Article citation information:

Majewski, P., Spychała, J., Żokowski, M. Some problems with

vibroacoustic method in relation to the transmission gearbox of a military

helicopter. Scientific Journal of the

Silesian University of Technology. Series Transport. 2016, 93, 79-90. ISSN: 0209-3324.

DOI: https://doi.org/10.20858/sjsutst.2016.93.9.

Paweł MAJEWSKI[1],

Jarosław SPYCHAŁA[2],

Mariusz ŻOKOWSKI[3]

SOME PROBLEMS WITH

VIBROACOUSTIC METHOD IN RELATION TO THE TRANSMISSION GEARBOX OF A MILITARY

HELICOPTER

Summary. The

article presents the results of a laboratory gear stage with regard to

deepening its consumption. In addition, the study looked at the construction of

the transmission gearbox of a military helicopter, according to the basic

kinematic results of the analysis of vibroacoustic signals, in order to

determine the diagnostic criteria for the assessment of the technical

condition of a military helicopter’s transmission gearbox.

Keywords: transmission gear, vibroacoustics,

gearbox, helicopter

1. INTRODUCTION

The issue of monitoring and diagnosing the

technical condition of machines, as well as detecting the damage and wear of

their components, is a subject of interest to all personnel performing

operational maintenance duties. This is for the following reasons: safety,

economy and time. However, the methods and measures used, which take the form

of implemented control measurement systems, along with the defined current

services are not always adequate, such that these machines are often damaged.

This is a problem faced by the aviation

engineering services of the Polish Armed Forces, which operate combat

helicopters, including their main transmissions. In the main, the only aspect

of the transmission gear of a helicopter that is constantly monitored is the value

relating to temperature and oil pressure, as well as the rotational speed of

the input shaft. Although magnetic plugs in transmission gear trap the products

that cause wear and tear in the lube oil, there is no system to monitor

its vibrations. Additionally, the evaluation of the main transmission

gear’s technical condition is carried out periodically, during planned

maintenance works. Despite the above-mentioned measures, damage still occurs,

which is why the Air Force Technical Institute has attempted to determine the

possibilities of using the vibroacoustic method to evaluate the technical

condition of the main transmission gear of a combat helicopter under conditions

as discussed below.

The literature presents many methods for

diagnosing transmissions on the basis of the analysis of the vibroacoustic

signal measured with the housing of the gear. The existing methods were

classified into four groups: time domain analyses, frequency domain analyses,

time-frequency analyses and others [1-4]. The aforementioned methods are based

on known symptoms of damage to rolling bearings and gear wheel transmission.

2. GENERAL CHARACTERISTICS OF THE TEST OBJECT

The test object is the main

transmission located on board the helicopter, as shown in Figure 1, with a schematic

diagram presented in Figure 2.

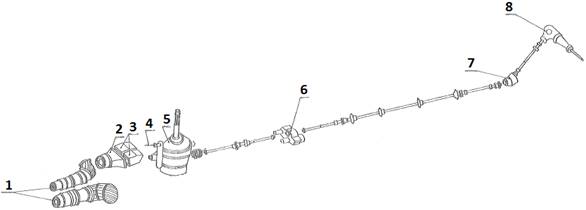

Fig. 1. View of the transmission’s

location in relation to the basic sub-assemblies of the helicopter

(1 = engines, 2 = fan, 3 = oil

cooler, 4 = fan drive shaft, 5 = main transmission gear, 6 = drive box, 7 = intermediate

transmission, 8 = rear transmission)

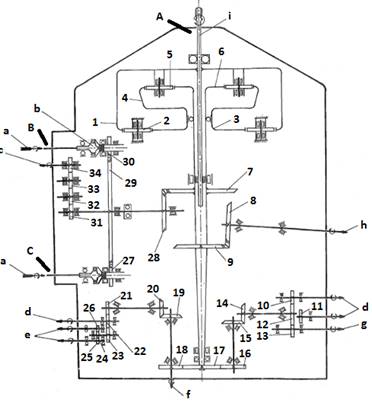

Fig. 2. Kinematics of the main

transmission

The design of the transmission and

its location on the helicopter causes the occurrence of a series of

extortions, which appear in the vibroacoustic signal. First of all, the

transmission is powered by two turbine engines, through an idle run clutch (b)

and an axle shaft (a). In the engine, apart from a series of

mechanical generators coupled with it, the most important elements are the

power turbine, generating useful power for the gear, and the turbocharger

rotor, which is not coupled kinematically with the engine. Secondly, the

transmission of the torque onto the rotor shaft (i), coming from the

propulsion turbine, takes places in the course of three stages of the

transmission gear. The first stage of the gear transmits rotations from two

engines through the idle run clutch and cogwheels 27 and 30 onto cogwheel 29

with helical wheels. The second gear stage consists of two bevel gear wheels 28

and 7 with spiral teeth. The third stage is a closed planetary-differential

gear with cogwheels 1, 2, 3, 4, 5 and 6. Sprocket 6, located on one shaft with

conical sprocket 7, is a drive wheel (sun wheel) of the transmission gear.

Sprockets 5, comprising five pieces, are satellites of the planetary gear.

The satellite yoke creates one whole with powered sprocket 1 and is connected

with the rotor shaft. Sprockets 2, comprising seven pieces, are transitional

wheels, which close the system. The body of these wheels is stationary.

Thirdly, the propulsion from the transmission is transferred onto one more

series of receiving generators, including the tail propeller and the gearbox

generators. Transmission of the drive to the tail propeller (h) is achieved

through the first and second stages of the gearbox, which is common for the

carrier rotor, and through an additional stage, which increases the rotational

speed, consisting of two conical gears, 9 and 8, with spiral teeth. Drives of

the main gearbox generators are directed to the front, left and right sides of

the gearbox body. To the front side, the fan drive is directed (c) from

sprocket 29, through 31, 32, 33 and 340. To the left side, drives of the

carrier rotor rotational speed accelerator (e) and the hydraulic pump (d) are directed

through sprockets 19 and 20 and cylindrical sprockets 21÷26. To the right side,

the drives of two hydraulic pumps (d) and the compressor (g) are directed

through sprockets 17 and 16, conical sprockets 15 and 14 and cylindrical

sprockets 10÷13. Apart from the assemblies of the above-mentioned toothed

kinetic pairs, there are also a number of bearings.

For such complex kinematics, the

relations describing characteristic frequencies are presented below:

-

rotational frequency of the turbocharger fTS (100% rotations

corresponds to 19,500 rpm)

![]() (1)

(1)

-

rotational frequency of the turbocharger fTN (100% rotations

corresponds to 15,000 rpm)

![]() (2)

(2)

-

characteristic frequencies for gears with fixed axes; for sprockets 7 to

34, for example, with a pair of teeth z30 and z29, the

relation is as follows:

![]() (3)

(3)

-

gearing frequency

![]() (4)

(4)

-

frequency of sidebands (similarly for other frequencies)

![]() (5)

(5)

-

frequency of carrier rotor blade passing (k = blade number, five pieces)

![]() (6)

(6)

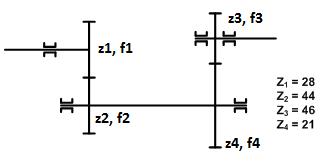

Sprockets z1 to z6

form a planetary gear, with a layout as shown in Figure 3.

OUT IN

Fig. 3. Planetary gear

layout

The planetary gear has w degrees of freedom:

![]() (7)

(7)

where:

n = number of mobile links,

p = number of rotational links,

k = mesh number.

The rotational frequencies of the

planetary gear assembly are determined according to the relations:

![]() (8)

(8)

![]() (9)

(9)

![]() (10)

(10)

![]() (11)

(11)

Rotational frequency values for

rated operating conditions are summarized in Table 1, which, with the knowledge

of the number of gear teeth and appropriate bearing parameters, enabled the

determination of the remaining characteristic frequencies associated with

symptoms of bearing [6] and transmission gear [7] damage.

Table 1.

Values of the rotational frequencies

of the main transmission gear, propulsion unit and the rotor

|

Designation |

Value [Hz] |

Designation |

Value [Hz] |

|

fTS |

325 |

f16 |

49.3 |

|

fTN |

250 |

f15 |

49.3 |

|

fŁ |

20 |

f14 |

59.6 |

|

f30 |

250 |

f13 |

33.5 |

|

f29 |

86.8 |

f12 |

59.6 |

|

f28 |

86.8 |

f11 |

40.6 |

|

f27 |

250 |

f10 |

40.6 |

|

f26 |

39.7 |

f9 |

40.8 |

|

f25 |

39.7 |

f8 |

53.9 |

|

f24 |

39.7 |

f7 |

40.8 |

|

f23 |

39.7 |

f6 |

40.8 |

|

f22 |

40.6 |

f5 |

1.5 |

|

f21 |

59.6 |

f4 |

-8.8* |

|

f20 |

59.6 |

f3 |

-8.8* |

|

f19 |

49.3 |

f2 |

-14.6* |

|

f18 |

49.3 |

f1 |

4 |

|

f17 |

40.8 |

*opposite direction |

|

3. LABORATORY TESTS OF A DOUBLE REDUCTION GEAR

WHEEL TRANSMISSION

Planned vibration measurements of

the helicopter’s main transmission were to be carried out without the signal

informing about the momentary rotational speed, thus limiting the possibility

of applying certain algorithms, e.g., time synchronous averaging. A prepared

laboratory bench without the phase marker was designed to validate the applied

algorithms for the evaluation of a combat helicopter’s technical condition. The

expected results concerned the information about the general level of

vibrations and the possibility to detect damage to the bearings and the teeth

of the transmission.

The gear wheel transmission, as

presented in Figure 4, was tested.

Fig. 4. View of the tested

transmission and its kinetic diagram

On implementing, in three subsequent

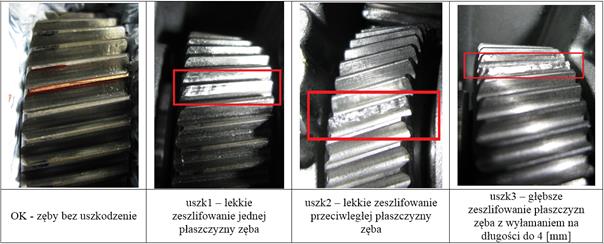

stages, a deepening damage to tooth z3 (Fig. 5), with stable ranges

of the rotational speed, gearbox body vibrations were measured in three,

mutually perpendicular, directions and later related to the condition without

the damage.

dam3: deeper grinding of

the tooth planes, with a chipping at a length up to 4 mm dam2: slight grinding of

the opposite plane of the tooth dam1: slight grinding of

one plane of the tooth OK – teeth without damage

Fig. 5. View of subsequent damage

stages of sprocket z3

After that, a number of analyses in

the time and frequency domains were carried out.

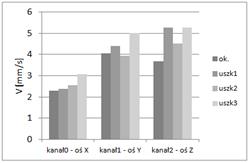

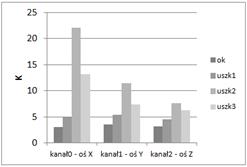

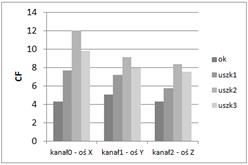

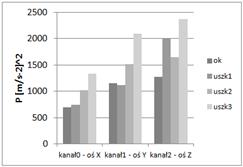

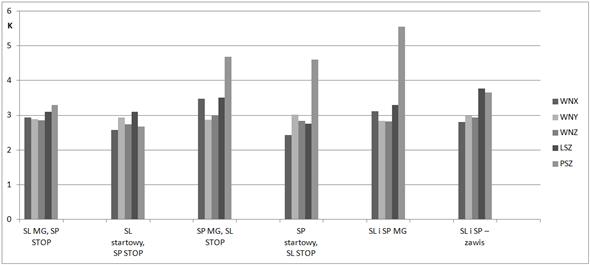

In the time domain, in the band 10 Hz÷10 kHz, values were determined for

effective vibration speed V, kurtosis K, peak factor CF and signal power P, as

presented in Figure 6.

|

channel0 – axis x

channel1-axis Y channel2 –

axis Z OK dam1 dam2 dam3 |

channel0 – axis x

channel1-axis Y channel2 –

axis Z ok dam1 dam2 dam3 |

||||||||

|

channel0 – axis x

channel1-axis Y channel2 –

axis Z ok dam1 dam2 dam3 |

channel0 – axis x

channel1-axis Y channel2 –

axis Z ok dam1 dam2 dam3 |

Fig. 6. Results of time domain

analyses

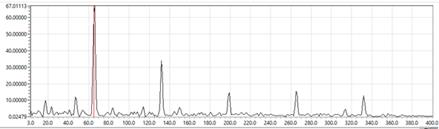

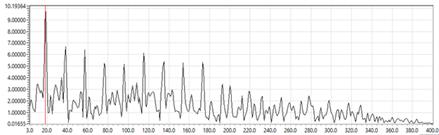

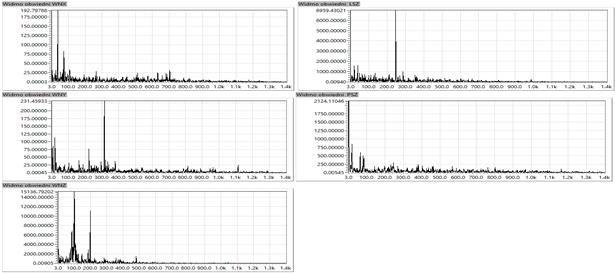

In the frequency domain, amplitudes

of individual harmonics, resulting from the kinematics of the tested

transmission, and a spectrum of the envelope signal were determined (envelope

narrowband analysis method with the use of Hilbert’s transformation; see Fig.

7).

The increase in transmission damage

causes an increase in the analysis parameters in the time domain.

Narrowband envelope analysis allowed the determination of modulating

frequencies, including, for the condition without damage (marked OK), frequency

f1=67 Hz and the number of its times, while, for damage conditions,

bearing information about gearing z3 with frequency f3=19Hz

and the number of its times. Frequency amplitude f3 increased along

with the damage. However, one inconvenience is the fact that it is a rotational

frequency, which also carries information about imbalance. It was assumed that

damage to therolling bearings on a lab bench and on an actual, technical object

was detectable using this method.

|

|

|

|

|

|

|

|

Fig. 7. Frequency

domain analyses results: envelope spectrum

4. TESTS OF THE MAIN TRANSMISSION

GEAR OF THE HELICOPTER

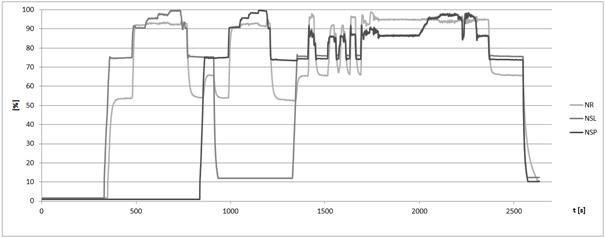

The measurements of the main

transmission body vibrations were taken during the on-ground test of the

helicopter, at set and temporary ranges, which changed the speed of the propulsion

units to the maximum acceptable (hovering of the helicopter). A sample profile,

determined on the basis of parameters recorded by the on-board recorder,

including rotational speed values of the left (NSL) and right (NSP) engine

turbochargers and the rotor (NR), is presented in Figure 8.

Fig. 8. Profile of the on-ground

helicopter test

Due to structural reasons

(non-magnetic body, no process openings, no planes with the possibility to

use adhesive sensors) and safety reasons, there was a limitation in terms of

the possibility to install sensors, which can measure temporary vibrations of

the transmission’s body. For this reason, accelerometers were fixed (Fig.

2) at measurement points: A (bonding method) - three remaining, perpendicular

directions, marked WNX, WNY and WNZ; and B, C (with the permanent magnet) -

vertical direction marked with LSZ and PSZ. Information about the current rotational

speed was initially determined from the test sheets and data indexing,

corrected with values from Figure 8 and determined by the vibration signal

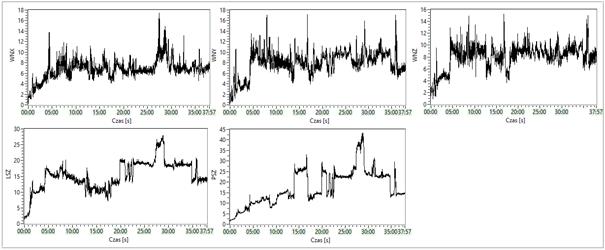

spectrum. As in the scope of laboratory tests, a number of analyses in the time

and frequency domains were carried out. In the time domain, i.e., in the band

45÷1,590 Hz, 25÷10 kHz, 190÷340 Hz, 2 Hz÷10 kHz (see Fig. 9), the

effective vibration speed V values and its maximum values were determined for

the whole sample.

Time [s] Time [s] Time [s] Time [s] Time [s]

Fig. 9. Course of changes of the

effective vibration speed in the band 2 Hz÷10 kHz

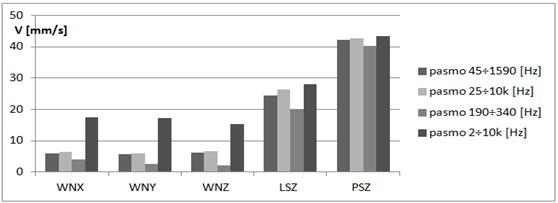

Peak vibration speed values at

particular points for individual bands are presented in Figure 10. These values

are related to the assumed limit values. Points B (vertical axis marked LSZ)

and C (vertical axis marked PSZ) are defined by the producer for the propulsion

unit (being 45 mm/s → warning value and 60 mm/s → limit value).

Point A (directions WNX, WNY and WNZ) is defined by the standard [8]. Only in

the band 2 Hz÷10 kHz, at point A, was the assumed limit value found to be

exceeded.

band band band band

Fig. 10. Peak vibration speed values

at particular points for individual bands

In the time domain were determined

the kurtosis K value (Fig. 11), the CF peak factor and signal power P, within

stable ranges of the operation of the left or right engine and two at the same

time.

hovering starting, starting,

Fig. 11. Kurtosis value for

individual directions in stable ranges of the rotational speed

The above analyses and a number of

others from the scope of the time domain, due to the lack of explicit

levels determining the acceptable limit values, were treated as informational

and a reference for comparison in the case of extending the population of

studied objects.

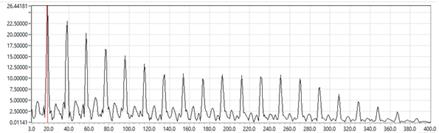

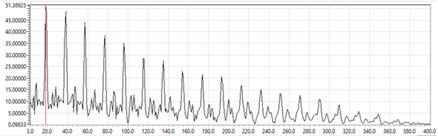

In order to detect damage to the

bearings and transmission wheels, envelope spectrum analysis was used

(narrowband envelope analysis method). Frequencies were found in this spectrum,

which correspond to the kinematic calculations, part of which were not linked

to the identified kinetics of the studied transmission gear (Fig. 12).

Fig.12. Envelope spectrum (left

engine starting, right engine off)

5. CONCLUSION

The use of vibroacoustic testing to

assess the technical condition of the transmission is an issue widely discussed

in the literature. A number of methods to process a measured signal, with

different efficiency, has been developed. There are also certain requirements,

which need to be satisfied, e.g., correct parameters describing the tested

kinematics, allowing for the determination of characteristic frequencies

and the appropriate number of sensors located in the correct places. Due to

operational limitations and a given technical object, it was impossible to use

the phase marker, because, having the reference signal, it was possible to use

other damage detection algorithms.

The results presented above

regarding studies associated with the diagnostics of the main transmission of a

helicopter might indicate a potential for monitoring its sub-assemblies with

the vibroacoustic method. However, we need to expand the population of objects

and verify the parameters describing the kinematics, thereby enabling

characteristic frequencies to be determined.

References

1.

Paul Samuel, Darryll Pines. 2005. “A review of vibration-based

techniques for helicopter transmission diagnostics”. Journal of Sound and Vibration 282: 475-508.

2.

Lei Yaguo, Jing Lin, Ming Zuo, Zhengija He. 2014. “Condition monitoring

and fault diagnosis of planetary gearboxes: a review”. Measurement 48: 292-305.

3.

Aherwar Amit, Saifullah Khalid. 2012. “Vibration analysis techniques for

gearbox diagnostic”. International

Journal of Advanced Engineering Technology 3(2).

ISSN: 0976-3945.

4.

Randall Robert, Antoni Jerome. 2011. “Rolling element bearing

diagnostics – a tutorial”. Mechanical

Systems and Signal Processing 25: 485-520.

5.

Randall Robert. 2011. Vibration-based

Condition Monitoring: Industrial, Aerospace and Automotive Applications.

Chichester: Wiley. ISBN: 978-0-470-74785-8.

6.

Cempel Czesław. 1982. Podstawy wibroakustycznej diagnostyki

maszyn. [In Polish:

Fundamentals of Vibroacoustic Diagnostics

of Machines].Warsaw: WNT.

7.

Bartelmus Walter, Zimroz Radosław. 2011. “Vibration spectra

characteristic frequencies for condition monitoring of mining machinery

compound and complex gearboxes”. Prace

Naukowe Instytutu Górnictwa Politechniki Wrocławskiej 133.

8.

Polski Komitet Normalizacyjny.

1996. Polska Norma PN-ISO 8579-2:

Przepisy Odbioru Przekładni Zębatych. Określanie Drgań Mechanicznych Przekładni

Zębatych Podczas Badań Odbiorczych. [In Polish: PN-ISO

8579-2: Provisions Concerning the Determination of Mechanical Vibrations

of Gears During Acceptance Testing] Warsaw: Polski Komitet Normalizacyjny.

Received 07.06.2016; accepted in

revised form 02.10.2016

![]()

Scientific Journal of the Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International