Article citation information:

Buchalik, R. Evaluation of a conceptual vehicle steering system for

independent wheel control. Scientific

Journal of Silesian University of Technology. Series Transport. 2017, 94,

19-26. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.94.2.

Ryszard BUCHALIK[1]

EVALUATION

OF A CONCEPTUAL VEHICLE STEERING SYSTEM FOR INDEPENDENT WHEEL CONTROL

Summary.

This paper presents a brief description of an unconventional steering system

involving electronic stability control and its influence on vehicle motion. The

proposed configuration enables individual changes in steering angle for each

single wheel, in contrast to the mechanical linkage solution. An analysis of

vehicle behaviour during emergency braking on a heterogeneous surface is

conducted, especially with regard to the undesirable rotation of the vehicle

body. The benefits of using this active steering system, implemented in the

steer-by-wire mode, are characterized, while the problems for further

consideration and the potential benefits of such a solution are described.

Keywords:

steer-by-wire, drive-by-wire, Ackermann geometry, independent four-wheel

steering, toe angle, vehicle steering, cornering control

1. INTRODUCTION

The number of vehicles used across

the world is constantly growing at a very fast rate. This causes several

complications related to safety, infrastructure, environmental pollution,

financial cost (purchasing, operating, recycling), social and medical problems.

One of the most important issues is the active safety of a car. This area of

research is still in the phase of intensive development among automotive

manufacturers, given that customers constantly replace their vehicles in search

of more state-of-the-art requirements.

2. ACTIVE STEERING SYSTEMS

One of the most significant aspects

of active safety involves the design of the steering system, which has

undergone significant changes in recent decades. Among the changes has been

power steering, which is commonly used nowadays. It allows less restricted

adaptation of wheel geometry, self-aligning torque, tyre width (friction during

rotation at standstill) and steering ratio over an entire or partial range.

Some systems are able to facilitate self-manoeuvring (e.g., Autonomous Park

Assist). Another implemented solution, albeit much less common today, is the

possibility of linking the steering wheel with the rear axle, which can be done

in a passive way. For example, the angle of the axis of rotation (connection to

the structure) of the rear wheel’s control arm can be designed in such a way

that, when the forces resulting from the cornering occur (load down at the

vehicle’s external side, centrifugal force), the angle of the wheel remains

appropriate. This solution is widely used in many commercial cars [6]. For the

Porsche 928, a solution called the Weissach axle was used to control the angle

of the wheel during cornering and decelerating in order to create a lateral

force on the rear axle. Through such operations, an understeer gradient can be

shaped in some situations. Obvious examples of passive steering are a trailer

and an articulated bus. That said, in this paper, the focus is on vehicles with

two axles. Currently, some systems available on the market are able to actively

control the rear axis wheel’s steering angle in a comparable way to that for

the front wheels, e.g., those of Renault 4Control (Talisman, Laguna), Delphi

Quadrasteer (Chevrolet Silverado) and Nissan HICAS, as well as solutions

designed by Toyota and Honda. Typically, the actuator facilitates power

steering in the front axis either electrically through a rack and pinion or

hydraulically. At low speeds, for example, during a parking manoeuvre, the

front and rear wheels twist in opposite directions. This reduces the turning radius

of the vehicle and, most importantly, the necessary space in which to make a

turn. While driving at higher speeds, all the wheels twist in the same

direction, which improves overall stability because the car does not rotate so

intensively around its vertical axis. The advantages of the active system,

compared to the passive one, are as follows: a wider range of possible steering

angles of the wheel, the possibility of adjusting the direction, and the value

of turning to the current undesirable kind of slip (understeer or oversteer,

specified by the electronic traction control and its work characteristics). The

tendency to understeer or oversteer is varied due to factors that cannot be

foreseen at the design stage, such as the state and geometry of the road

surface, the characteristics of the tyres, the distribution and value of the

vehicle load, the longitudinal force of each tyre (braking or accelerating),

cornering and the dynamic state of the whole vehicle body, and the unsprung

mass. Another possible steering modification is when the steering angle of the

front wheels, resulting from the current angle of rotation of the steering

wheel (rudder), adds or subtracts a certain value by summing the planetary

gear. This can be used to implement the variable steering gear ratio depending

on driving conditions and driver preferences and based on the data collected by

the electronic stability control and a special algorithm, e.g., BMW Active

Steering.

A crucial

issue is the shape of steering linkage geometry, which binds the rotation angle

of one wheel (relative to the pivot angle) with an equivalent angle of the

second wheel on the same axle. The starting point for further consideration is

Ackermann geometry, which ensures the correct kinematics of the wheel, i.e.,

lines that are perpendicular to the free rolling direction of all four wheels

(on the ground/road plane) starting at the points of contact that intersect

with the ground at exactly one point. In fact, there are exceptions from this

principle [7], especially due to a greater downward force on the vehicle’s

outer side during cornering, making it possible for larger centrifugal forces

to transfer. The dependence of the lateral force generated by the tyre, which

(in the absence of other excitations) is mainly the centrifugal one, depends on

the wheel sideslip angle, that is, the difference between the velocity

direction and the direction of free rolling. The maximum value of the lateral

force, which is possible to transfer, increases with the vertical load exerted

by the body of the car (gravity force and accelerations). The steering linkage

geometry should be designed with respect to the above- mentioned issues and

provide the widest possible range of steering angles in order to reduce the

minimum turn radius. Usually, while tight cornering at low speed, kinematic

inconsistency occurs, which results in a higher rolling resistance and

increased tyre wear. The steering linkage geometry is always a compromise

between many different desired characteristics. To find the optimum angle of

each of the two steered wheels, at an arbitrary turning radius, it is necessary

to know, among other things, the mass distribution of the vehicle, the state of

its longitudinal motion (speed, acceleration, deceleration) and the dependence

of the lateral force transmitted by the tyre from the vertical load and

longitudinal force, as well as other characteristics of the suspension, its

kinetics, including elastokinematics, the road profile and surface type. Not

all of them can be predicted at the design stage, so it is proposed to consider

a system that allows for the independent control of the steering angle of the

left and right wheel. Such a solution is possible only in drive-by-wire

architecture by implementing computer-controlled actuators, although physical

connections can be preserved as required by the law [10].

While the literature describes the testing of

prototype transporter robots and cars with a four-wheel swivel [2, 5], as well

as prototypes built by big car manufacturers (Toyota Fine-T, Nissan Pivo), they

mainly move at low speed, with their main advantage being manoeuvrability. The

following discussion focuses on behaviour at high speed under real driving

conditions.

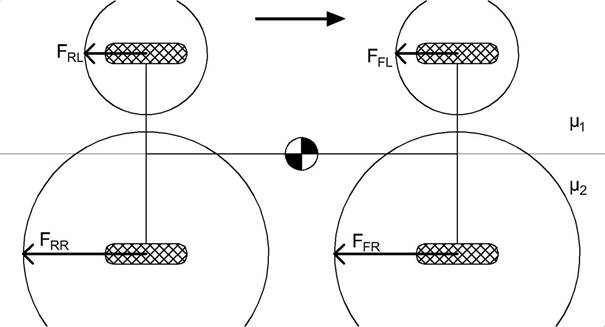

3. EMERGENCY BRAKE WITH ACTIVE STEERING

An example of a situation in which

an active steering system could bring some benefit is the breaking process of a

car on heterogeneous surfaces. Figure 1 shows the top view of a car moving from

left to the right, performing emergency braking. The left-hand side wheels run

on the surface with lower friction coefficient μ1, whereas the right-hand

side wheels run with coefficient μ2. Such a situation may occur during

partial running onto a roadside covered with snow, when the central part of the

road is dry. In the following discussion, a simplified model of the tyre was

used, with the assumption that the sum of the longitudinal and lateral forces

transmitted by the tyre have a constant maximum value, which is represented by

the vector starting at a tyre-surface contact point and ending inside a

delineated circle [4]. The circle radius represents the maximum possible

friction force. In the presented situation, the driver (or autonomous driving

program) attempts to maintain a straight-line trajectory until the vehicle comes

to a complete stop of the vehicle. Each of the four forces depicted in Figure 1

is a source of torque around the gravity centre of the car. The radii of these

moments are all the same, i.e., equal to half of the axis length. However, the

value of forces that tends to turn the vehicle body anticlockwise (FRL

and FFL) is smaller than the corresponding forces at the right-hand

side of the vehicle, which strives to turn it clockwise. As shown, forces

acting on the vehicle cause it to rotate relative to the centre of mass, which

is obviously undesirable. The first method to counteract this is a partial

reduction of the braking force, especially for the more adhesive wheels. This

causes a reduction in the whole body-rotating torque and allows the tyres to

transmit lateral forces, which counteract the rotation. However, in this case

the braking distance is elongated. The presented situation is an important

issue when creating an algorithm for the anti-lock braking system’s (ABS’)

controller. Currently available systems use advanced computational methods in

order to find the optimum configuration [8]; however, there are some general

principles involved. In the case of front wheels, it is desirable to achieve a

maximum braking force. In the case of rear wheels, seeking to reduce the

braking torque on wheels with better traction makes it possible to reduce the

rotating torque and transmit a lateral force with the wheel, whose grip is not

fully utilized in the longitudinal direction. This helps to maintain the car’s

stability.

Fig. 1. Braking with a conventional system

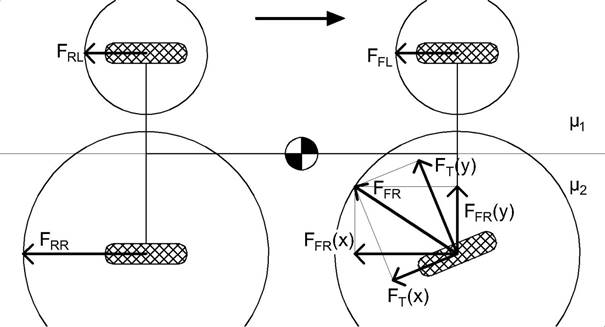

Figure 2 shows a possible configuration of wheels in

the same situation as described above, which involves the possibility of

independently adjusted steering angles. In this case, the front-right wheel is

set at an angle, in which the force FFR is generated. It can be

decomposed into the longitudinal component FFR(x), which causes

deceleration, and the FFR(y) component, which counteracts the

rotation relative to the gravity centre of the vehicle body. The first step is

to determine the direction of force FFR and thus the ratio of

longitudinal to lateral forces. This should be done in a way that does not

reduce the deceleration too much, while simultaneously achieving a significant

contribution to the balance of torques in relation to the gravity centre. A

tyre, whose direction of motion is not identical to the free rolling direction

becomes a source of force FT(y). After the direction of force FFR

is designated, a lateral force dependence relative to the angle of sideslip for

the specified tyre type and operation conditions should be used to find this

angle. The camber, castor, scrub radius, forces, kinematics (including

elastokinematics) and other important design features should be taken into

account, as well as their current value and change during the rotation around

the pivot axis. As force FT(x) results mainly from the operation of

the brake system, it should be correctly set, for example, by components of the

ABS and the electronic stability program in order to achieve the maximum

overall wheel reaction. The total force generated by tyre FT is of

course equal to force FFR acting on the vehicle body. A

two-dimensional model was used, while the vertical dynamics related to the

action and kinematics of suspension, were omitted. The next stage of the

development, according to the presented concept, is a system with four-wheel

(as opposed to only two-wheel) independent steering, in which the rear axle can

be used in a similar way. The main advantage of the described solution is a

significant reduction or elimination in the torque, which rotates the car’s

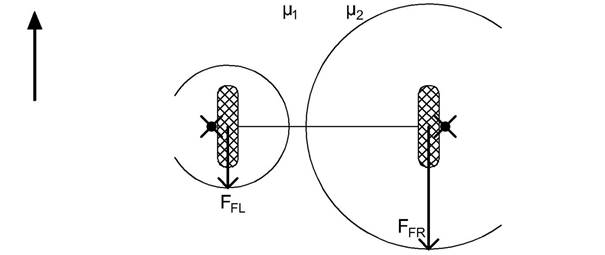

body. Such an effect may also be achieved in other ways. One possibility is an

appropriate driver response, causing the steering wheel to rotate in the correct

direction to counteract the rotation of the vehicle. A second solution involves

the negative scrub radius shown in Figure 3, with the cross marks indicating

the points where the pivot axle crosses the road level. In this situation, when

the central point of application for the decelerating force generated by the

tyre is not in the axle pivot, this causes a torque in the steering system,

which tends to turn a wheel. If this value on both sides of the vehicle is not

equal, the rotational force on the steering wheels appears in the direction of

counteracting the rotation of the car [7]. This has a dual effect: firstly, the

driver may need to correct the position of the steering wheel; secondly, it may

cause some wheel geometry changes, as an effect of elastokinematics, which, in

a predicted way, counteracts rotation, although this kind of action is

obviously limited.

Fig. 2. Braking with an independent front-wheel

steering system

As mentioned

before, the advantage of the fully independent left and right steering system

is to maximize the use of the longitudinal grip of the wheels on the surface

with a lower friction coefficient. For a conventional steering linkage

solution, the wheel with less traction also transmits lateral forces, causing a

decrease in the longitudinal force maximum value, which intensifies the

undesirable car torque relevant to the gravity centre. In the presented case,

the steering wheel angle will be in the range of about 0-20°, given that, for

standardized tyres, in this range of tyre sideslip, an increase in the lateral

force up to its maximum occurs [1].

In fact, the maximum total force transmitted by the

wheel as a function of this force direction is not constant, as assumed above

(circle in Figs. 1-2); rather, in most cases, it has a shape that is more

similar to an ellipse than a circle (higher force FT(y)), as shown

on the graph, which actually increase the positive effect of the proposed

solution. The value of FFR in Figure 2 could be greater.

The forces presented in Figure 1 are twice as strong

at the vehicle’s right-hand side, while the friction coefficients are also

obviously 1:2 to each other. After the introduction of modifications shown in

Figure 2, the torque relative to the gravity centre disappears. The moment of forces

generated by the right-rear wheel and that emanating from the two left wheels

are balanced. Torque from the front-right wheel is zero because of the angle

(in line with the gravity centre). Therefore, it behaves in a way that is

theoretically perfectly, maintaining the desired vehicle position. In the case

of four-wheel independent steering, there is a possibility of changing the

proportion of forces counteracting the rotation between axes. Algorithms to

control this aspect should be similar to those implemented in traction control

systems. The proposed system should be integrated with other systems of the

car, especially the anti-lock braking. In real situations, the flexibility of

components, including tyres, should be taken into account. As a result of using

active independent steering, the toe angle can be constantly modified without

limitation. In emergency situation, this feature, together with skid steering,

can be used to safely stop the vehicle. This technique can also be used to

maintain control in the case of the failure of one or more of the actuators

responsible for wheel twisting, in which braking force is applied to individual

wheels [9]. Currently, steer-by-wire systems are in the phase of development,

including in relation to changing views, needs and limitations on the part of

the driver, for example [3]. In a car with four-wheel independent steering,

this is seems to be much more important issue, due to the car’s less intuitive

behaviour. This is not a problem in autonomous vehicles, where the proposed

system could bring significant benefits. Independent steering can be used to

automatically compensate for the bump and roll steering effects, which allow

for more freedom when shaping the geometry of the connecting rods.

Fig. 3. Negative scrub radius

During cornering in a car with two independent,

actively steered wheels of the front axle, there is a limited possibility of

adjusting the position of the vehicle body’s centre of rotation in the

longitudinal direction with a suitable shaping of the sideslip angle at every

wheel, which results from setting two controlled wheels. In the case of

four-wheel steering, the centre of rotation can be chosen freely, with the only

limitation being the speed of steering and the maximum steering angle. The

proposed system can be combined with other systems allowing for the geometry of

the wheel to change while driving. Active independent steering can be used to

improve the behaviour of the car during manoeuvres at high speeds, while

providing profit due to the significant enlargement of autonomous parking

system limits. Systems with four-wheel steering offer, among other things,

every advantage of vehicles with rear-axle steering implemented in any method,

in particular, limiting the rotary movements of the body during cornering at

high speeds. Another important issue is the process of entering into a turn,

when the vehicle body starts to lean outside; as such, the steering angle of

every wheel could be properly set at every moment to obtain a response to the

road situation and vertical forces. In conventional steering, the linkage with

the mechanical stability of the structure usually remains. In the proposed

system, this aspect may cause some problems, but this should be considered

according to tyre grip characteristic, as well as the directional and

rotational stability.

4. CONCLUSION

Nowadays, in the era of the automation and

autonomization of transport processes, safety should be a priority

consideration. The obvious limitation, which results from the law of physics,

cannot be avoided, but can be shaped in a sophisticated way. According to a

number of practical problems connected with the proposed solution, the effects

resulting from independent steering can only be partially used in order to slightly

improve vehicle behaviour. As shown above, this could bring some benefits when

correctly controlled. Therefore, further numerical calculations and

experimental validations should be conducted.

References

1.

Abe Masato. 2015. Vehicle Handling Dynamics. Waltham:

Elsevier Ltd.

ISBN 978-0-08-100390-9.

2.

Lam Lun Tin, Huihuan Quian, Yangsheng Xu. 2010. Omnidirectional steering

interface and control for a four-wheel independent steering vehicle”. IEEE/ASME Transactions on Mechatronics, Vol.

15, No. 3: 329-338. ISSN: 1083-4435.

3.

Odenthal Dirk,

Tilman Bunte, Heinz-Dieter Heitzer, Christoph Eicker. 2002. “How to make steer-by-wire

feel like power steering.” In 15th

Triennial World Congress:

187-192, 2002, Barcelona, Spain.

4.

Prochowski Leon.

2008. Mechanika ruchu. [In Polish: Movement mechanics]. Warszawa:

Wydawnictwo Komunikacji i Łączności. ISBN 978-83-206-1701-6.

5.

Qi Ziming, Xu

Zhao, Kuang Ma, Matthew King, Wei-Chen Lee, Ji-Wei Lin, Shao-Min Lee.

2015. “4-wheel independent in-wheel-motor drive and independent steering

electric vehicle safety analysis method based on mass re-distribution

experiment”. In Proceedings of the

Sixth International Conference on Automation, Robotics and Applications:

22-27, 17-19 February 2015, Queenstown, New Zealand.

ISBN 978-1-4799-6467-3.

6.

Reimpell

Jörnsen, Jürgen Betzler. 2008.

Podwozia samochodów. Podstawy konstrukcji. [In Polish: Chassis. Fundamentals of design]. Warszawa: Wydawnictwo Komunikacji i Łączności. ISBN

978-83-206-1400-8.

7.

Reński Andrzej.

2011. Bezpieczeństwo czynne samochodu.

[In Polish: Active safety of a car]. Warszawa: Oficyna Wydawnicza

Politechniki Warszawskiej.

ISBN 978-83-7207-904-6.

8.

Układ stabilizacji toru jazdy ESP. Informator

techniczny Bosch. [In Polish: Electronic

Stability Program (ESP). Bosch Technical Information]. 2000. Warszawa: Wydawnictwo Komunikacji i Łączności. ISBN

83-206-1365-5.

9.

Wang Rongrong, Hui Jing, Chuan Hu, Mohammed Chadli, Fengjung Yan. 2016. “Robust H1 output-feedback yaw control for in-wheel motor driven electric

vehicles with differential steering”. Neurocomputing,

173: 676-684. ISSN: 0925-2312.

10.

Waizuddin Ahmed, Rawat Vaibhav, Yangsheng Xu. 2016. “An active steering system for road vehicles”. International Journal of Advances on Automotive and Technology,

Vol. 1, No. 1: 1-5. ISSN: 2536-4480.

Received

26.10.2016; accepted in revised form 10.01.2017

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License