Article citation information:

Vinogradov

B., Ostashko I. Substantiation of key parameters of a centrifugal mill intended

for grinding solid residue from the pyrolysis of used automobile tyres. Scientific Journal of Silesian University

of Technology. Series Transport. 2016, 91,

133-141. ISSN: 0209-3324.

DOI: 10.20858/sjsutst.2016.91.14.

Igor OSTASHKO[1],

Boris VINOGRADOV[2]

SUBSTANTIATION OF KEY

PARAMETERS OF A CENTRIFUGAL MILL INTENDED FOR GRINDING SOLID RESIDUE FROM THE PYROLYSIS

OF USED AUTOMOBILE TYRES

Summary. The study presents the results of an investigation

into centrifugal mills with an energy-saving working body. Rational geometric

parameters of the working body of the centrifugal mill, which grinds the

solid residue from the pyrolysis of used tyres, have been justified on the

criterion of the lowest specific energy consumption during the grinding

process. A method to determine the dependence of the in-grinding power

consumption on the basic parameters of the working body has been developed, while

an analytical expression to determine the power consumption for grinding

the solid residue from the pyrolysis of used tyres has been obtained. It has

been found that the power consumption in the grinding process linearly depends

on the rotational speed of the working body, which is to the 0.3 power on the

average size of solid particles.

Keywords: centrifugal

mill, working body, power consumption, solid residue from pyrolysis.

1. INTRODUCTION

Centrifugal

mills have been widely used in many industries for grinding various abrasives

[1]. The main structural element in most centrifugal mills is a working body

containing beater elements in the form of blades and baffles. The grinding

process in these mills is performed through a high speed transferred to the material,

which results in significant power consumption.

The aim of

the article is to study the main parameters of a centrifugal mill for fine

grinding of the solid residue from the pyrolysis of waste tyres with the lowest

specific power consumption.

2. PRESENTING MAIN

MATERIAL

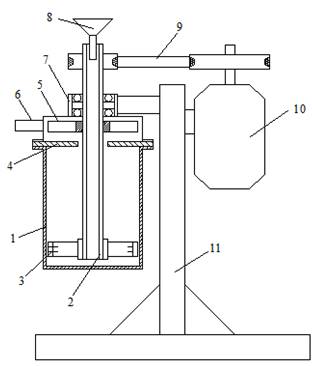

After a careful study of various

designs of centrifugal mills and preliminary laboratory tests, a new design of

the centrifugal mill has been developed and presented (Fig. 1 [2]), which

allows for grinding granular materials, such as the solid residue from used tyre

pyrolysis, with the lowest specific power consumption.

Fig. 1. Centrifugal mill: 1 -

grinding chamber; 2 - hollow shaft; 3 - working body; 4 – ring for

classification; 5 - impeller; 6 - outlet; 7 - bearing assembly; 8 - hopper;

9 - belt drive; 10 - motor; 11 - support column.

The design feature of the proposed

mill is the shape of the working body and the method of discharging the

finished grade, which can significantly reduce the specific energy consumption

during the grinding process, thereby facilitating the classification of the

ground material directly in the mill.

Preliminary studies were carried out

on the mill, in which the grinding chamber was shaped as a regular

cylinder with a diameter of 0.3 m. In the course of the studies, the rational

design and technological parameters of the mill were determined in terms of

minimum specific energy consumption during the grinding process [3]. It has

been found that: a grinding chamber’s effective filling level is 25-30% of its

volume; an active length of the working body is shifted to its periphery by as

much as 15-25% of its volume, depending on the rotational speed; the gap

between the beaters is between 3 and 5 mm; and the specific energy consumption

for grinding the class of less than 43 µ with a two-beater working body is 57

kWh / t, while it is 21 kWh / t for a four-beater working body.

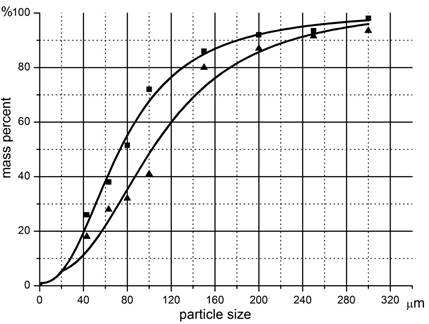

The study of the granulometric

composition of the ground material (Fig. 2) shows that an increase in the

number of beaters from two to four results in increased efficiency, while specific

energy consumption is decreased by 180% at the same time. However, a further

increase in the number of beaters increases the specific energy consumption

with no change in output. This can be explained by the fact that the

two-beater working body does not cover the entire area of intense grinding,

while the increased number of beaters reaches beyond this area.

Fig. 2. Granulometric composition of

solid pyrolysis residue milled for 1 min by working bodies with different

numbers of beaters: 1 - four beaters; 2 - two beaters.

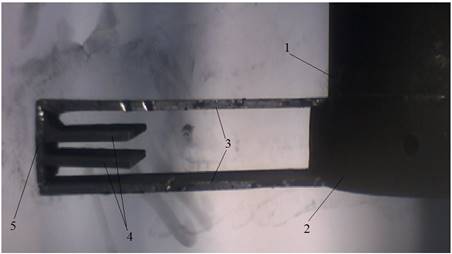

Strength calculations have confirmed

the advisability of the closed-type

working body design (Fig. 3). This type of working body design allows for grinding

due to impact and friction. In this case, larger particles, whose size > 100

µ, are mostly destructed by their impact interaction with the working body in

the peripheral area, while particles, whose size < 100 µ, are mainly

destructed due to friction forces, which arise from the material interaction

with the grinding chamber walls and the working body.

Fig. 3. Working body of the new

design: 1 - hollow shaft; 2 - working body mount; 3 - beaters; 4 – beater in

the area of intensive milling; 5 - end beater.

In an idling mode, i.e., in the

absence of material feed, the working body of this design consumes the power

determined by formula in [3]:

![]() , (1)

, (1)

where ρm is the

density of the medium that interacts with the working body (kg / m3),

ξ is the drag coefficient, A0 is a parameter that takes

into account the geometry of the working body,

(k

ωw) is the relative angular velocity of the working

body, ωw is the angular velocity of the working body,

and k is the slip coefficient, which

characterizes the speed of the working body’s interaction with the medium. In

turn,

![]() ,

,

where ωair is the angular

velocity of the air.

The unknown terms in Equation (1)

are ξ, k. To determine the

terms, two separate cases were considered: when the mill was operated with either

the grinding chamber removed or the grinding chamber mounted, no material

charged. The power consumptions N1

and N2 can, respectively, be

determined based on the following equations:

![]() (2)

(2)

![]() (3)

(3)

where N1, N2,

k1, k2 are the power consumptions and coefficients of slipping with the removed

and mounted grinding chamber, respectively.

The working body power consumption N1, N, at different rotational speeds,

and the air angular velocity ωair

were experimentally determined with the grinding chamber removed with the use

of a cup anemometer.

To determine the N1, N2 power consumptions of the working

body, the total power consumption was first measured using the following

formula: NΣm = Nlost + Ni, where Nlost

is the power lost in the mill’s electromechanical transmission with the working

body removed, and i is the experiment

number 1 or 2. Then, the power consumed by the working body was be determined

by the formula: Ni = NΣm - Nlost.

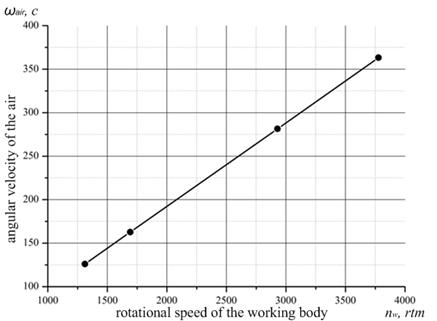

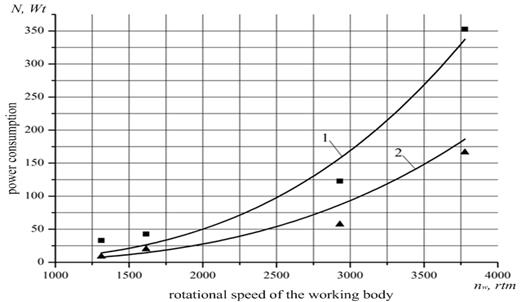

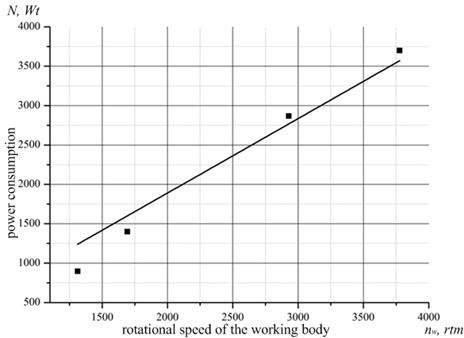

Fig. 4 and Fig. 5 show the

dependence of the angular velocity of the air and working body power

consumption on the rotational speed. Fig. 6 shows the experimental dependence

of the working body power consumption on the rotational speed when the

grinding chamber is loaded with solid residue of tyre pyrolysis with average

particle size dav = 43 µ.

Fig. 4. Angular velocity of the air

flow: ωair – angular

velocity of the air;

nw

– rotational speed of the working body.

Fig. 5. Curves of power consumed by

the working body: 1 - with the grinding chamber removed; 2- with the grinding

chamber mounted.

By knowing the angular velocity ωair0 of

the air during the rotation of the working body with the grinding camera

removed, along with the power consumption, we can determine the relative

angular velocity k1 ∙ ωw

= ωw-ωair0 and drag coefficient ξ. Assuming that the drag coefficient is the same whether the

camera is removed or mounted, we calculate the relative angular velocity of the rotor

with the chamber mounted as follows: k2

∙ ωr = ωr – ωac (ωac is the angular

velocity of the air during the working body rotation in the grinding chamber).

The experimental data show that the

air velocity is directly proportional to the working body rotational speed

(Fig. 4), while the slip coefficients are k1

= 0.92, k2

= 0.83, and the drag coefficient is ξ

= 12.6. The experimental results also confirm the adequacy of Equation (1), namely,

that the power consumed by the test working body, which operates in an empty

chamber, depends on the rotational speed taken to the third power (Fig. 5).

Fig. 6 shows an experimental

dependence of wattage consumed by the working body, which operates with the

grinding chamber loaded. The material taken was the solid residue from the

pyrolysis of used tyres, with an average particle diameter of dav =

43µm. Meanwhile, the degree of filling in the grinding camera was Vm / Vc = 0.27 (Vm, Vc represent the volumes of

the material and the chamber, respectively) and the material bulk density was

445 kg / m3.

Fig. 6. Dependence of power

consumption on the rotational speed of the working body during the grinding

process.

In contrast to an empty chamber,

where air is the medium, the power consumption in the loaded grinding chamber is

linearly dependent on the rotational speed of the working body. This can be

explained by the fact that, during the grinding process, the material

influenced by centrifugal forces is unevenly distributed throughout the inside

of the grinding chamber and concentrated along its walls. This reduces an

active area of the working body, which results in further changes in the

distribution of the forces of resistance. Based on the analysis of Equation (1)

and the experimental data (Fig. 6), a conclusion can be made that the dependence

of A0 (the parameter

characterizing the size of an active part of the working body) on the

rotational speed takes the following form:

![]() , (4)

, (4)

where ν

= 1.72 is the coefficient, which takes into account the decrease in an active

part of the working body.

To determine the power consumption,

we substitute the values of ν and assume that coefficients ξ are

equal for either an empty or a loaded grinding chamber, while an average

diameter of solid particles dav

= 43 µm. In turn, Expression (1) takes the following form:

![]() . (5)

. (5)

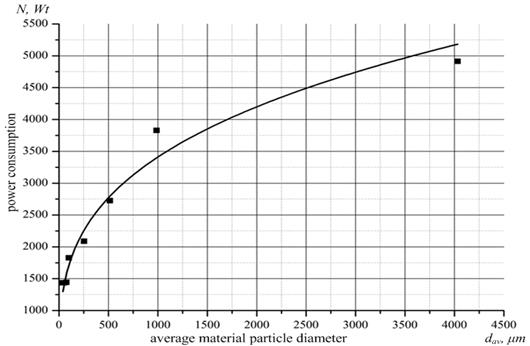

Fig. 7 shows the experimental

dependence of the power consumption on the average material particle diameter

at an angular velocity of 389 s-1. Increased power consumption in

relation to the increase in the average particle diameter may be explained by

an increase in the relative angular velocity of the interaction between

the working body and the medium.

Fig. 7. Power consumption change

with average particle diameters at an angular velocity of 389 s-1.

When working with the material feed,

slip coefficient k2

undergoes changes due to the reduction in the rotational speed of the

medium; the drag coefficient ξ

is also subject to a change, since the parameters of the medium have

changed. It is therefore necessary to consider the product of the two

coefficients as a function of the average material particle diameter dav.

![]()

Experimental dependence of power consumption on the average diameter of

particles in the grinding chamber (Fig. 7) can be approximated with a

dispersion of R = 0.97, according to the following

function:

![]() . (7)

. (7)

By equating the power consumptions defined by Formulas (5) and (7), we

obtain:

![]() . (8)

. (8)

Thus, the general formula, which will determine the wattage consumption

for grinding the solid residue from the pyrolysis in the centrifugal mill,

takes the following form:

![]() . (9)

. (9)

3. CONCLUSIONS

1. The proposed design parameters of the working

body and the mill as a whole will provide the minimum specific power

consumption during the material grinding.

2. The formula obtained by the authors can be

used to determine the power consumed by the centrifugal mill’s working

body for grinding the solid residue from the pyrolysis of used tyres.

3. It has been found that, during the grinding

process, the power consumption linearly depends on the rotational speed of the

working body and is proportional to an average size of solid particles, which

are taken to the 0.3 power.

4. The method developed by the authors allows for

obtaining a dependence of power consumption by the centrifugal mill’s working

body on its basic parameters, as well as the parameters of the material to

be ground.

References

1.

Бардовский

А. Д., Л. А.

Летин, Н. М.

Кряжев, И. И.

Дерба, Е. В.

Пухучкин. 2002. Определение

параметров

центробежной

мельницы

роторно-струйного

измельчения

при помоле

отходов

карбонатного

сырья. Горный

информационно-аналитический

бюллетень 1: 204-206.

Мoscow: МГГУ. [In Russia: Bardovskiy A. D., L. A. Letin,

N. M. Kryazhev, I. I. Derba, E.V. Pukhuchkin. 2002. „Defining the parameters

of a centrifugal rotor-jet mill when milling waste carbonate raw materials”. Mining Informational

and Analytical Bulletin 1: 204-206.

Moscow: Moscow State Humanities University.]

2.

Виноградов

Б. В., И. О.

Осташко. 2009. Об

энергетических

характеристиках

центробежных

мельниц с

S-образным

рабочим органом.

Вісник

НТУ „ХПІ” 25: 164-169. [In Ukraine: Vinogradov B. V.,

I. O. Ostashko. 2009. „On the energy performance of centrifugal mills with an

S-shaped working body”. Bulletin of the Kharkiv Polytechnic

University 25: 164-169. Kharkiv: Kharkiv Polytechnic University].

3.

Виноградов

Б. В., И. А.

Осташко, В. И.

Емельяненко.

2009. „Измельчение

твердых

остатков

процесса

пролиза

изношенных

автомобильных

шин в

центробежной

мельнице”. Вопросы

химии и

химической

технологии 2:

159-161. [In Ukraine:

Vinogradov B. V., I. O. Ostashko, V. I. Emel'yanenko.

„Shredding of solid residue pyrolysis of used tyres in a centrifugal mill”. Issues of

Chemistry and Chemical Technology 2: 159-161. Dnepropetrovsk: Ukrainian

State University of Chemical Technology].

4.

PL

216901 B1. Układ mechaniczny

strojony w sposób płynny. [In Polish: Smoothly

tuned mechanical system.]. Homišin Jaroslav. 2014. Warsaw: Polish Patent

Office.

5.

Grega

Robert, Jozef Krajňák. 2012. „The

pneumatic dual-mass flywheel”. Scientific Journal of Silesian University of

Technology. Series Transport 76: 19-24.

ISSN: 0209-3324.

6.

Homišin

J., P. Kaššay, M. Urbanský. 2011. „High-flexibility characteristics of pneumatic flexible shaft couplings”. Pneumatyka

79(2): 26-29. ISSN 1426-6644.

7.

Mantič M., J. Kuľka, J. Krajňák, M. Kopas, M. Schneider. 2015. „Influence of selected digitization methods on final

accuracy of a 3D model”. Production Management and Engineering Sciences: 475-480. Proceedings

of the International Conference on Engineering Science and Production

Management (ESPM 2015). Tatranská Štrba, High Tatras Mountains, Slovakia, 16th-17th

April 2015. Edited by Majerník M., D. Naqib, B. Martin.

Boca Raton, FL: CRC Press, Taylor & Francis Group. ISBN: 978-1-138-02856-2.

Received 11.12.2015; accepted in revised form 02.05.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License