Article citation information:

Warczek, J. A study on exposing the driver of a commercial vehicle to

mechanical vibration. Scientific Journal

of Silesian University of Technology. Series Transport. 2017, 94,

229-238. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.94.20.

Jan

WARCZEK[1]

A study oN exposing the driver of a commercial vehicle

to mechanical vibration

Summary.

This article presents the results of research whose objective was to assess the

risks of vibration in the workplace to a driver of a commercial vehicle. Under

current EU law on working time, daily vibration exposure for drivers of

commercial vehicles should be determined for every nine hours of work. Research

on nuisance vibrations on a driver was carried out on a commercial vehicle

operated under normal conditions in urban traffic and outside urban areas.

Vibration exposure assessment was separately made for each direction of

vibration influence. The obtained results enable us to conclude that drivers of

commercial vehicles are exposed to harmful vibrations, which largely exceed the

limits of exposure to mechanical vibrations in general.

Keywords: exposure to vibration, commercial vehicle, work

safety

An important factor that impacts on

traffic safety is the psychomotor performance of the driver. Any decrease may

result from the harmful effects of vibration, to which the driver is exposed

during transport tasks. The degree of the impact of vibration is dependent on

many factors. The most important of which include the extortion and propagation

of vibration in the mechanical structure of the vehicle [6]. The basic elements

of the mechanical structure of the car responsible for minimizing vibrations

are cushioning units, such the suspension system for the wheels, pneumatic

tyres, suspension systems of the engine, the transmission system, and the

suspension of the drivers cab with a seat suspension system. The greatest

energy resulting from mechanical vibrations takes over the suspension of the

vehicle, along with the chassis. The system consists of elements connecting the

wheels to the frame of a commercial vehicle [1], which adapt to all the loads

acting on the wheels. A typical solution for the chassis and suspension

consists of:

axis

of the wheels (rigid beam axle wheel or driving axle housing)

bearing

units of the wheels

road

wheels (rigid metal rims with pneumatic tyres)

elastic

elements (steel or pneumatic spring)

vibration

dampers (viscous dampers and vibration-isolating elements based on elastomers)

guide

elements in the suspension system (control arms, radius rods)

The purpose of the suspension system

and pneumatic wheels is the amortization of the body, or the mitigation of

vibrations that are caused, for example, by driving on bumpy roads. On the

other hand, the elastic fastening of the wheels to the body results in the

potential for resonant vibrations, which adversely affect the ability to

transfer forces from the dynamic system of the vehicle to the road surface.

Excessive vibrations of the wheels also cause considerable dynamic loads of the

tyres and the road surface. This is why the suspension system involves the

efficient use of vibration dampers in the form of hydraulic shock absorbers [7,

8].

By damping and mitigating the

dynamic interactions between the uneven road surface and the wheels of the car,

the suspension system ensures a comfortable ride at an appropriate level,

together with the protection for passengers and cargo, while maintaining

security due to the adhesion of wheels to the surface [5, 11]. The issues are

particularly important when driving at the high speeds that modern commercial

vehicles can reach.

2. RESEARCH PROBLEM

The cabin, which is a separate part

of the body of the truck, is the workplace of the driver. In modern commercial

vehicles, it is elastically mounted to the frame by elastic means (steel or

pneumatic springs) and damping elements (hyperviscous dampers). In addition,

the cabin is protected against high-frequency vibrations using metal-rubber

connectors. Flexible cab suspension meets the need of isolation from the

vibration of the vehicle frame, due to the transfer of vibration from the

wheels and the powertrain. Inside the cabin are seats for the driver and

passengers, as well as devices used to control the vehicle and parameters of

the vehicle systems.

The drivers seat is usually placed

on seat tracks attached to the cab floor, so that it can be set relative to the

cockpit in order to adapt to the anthropometric measurements of the driver.

Suspension of the modern drivers seat is based on regulated elastic and

damping elements. Armchairs in modern trucks are equipped with pneumatic

suspension. By changing the air pressure in air cushions, it is also possible

to adjust the vertical position of the seat [1, 2]. Air cushions, placed in the

headrest, allow for a proper fit of its shape to the silhouette of the driver.

Accordingly, the assumed

distribution of vibration is as follows:

locally,

it is propagated into the body through the hands

generally,

it penetrates the body through the pelvis, legs and back

Drivers of commercial vehicles are

mainly exposed to whole-body vibration due to the work done in a sitting

position. The vibration energy of seats is transmitted to the human body by the

back, pelvis and sides. The negative effects of vibration of a general nature

mainly concern the human skeleton and internal organs. The skeletal lesions

occur primarily in the lumbar spine. Adverse changes in the internal organs, as

a consequence of the impact of overall vibration, are mainly the result of the

stimulation of individual organs by the resonant vibration [7, 9]. This can

lead to the appearance of disturbances in the activities of these organs and,

in extreme cases, mechanical damage to these organs. Even when low energies of

vibration intrude the human body after long exposure times, there are negative

effects of their influence in the form of psychosomatic reactions (fatigue,

elongation of reaction time etc.).

Acceptable exposure to vibration for

drivers of commercial vehicles is determined by the legal acts that define the

daily exposure to vibration. The determination of daily vibration exposure for

professional drivers in the conducted research has been divided into stages:

identification

of the series of separate operations performed by the driver during the working

day

indication

of the operations to be assessed

determination

of the values of effective vibration acceleration (RMS) for each operation

determination

of the average daily exposure times for each operation

calculation

of the daily exposure to vibration

According to the current European

Parliament and Council Regulation No. 561/2006 of 15 March 2006, the daily

driving time, which is understood as the total driving time between the end of

one daily rest period and the beginning of the following daily rest period, or

between a daily rest period and a weekly rest period, shall not exceed nine

hours and can be twice-weekly extended to 10 hours [10]. In planning the

driving time, 45 minutes should be allocated for breaks. It must therefore be

assumed that the daily vibration exposure for drivers of commercial vehicles,

subject to working time registration, should be determined for at least nine

hours of work.

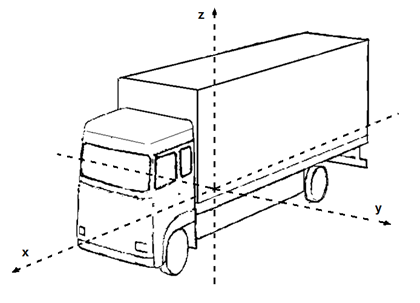

Research on the vibration nuisance

regarding the driving position was carried out on the MAN TGL 12.240, which is

a two-axle commercial vehicle with a box-shaped construction with a permissible

total weight of 12,000 Mg [2]. The scheme adopted in the research regarding

directions of the measurements of vibration acceleration is shown in Figure 1.

Fig. 1. Directions of vibration measurements in the tested vehicle

The suspension system of the tested

vehicle comprised parabolic springs and a stabilizer on the front axle, and air

springs and a stabilizer on the rear axle. The car was equipped with a low,

elongated cabin, which used four-point suspension. The cabin was amortized from

the frame in the front section by means of mechanical springs, with gas ones in

the rear. They subsequently entered the hydraulic shock absorbers via all four

points of support.

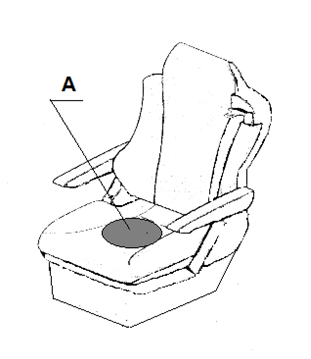

The drivers seat in the test

vehicle was equipped with a pneumatic suspension, which facilitated

longitudinal adjustment of the seat height and adjustment of the seat tilt. The

seat also provided a rest position and the rapid lowering of the seat for easy

entry and exit from the car. Views of the drivers seat in the cabin and the

method of affixing of measuring pads using acceleration sensors are shown in

Figure 2.

During the measurements, the driver

was subjected to vibrations, whose main source was uneven surface and changing

traffic conditions resulting from changes in the volume of traffic on the whole

route. The measurements were carried out while driving without a load. The test

vehicle moved along roads located in urban areas and on rural roads. Vibration

tests were also conducted on the seat while moving on the highway. The route

was chosen in such a way as to best reflect the working conditions of the

driver during a typical day of work, that is, in changing traffic, which is

associated with the distance from the city centre, and variable surface

conditions resulting from the road class.

The measuring set used in the study

consisted of a triaxial acceleration converter mounted on a rubber vibration

pad (Fig. 2b), which cooperated with the data acquisition and analysis module.

The converter was set up in such a way that the x direction coincided with the

direction of straight-ahead driving.

|

a) |

b) |

|

|

|

Fig. 2. View of the drivers seat in

the MAN TGL: (a) the scheme of placing the vibration acceleration sensor on the

seat and (b) the rubber cushion (A) of the vibration acceleration sensor

During the study, effective values

of vibration acceleration a(t) were recorded in three directions consistent

with Figure 1. Effective values characterizing the energy impact of vibration

on the driver were determined according to Formula 1.

![]() (1)

(1)

where

T represents the time of measurement and a(t) represents the instantaneous

values of vibration acceleration.

The recorded vibration signals

indicate a stationary character on the roads with a good surface and a pulsed

(non-stationary) character on suburban roads in a poor state with many ruts and

flumes. The measured values of vibration acceleration were also influenced by

driving style (traffic flow), which changed during the experimental passage.

4. RESULTS AND ANALYSIS

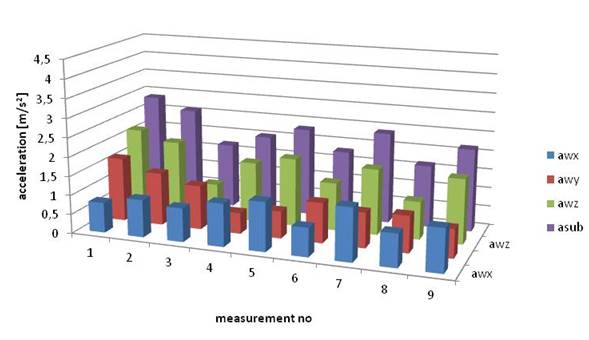

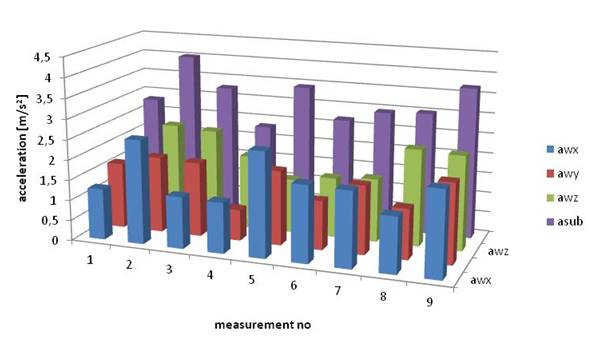

Measurements of RMS vibration

acceleration were made in three directions: x, y, z. The measurements were

carried out in a cyclic mode, yielding a series of effective value vibration

acceleration in a given direction of measurement. The results were divided by

the types of road on which the vehicle moved according to the adopted

classification for roads: urban, extra-urban and motorway. To assess the

harmfulness of vibrations to humans, we used the vibration energy measure,

marked out for an appropriately selected frequency band. The effective value of

vibration acceleration awRMS for each direction of measurement (x,

y, z) for a cycle involving an 1 h ride was determined as:

![]() (2)

(2)

where

T represents the reference time of 1 hour and aj represents the instantaneous values of vibration acceleration recorded

at time tj.

Substitute values of vibration

acceleration asub,i have been designated as the sum of the vector

acceleration operating in three orthogonal directions (Equation 3). This is a measure

of the impact of vibrations mainly used in local vibration analysis. In the

case of drivers of motor vehicles, the presence of seat vibration is associated

with the relative movements of the seat and cabin floor together with the

cockpit. The relative movements of the driver on the seat give the effect of

local vibrations penetrating the body through the hands, which rest on the

steering wheel.

![]() (3)

(3)

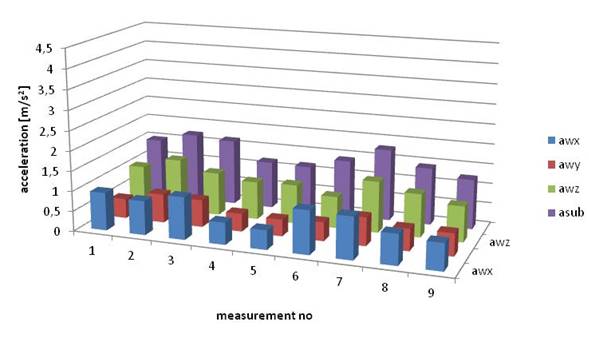

The results of effective value

measurements (aRMS) of vibration acceleration for various directions

of measurement, as well as the resultant acceleration, are shown in Figures

3-5. The numbers of measurements represent the consecutive hours of

observation.

Fig. 3. The results obtained for roads in urban areas

Fig. 3. The results obtained for roads in urban areas

Fig. 4. The results for roads in

extra-urban areas

Fig. 4. The results for roads in

extra-urban areas

Fig. 5. The results for highways

Fig. 5. The results for highways

The daily vibration

exposure in each direction of the measurement of vibration acceleration for

different types of road was calculated according to Formula 4, which

incorporates a nine-hour working time limit for drivers:

![]() (4)

(4)

where awRMS(x,y,z) represents the

effective value of vibration acceleration for a specific

operation in the direction x, y or z (m/s2); n

represents the number of

occasions involving 1 h measurements (n = 9); i represents the numbers of successive 1 hr vibration observations; ti

represents the duration of the operation equal to

3,600 (s); T0 represents

the reference time equal to 32,400 (s); and k(x,y,z)

represents the value of the weighting

factor. For the directions x, y, k = 1.4; for the direction z, k = 1.

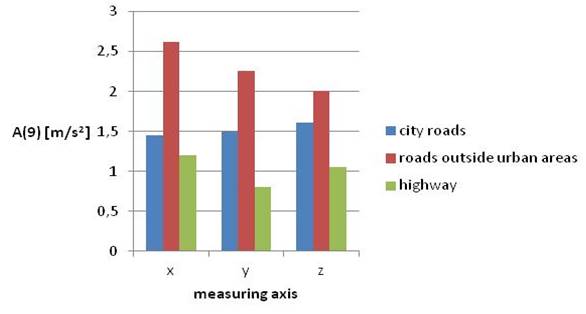

A summary of the

research results concerning the driver of a commercial vehicles exposure to

vibrations while driving on various road surfaces is shown in Figure 6.

Fig. 6. The value of the drivers exposure to vibrations (for nine hours) when

driving on roads of different categories

Fig. 6. The value of the drivers exposure to vibrations (for nine hours) when

driving on roads of different categories

Vibration

exposure assessment was separately conducted for each direction of vibration

influence. In the case of movement on roads located in urban areas, the highest

values occurred in the vertical direction. In non-urban traffic, the maximum

values of exposure occurred in the longitudinal direction. Similarly, in

motorway traffic, the highest value of exposure occurred in the direction of

the longitudinal axis of the vehicle. For all tested directions, the effects of

vibration energy on the vehicle driver while driving on the selected road types

were the selected maximum values; this is consistent with the assessment

procedure specified in the standard [3].

5. SUMMARY

For a driver of a commercial

vehicle, who is used to roads of different categories, the daily exposure level

depends largely on the condition of the road surface. The test vehicle was in

good condition, which was confirmed before and after the conducted research by

service inspections. It transpires that, during transportation tasks, in the

shuttle cycle, when using roads outside urban areas, the exposure limits for

vibration are likely to be substantially exceeded. This is particularly

important when planning driving routes, where route selection may result in a

negative impact on the vehicle driver. Limit values for exposure to general

vibrations in an eight-hour working cycle are set out in the Annex to the

Regulation of the Minister of Labour and Social Policy of 29 November 2002

[4]. According to this document, vibrations that have a general impact on the

body should not exceed the value of daily exposure A(8) for 0.8 m/s2.

Summing up the results of this

research, it is clear that drivers of commercial vehicles are exposed to

harmful vibrations, which significantly exceed the limits of exposure to

general mechanical vibrations. There is also an incompatibility between the

regulation of drivers working time and the standards related to daily exposure

to vibrations. It is therefore important to continue working on design

solutions that can reduce the value of drivers exposure to mechanical

vibrations, as well as synchronize the legal frameworks for the regulation of

drivers working time and daily vibration exposure.

References

1.

Prochowski

Leon, Żuchowski Andrzej. 2016. Trucks and

buses. Warsaw: WKiŁ. ISBN

9788320619706.

2.

MAN TGL 12.240 User Manual.

3.

PN-EN

14253+A1: Drgania mechaniczne. Pomiar i obliczanie zawodowej ekspozycji na

drgania o ogólnym działaniu na organizm człowieka dla potrzeb ochrony zdrowia.

Wytyczne praktyczne. Styczeń 2011. [In Polish: PN-EN 14253+A1: Mechanical

vibration. Measurement and calculation of occupational exposure to vibrations

of the general impact on the human body for health. Practical guidance.

January 2011].

4.

Rozporzšdzenia

Ministra Pracy i Polityki Społecznej z dnia 29 listopada 2002 r. w sprawie

najwyższych dopuszczalnych stężeń i natężeń czynników szkodliwych dla zdrowia w

rodowisku pracy (Dz. U. z 2002 r. Nr 217 poz. 1833; Dz. U. z 2005 r. Nr 212

poz. 1769; Dz. U. z 2007 r. Nr 161 poz. 1142; Dz. U. z 2009 Nr 105 poz. 873;

Dz. U. z 2010 Nr 141 poz. 950). [In Polish: Regulation of the Minister of

Labour and Social Policy of 29 November 2002 on the maximum permissible

concentration and intensity of harmful factors in the work environment (Dz. U.

z 2002 r. Nr 217 poz. 1833; Dz. U. z 2005 r. Nr 212 poz. 1769; Dz. U. z 2007 r.

Nr 161 poz. 1142; Dz. U. z 2009 Nr 105 poz. 873; Dz. U. z 2010 Nr 141 poz.

950)].

5.

Warczek

Jan, Rafał Burdzik, Łukasz Konieczny. 2016. Analysis of the forces generated

in the shock absorber for conditions similar to the excitation caused by road

roughness. Dynamical systems: theoretical and experimental analysis. Łód,

Poland, December 7-10, 2015. In Jan Awrejcewicz (ed.), Springer Proceedings in Mathematics & Statistics, Vol. 182, P.

373-383. Berlin: Springer International Publishing.

6.

Burdzik

Rafał, Aleksander Lisiecki, Jan Warczek, Łukasz Konieczny, Piotr Folęga,

Agnieszka Szkliniarz, Grzegorz Siwiec. 2016. Research on vibration properties

of copper-titanium alloys. Archives of

Metallurgy & Materials, Vol. 61, Iss. 1: 315-322. ISSN 1733-3490.

7.

Warczek

Jan, Jakub Młyńczak, Rafał Burdzik, Łukasz Konieczny. 2015. Simulation of a

visco-elastic damper based on the model of the vehicle shock absorber. Journal of Vibroengineering, Vol. 17,

No. 4: 2040-2048. ISSN 1392-8716.

8.

Warczek

Jan. 2014. The diagnostic model of a nonlinear viscoelastomeric damper. Diagnostyka, Vol. 15, No. 4l: 29-34.

ISSN 1641-6414.

9.

Kozuba

Jarosław, Pila Jan. 2015. Selected elements influencing pilot situational

awareness. Advances in Military

Technology, Vol. 10(2): 45-55. ISSN 18022308.

10.

Regulation

(EC) No. 561/2006 of the European Parliament and of the Council of 15 March

2006 on the harmonization of certain social legislation relating to road

transport and amending Council Regulations (EEC) No. 3821/85 and (EC) No.

2135/98 and repealing Council Regulation (EEC) No. 3820/85 (Text with EEA

relevance): Declaration.

11.

Konieczny Łukasz, Rafał Burdzik, Jan Warczek, Piotr

Czech, Grzegorz Wojnar, Jakub Młyńczak. 2015. Determination of the effect

of tire stiffness on wheel accelerations by the forced vibration test method. Journal of Vibroengineering, Vol. 17,

Issue 8: 4469-4477. ISSN 1392-8716.

Received 27.11.2016;

accepted in revised form 15.01.2017

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License