Article citation information:

Gustof, P., Hornik, A., Czech, P., Jędrusik, D. The influence of engine

speed on the thermal stresses of the piston. Scientific Journal of Silesian University of Technology. Series

Transport. 2016, 93, 23-29. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2016.93.3.

Piotr

GUSTOF[1], Aleksander HORNIK[2], Piotr CZECH[3], Damian JĘDRUSIK4

THE

INFLUENCE OF ENGINE SPEED ON THERMAL STRESSES OF THE PISTON

Summary. In

the paper, numeric calculations relating to the influence of engine speed on

thermal stresses of the piston in a turbocharged diesel engine in the initial

phase of its work were carried out. The calculations were based on experimental

studies and the data resulting from them. They were made using a geometrical

model of the piston in a turbocharged diesel engine with a capacity of 2,300 cm3,

with a direct fuel injection to the combustion chamber and a power rating

of 85 kW. Modelling of the thermal stresses of the piston was carried out for

the engine speed n=2,000 min-1 and n=4,250 min-1.

Keywords: diesel

engine, thermal stresses, piston

1. INTRODUCTION

Along with an increase in the

mechanical loads, increasing engine power is also accompanied by an increase in

thermal loads. These loads have a significant influence on features of the

engine, such as the exhaust blowing through to the crankcase, the engine oil

wear or the level of pollutants emitted by the engine into the atmosphere. In

particular, a piston experiencing thermal stresses, which are variable

over time, is exposed to these effects. Already at the stage of preliminary

design work, knowledge of the thermal loads of the piston will be required.

Such information can be obtained by suitable modelling of the temperature

distribution in the studied cross sections of the piston’s characteristic

surfaces. Design works and model tests are very expensive and prolonged.

However, the application of mathematical models and suitable computer

techniques allows for determining the temperature distribution for different

materials, sizes and shapes of the piston [1, 8]. Subsequent analysis of this

information helps to formulate initial design assumptions, as well as modernize

existing solutions for operating the engine at various speeds and loads. Very

good results in studies on thermal stresses of the piston are provided by the

application of the finite element method. However, in order to carry out

any numerical calculations, some assumptions and use of empirical methods of

data gathering for each of the analysed operation conditions of the engine are

needed.

2. ANALYSES OF THE

INFLUENCE OF SELECTED PARAMETERS ON THE THERMAL LOADS OF THE PISTON

The conditions of the engine

operation include a change in the effective pressure. Assuming that mechanical

efficiency is constant, an increase in the average effective pressure is

equivalent to a higher heat emission, which leads to an increase in the piston

temperature. The influence of the increase in the average effective pressure on

unit heat flux for the parameter characterizing the heat load of the

cylinder results from the following dependence:

![]() (1)

(1)

where:

b = coefficient of the amount

of strokes (for four strokes, b=2)

η =

fill coefficient

cm = average

velocity of the piston [m/s]

D = diameter of the cylinder

[dm]

pd = pressure at

the inlet valve [MPa]

Td = temperature at

the inlet valve [K]

pe = average

effective pressure [MPa]

ge = actual fuel consumption [g/kWh]

T0 = ambient

temperature (T0=293 K)

The increase in the average

effective pressure of a diesel engine is achieved by injection of a higher dose

of fuel per working cycle into a cylinder. Thus, a higher amount of heat is

transferred to the piston while reducing the excess air ratio. The lower the

excess air ratio λ, the larger the relative amount of heat that may be

released from the fuel in the cylinder. The temperature changes are analogous

to the changes in engine power. Both the mixture enrichment and impoverishment

cause a drop in the temperature of the piston. With a too-rich mixture, a large

part of the fuel is not burned. A lean mixture burns slowly, reducing the combustion

temperature, despite the fact that, as a result of chronic combustion, the temperature

of the exhaust gas increases. In a diesel engine, an increase in the engine

load leads to a decrease in the excess air ratio λ, resulting in the

supply of more fuel. It leads to an increase in the amount of heat released in

the engine’s combustion chamber and in the temperature of the elements

surrounding it.

Another parameter affecting the

thermal load on the piston is the engine speed. The influence of this

parameter is quite complicated. On the one hand, an increase in the engine

speed is equivalent to an increase in the frequency of combustion in the

cylinder, increasing the amount of heat in the combustion chamber. On the other

hand, it affects the change in the engine-filling efficiency and thus the

course of the combustion process itself. In a diesel engine, the amount of fuel

being provided into the cylinder does not depend on the engine-filling

efficiency with air, given that, for all rotational speeds, the engine sucks in

a different, albeit maximum, value of the air mass. The amount of the injected

fuel depends on the curve of the dosing characteristic of the injection pump

and on the excess air ratio, which in turn depends on both the amount of intake

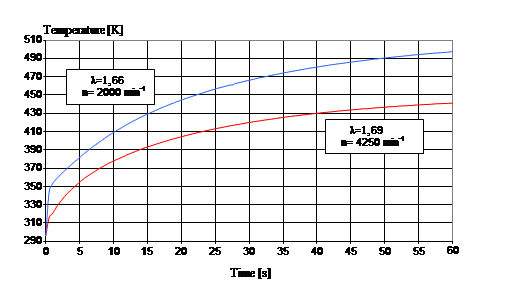

air and injected fuel. Figure 5 shows the course of the calculated maximum

values of the piston head surface temperature during a 60-second operation

of a turbocharged diesel engine, calculated by counting from the engine

start its two rotational speeds n=2,000 min-1 and n=4,250 min-1.

Fig. 1. The course of

maximum temperature on the surface of the piston head for two engine speeds

Based on the calculations, it was

found that an almost twofold increase in the rotational speed of a turbocharged

diesel engine for the same load causes lower thermal loads of the piston

head [6]. This is due to a higher speed of heat exchange between the piston and

its environment, in comparison with the amount of heat generated in the

combustion chamber of the engine.

3. MODELLING OF THERMAL STRESSES OF AN ENGINE

PISTON

After starting the engine, the

piston heats up until it reaches a state of equilibrium, which results from the

balance between the heat taken from hot gases in the combustion chamber and

transformed into useful work, and the heat transferred to the environment by,

among others, the coolant and the combustion gases. Determination of thermal

stresses of the piston by means of modelling requires the assumption of

equations and mathematical expressions for the calculations, describing the

process of heat exchange in such a way that the model is able to reflect the

actual processes occurring on the characteristic surfaces. This model was

created for the piston on the basis of the differential equation of the heat

flow in solids.

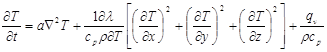

(2)

(2)

where:

a = coefficient of temperature compensation,

cp = specific heat capacity at

constant pressure [J/kgK],

ρ = density [kg/m3],

T = temperature [K],

qv = volumetric efficiency of the

internal heat source [W/m3],

λ = thermal conductivity [W/mK].

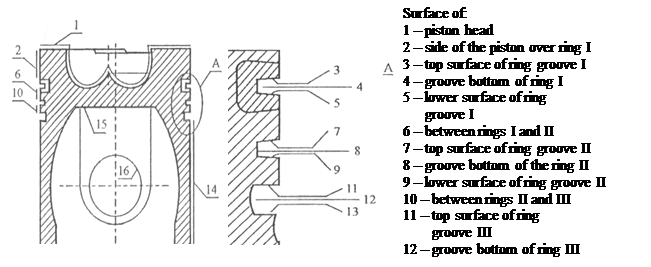

The numerical calculations of the

stresses were performed by means of the COSMOS/M program based on the knowledge

of the temperature distribution for assumed operating conditions of the studied

engine. In the program, an actual three-dimensional discrete geometric model of

the piston was created based on the real component. In the model, 16

characteristic surfaces of the piston were distinguished, for which the

temperature distributions and specific values of type III boundary conditions

(Fourier conditions) were determined. These conditions determine the

temperature of the medium surrounding the piston and the heat transfer

coefficients of the characteristic surfaces. These surfaces are shown in Figure

7 [4].

Fig. 2. Characteristic surfaces of the piston

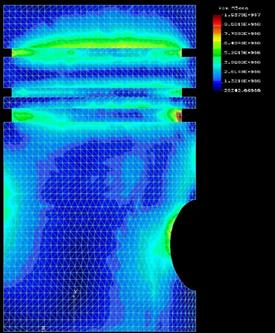

For individual piston surfaces, the

conditions of heat exchange equivalent to those in the combustion chamber

for each cycle of the engine were assumed in the calculations. Based on the

recorded indicator diagrams and the calculated total heat transfer coefficient,

the temperature of the working medium surrounding the combustion chamber

and the values of the heat transfer coefficient for the engine speed of n=2,000

min-1 and speed of n=4,250 min-1 were determined [2-5]. Figures 3, 4, 5

and 6 show the exemplary values of thermal stresses of the piston during a

non-stationary heat flow, corresponding to 10 and 20 seconds of engine

operation measured from its start-up.

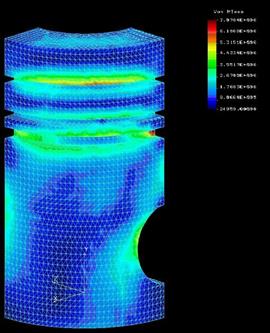

Fig.

3. Thermal stresses of the piston after 10 seconds for n=2,000 min-1,

l=1.66

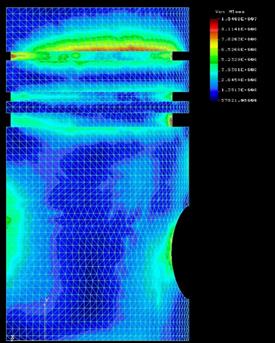

Fig.

4. Thermal stresses of the piston after 10 seconds for n=4,250 min-1,

l=1.69

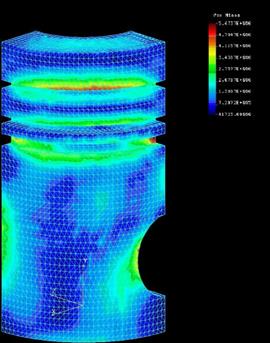

Fig.

5. Thermal stresses of the piston after 20 seconds for n=2,000 min-1, l=1.66

Fig.

6. Thermal stresses of the piston after 20 seconds for n=4,250 min-1,

l=1.69

4. CONCLUSION

Based on the preliminary results of

the calculations, it can be concluded that maximum values of thermal stresses

of the piston are found mainly in the ring portion and on the surface of the

piston head. On the other hand, the lowest values are found in the guide part.

The obtained maximum values of thermal stresses for the engine speed of

n=2,000 min-1, where λ=1.66, are bigger than thermal stresses for the

engine speed of n=4,250 min-1, where λ=1.69. According to the authors, the

thermal stresses represent an important factor, together with mechanical

stresses, in the design and subsequent operation of the piston for a specified

model and type of engine. However, the calculations should be verified

experimentally in order to obtain the results of numerical calculations, which

ought to correspond with real thermal stresses in the engine during the

warming-up stage in the future [7].

References

1.

Kwaśniowski

Stanisław, Zbigniew Sroka, Wojciech Zabłocki. 1999. Modeling of Thermal Loads on Components of Internal

Combustion Engines. Wroclaw: Annexe Publishing the Technical

University of Wroclaw. ISBN 978-8-3708-5394-5.

2. Piotr Gustof. 2001.

“Determination of the course of the temperature load for the full working cycle

in the cylinder of supercharged Diesel engine”. Scientific Journal of

Silesian University of Technology. Series

Transport 43: 5-11. ISSN: 0209-3324.

3.

Piotr Gustof, Aleksander Hornik, Damian Jędrusik.

2008. „Determination of values and temperature distribution in the piston of

supercharged Diesel engine”. In: Conference

Series: Materials Science and Engineering No.7-M: 231-237. Publisher Cracow

University of Technology. Cracow.

4.

Piotr Gustof,, Aleksander Hornik,. 2009. „The

influence of the engine load on value and temperature distribution in the

piston of the turbocharged Diesel engine”. Journal

of Achievements in Materials and Manufacturing Engineering 35 (2): 146-153.

5.

Piotr Gustof, Aleksander Hornik. 2010.

„Nonstationary heat flow in the piston of the turbocharged engine”. Transport Problems 5 (1): 41-46.

6.

Aleksander Hornik. 2011. „The influence of the

engine speed on the temperature distribution in the piston of the turbocharged

diesel engine”. Transport Problems 6

(3): 93-98.

7.

Piotr Gustof , Aleksander Hornik. 2012. „The

concept of experimental verification of modeled thermal loads of selected

elements of combustion chamber in supercharged Diesel engine” Scientific Journal of Silesian University of Technology. Series Transport 77:

43-48.

8.

Ramesh Babu , Guru Mahesh, Harinath Gowd.

2014. „Modeling and thermal analysis of SI engine piston using FEM”. International Journal of Mechanical and

Engineering and Robotics Research 3 (1).

Received

26.07.2016; accepted in revised form 01.10.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License