Article citation information:

Breus, A., Pavlenko, V. Effect

of impulse bias potential on formation of wearproof coating

deposited by plasma fluxes. Scientific

Journal of Silesian University of Technology. Series Transport. 2016, 92, 17-22. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.92.2.

Andrey BREUS[1], Vitaliy PAVLENKO[2]

EFFECT OF IMPULSE BIAS

POTENTIAL TO FORMATION OF WEAR-PROOF COATING DEPOSITED FROM PLASMA FLUXES

Summary. Plasma-based technology is used to deposit a

wear-proof nanostructured coating on plunger tappets

of pump of aviation oil system block, which allows increasing the life of the

parts up to 3–5 times. For the nanostructured coatings, which are formed

at the impulse bias supply, the electric field strength is 103-104

times greater than for the microstructured coatings. It

results in significant change of activation energy of the process of strong

bond formation in the growing coating, which makes it possible to obtain high

qualitative characteristics of the coating.

Keywords: plasma-based deposition; nanostructured coatings; impulse bias

1. INTRODUCTION

Nowadays

new technologies and materials are widely applied for transport quality

improvement and increasing of its service life [1]. Ion-plasma technologies

have been used for the last 50 years to change the surface properties for various

applications [2-5]. The method of plasma immersed ion implantation and

deposition (PIII&D) has become especially widespread [6, 7]. The essence of

this method is that the work piece, located on the substrate,

is under negative potential, which makes it possible to accelerate the ions in

the electrostatic layer, which is formed between the work piece and

plasma. The energy supplied by ions to the growing coating, allows activating a

range of processes, simultaneously avoiding the significant increase of the

work piece temperature. When the coating is deposited without plasma and

PIII&D method, the typical temperature of the work piece should reach

the value of more than 0.6Tm

(where Tm is melting

temperature) to obtain the coating with proper characteristics. PIII&D

methods allow increasing the work piece temperature only to the value of about

0.4Tm, which make it

possible to prevent recrystallization and loss of positive characteristics

obtained at preliminary heat treatment. However, the temperature of 0.4Tm allows obtaining microstructured coatings, thus limiting the work piece

service properties. To overcome this limit, a transition from “traditional” microstructured coatings to nanostructured coatings with

grain size of about 10-9 m should occur. The temperature should be

lowered to the values of about (0.2…0.3)Tm to obtain such coatings; a big number of

crystallization grains appears at such condition, which facilitates the formation

of fine-grained structure. However, the speed of strong bonds formation is very

low in the coating due to the low temperature; the mechanical characteristics

of obtained coatings are not adequate because of big number of pores.

To

obtain nanostructured coatings we can apply the impulse high negative potential

to the substrate coupled with the background constant (floating) negative

potential. We used the technique to deposit wear-proof coating to the plunger tappets of pump of aviation oil system

block, and the life of the part was increased up to 3–5 times comparing to the

un-treated samples. Microscopic investigation shown that a nanostructured

coating is formed under the influence of the impulse bias supply. The purpose

of this paper is to describe the possible mechanism of coating formation

under such conditions.

2. EXPERIMENTAL RESULTS

The experimental setup is shown

schematically in Fig. 1 (left); the work pieces are shown in Fig. 1

(right).

Fig. 1. Experimental setup and work pieces

The setup includes vacuum chamber

with a vacuum arc plasma source mounted on a flange of the chamber. An

evaporated cathode was made of titanium. A rotating substrate with fixtures for

work pieces installation was located in the chamber. When operating the plasma

source, the dc arc current was applied between the cathode and the grounded walls

of the vacuum chamber, which served as anode. A source of impulse bias

(2 kV, 1 µs, 1 kHz) was used to supply power

to the substrate. An automated gas-handling system maintained a nitrogen

pressure of 0.1 Pa. The time of the work pieces

exposure to the plasma was 20 min. TiN coatings with columnar structure with diameter

of about 30 nm and microhardness of 20 GPa were obtained on the surfaces

of the work pieces as a result of the plasma treatment; the temperature of the

samples did not exceed 450 K at the experiment. The coatings with the diameter

of the columnar structure of about 200–400 nm and the same microhardness can be obtained at constant bias potential of

100 V and the temperature of the samples of 750 K, which is not allowed by

the specifications for the work pieces. To describe the experimental results,

the following theoretical model was developed.

3. THEORETICAL MODEL

The model is based on

the fact that electrical field strength is higher in those areas of conductor

where the radius of curvature is smaller. We apply the known assumptions [8] to

the model, when the grain of the growing coating with radius Rnano

rests on the grain of the substrate (work piece) with radius of Rmicro.

The electrostatic potential can be calculated by use of formula for spherical

charge qi:

![]() . (1)

. (1)

For charges

equilibrium we need the equality of potentials jnano = jmicro, which results

in:

![]() . (2)

. (2)

Since the field at

the outer surface of the conductor is:

![]() , (3)

, (3)

where s is the local surface charge density, which is

proportional to the total charge divided by radius squared, we can state that:

![]() . (4)

. (4)

The ratio between the

strength Еmicro and the value of the bias potential Us applied to the substrate

can be determined by use of the cathode layer thickness s:

![]() (5)

(5)

![]() . (6)

. (6)

The presence of

electric field on the grain surface results in changing the rate of formation

of strong bonds between the deposited ions and grains of coating on the

substrate surface. This rate is proportional to the probability described by

factor exp(-ea/kT), where ea is the energy

of bond formation, T is the substrate

temperature [9]. Considering the influence of the additional electric field to

the probability of the strong bond formation, we can write:

![]() (7)

(7)

where Deа is the work, carried

out by electric field Еnano to

overcome the repulsive force between the ion and the grain at the distance of

around lattice parameter a0:

![]() (8)

(8)

Then finally, we can write:

. (9)

. (9)

High negative

potential supplied to the grain surface, results in generation of strong

electric field, which can reduce significantly the activation energy of the

process of strong bond formation according to formula (9), thus compensating low

temperature T of the growing surface.

The need to supply

the high potential at specifically pulse mode is conditioned by two

constraints. The first is the requirement to sustain a relatively low

temperature of the work piece thus lowering the heat current supplied by ions

to the substrate after acceleration in the cathode layer. The second

constraint is imposed by the rate of change of work piece geometry, which

becomes negative (the work piece coating and surface layer are predominantly sputtered),

when the energy of ions exceeds the value of approximately 500 eV. Hence,

to deposit a wear-proof coating at low temperatures, we need to supply the high

impulse negative potential, when the ratio of the impulse duration to the impulse

period is significantly smaller than one.

To justify the proposed

mechanism of influence of the impulse bias supply to the substrate at the coating

growth, we calculated the probability Pa(Us, Rnano, T) of the strong bond formation of the

system “nanostructured coating – microstructured work

piece” with respect to the probability Pa(0, Rmicro, T) of the strong bond formation of the

system “microstructured coating – microstructured

work piece”.

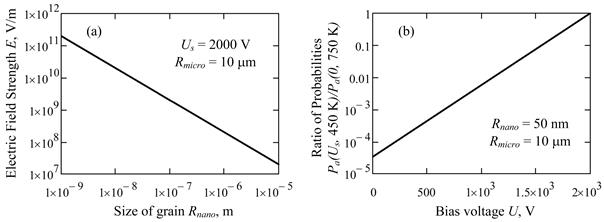

Fig. 2a shows the

results of calculations of electric field strength on the surface of a grain of

a coating at dependence on the grain radius

Rnano, when the radius of the grain of

the substrate material is Rmicro = 10 µm. The amplitude of

the impulse bias of Us = 2000 V

and the plasma sheath thickness of s = 0.1 mm

are considered as parameters. Then we considered the growth of a nano-sized grain of a coating with radius of Rnano = 50 nm

on a surface of a micro-sized grain of substrate with radius of Rmicro = 10 µm.

The results of calculation of ratio Pa(2000 V, 50 nm, 450 K)/Pa(0, 10 µm, 750 K)

are shown in Fig. 2b. These results allows comparing the growth of the

wear-proof coating when the substrate temperature is low (T = 450 K) but high bias potential is supplied (Us = 2000 V) which

corresponds to conditions in our experiment, with the deposition of the

wear-proof coating when the substrate temperature is high (T = 750 K) and the bias potential is not supplied (Us = 0) that is

close to a conventional process of growth in plasma.

Fig. 2. Electric field strength E at dependence on radius Rnano

of a grain of coating at interaction with a grain of work piece (substrate) of radius

Rnano = 10 µm (a), and ratio of probabilities Pa(2000 V, 50 nm, 450 K)/Pa(0, 10 µm, 750 K)

at dependence on voltage U (b)

According to the calculations, the electric field strength for the

nanostructured coatings exceeds 103-104 times the

strength obtained for microstructured coatings, when

the impulse of high bias potential is applied to the substrate. At the

potential of 2000 V and coating with grain sizes of 50 nm deposited

on the surface with grain size of 10 µm, the probability Pa(2000 V, 50 nm, 450 K)

of strong bonds formation at the substrate

temperature of 450 K equals the probability Pa(0, 10 µm, 750 K) of strong bonds formation at the substrate temperature of 750 K.

Thus, impulses of high negative potential allows changing significantly the

activation energy of the process of strong bonds formation in the growing

coating, which makes it possible to obtain high quality characteristics of

coating at growth temperature of about 450 K.

4. CONCLUSION

The developed

model allows describing adequately the effect of high negative impulse potential

applied to the substrate for deposition of wear-proof nanostructured coating.

The model can be useful to describe the changes in quality characteristics

of a surface layer, which depend on bonding energy between the atoms of growing

coating such as microhardness, adhesion, inherent

stress, reflecting power, friction factor, durability, etc.

References

1.

Posmyk Andrzej. 2012. “Wpływ

nowych technologii i materiałów na poprawę jakości

transportu”. [In Polish:

“Acting of new technologies and materials on transport quality improvement”]. Scientific Journal of Silesian University of

Technology. Series Transport 78: 133-138. ISSN 0209-3324.

2.

Chen

Francis, Jane Chang. 2003. Lecture notes on principles of plasma

processing. New York: Plenum/Kluwer Publishers. ISBN 978-0-306-47497-2.

3.

Keidar Michael, Alex Shashurin, Olga Volotskova, Mary

Ann Stepp, Priya

Srinivasan, Anthony Sandler, Barry Trink. 2013. “Cold

atmospheric plasma in cancer therapy”. Physics of Plasmas 20. ISSN

1089-7674. DOI: 10.1063/1.4801516.

4.

Mariotti Davide,

R. Mohan Sankaran. 2011. “Perspectives on atmospheric-pressure plasmas for nanofabrication”. Journal of Physics D: Applied Physics

44.

ISSN 0022-3727. DOI: 10.1088/0022-3727/44/17/174023.

5.

Martina Filomeno, Jorn Mehnen, Stewart W. Williams, Paul Colegrove,

Frank Wang. 2012. “Investigation of

the benefits of plasma deposition for the additive layer manufacture of Ti-6Al-4V”. Materials

Processing Technology 212: 1377-1386.

ISSN 0924-0136. DOI: 10.1016/j.jmatprotec.2012.02.002.

6.

Metel Alexander. 2002. “Plasma immersion ion implantation based on glow discharge with

electrostatic confinement of electrons”. Surface

and Coatings Technology 156:

38-43. ISSN 0257-8972. DOI: 10.1016/S0257-8972(02)00070-1.

7.

Lieberman Michael,

Allan Lichtenberg. 2005. Principles of plasma discharges for materials

processing. New York: Wiley InterScience. ISBN

978-0-471-72001-0.

8.

Feynman Richard,

Robert Leighton, Matthew Sands. 1963. The

Feynman Lectures on Physics. Boston, MA: Addison-Wesley Co. ISBN 0-201-02115-3.

9.

Kittel

Charles, Herbert Kroemer. 1980. Thermal

Physics. New York: W.H. Freeman and Co. ISBN

978-0716710882.

Received 15.01.2016;

accepted in revised form 25.07.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons Attribution

4.0 International License