Article citation information:

Petroci, J., Mantic, M., Kulka, J., Boslai, R. Design of a compact dual-purpose starting clutch in the drive of a prototype vehicle. Scientific Journal of Silesian University of Technology. Series Transport. 2016, 91, 107-112. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.91.11.

Ján PETRÓCI[1],

Martin MANTIČ[2],

Jozef KUĽKA[3],

Róbert BOSLAI[4]

design of A Compact Dual-Purpose Starting Clutch IN THE Drive of A Prototype Vehicle

Summary. Initially, the development of a dual-purpose

clutch was based on racing experiences and application requirements, as well as

the results from testing the new power unit in the existing prototype

vehicle. In order to achieve the highest possible driving range of the prototype

vehicle, it has been necessary to eliminate the maximum possible losses and

drive in unnecessary components. The design aimed to achieve simple access,

reliability and low weight.

Keywords: centrifugal clutch, prototype,

engine

1.

INTRODUCTION

The internal combustion four-stroke

engine Honda GX 25, which is designed for small agricultural and garden use, involves

a manual starting system. Output power is transmitted through a simple

centrifugal clutch mounted on the flywheel. A crank shaft on the starter

mechanism side is designed with a relatively low metric 6mm thread and a surface

with a diameter of 11mm, meaning that it is not sufficiently sized to

transmit the torque of the electric motor used for starting the prototype drive

unit. Applicable electric motors for radio-controlled cars generate high stress

on the crankshaft as well as on the gear mechanisms, which in turn breaks the threaded

part. Automotive-type starter motors, which are used in small motorcycles with

a sliding pinion gear, are also unsuitable given the small dimensions of the

thread shaft. In other words, when the slide pinion bumps into the starter

flywheel, a bending force impacts on the crankshaft, resulting in bending and

breakage. Basic theoretical principles, which are necessary when addressing these

matters, are described in [1], [2].

2.

CONSTRUCTION

The crankshaft is shaped on the

outlet cone and features a key for the precise assembly of the flywheel, which

is used for cooling and driving the centrifugal clutch, and a magnetic pulse that

controls the ignition system by magnets moulded into the flywheel.

The dimensions of the engine

compartment in the existing prototype require a compact design of the power

unit and a crankshaft speed sensor to initiate the run-up mechanism. The design

of the components must be focused on simplicity, reliability, low weight and

compact dimensions.

The appropriate solution for

transferring the torque of the engine and the starting mechanism involves a

pair of automatic centrifugal clutch. Questions concerning engine dynamics and related

problems are analysed in [3], [4].

To meet the competition rules, both automatic

clutches must be constructed to engage different speeds in order to prevent the

transmission of torque from the electric starter motor to the driven wheel via

the clutch and shaft. To comply with this rule, centrifugal clutch springs

for the wheel drive stiffen the coupling elements with a lower weight or a

bigger radius.

The difference in clutch engagement

speed is shown in Fig. 1.

Fig. 1. Clutch engagement diagram

The following calculates the centrifugal force

acting on the operating coupling elements:

![]() (1)

(1)

The mass of the clutch element in

relation to the centrifugal force must be calculated according to the part that

is particularly affected. The weight of the mounting part of the element, which

moves around the guide pin, must not be included in any calculation.

The dimensions of the centrifugal

clutch elements for the torque transmission depend on the friction linings’

coefficient, their number, the friction radius, the centrifugal force and the

spring force, which keeps the coupling elements in the off position.

The following equations are for

calculating the linear spring stiffness and friction torque:

![]() (2)

(2)

![]() (3)

(3)

![]() (4)

(4)

In order to save as much space as

possible when mounting the engine, three narrow clutch elements were

constructed. Torque and heat transfer of the three elements will be more

reliable in racing when using the start-stop power unit system to save fuel.

The course of the load in relation

to time when using the start-stop system, as commonly used in Shell Eco-marathon

races, is shown in Fig. 2.

Fig. 2. Engine load during races

3. DESIGN

To avoid losses in the starting

mechanism drive, the spur gear with mounted centrifugal clutch elements rotates

around the engine crankshaft on ball bearings, which are secured on the outer

bearing ring with screws. Mechanical losses involving the driving mechanism are

serious problems, as discussed in [5], [6]. The mechanical losses, which are

connected to mechanical vibrations, are usually considered as negative

phenomena [7]. With regard to simplicity, interchangeability of parts and

reliability, the same construction and number of friction elements for the drive

clutch are used. The difference between the starter and drive clutch

construction is stated in chapter 2.

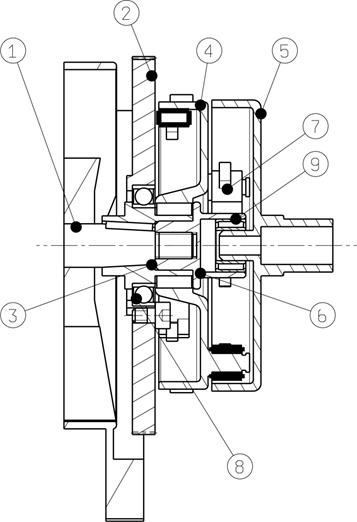

The complete assembly cut-out of the

dual-purpose drive clutch without tension springs and cooling holes in the friction

wheels is shown in Fig. 3.

Fig. 3. Dual-purpose drive clutch cut-out:

(1) crankshaft, (2) starter spur gear, (3) hub, (4) toothed flywheel, (5)

centrifugal drive clutch friction wheel, (6) nut, (7) clutch element, (8) ball

bearing and (9) needle bearing

Each rotating disc in the dual

clutch must be precisely balanced and manufactured to avoid crankshaft and

bearing failure, which result from the small dimensions and design of the

original power unit.

The used hub, which is mounted on the

output side of the crankshaft with a key, creates more space, as well as offers

more options to use other parts, such as bearings, locking keys and surfaces.

To achieve the minimum inertia and weight in each part, the spur gear, engine

flywheel and output friction wheel are designed with holes on their faces. Heat

transfer and the cooling of friction clutches are important in terms of making

them reliable in the course of every race lap. The design of every race

component also aims for simplicity regarding the speed of changing and

repairing each part or the whole assembly. Simply put, easy access for screws,

nuts and locking rings must take place.

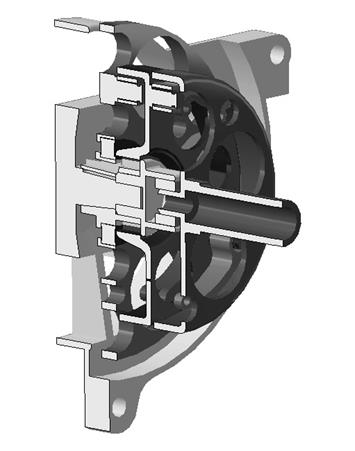

Fig. 4. 3D cut-out of a complete dual-purpose

clutch assembly

4. CONCLUSIONS

1.

One of the possible complex designs of a starting

and drive mechanism for small power units aimed to avoid the maximum possible

losses.

2.

This design was compromised by low part inertia,

reliability, simplicity and tough race conditions.

This

paper was elaborated within the framework of the following projects:

VEGA1/0197/14 – research on new methods and innovative design solutions in

order to increase efficiency and to reduce emissions of transport vehicle

driving units, together with the evaluation of possible operational risks; VEGA

1/0198/15 – research on innovative methods for emission reduction of driving

units used in transport vehicles and optimization of active logistic elements

in material flows in order to increase their technical level and reliability;

and KEGA 021TUKE–4/2015 – development

of cognitive activities focused on innovations in educational programmes in the

discipline of engineering, as well as building and modernizing specialized

laboratories specified for logistics and intra-operational transport.

References

1.

Pavlenko

S. et al. 2008. Časti strojov II. [In

Czech: Machine parts II]. Prešov: FVT. ISBN 978-80-553-0103-7.

2.

Heisler

H. 2002. Advanced Vehicle Technology.

Warrendale: SAE International. ISBN-9780080493442.

3.

Dekys

V., A. Sapietova, O. Stevka. 2013. „Understanding the dynamical properties of machines

based on the interpretation of spectral measurements and FRF”. In. 51st International Scientific

Conference on “Experimental Stress Analysis”: 106-112. Litomerice, Czech

Republic. 11-13 June 2013.

4.

Izrael

G., J. Bukoveczky, L. Gulan. 2011. „Utilisation of modeling, stress analysis,

kinematics optimisation, and hypothetical estimation of lifetime in the design

process of mobile working machines”.

Scientific Proceedings Faculty of Mechanical Engineering STU Bratislava 19:

23-28. ISSN 1338-1954. DOI: 10.2478/v10228-011-0004-1.

5.

Łazarz

B., G. Wojnar, H. Madej, P. Czech. 2009. „Evaluation of gear power losses from

experimental test data and analytical methods”. Mechanika 6(80): 56-63. ISSN 1392-1207.

6.

Figlus

T., Ł. Konieczny, R. Burdzik, P. Czech. 2015. „The effect of damage to the fuel

injector on changes of the vibroactivity of the diesel engine during its

starting”.

In International Conference on “Vibroengineering”:

180-184. Katowice, Poland. 14-15 October 2015. Vibroengineering Procedia 6. ISSN 2345-0533.

7.

Konieczny

Ł., R. Burdzik, J. Warczek, P. Czech, G. Wojnar, J. Młyńczak. 2015. „Determination

of the effect of tire stiffness on wheel accelerations by the forced vibration

test method”. Journal of Vibroengineering

8 (17): 4469-4477. ISSN 1392-8716.

Received 09.12.2015; accepted in revised form 19.03.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License