specified rigidity, while there is a lack of friction between the foundation

and the slab resting on it [2]. The current state of knowledge regarding the

impact of thermal loads on the durability of concrete pavements has inspired

research on the role of friction between the slab and the road foundation [6,8].

The current empirical and theoretical considerations on rigid slabs, subjected

to thermal load, have shown that, regardless of the accepted gradient of

temperatures, a free slab made of concrete takes a characteristic shape, which

resembles a bowl. The theoretical flexion of the slab, in the case of a

positive gradient, is presented in Fig. 3.

Fig. 3. Free slab with specified

weight and temperature distribution

Temperature fluctuations cause a change in

volume in slab pavements. In the case of steady temperature influences on the

whole thickness of a slab, axial deformations are created, while, in the case

of unsteady temperature distribution, flexion of the slab occurs. In

theoretical terms, a homogenous isotropic body, supported in a statistically

determined way, is subjected to a temperature field, which is a linear function

of the Cartesian coordinates that are deformed during a state of stresses equal

to zero [12]. In actual cases, when a slab cannot be easily deformed because of

its own weight, the friction and reaction of subsoil or the limitations

presented by other slabs, temperature stresses appear in the slab. Combining

such stresses with those coming from other additional loads, e.g., wheel

pressure can lead to a situation in which the presenting maximum stresses

exceed the values of allowable stresses, which in turn leads to damage to the

slabs, such as scratches or cracks.

The current state of knowledge on the

temperature distribution in concrete pavements, although relatively poor,

confirms the legitimacy of the above use of simplifications in a significant

way. The results of the research on temperature distributions in airport slabs,

under different climate conditions in Poland, as well as research conducted on

national road or airport concrete pavements [1,9], reveal that the climate and

its changeability, as opposed to the thickness of the slab, particularly

determine the distributions and occurring temperature gradients. The

significant changeability climate within Poland means that, from the point of

view of durability analyses, knowledge about the occurrence of actual

temperature distributions is necessary for measuring cycles in the long run.

If it is assumed that the difference

in temperature fluctuations in summer and winter on two following consecutive

days is as high as 30°C, it is necessary to perform a daily analysis of the

occurring stresses and deformations of the slab. The perfect tools for

conducting such analyses are programs based on the FEM, which additionally

allows for a detailed analysis of not only the influence of the size of the

gradient, but also the nature of temperature distributions in terms of slab

thickness.

5. ANALYSIS OF THE DISCRETE MODEL

This study presents an example of

numerical simulation with the use of a solid model using the FEM. The MSC

Nastran for Windows system was used to determine the movements and stresses in

continuously reinforced concrete pavements with static loads for a chosen field

of temperatures.

Modelling reinforced concrete poses

a significant number of problems caused mainly by the structure and properties

of the material. Reinforced concrete constructions combine two materials of a

different quality, namely, concrete and steel. Steel is a relatively homogenous

and well-tested material, while concrete is a composite of aggregate, sand,

cement and water, which reveals microvoids. Even for small deformations, there

is physical non-linearity. Concrete indicates high levels of endurance in terms

of compression and minimum levels for stretching in relative terms. In the

stretched areas, concrete has tendencies to become scratched and, when

compressed, to be crushed, which changes the properties of the material. In

general, the reaction of reinforced concrete is non-linear involving complex

laws of behaviour. The procedures for calculating the FEM in reinforced

concrete are based on incremental iterative methods.

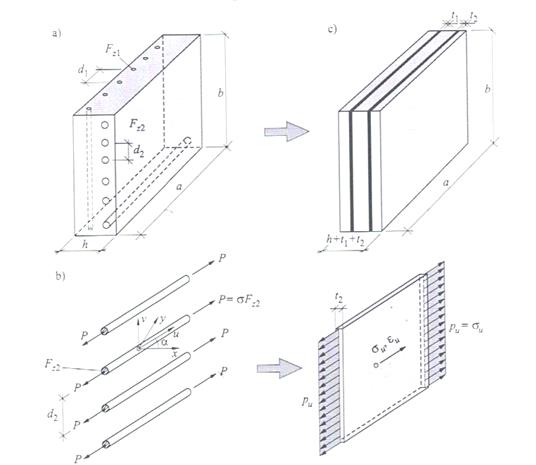

Fig.

4. The replacement model of a reinforced concrete shield [12]

In the analysed model of the

reinforced concrete shield, as shown in Fig. 4, the arrangement of reinforcement

bars is replaced by a slab element of thickness. As a result, the reinforced

concrete shield converts to a layer shield, with a layer of concrete, which is

h thick, and steel, which is t1, t2 thick, assuming that

there is full cooperation between the two materials, which means that the

compatibility of movements and deformations on their touching takes place. The

model of a reinforced concrete airport slab was made using the Femap program.

The particular stages of construction of the model are:

-

Creating

a square plane sized 10x10 [m] and providing the material properties for steel

and concrete (Table 1) [4].

Table 1. Material properties

of concrete and steel

|

Material |

Concrete |

Steel |

|

Young module [MPa] |

32,000 |

210,000 |

|

Poisson ratio [-] |

0.7 |

0.3 |

|

Density [g/mm3] |

2.4E-9 |

7.85E-9 |

-

Dividing

a plane into 10,000 finite elements and providing the third dimension of a slab

by drawing, at the height of 0.3 m, a solid consisting of 60,000 elements.

-

Removing

nodes placed at the bottom part of the solid to a distance of 0.1 m in order to

create elements of the GAP type in order to replicate the reaction of the

subsoil to the reinforced concrete. The created geometric model, sizeD

10x10x0.3 [m], is the only slab of a continuously reinforced concrete pavement that

is surrounded by all four sides by the other slabs.

-

Two

layers of fabric, composed of steel rods with a diameter of 10 mm, were placed

in a model of concrete. In order to make trusses, rod-type elements were used.

Rods are used in the analysis of truss constructions, which include axial

stresses (compression, stretching), apart from bending.

Top and bottom reinforcement Gap-type elements 3D elements

Fig. 5. Solid model of a slab with

marked reinforcement

The present example is only part of the entire

analysis of thermal loads with regard to the impact of daily temperature

fluctuations on displacements and stresses in continuously reinforced concrete

pavements with the use of numerical analyses. To simulate the operation of

reinforced concrete at negative temperatures, a load in the form of a positive

gradient of temperature of -16/0°C was used, where the lowest temperature occurs at the bottom of

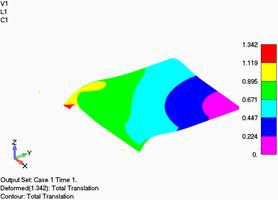

a slab. According to the map of displacements below, it is shown that

the negative temperature at the bottom part of the plate causes its shrinkage,

whereas higher temperatures in the upper layers cause its stretching. Maximum

displacements occur at the free corner of the slab. The greatest maximum

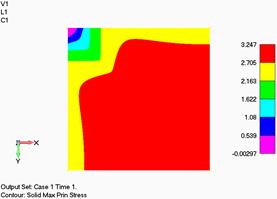

stresses mainly occur at the bottom of the slab, within a layer in which the

lowest temperature and the subsoil are affected (Fig. 6).

|

|

|

|

Fig. 6. Finite displacements and

deformations [mm] and maximum main stresses at the |

|

In the case of loads with a positive gradient of temperature within a

range 0/-16°C, the lowest temperature occurs mainly in the upper layer of a

slab, which causes the

shape of deformation to be reversed (Fig. 7).

|

|

|

|

Fig. 7. Entire displacements and

deformations [mm] and maximum main stresses |

|

6. CONCLUSION

The overall analysis of the results

and their comparison with other concrete pavements, including unreinforced and

interconnected [1,2] types, in terms of the implementation of higher usable

loads and increased traffic, highlights the need to use new, stronger and safer

surfaces and, in turn, modern calculation methods for determining optimal

constructions.

According to the previous numerical analysis, it can be concluded that:

-

The presented analysis performed in the study

indicated the possibility of using professional FEM programs for the entire

analysis of the state of displacements and stresses in slabs and dowels.

- The use of reinforced concrete slabs

provides the possibility for avoiding the use of dilatation in slabs, which

prompts the need to use dowel joints in the weakest places within surface

constructions.

- Greater analysis enables a selection

of examples, which, due to strength and safety reasons, are the most beneficial

- The complex nature of the occurring

stresses in the vicinity of reinforcement requires additional analyses with the

use of models on a different scale.

References

1.

Dacko M., R.

Brodzik. 2008. “Numeryczna analiza wpływu obciążeń termicznych na stan przemieszczeń

i naprężeń betonowych płyt lotniskowych.” Biuletyn WAT 2: 23-43. [In Polish: “Numerical analysis of the effect

of thermal stress on the state of displacement and stress of airport concrete

slabs”. WAT Newsletter 2: 23-43]. ISSN

1234-5865.

2.

Dacko M., R.

Brodzik. 2007. “Numeryczna analiza betonowych dyblowanych płyt lotniskowych”. Drogownictwo 6: 196-202. [In Polish: “Numerical

analysis of airport concrete slabs”. Road

Construction 6: 196-202]. ISSN: 0012-6357.

3.

El-Rashidy

R.A., S. Grant-Muller. 2016. “The evaluation of redundancy for road traffic

networks”. Transport 31(41): 427-439.

DOI: http://dx.doi.org/10.3846/16484142.2016.1255913.

4.

EN 206: 2014. Concrete - Requirements, Properties,

Production and Conformity. Warsaw: Polish Committee for Standardization.

5.

Janulevičius

A., G. Pupinis, J.s Lukštas, V. Damanauskas, V. Kurkauskas. 2017. “Dependencies

of the lead of front driving wheels on different tire deformations for a MFWD

tractor”. Transport 32(1): 23-31.

DOI: http://dx.doi.org/10.3846/16484142.2015.1063084.

6.

Nita P.

2005. Betonowe nawierzchnie lotniskowe:

Teoria i Wymiarowanie Konstrukcyjne. [In Polish: Airport Concrete Surfaces: Theory and Structural Dimensioning].

Warsaw: ITWL. ISBN 8391433765.

7.

National Road Construction

Programme/Ministry of Infrastructure and Construction. National Road Construction Programme for 2014 to 2023 (with a View to

2025). Available

at: http://mib.gov.pl/2-program_ budowy_drog_krajowych.htm.

8.

Paleczek W.

2001. “Analiza tarcia płyty betonowej o podłoże pod wpływem jej zmian

termicznych.” Drogownictwo

3: 68-72. [In Polish: “Analysis of

friction of the concrete slab on the ground under the influence of the thermal

changes”. Road Construction 3:

68-72]. ISSN 0012-6357.

9.

Petho L., P. Bryant, J. Jones, E. Denneman 2016.

“EME2 pavement and mix design”. Road & Transport Research 25(4).

ISSN: 1037-5783.

10.

Petruccelli

U., S. Carleo. 2017. “Cost models for local road transit”. Public Transport 1-22. DOI: 10.1007/s12469-017-0162-2.

11.

Polish

experiences with concrete pavements without transverse slots”. Available at: https://www.gddkia.gov.pl/userfiles/articles/d/dylatacje-nawierzchni-betonowych_10814/2007_2_30-33.pdf.

12.

Rakowski G.,

Z. Kacprzyk. 2016. Metoda Elementów

Skończonych w Mechanice Konstrukcji. Warszawa: Oficyna Wydawnicza

Politechniki Warszawskiej. [In Polish: Finite Element Method in Structural

Mechanics. Warsaw:

Warsaw University of Technology Publishing House]. ISBN 978-83-7814-471-7.

13.

Szydło A.

2004. Nawierzchnie Drogowe z Betonu

Cementowego. Kraków: Polski Cement Sp. z o.o. [In Polish: Road Surfaces of Cement Concrete.

Cracow: Polish Cement Sp. o.o.] ISBN 838947803X.

14.

The World of Concrete Roads Made with Concrete technology: Achievements and

Challenges. Available at:

http://www.swiatbetonu.pl/realizacje/drogi.

Received 20.02.2017; accepted in revised form 17.04.2017

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License