Article citation information:

Garbala, K., Piekarski, W., Andrzejewska, S., Witaszek, K. Analysis of

operating parameters and indicators of a compression ignition engine fuelled

with LPG. Scientific Journal of

Krzysztof

GARBALA[1], Wojciech PIEKARSKI[2], Sylwia ANDRZEJEWSKA[3], Kazimierz WITASZEK[4]

ANALYSIS

OF OPERATING PARAMETERS AND INDICATORS OF A COMPRESSION IGNITION ENGINE

FUELLED WITH LPG

Summary. This article presents the possibilities for using alternative fuels to

power vehicles equipped with compression ignition (CI) engines (diesel).

Systems for using such fuels have been discussed. Detailed analysis and

research covered the LPG STAG autogas system, which is used to power dual-fuel

engine units (LPG+diesel). A description of the operation of the autogas

system and installation in a vehicle has been presented. The basic algorithms

of the controller, which is an actuating element of the whole system, have been

discussed. Protection systems of a serial production engine unit to guarantee

its factory-controlled durability standards have been presented. A

long-distance test drive and examinations of the engine over 150,000 km in a

Toyota Hilux have been performed.

Operating parameters and performance indicators of the engine with STAG

LPG+diesel fuelling have been verified. Directions and perspectives for the

further development of such a system in diesel-powered cars have been also

indicated.

Keywords: Diesel

engines; dual-fuel (LPG+diesel); STAG LPG+diesel

1. INTRODUCTION

In the last decade, a growing

interest among the authors of research papers published in industry magazines

on the issue of supplying CI engines (diesel) with gas fuels has been observed.

This is partly caused by the economic reasons, which directly influence a

reduction in the costs of the operation of the vehicle. In the case of high

mileage, the operation of such a car is clearly less expensive. Savings

can be up to around 35%, which means that the ROI time for the autogas system

installation is short. The use of alternative fuels to power diesel engines in

cars allows strict exhaust emission standards to be met without the necessity

of using complex systems for the neutralization of toxic components in fumes.

In the process of diesel combustion combined with LPG combustion, the vehicle

generates a reduced amount of the harmful components found in fumes (carbon

monoxide, carbon dioxide, nitrogen oxides and PM particles), thus, it is more

environmentally friendly. Such a supply can be an alternative to electrical

motors, particularly in trucks, where the installation of electrical drives is

limited by the drive distances and total weight [1-4].

2. CHARACTERISTICS OF FUELS USED TO SUPPLY

DIESEL ENGINES

The

conventional fuel used to power CI engines is diesel. This is a mixture of

hydrocarbons containing 14÷20 atoms of carbon per molecule, which has

a boiling temperature within the range of 150°C÷380°C. Diesel is

manufactured from petroleum with a secondary processing of the heavy

fractions left from petroleum distillation. Its properties must be modified

through special additives, which improve fuel performance, even when small

amounts are added. Fuel obtained in this way does not meet all the requirements

as diesel includes paraffinic and naphthenic hydrocarbons, as well as aromatic

hydrocarbons [5].

The amount

of individual hydrocarbon fractions in diesel has an impact on its physical and

chemical properties. This influences the parameters and performance indicators

of operating engines, particularly on the toxicity of fumes and the engine’s

operating efficiency. The high content of aromatic hydrocarbons makes the fuel

self-ignition delay longer, which causes a generation of build-ups in the

combustion chamber and increases emission of solid particles. This, in turn,

leads to a reduction of the content of heavy hydrocarbons and sulphur in

diesel, which influences the lubricity and density. Additionally, fuels for

diesel engines should have the following properties: high capabilities of

spraying, mixing with air and evaporating, which influences cold engine starts.

The important properties of diesel include the ability to generate

self-ignition after the injection of a measured dose of fuel to the cylinder

and to achieve full and complete combustion. This is influenced by many

factors, such as fractional composition, viscosity, volatility, surface

tension, density, solidification and cloud point. Paraffinic hydrocarbons show

the best ability to self-ignite. Their disadvantage is the high solidification

temperature, which causes the blocking of the engine fuelling system in low

ambient temperatures [6, 7].

The leading trend in the development of modern CI engines (diesel) is the

search for and application of various alternative fuels. Such fuels may include

vegetable oils or their esters, ethers, alcohols, LPG, CNG or LNG, biogas,

hydrogen or synthetic fuels [8, 9].

3. POSSIBILITIES OF SUPPLYING DIESEL ENGINES

WITH LPG

CI engines have been fuelled only

with diesel oil for years. This fuel shows good self-ignition properties (high

cetane number). While LPG-type fuels show a high octane number and a high

resistance to spontaneous ignition as a consequence. This causes problems with

using this fuel to power diesel engines. This is why a combination of both

diesel and LPG is needed. Supplying LPG to a diesel engine can be carried out

by using various methods [10, 11]:

- mixer,

- injector

assembly in the intake manifold,

- injector

delivering fuel via the suction valve,

- injector

in the combustion chamber.

4. LPG

STAG AUTOGAS SYSTEM FOR POWERING DUAL-FUEL ENGINE UNITS (LPG+DIESEL)

With the

development of the automotive industry and market demand for gas systems for vehicles

equipped with CI engines (diesel), the Centre for Research and Development of

AC S.A. started research work into commercial LPG systems dedicated for such

systems. The work made use of the extensive experience with LPG systems

for spark-ignited engines. High requirements were set for future LPG systems

supporting diesel engines. The focus was put on operational properties,

such as the life and durability of the engine unit. From a commercial

point of view, it is the first and most important criterion specified for such

systems. Economic and performance factors were also taken into consideration,

as they are equally important.

The

dual-fuel system allows us to extract energy from new diesel resources (e.g.,

burning solid particles in the cylinder). If the autogas installation is

properly installed and tuned, it is possible to gain a significant increase in

power and torque by 10%÷30%, while reducing the operating costs and

improving engine parameters and performance indicators. In diesel engines with

a mechanical injection, the gas is injected into the intake manifold, which

results in a more efficient burning of diesel, the additional combustion of gas

increases the power of the engine and the combustion thermodynamic efficiency

is improved. The vehicle shows better dynamic qualities thanks to the power and

torque increase. Financial benefits (savings) are present in both dynamic

driving and eco-driving [12].

The

controller is an important element of such an autogas system. For the needs of

CI engines, a new design of a controller specifically dedicated to such engines

(STAG diesel controller) has been introduced. It can be used for fuelling 2÷16

cylinder engine units. The whole system has been based on the latest

technical and technological solutions, enabling the dosing of the gas fuel with

air, which are then mixed with diesel in the cylinder. The controller does

not exclude driving on diesel oil alone, as the autogas system does not

interfere with the internal parts of the engine. The controller is capable of

the intelligent controlling of the fuel dosing process during engine operation.

This is possible when the following sensor measurements are read: exhaust

temperature or oxygen sensor (lambda probe). An advanced algorithm for

sequential gas injection is based on the current demand for fuel. Measurements

cover the amount of injected oil as well. The engine protection system has been

extended with a temperature control system for the safety of the unit. The

system is also able to read the ATF ratio and control it with an independent

wideband lambda probe dedicated for CI engines (diesel). Figure 1 presents

the STAG diesel controller, while Table 1 describes its functions and its

technical and operating capabilities.

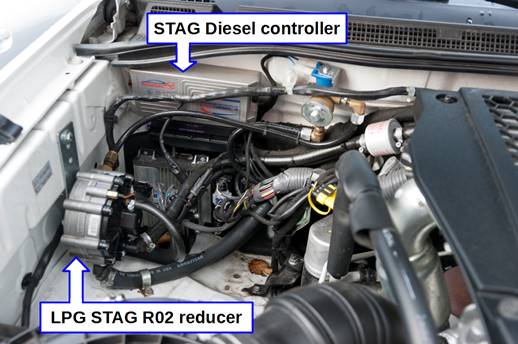

Fig. 1. STAG diesel controller and LPG STAG R02 reducer

Table 1.

Key technical

parameters of the STAG diesel controller

|

Supported engines |

Diesel with mechanical injection |

|

Diesel with common rail electronic injection |

|

|

Diesel with unit injectors |

|

|

Fumigation options |

LPG or CNG |

|

Control systems and

algorithms |

Advanced algorithm of sequential gas injection |

|

Precise gas dosing based on current engine demand |

|

|

Measurements and

control of injected diesel in common rail engines |

|

|

Advanced

algorithm for engine protection |

|

|

Controlled

exhaust gas temperature for improved safety of the drive unit |

|

|

Reading a

wideband oxygen sensor, control of air-to-fuel rate with an independent

wideband oxygen sensor designed for diesel engines (optional installation |

|

|

Support for cars

provided with cruise control |

|

|

Modification of

gas injection sequence |

For the

purpose of gas pressure reduction, the STAG R02 reducer (Fig. 1) was used.

The basic features distinguishing the STAG R02 are the compact size and

unique design, including two aluminium castings and Actherm-rated cover, which

prevents gas cooling, thus, providing excellent thermal insulation. Due to its

unique design, the AC R02 heats up very quickly, such that switching to gas is

also performed quickly. Therefore, no additional work, such as temperature

correction, is required of the controller. Its high thermal efficiency and

resistance to LPG contamination make the reducer the best option when selecting

autogas system components. Table 2 presents the technical specification of the

applied reducer.

Table 2.

Technical

specifications of the LPG STAG R02 reducer

|

Material |

Two aluminium castings and a cover made of

hard, resistant plastic |

|

Weight |

1.56 kg |

|

Dimensions |

125x122x89 |

|

Maximum

inlet pressure |

30 bar |

|

Outlet

pressure |

0.9-1.5 bar |

|

Gas

inlet diameter |

M10x1 |

|

Gas

outlet diameter |

Hose Ø12 |

|

Water

outlet diameter |

Ø16 |

|

Maximum

engine power |

100 kW (136 hps) |

|

Approval |

67 R - 01 6865 |

The LPG

supply system was equipped with the ACW01 injection rail (Fig. 2). This type of

injector is designed for sequential gas injection in compression injection and

spark injection engines. It ensures the precise dosing of vaporized gas to the

intake duct separately for each engine cylinder. As with all other AC injection

rails, this rail exhibits high durability, which has been confirmed in

long-distance road tests for various makes of car and various road and weather

conditions. Additionally, the AC rail is provided with 2Ω coils, which

eliminate the risk of overloading the control systems. The coils have been

equipped with IP67-rated connections. The main component is the body, which is

made of anodized aluminium. The connections are made of brass, while the

sealing is based on rubber compounds compatible with other elements. The

technical specification of this injection rail is presented in Table 3.

Fig. 2. ACW01 injector

rail

Table 3.

Technical

specifications for the ACW01 injection rail

|

Rated operating pressure |

0.95÷1.2 bar |

|

Maximum operating pressure |

4.5 bar |

|

Injector opening time |

~2.1 ms |

|

Injector closing time |

~1.5 ms |

|

Performance range |

11÷29 kW/cylinder |

|

Maximum flow |

90 l/min for p=1 bar |

5. TESTING THE OPERATING PARAMETERS OF A

COMPRESSION IGNITION ENGINE FUELED WITH LPG

The STAG

diesel system was installed in a new Toyota Hilux with a CI engine. Figure 3

presents the vehicle (test unit) with the locations of the LPG system

components. Table 4 specifies the technical parameters of the Toyota Hilux.

Measurements and test drives of the LPG+diesel system were performed over

a distance of 150,000 kilometres.

Test-driving was performed in the

city, on express roads, on country drives and under extreme conditions

(off-road). This mode of testing offered an exact representation of the operating

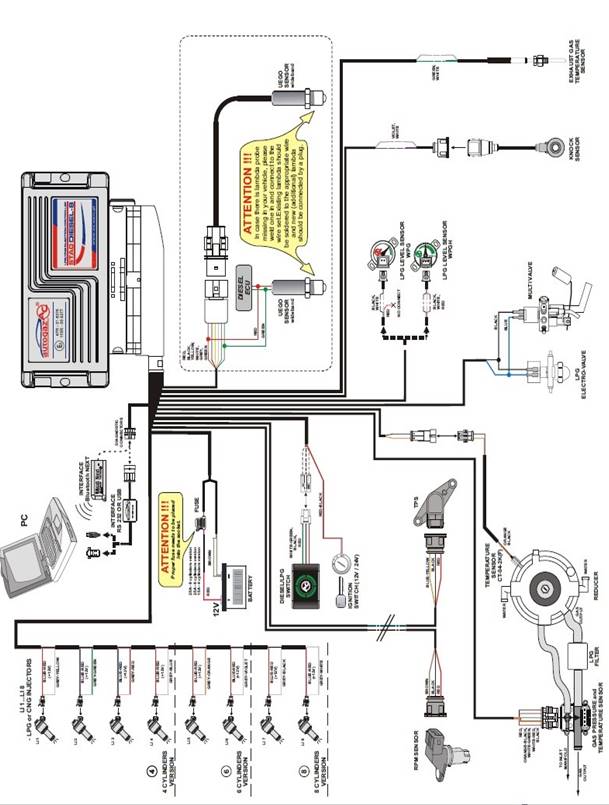

conditions for this type of vehicle. Figure 4 presents a diagram of the STAG

diesel in the LPG+diesel system.

Table

4.

Technical (factory) specifications

of the test vehicle, Toyota Hilux

|

Type |

Pickup |

|

Year of

manufacture |

2012 |

|

Emission

standard compliance |

EURO 5 |

|

Engine type |

Turbocharged

with an intercooler |

|

Capacity |

2,494 cm2 |

|

Number of

cylinders |

4 |

|

Fuel supply |

Common rail

with electronic injection control |

|

Maximum power |

106 kW at

engine rpm of 3,400 |

|

Maximum torque |

343 Nm at engine rpm of 2,000 |

|

Maximum speed |

|

|

Transmission |

Five-gear,

manual |

Fig. 3. View of the test unit (vehicle) with the locations of the LPG

system components

Technical inspections of the engine

were performed every 10,000 km. These checks involved measurements of the

compression ratio and valve clearance. Inspections of the cylinder working

faces, valve guides and valves (valve face) were also carried out. Visual

inspections of these elements were performed with the use of an endoscope. The

results of engine unit tests were compared with the manufacturer’s

requirements.

It was observed that the wear of

individual components did not exceed the factory limits. Therefore, it can be

concluded that the installation of an LPG+diesel fuelling system does not

significantly affect the durability of the engine unit.

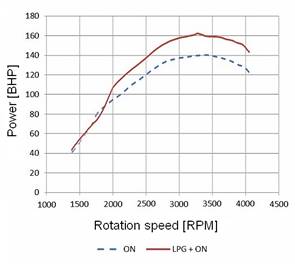

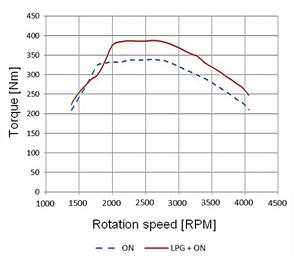

Figure 5 presents the speed

characteristics of the tested vehicle. The measurements of the torque and

power trends vs. rpm were performed for the three fuelling systems:

- only diesel,

- only LPG+diesel.

Analysis of the curves shows an increase in torque and power, respectively. The engine power increase in the LPG+diesel mode was 20 hp and the torque increase was 42 Nm. Analysis of torque curves indicates a shift in the maximum torque towards higher engine speeds. This results in a lower ratio of engine flexibility to its power. As a consequence, the engine is more dynamic, which directly influences acceleration in different gears.

Long-term tests covering

150,000 km in urban, country and off-road conditions allowed us to estimate the

economy of the dual-fuel system: the average reduction of the operating costs

related to the engine demand for diesel in mixed cycles was 31%.

Fig. 4.

Diagram of the STAG diesel-based LPG+diesel system

Fig. 5. Power and torque

characteristics of the tested vehicle

6. CONCLUSION

Summing up the results of the tests

presented in the research paper leads to the conclusion that there are

extensive possibilities for the application and development of CI engines with

dual-fuel (LPG+diesel) systems. This is supported by the excellent distribution

of LPG fuelling stations in Poland. It is a very important element for vehicle

operation, as the number of CNG stations in still limited in Poland.

Using the fuelling system presented

in the tested vehicle ensures a reduction in the operating costs related

to fuel by 31% when compared to diesel. Additionally, the power and torque

levels were observed to be 20% higher, which makes the car much more dynamic to

drive. A further benefit of the dual-fuel system is the reduction of

harmful exhaust gases, resulting from the limited emissions of nitrogen oxides,

solid particles and carbon dioxide, which are released into the natural

environment. Long-term operating tests over a distance of 150,000 km were

performed under urban, country and off-road conditions, confirming the reliability

of dual-fuel (LPG+diesel) systems. The results of the inspections of the

technical condition of the engine did not show any increased wear on the

engine components, which means that the engine parameters remain within

the standards and technical specifications of the manufacturer.

References

1.

Tiraa H.S., J.M. Herrerosb, A. Tsolakisa, M.L.

Wyszynski. 2012. “Characteristics of LPG-diesel dual fuelled engine operated

with rapeseed methyl ester and gas-to-liquid diesel fuels”. Energy 47(1): 620-629.

2.

Poonia M.P., A. Ramesh, R.R. Gaur, A. Joshi.

2012. “Effect of pilot fuel quantity, injector needle lift pressure and load on

combustion characteristics of a LPG diesel dual fuel engine”. International Journal of Engineering and

Innovative Technology 2(1):

26-31.

3.

Deo Raj Tiwari, Sinha P. Gopal. 2014. “Performance

and emission study of LPG diesel dual fuel engine”. International Journal of Engineering and Advanced Technology 3(3):

198-203.

4.

Ashok B. Ashok S. Denis, Kumar C. Ramesh.

2015. “LPG diesel dual fuel engine: a critical review”. Alexandria Engineering Journal 54(2):

105-126.

5.

Baczewski K., T. Kałdoński. 2004. Fuels

for Diesel engines. Warsaw: Transport and Communication Publishers.

6.

Lotko W., R. Longwic, K. Górski. 2000. “Study of chosen parameters of the combustion

process of diesel fuel in transient conditions”. Journal of KONES Internal Combustion Engines 7(1-2): 330-341.

7.

Samaras Z. 1999. “Emissions reduction via improvements in engines and

fuels: the Tehran case”. Journal of

Urban Technology 6(1): 63-87.

8.

Subbaiah1 G.V., K.R. Gopal. 2011. “An experimental investigation on the

performance and emission characteristics of a diesel engine fuelled with rice

bran biodiesel and ethanol blends”. International

Journal of Green Energy 8: 197-208.

9.

McTaggart-Cowan G.P., C.C.O. Reynolds, W.K. Bushe. 2006. “Natural gas

fueling for heavy-duty on-road use: current trends and future direction”. International Journal of Environmental

Studies 63(4): 421-440.

10.

Ambrozik,

A., P. Kruczyński, P. Orliński. 2003. “Influence of diesel engine fueling with

different fuels on self-ignition delay in aspect of ecology”. Eksploatacja I Niezawodnosc –

Maintenance and Reliability 3: 50-55.

11.

Luft S. 2003. “Dual-fuel compression ignition

engine: selected problems of combustion process”. Journal of KONES Internal Combustion Engines 11(3-4): 31-38.

12.

Unpublished research data of

the Centre for Research and Development of AC S.A.

Received 12.05.2016;

accepted in revised form 25.08.2016

![]()

Scientific Journal of