Article citation information:

Markiewicz, T., Kaczmarczyk, Ł., Fabiś, P. Influence of intake system

modification on the formula student engine power. Scientific Journal of Silesian University of Technology. Series

Transport. 2017, 94, 139-149. ISSN: 0209-3324. DOI:https://doi.org/10.20858/sjsutst.2017.94.13.

Tomasz MARKIEWICZ[1],

Łukasz KACZMARCZYK[2], Paweł FABIŚ[3]

INFLUENCE OF INTAKE

SYSTEM MODIFICATION ON THE FORMULA STUDENT ENGINE POWER

Summary. This paper is a summary of the design and

workmanship of the formula student engine intake vehicle, for simulation

research projects were conducted on the intake system. In the process, the most

favourable model system was selected, which was capable of producing a

satisfactory range of the characteristics of the engine. For chosen models, the

intake system was also determined in terms of its impact on the power and

torque of the test vehicle, which was driven by a four-cylinder engine with a displacement

of 0.6 dm3.

Keywords: Formula Student, intake,

engine power

1. INTRODUCTION

In classical internal combustion piston

engines, the function of the intake system was to bring refrigerant to the

cylinder engine while maintaining the smallest possible flow resistance, with

the aim of obtaining a large ratio of filling cylinders. The flow resistance

factor depended on the shape of the intake manifold, the length and shape of

the intake ducts, and the air filter, which is an indispensable piece of

equipment in the intake system. The intake system of the internal combustion

engine was designed in such a way as to provide a suitable amount of air

to the engine during its operational cycle at any speed. When designing the

intake system for not charge engines,

which predominantly operate under negative pressure, it should be taken into

account that the wave motions are generated as a result of the movement of the

piston towards the bottom dead-centre position. However, in the case of

supercharged engines, which almost always work under hypertension, it is

important to carefully select the size of the plenum and the size of the inlet

channels at the design stage [14]. Properly designed intake systems should

allow for the uniform filling of all cylinders.

2. INLET SYSTEM OF THE TURBO ENGINE

The role of the intake manifold is

to supply air to the head of the spark-injection engine, while the amount of

moved air is adjusted by a throttle valve, which is part of the system. An

essential element of the intake manifold is an air chamber, which acts as a

plenum from which the individual cylinders absorb air. Runners, or short intake

channels, represent the second element, which are an extension of the inlet

head and combine the opening of the plenum. In the case of the plenum, it is

necessary to take into account the following important factors:

-

capacity

-

uniformity

of the air supply to the individual cylinders

-

shaping

the opening (inlet) of the individual runners to achieve the maximum flow [2]

The basic shape of the intake

manifold is determined by its use. Typically, the manifold is followed by a

damper, which is placed in front of the so-called air chamber, along with the

plenum, which supplies air to all the cylinders.

One advantage of the damper cylinder

is the smaller flow losses, which means that it is more suitable to use maximum

power. In the case of a throttle being placed before the manifold, accuracy is

increased, such that you can control the fuel injection and ignition at low

engine speeds, which makes this solution more suitable for road vehicles. A

preferred situation has also been designed for the intake manifold of a road

vehicle in such a way that the damper is placed centrally between the channels

of [1].

The most important role of the

plenum is to compensate the airflow to the individual cylinders. Unfortunately,

car manufacturers use a compact, aesthetically pleasing layouts, locating the

air intake on one end. This is not a problem at the design stage when topping

up the engine plenum, but when the airflow starts to rapidly increase in real

situations, a large disturbance ensues, which results in uneven delivery to the

air cylinder [2]. The arrangement of individual dampers with a single throttle

involves two different applications, but with many features in common. In both

cases, the inlet, which takes air to the intake ports, should ideally comprise

short runners into the combustion chamber. The size of the cone relative to the

inlet runners should be prudently selected.

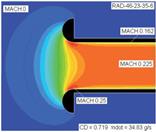

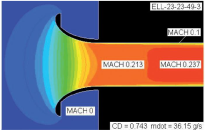

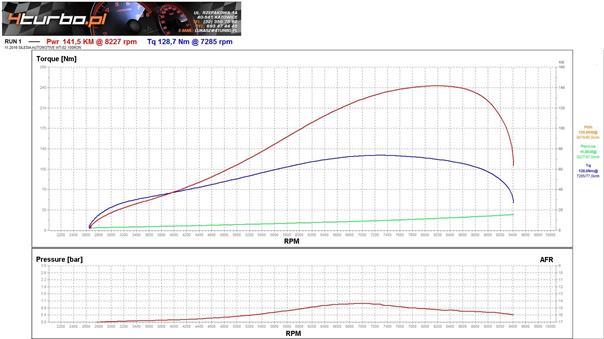

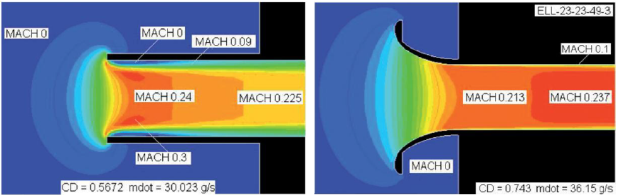

Figure 1 shows how the shape of the

intakes of the runners impacts on the speed of the airflow. On the left side,

you can see the speed of the flow in the event of the termination of a simple

tube, while the right tube forms a conical or bell shape [9].

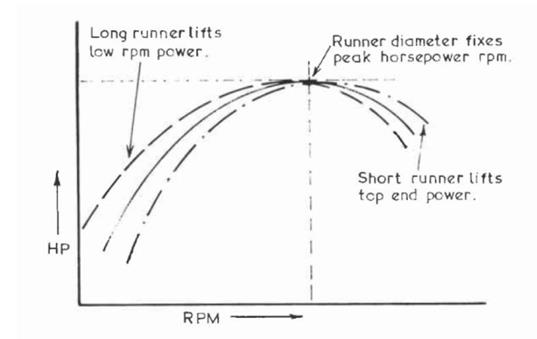

The length of the runners has a

significant impact on the amount of air that enters the combustion chamber when

the intake valve is opened and the engine is not running under pressure (top

up). In turbocharged engines in general, the best results are obtained using

long runners, which will result in a wide range of flat torque curves at low

speeds, while the turbocharger will maintain a relatively high power at the end

of the curve [1]. The literature contains information certifying that the

runner is a tool for controlling the engine, given that the diameter and the

length influence the shape of the power curve.

Fig. 1. Comparison of velocity flows for a simple inlet (left side) and

a cone inlet (right side); mdot: mass

flow per second [9]

Fig. 2. Chart of the influence of the diameter and the length of a

runner on engine power [2]

In principle, the diameter will

involve a fixed rotation, in which the engine produces maximum power to the

extent that the thick runner allows the engine to freely download air at high

speed, while reducing power to the lower range. The length of the channels

enables the extension of the power curve in the vicinity of the point

determined by their diameter (Fig. 2). Short runners work in an opposite way:

i.e., lower power and torque in the lower range help the engine to maintain

power through the peak [2]. One of the important points in the design of the

intake manifold is the connection between plenum and runners, which is the

place where the inlet openings to the runners should be chosen carefully, with

the most preferred combination resulting in the formation of a hole in the

bell-shaped inlet, or “trumpet” [1].

Fig. 3. Signing and shape of inlet ends [9]

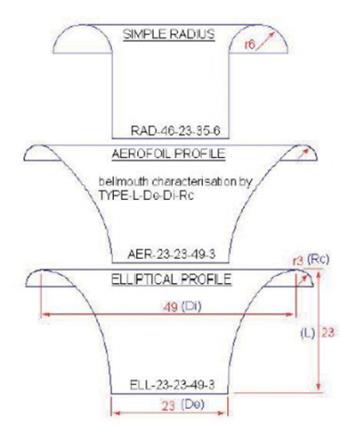

The construction of the bell inlet

or so-called “trumpet” in the internal combustion engine’s end runner intake

piston has been copiously addressed in the technical literature. Modern

computational fluid dynamics offer the possibility or even the ability to carry

out computer simulations to determine the optimal shape of “trumpets”. Figure 3

shows three types of bell-shaped inlet runner, which have been analysed. Each

type of bell is characterized by fundamental values such as L (length), Do

(diameter output), Di (diameter input) and R (radius zone) (Fig. 4). There are

different bell types: they may involve a straight pipe, the normal radius of an

aerodynamic profile or that of an elliptical profile. During Blair’s analysis,

a wide range of diameters and dimensions was tried and tested for each type of

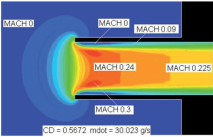

bell. Figures 6a-c represent the Mach number (speed of particles) for a normal

radius and an elliptical profile.

|

a) |

b) |

c) |

|

|

|

|

|

Fig.

4. Velocity stream flows and their decomposition for: a) fillet pipe, b)

elliptic profile and c) straight pipe [9] |

||

Simple rounding (Fig. 4a) shows a

significantly smaller contraction stream, which is evident for a straight pipe

(Fig. 4c). In contrast, an elliptical profile hardly narrows the stream, which

means that the flow is smooth and even. Additionally, as shown in Figure 4c,

when the tube terminates in a straight, sharp dissection, the influence

coefficient is 0.5672 and the measured mass flow rate us 30,023 g/s. As seen in

Figure 4a, when the inlet end is rounded with an ordinary radius, the influence

coefficient is 0.719 and the mass flow is 34.83 g/s. In Figure 6b, when the

bell is more refined, the elliptical profile’s drag coefficient is 0.743 and

the measured mass flow is 36.15 g/s. Considerable increases are observable in

the flow rate (27%) and the mass flow (16%) due to the addition of even a

simple rounding at the end of the inlet tube. A properly designed bell inlet runner

has a better flow rate of 3.5% compared to the normal rounding runner

connection with a plenum manifold. In terms of design, it is noted that a low

and large outer diameter bell mouth is the most optimal solution. The length L

of the bell should be equal to the initial diameter Do, while the entry

diameter Di should have a starting material diameter of 2.13. While the

literature does not provide any analysis of rounding, authors have nevertheless

suggested that rounding should have a diameter input of 0.08 [9]. Based on all

the information collected while designing the intake and its components, a

Student Formula-class first-intake manifold vehicle, known as WT-02, was created.

3.

INLET MANIFOLD

CONSTRUCTION FOR THE FORMULA STUDENT CAR

The object of the research is the

Formula Student racing class vehicle WT-02, equipped with a four-cylinder,

four-stroke spark-ignition engine, which has a capacity of 600 cm3.

Although this engine was originally powered by a carburetted system, in the

course of adapting the vehicle, the engine was converted to a multipoint

injection system.

|

|

|

|

Fig. 5.

View of the car and engine |

|

During the project construction, in

order to increase the dynamic qualities of the vehicle, a charging system using

a turbocharger was applied. The test engine and vehicle are shown in Figure 5.

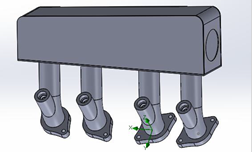

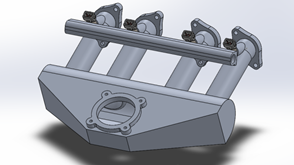

The students involved on the project

made modifications to the engine intake system, while the inlet manifold was

designed using the SolidWorks CAD program. The priority was to create a

modified intake manifold, which would result in a high-power supercharged

engine and be characterized by low flow resistance.

|

|

|

Fig. 6.

Inlet manifold (Version I) before optimalization |

Fig. 7.

Inlet manifold (Version I) after optimalization |

We originally used a compact

manifold (Version I) (Fig. 6), so that the entire intake system would fit in

the frame of the vehicle and satisfy the requirements of the Formula Student

competition rules. This involved a charge air cooler mounted on the right side

of the vehicle, which also determined the location of the intake manifold. The

manifold was attached directly to the throttle and fuel strip using fuel

injectors. After analysing a number of solutions in the literature on the

design of an intake manifold, we selected the design as shown in Figure 7. In

this manifold, we changed where the throttle was fixed and used a bell-shaped

inlet at the entrance to each runner. The use of such a solution should allow

for a reduction in the coefficient of flow resistance.

4. FLOW SIMULATION RESULTS

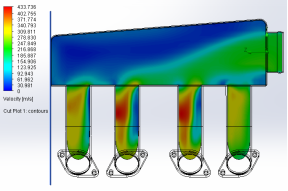

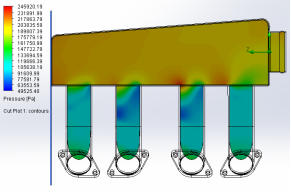

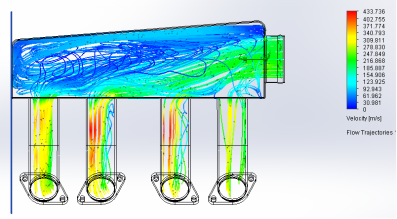

Flow simulations were carried out

for two intake manifolds. The analysis was carried out in relation to the inlet

side manifold (Version I) and the central inlets (i.e., “trumpets”) that had

formed in the so-called runners (Version II). In time-mapping the engine and

the first road tests, it was noted that, in the engine equipped with a lateral

inlet manifold, a smaller amount of air was supplied to one of the cylinders.

|

|

|

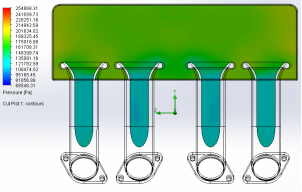

Fig. 8.

Visualization of the parts’ flow velocity |

Fig. 9.

Visualization of pressure decomposition |

Fig. 10.

Movement of the parts inside the manifold

The study was conducted using the

Flow Simulation Solid Works 2014 package (academic version). The set pressure

corresponded to the current inlet pressure of the engine or a 1.0 bar at the

manifold outlet (inlet to the cylinder) when the simulation of atmospheric

pressure prevailed.

|

|

|

|

|

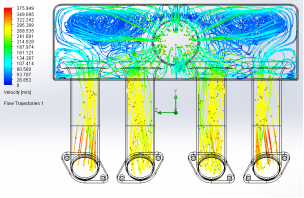

Fig. 11.

Visualization of the parts’ flow velocity |

Fig. 12.

Visualization of pressure decomposition |

|

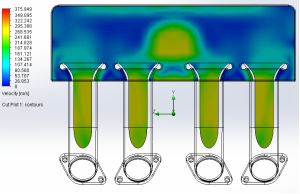

Figures 11-13 show the results of the

flow simulation for the second version of the engine intake manifold.

Fig. 13.

Movement of the parts inside the manifold

A visible improvement in the second

version of the inlet manifold provided a uniform distribution factor for each

cylinder of the engine. In addition, there was an improvement in the uniformity

of pressure distribution throughout the volume of the manifold.

5.

RESEARCH RESULTS AND DISCUSSION

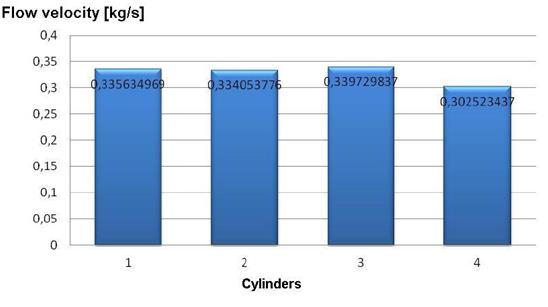

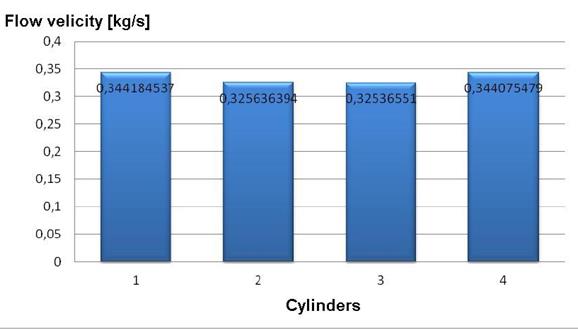

The simulations allowed us to

determine the maximum flow rate factor for both versions of the intake

manifold. Figure 14 shows the results of the maximum flow velocity for each

cylinder.

|

|

|

||

|

b) |

|

||

|

Fig. 14.

Maximum flow velocity for the manifold: a) Version I and b) Version II |

|||

An improvement in the velocity distribution in

each runner is visible, while the maximum value of flow velocity can be more

clearly observed. The improvement in the medium flow through the intake

manifold in turn improves the filling factor, while increasing the output

parameters of the engine. Figure 15 shows the external characteristics of the

engine manifold used in Versions I and II.

The maximum torque and maximum power are shown

in Table 1.

Table 1. Comparison

of the engine parameters

|

Parameters |

Inlet manifold Version II |

Inlet manifold Version I |

|

Power [kW/KM] |

103.3/141.5 |

74/100 |

|

Torque [Nm] |

128,7 |

104.2 |

|

Power

RPM [min-1] |

8,227 |

7,734 |

|

Torque

RPM [min-1] |

7,285 |

5,930 |

The measurements obtained using a

chassis dynamometer, as shown in Table 1, confirm the changes in the intake of

the engine, the effect of which is a significant increase in power and torque,

as well as an increase in the dynamics of the vehicle movement.

6.

CONCLUSIONS

Simulation studies were carried out on the bench, with the vehicle

driven by a ZI engine, in order to make design changes to the intake system,

evaluate the influence of the intake manifold’s structure on the performance of

the vehicle and engine, and observe changes in the flow of refrigerant through

the intake manifold. The research produced the following conclusions:

1. Introducing the central inlet

manifold caused an alignment of factors discussed in the chapter among

individual channels (runners). This resulted in a uniform operation of the

engine in terms of idle speed.

2. The use of bell-shaped inlets, also

known as “trumpets”, increased the flow rate through the intake manifold. A 3%

increase in the flow velocity was registered in relation to the collector-free

trumpets and the inlet side refrigerant.

3.

Changing

the structure of the intake manifold can result in an increase in power and torque.

Engine power increased by 39% and torque by 23.5%.

It seems reasonable, therefore, to continue research on the optimization

settings of the engine and reducing the resistance of the flow through the

intake system.

a) |

|

|

|

b) |

|

|

|

Fig. 15. Maximum power and torque charts for the manifold: a) Version

I and b) Version II |

References

1.

Systems.

Cambridge: Robert Bentley, Inc.

2.

Bell A. Graham. 2002. Forced Induction Performance Tuning: A Practical Guide to Supercharging

and Turbocharging. Sparkford: Haynes Publishing.

3.

Kordziński Czesław, Środulski Tadeusz. 1968. Inlet Systems of Combustion Engines.

Warsaw: Publishing Communications and Associations.

4.

Luft

Sławomir. 2003. Fundamentals of Engine Construction. Warsaw: Wydawnictwa Komunikacji i

Łączności. ISBN: 9788320618068.

5.

Mysłowski Janusz. 2006. Engines Charging.

Warsaw: Publishing Communications and Associations. ISBN: 978-83-206-1964-5.

6.

Zając Piotr.

2009. Car Engines. Warsaw: Publishing

Communications and Associations. ISBN: 978-83-206-1735-1.

7.

Zając

Piotr. 2010. Car Engines:

Fuelling, Cooling, Oiling, Inlet and Exhaust Systems. Warsaw: Publishing Communications and Associations. ISBN: 978-83-206-1783-2.

8.

Zając Piotr, Leon Maria Kołodziejczyk. 2001. Combustion Engines. Warsaw: School and

Pedagogical Publishing House. ISBN: 9788302079870.

9.

Blair Gordon, Melvin Cahoon. 2006. Race Engine Technology Magazine. Simon

Moss Publishing, September, p. 36-41.

Received 14.11.2016;

accepted in revised form 15.01.2017

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License