Article citation information:

Piľa, J., Korba, P., Hovanec, M. Aircraft brake temperature from a

safety point of view. Scientific Journal

of Silesian University of Technology. Series Transport. 2017, 94,

175-186. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.94.16.

Ján PIĽA[1], Peter KORBA[2],

Michal HOVANEC[3]

AIRCRAFT BRAKE TEMPERATURE FROM A SAFETY POINT OF VIEW

Summary. Safety is critical throughout all stages of

aircraft operation, from air mission to ground operation. One of the most important

airframe systems that influences the efficacy of ground safety is a wheel brake

system. Aircraft ground speed deceleration requires the dissipation of kinetic

energy, which depends on aircraft weight and speed. Significant levels of

aircraft kinetic energy must be dissipated in the form of heat energy. The

brakes of heavy aircraft are especially prone to overheating during landing and

taxiing on the ground. The aim of this paper is to focus on the dangers caused

by aircraft brakes when overheating and ways in which to eliminate brake

overheating problems from a safety perspective.

Keywords: brake, temperature, overheating, aircraft safety,

brake cooling

1.

INTRODUCTION

Wheels, tyres and brakes are critical to ensure safe and reliable

aircraft ground operation. The primary purpose of aircraft wheel brakes is to

decelerate and stop an aircraft by transforming the kinetic energy into heat

energy via friction and dissipation of heat to the surroundings.

The secondary function of aircraft wheel brakes is to hold the aircraft

stationary during the engine’s run-up and, in many cases, steer the aircraft

during taxi.

Aircraft brakes are arranged in multiple disk pairs, which are commonly

referred to as the brake heat sink. Two main methods of increasing aircraft

friction or drag are applied:

•

air friction: aerodynamic drag

(airbrakes, spoilers, flaps, reverse thrusters, drag shuts etc.)

•

ground friction: wheel brakes

(aircraft to ground drag)

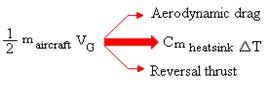

The weight and speed of an aircraft during landing and taxing determine

how much energy the brake friction material absorbs.

Brake sizing is based on heating during a single landing and takes into

account that ventilation has a limited effect, while neglecting the

contribution of possible thrust reversal, flaps and spoilers. This means that a

high part of the kinetic energy on landing will be converted into brake

heating; the part of the brakes that is involved is often referred to as the

heat sink. This event can be expressed by a simple formula of energy balance

[1, 2]:

where

m refers to mass, VG refers to ground speed, C refers to a specific

head of heat sink material and T refers to temperature.

Wide body and military aircraft brakes use multidisc of rotor and stator

brakes (Fig. 1). Brake housings contain several pistons for applications of the

normal force needed to develop the brake torque.

Fig. 1. Multidisc brake

Source: authors’ ABT Košice wheel and brake shop

The landing kinetic energy of modern aircraft equates to several million

joules. The brakes of large commercial aircraft must be capable of absorbing up

to 135 MJ of energy. This enormous energy, when absorbed by the brakes within

10-12 s after landing, imposes severe thermal gradients of thousands of degrees

centigrade per cm2 across the friction elements and brake bulk

temperatures of 1,000°C or more [3].

Brake materials have additional requirements, such as resistance to

corrosion, light weight, long life, low noise, stable friction, low wear rate, and

acceptable cost versus performance. The design of the brakes affects heat flow,

reliability, noise characteristics and ease of maintenance.

This energy conversion process produces very high energy fluxes at the

multiple friction interfaces, resulting in high temperatures and stresses in

the brake heat sink. The friction and wear characteristics of the friction

materials used in aircraft brakes are influenced by internal factors (such as

friction-material composition and heat sink mass) and external factors (such as

the amount of kinetic energy absorbed by the brake, the surface velocity of the

friction interfaces and aircraft deceleration requirements). Simply put, these

factors control the temperature at the interface as well as the normal and

tangential forces of the friction material.

Potential problems related to excessive brake energy are:

•

brake overheating

•

brake fire

•

brake fade

•

brake welding

•

failure of brakes or associated

components

•

fuse plug melt

2.

OVERHEATING OF BRAKES

During normal or emergency aircraft braking, the landing gear of the

aircraft is highly stressed and therefore deserves special attention. Due to

increased weight (Airbus A380 MTOW = 575 tonnes) and higher landing speed

(Airbus A380 = 240-250 km/h) of modern aircraft, as well as the requirement of

extreme braking for the shortest path (for the Airbus A380, it is 2000 ft =

609.6 m of runway), brakes overheating are a frequent phenomenon. It is

therefore understandable that the overheating of the brakes constitutes a

hazard. Overheated wheels and tyres pose a risk of possible explosion because

tyre pressure will increase considerably.

When parking the aircraft, it is therefore recommended to cool

overheated wheel brakes and tyres, as well as provide aircraft parking in

isolated areas. Using water as the cooling medium is not recommended unless it

is necessary to protect people in the vicinity of overheated wheels.

The ICAO recommendation is thus: too rapid cooling of a hot wheel,

especially if localized, may cause explosive failure of the wheel. Water fog

can be used, but intermittent application of short bursts of 5-10 s every 30 s

is recommended. Dry chemicals have

limited cooling capacity but are an effective extinguishing agent. Once the

tyres are deflated, any extinguishing agent may be safely used as there is no

further danger of explosion.

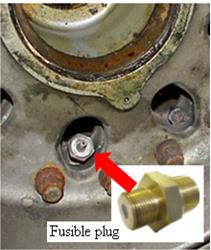

Thermal fuse plugs (Fig. 2) prevent the violent explosion of tyres when

maximum temperatures are exceeded. Most wheels of jet aircraft have fusible

plugs, which melt at specified temperatures (e.g., 177°C) and deflect the tyre

before dangerous pressures are reached.

The maximum temperature of the wheel may not be achieved in the period

up to 15 to 20 min when the aircraft exits the process of landing and taxiing.

Most modern large aircraft have temperature sensors built into the landing

gear.

Fig. 2. Fusible plug on the wheel disc

Source: http://www.airliners.net/forum/viewtopic.php?t=594267

Taxing over a longer period at a higher speed may increase brake temperatures

and cause subsequent fire in the wheel well at the stage of take-off for the

aircraft. In this case, a flight with landing gear extended for a period of

several seconds allows for rapid cooling of the brakes. Further, a flight with

extended landing gear may continue until the warning light “OWH” turns off.

Boeing 747 has prescribed a speed limit during taxiing (maximum 10

km/h-1) before stopping, followed by

landing gear checking and brake cooling.

During aircraft landing with intensive braking, in order to reduce

landing run distance, certain types of anti-skid devices are damaged by

overheating conditions.

The landing weight and interval before take-off play an important role

in respect of the brake temperature, which has to be very carefully monitored

in order to avoid exceeding the limit needed for energy stopping distance. Hot

brakes can severely decrease braking performance in the event of a rejected

take-off as well.

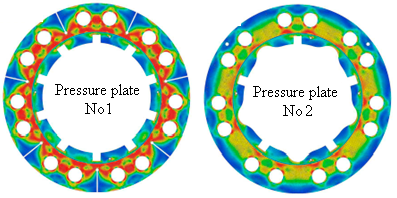

3. STRESS-STRAINS ANALYSIS OF BRAKE PLATES USING FINITE ELEMENT ANALYSIS

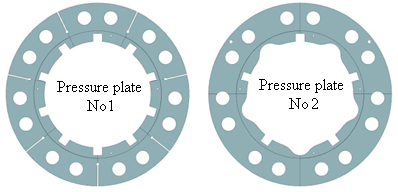

The aim of the numerical calculation was to compare two variants of

brake pressure plates from the Airbus A320. Stress-strain analysis was focused

on the identification of the most exposed areas, which could be the most

probable areas of crack initialization (Fig. 3).

Fig. 3. Crack in the brake pressure plate

Source: author’s ABT Košice wheel and brake shop

For this purpose, a nonlinear analysis was performed using the NX

Nastran program, in which a simulated load was applied to the pressure plate’s

plastic deformation (Fig. 5). For the purpose of comparison, the load applied

to both plates was identical.

Load conditions were established on the basis of input data and the

formation of plate loading during braking.

Input data were received by the company that performed the analysis:

•

material: steel size 17

•

density: 7,928 kg/m3

•

modulus: E = 19,3140 MPa

•

Poisson’s ratio: μ = 0.3

•

yield strength: Re = 280 MPa

•

tensile strength: Rm = 520 MPa

•

specific rate capacity: Cp = 0.49 kJ/kg°C

•

pulse expansion: α = 13.10-6 m/mK

•

coefficient of friction: f = 0.57

• contact force: Fn = 285 kN

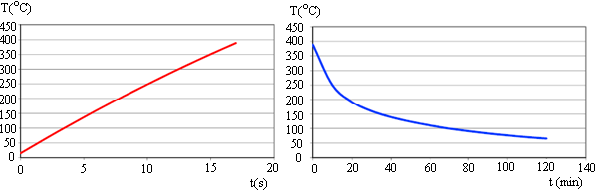

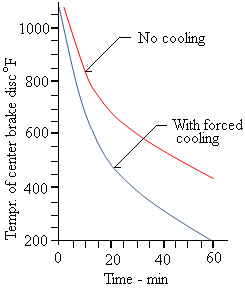

Figure 4 depicts the course of the brake temperature increase and the

brake temperature decrease (cooling).

Fig. 4. Brake temperature increase and decrease

Source: authors

According to the analysis (based on

a comparison of both models), it is evident that, under the same load

conditions, there are more striking plastic deformations on Plate 1 than on

Plate 2. A higher degree of plastic deformation of Plate 1 is linked to a

higher probability of material deterioration under cyclic stress-strain

conditions. Areas of material deterioration are mainly located at the end of

dilatation slots, which are missing from Plate 2 (Fig. 5). From this point of

view, the pressure from Plate 2 leads to better stress distribution around the potential stress concentrators (Fig. 5).

Fig. 5. Pressure plates from multidisc brakes

Fig. 6. Heat stress fields of pressure plates

Source: authors

4. BRAKE FIRE, FADE AND WELDING

When hydraulic fluid leaks onto the

hot brake components, the fluid causes fire to break out. A mixture of the two

types of hydraulic fluid lowers the temperature at which the fluid ignites,

that is, below the flashpoint of pure MIL-H-83282 fluid.

An aircraft maintenance mechanic

indicated that the two mixed hydraulic fluids, which are compatible, will

reduce the fire resistance of the fluid.

Exxon HyJet IV-Aplus fire-resistant

aviation hydraulic fluid has the following flammability:

·

flash point =

174ºC

·

fire point =

185ºC

·

auto-ignition

point = 427ºC

Another reason for a fire caused by

overheated brakes is their proximity to the hydraulic and electrical system. In

the case of Nigeria Airways flight 2120: “When the landing gear was retracted…

burning rubber was brought into close proximity with hydraulic and electrical

system components… causing the failure of both hydraulic and pressurization

systems that led to structural damage and loss of control of the aircraft.” The

cause of the crash was found to be under-inflated tyres, which in turn caused

overheated tyres to catch fire and the failure of the hydraulic systems.

Brakes can overheat for many

reasons. A “dragging brake” can heat up on a long taxi and take-off run. When

retracted into the wheel well, this can cause all sorts of problems. Taxiing

too fast over long distances can cause these temperatures to become so hot that

wheel well fires can develop after take-off. On large aircraft, brakes will

reach their hottest point up to 15 min after landing.

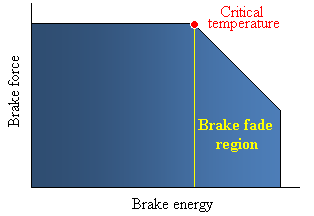

Brake fade is a term used to

describe the partial or total loss of braking power used in a vehicle brake

system (Fig. 7). Brake fade occurs when the brake pad and the brake rotor no

longer generate sufficient mutual friction to stop the vehicle at its preferred

rate of deceleration. The brake pad in any brake system is designed to work at

certain operating temperatures.

Fig. 7. Brake and brake fade region

Source: authors

New generations of passenger and

freight aircraft are equipped with carbon brakes, as opposed to steel brakes

found on relatively older aircraft. Carbon brakes have different

characteristics and should be operated differently than steel brakes. When

operating an aircraft equipped with steel brakes, the aircraft is required to

use full reverse thrust and minimum braking to minimize the heat input into the

brake assembly (rotors and stators). On long runways, braking can be delayed

until the taxi speed is reached. This is especially convenient when the

aircraft is not on the ground long enough for the brakes to cool. Carbon brakes

have better properties in comparison to steel brakes: they are lighter and can

absorb much more heat during a high-speed rejected take-off, as their stopping

capability improves as they are warmed up [1,

2].

Maximum steel brake life can be

achieved during taxi by using a large number of small and light brake

applications, allowing some time for brake cooling between applications. Carbon

brake wear is primarily dependent on the total number of brake applications:

one firm brake application causes less wear than several light applications [4]. Carbon brakes are not susceptible to “welding”.

5. TEMPERATURE SENSING AND

MONITORING SYSTEM

The heating of aircraft wheels and tyres

presents a potential explosion hazard, greatly increased when fire is present.

Modern

passenger airliners are equipped with “BRAKE HOT” (Airbus) or “BRAKE OVHT” (Boeing)

warnings for individual wheel brakes on the alert displays when the temperature of a brake

rises above a predetermined level and turns off when all the brakes have cooled

to a certain level.

The

reason for the “BRAKE HOT/OVHT” warning is to eliminate the possibility of

flames caused by hydraulic fluid (in the case of a leak of hydraulic fluid)

when the landing gear is retracted into the wheel well. A warning will

automatically start when the temperature reaches 400°C at the hottest part of

the brake lining. The temperature of 400°C ensures the lowest limit of the

auto-ignition of all hydraulic fluids used in the brake system. This mainly

involves liquid Hyjet IV or IV+, whose temperature of auto-ignition (427°C) is

specified under test conditions (under real conditions, the temperature of

auto-ignition is considered to be much higher). The temperature indicated in

the cockpit associated with the “BRAKE HOT” signal depends on the type and

location of the temperature brake sensor. This temperature occurs in between

185°C and 260°C for carbon brakes. If the temperature is above this value, the

alarm “BRAKE HOT” is signalled as “ON”, which means that take-off is not

possible, as this may cause a fire in the landing gear wheel well in the event

of hydraulic fluid leakage. Published ECAM procedures require a delay in

take-off until the alarm goes to “OFF”. The alarm goes out when the temperature

is 10°C below the temperature of triggering a warning, e.g., 290°C.

Brake

temperatures of each wheel are monitored in order to report brake temperature,

warn the crew of brake overheat and indicate any malfunction, such as a

dragging brake. A brake temperature monitoring system:

•

prevents take-off with a hot brake

•

prevent landing gear retraction with a hot brake

•

monitors for residual braking due to a dragging brake

The

“ON” warning appears at 300°C. To achieve an acceptable level of fire safety

during a flight, Airbus uses a number of measures related to the “BRAKE HOT”

signal. Some operators report that their activity is influenced by the time

required for brake cooling, which is associated with signalling (e.g., 300°C).

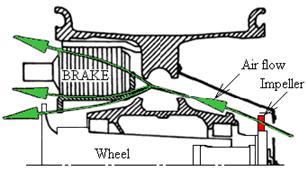

6. BRAKES COOLING

Military

and commercial aircraft are being designed for short turnaround times and short

landings distances. These aircraft determinations reduce brake cooling times

between usage and short landing distances, often resulting in the increase in

brake applications. Therefore, brakes are sometimes applied while they are

still hot and when the available kinetic energy in the brake is correspondingly

reduced.

There

are two ways of attacking the problem:

•

make a thorough analysis of the expected

operations and design the brake accordingly

•

provide the brake with a cooling device

Analyses

are provided by the brake manufacturer based on the mission profile data

(temperature spectrum for a particular brake).

The role of any cooling medium is cooling, i.e., reducing the

temperature of the object. This is done on the principle of the output of heat

being by conduction, convection and radiation.

The most widely used principle of brake cooling is heat transfer by convection. Heat transfer

by convection involves the movement of groups of molecules within fluids, such

as liquids or gases (cooling medium) from one place to another.

Although water is a very effective coolant, it is technically and

economically feasible in any airport. On the other hand, there are certain problems associated with the very

intensive cooling effect of overheated brake parts, such as heat shock, which

results in changes in the crystal structure of the materials. Moreover, in

brake discs, cracks can result in brake life reduction. Less serious, but still

an existing problem, is the fact that streams of water, if applied to the

wheel, cause a washout of graphite lubricant materials from the wheel bearing. While air, like water, is a commonly used refrigerant, its cooling

effect is significantly lower than that of water. In order to move heat from an air-cooled

object, the air stream flow to the cooled object needs to be of a high speed.

The higher the speed of the airflow acting on the cooled object, the higher the

transport of thermal energy. In many operating manuals for

propeller aircraft, the necessity to maintain the propeller speed to a proper

regime is stated, in order to create cooling airflow to the wheels.

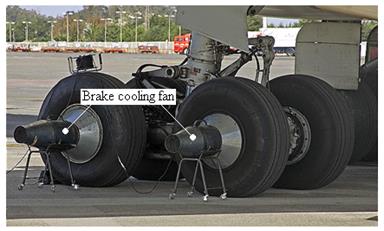

Fig.

9. Forced air brake cooling

Source: Norman S. Currey. 1988. Aircraft Landing Gear Design: Principles

and Practices

Airbus A330 and A380 aircraft can be optionally supplied with integrated

brake cooling fans. These fans are mounted on the brake assemblies of each

brake and thus increase the weight of the aircraft.

Airbus wheel parameters include the following:

·

A380

main wheel tyres that are 1.4 m high and 53 cm wide

·

Maximum

brake temperature for take-off for A320, A330 and A380 is 300°C. This limit

prevents hydraulic fluid leakage, such that any hydraulic fluid that comes into

contact with the brake units will not auto-ignite.

Fig. 8. Forced air brake cooling for

aircraft

Source: http://www.airliners.net/forum/viewtopic.php?t=594267

7.

CONCLUSION

Wheels

and brakes are vital aircraft units, as well as being the most stressed parts

of any aircraft. They are required to safely stop and operate the aircraft on

the ground, often under appalling conditions, during both take-off and landing.

In times of ground operation, they must withstand, absorb and safely dissipate

the tremendous kinetic energy during the slowing-down of an airplane and

bringing it to a safe stop.

Brake

overheating is a potential hazard that can lead to brake fire, brake fade and

brake welding and is considered as a serious problem for modern heavy aircraft,

which is multiplied by short turnaround times and short landings distances for

aircraft. Intensive brake applications, on the one hand, can save fuel and

speed up aircraft turnarounds; on the other hand, the level of safety can be

diminished, while the brake and wheel overhaul may be needed to be more

frequent. From the analysis of the wheel and brake shops, it is clear that the

intensive use of brakes, during aircraft operations, is less concerned with

fuel safety and more about the considerable expense of brake and wheel

overhaul.

For diagnosis purpose, non-invasive methods can be

use. An interesting diagnostic methods are presented by the author in [5-16].

References

1.

Piľa Ján, Kozuba Jarosław, Korba Peter. 2014. Airframe Structure 1. Deblin: Polish Air

Force Academy Publishing.

ISBN 978-83-64636-01-1.

2.

Piľa Ján, Jarosław Kozuba, Grzegorz Peruń. 2014. Aircraft Airframe 1. Gliwice: Silesian

University of Technology Publishing.

ISBN 978-83-7880-230-3.

3.

Debashis Dutta, Bijeta Chaterjee.

2002. “High energy aircraft friction materials – yet another man-madewonder.”

Golden Jubilee commemoration lecture (tenth in the series). Available at: http://www.academia.edu/6964842/Aircraft_Brake_Friction_Materials.

4.

Boeing.

2009. “Operational applications of carbon brakes”. Available

at: http://www.boeing.com/commercial/aeromagazine/articles/qtr_03_09/article_05_1.html

5.

Madej

Henryk, Piotr Czech. 2010. “Discrete wavelet transform and probabilistic neural

network in IC engine fault diagnosis”. Eksploatacja

i Niezawodnosc - Maintenance and Reliability, Vol. 4(48): 47-54. ISSN:

1507-2711.

6.

Czech

Piotr, Henryk Madej. 2011. “Application of cepstrum and spectrum histograms of

vibration engine body for setting up the clearance model of the piston-cylinder

assembly for RBF neural classifier”. Eksploatacja

i Niezawodnosc - Maintenance and Reliability, Vol. 4(52): 15-20. ISSN:

1507-2711.

7.

Czech

Piotr. 2011. “An Intelligent Approach to Wear of Piston-Cylinder Assembly

Diagnosis Based on Entropy of Wavelet Packet and Probabilistic Neural Networks”.

In Jerzy Mikulski (ed.). 11th International Conference on Transport

Systems Telematics. Katowice Ustron, Poland. 19-22 October 2011. Modern

transport telematics. Book Series: Communications

in Computer and Information Science, Vol. 239: 102-109.

8.

Czech

Piotr. 2011. “Diagnosing of Disturbances in the Ignition System by

Vibroacoustic Signals and Radial Basis Function - Preliminary Research”. In Jerzy

Mikulski (ed.). 11th International Conference on Transport Systems Telematics.

Katowice Ustron, Poland. 19-22 October 2011. Modern transport telematics. Book

Series: Communications in Computer and

Information Science, Vol. 239: 110-117.

9.

Czech

Piotr. 2012. “Determination of the Course of Pressure in an Internal Combustion

Engine Cylinder with the Use of Vibration Effects and Radial Basis Function -

Preliminary Research”. In Jerzy Mikulski (ed.). 12th International Conference

on Transport Systems Telematics. Katowice Ustron, Poland. 10-13 October 2012.

Telematics in the Transport Environment. Book Series: Communications in Computer and Information Science, Vol. 329: 175-182.

10.

Czech

Piotr. 2012. “Identification of leakages in the inlet system of an internal

combustion engine with the use of Wigner-Ville transform and RBF neural

networks”. In Jerzy Mikulski (ed.). 12th International Conference on Transport

Systems Telematics. Katowice Ustron, Poland. 10-13 October 2012. Telematics in

the Transport Environment. Book Series: Communications

in Computer and Information Science, Vol. 329: 414-422.

11.

Czech

Piotr. 2013. “Diagnosing a Car Engine Fuel Injectors' Damage”. In Jerzy

Mikulski (ed.). 13th International Conference on Transport Systems Telematics.

Katowice Ustron, Poland. 23-26 October 2013. Activities of transport telematics.

Book Series: Communications in Computer

and Information Science, Vol. 395: 243-250.

12.

Czech

Piotr. 2013. “Intelligent Approach to Valve Clearance Diagnostic in Cars”.

In Jerzy Mikulski (ed.). 13th International Conference on Transport

Systems Telematics. Katowice Ustron, Poland. 23-26 October 2013. Activities of

transport telematics. Book Series: Communications

in Computer and Information Science, Vol. 395: 384-391.

13.

Czech

Piotr, Jerzy Mikulski. 2014. “Intelligent Approach to Valve Clearance

Diagnostic in Cars”. In Jerzy Mikulski (ed.). 14th International

Conference on Transport Systems Telematics. Katowice Ustron, Poland. 22-25

October 2014. Telematics - support for transport. Book Series: Communications in Computer and Information

Science, Vol. 471: 225-232.

14.

Czech

Piotr. 2013. “Diagnose car engine exhaust system damage using bispectral

analysis and radial basic function”. In Dawei Zheng, Jun Shi, Limei Zhang (ed.).

International Conference on Computer, Networks and Communication Engineering

(ICCNCE). Beijing, China. 23-24 May 2013. Proceedings of the International

Conference on Computer, Networks and Communication Engineering (ICCNCE 2013).

Book Series: Advances in Intelligent

Systems Research, Vol. 30: 312-315.

15.

Czech

Piotr. 2013. “Intelligent approach to valve clearance diagnostic in cars”. In Bronius

Baksys, Algirdas Bargelis, Stasys Bockus, Algimantas Fedaravicius, Vylius

Leonavicius, Pranas Ziliukas, Romualdas Dundulis, Tilmute Pilkaite (eds.).

Proceedings of the18th International Conference on Mechanika. Kaunas University

of Technology, Kaunas, Lithuania. 4-5 April 2013. Kaunas University of

Technology. Book Series: Mechanika Kaunas

University of Technology: 58-61.

16.

Czech

Piotr. 2012. “Diagnosis of industrial gearboxes condition by vibration and

time-frequency, scale-frequency, frequency-frequency analysis”. Metalurgija, Vol. 51, Issue 4: 521-524.

ISSN: 0543-5846.

Received 12.11.2016;

accepted in revised form 08.01.2017

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License