Article citation information:

Medvecká-Beňová S. Influence of the face width and length of contact on

teeth deformation and teeth stiffness. Scientific

Journal of Silesian University of Technology. Series Transport. 2016, 91, 99-106. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.91.10.

Silvia MEDVECKÁ-BEŇOVÁ[1]

INFLUENCE OF THE FACE WIDTH

AND LENGTH OF CONTACT ON TEETH DEFORMATION AND STIFFNESS

Summary. Gear teeth are deformed due to

load. Recently, given the increasingly evolving computer technology, supported

by the available literature, we have modern numerical methods at our disposal,

such as the finite element method (FEM), which serves as one of the methods for

the determination of teeth deformation in the gearing. This paper mainly deals

with deformation distribution across the teeth’s face width in relation to the load

width of the teeth when meshing occurs. The solution for teeth deformation of

spur gears is provided by the FEM.

Keywords: spur gear, deformation of teeth, face width, finite

element method, stiffness

1. INTRODUCTION

The

theoretical determination of teeth deformation in involute gears is difficult

because the teeth profile consists of an involute and smooth filet. Previous

experimental procedures were based on the static deformation measurements of

the gearing’s loaded constant force or the seismic measurement deviations when

turns are carried out. However, such procedures require the construction of a

suitable model and the use of appropriate machinery, given the limited value of

deformation quality measurement technology. The FEM, therefore, is preferable

in terms of solving the matter in question, given that it is one of the most

widely used numerical methods. Teeth deformation in spur gears is not consistent

for all examined gear teeth. Such deformation depends on the shape of the

teeth and, in turn, the basic parameters of the gearing, as well as the shape

and construction of the body wheel and the wheel load. This paper mainly deals

with teeth deformation with regard to the face width, with the FEM presented as

the solution to this problem.

2. DEFORMATION AND STIFFNESS IN THE TEETH OF

SPUR GEAR

As previously stated, the FEM is a solution

for the deformation of teeth when meshing occurs. We will focus on the value of

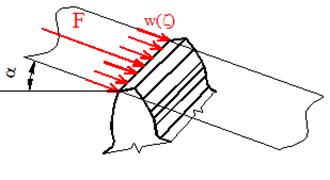

the total deformation in the direction of action forces (Fig. 1). To determine

the deformation of the gearing under a load, it is necessary to be aware of the apportionment

of the load on each gearing pair when two pairs mesh. Firstly, let us consider

the simplest, ideal load apportionment, which is when two pairs meshing and the load

is divided by half for each pair of teeth involved in the meshing. Exercises to

calculate the gearing strength, shafts, gear wheels etc. involve a combined

load, which is replaced by lonely forces (Fig. 2). In our case, we will examine

the problematic in hand with regard to deformation in the width of the teeth.

Fig. 1. Teeth deformation of teeth

Fig. 2. Explanation of the load across the

width of a single force

One of the ways to calculate teeth

stiffness is by analysing the total gearing deformation as determined by the FEM.

In general, the resulting stiffness c is defined by Equation (1):

![]() ,

[N/mm.μm] (1)

,

[N/mm.μm] (1)

where w is the load across the width of the

teeth [N/mm], while δ is the resulting deformation [μm].

3. FEM SOLUTION FOR TEETH DEFORMATION AND STIFFNESS

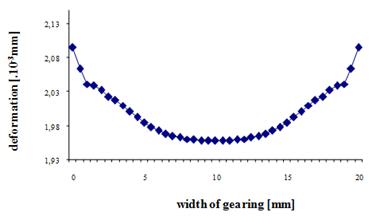

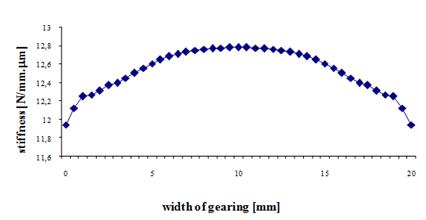

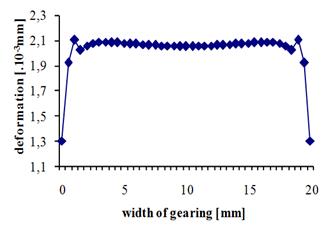

After carrying out an analysis of teeth

deformation in the spur gear, in order to evaluate the 3D approach to the FEM,

it was found that deformation and stiffness were not constant across the width

of the teeth, but change. For the spur gear model used in this example, the

number of teeth z=19, the module of teeth m=1mm, the load w=25N/mm (F=500N) and

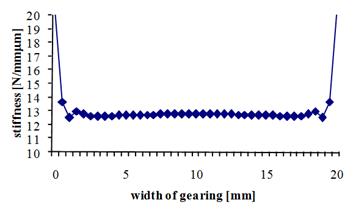

the gearing width b=20mm. Fig. 3 shows the course of the teeth deformation

and stiffness, when the spur gear is examined, if the width of the

teeth is consistent with the load width. The load is applied as shown in Fig. 1.

Under the influence of the free end of the teeth, but without any support

effect, there is a change to the beginning and the end of the meshing, while

the deformation of teeth expands and the stiffness of teeth reduces.

Fig. 3. Teeth deformation and stiffness when

the gearing width is consistent with the load width

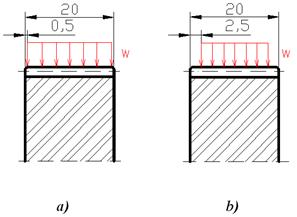

In practice, we encounter cases

where the load width is less than the gearing width. Therefore, let us consider

the case where the gearing width gearing remains unchanged (b=20mm), while the

load width is reduced on each side, firstly, by 0.5mm (Fig. 4a) and, secondly,

by about 2.5mm (Fig. 4b).

Fig. 4. Load width

Fig. 5. Teeth deformation and stiffness when the

gearing width is not consistent with the load width, as shown in Fig. 4a.

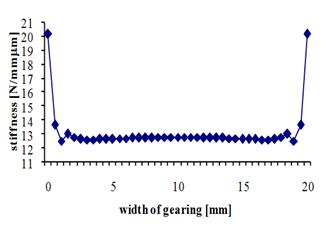

Fig. 5 shows the course of the teeth

deformation and stiffness in relation to Fig. 4a. This concerns a spur gear model

where the number of teeth z=19, the module of the teeth m=1mm, the load w=26.31579N/mm

(F=500N), the gearing width b=20mm and the load width bw=19mm.

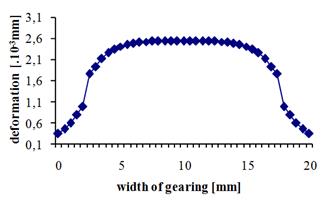

Fig. 6 shows the course of the teeth

deformation and stiffness in relation to Fig. 4b. It concerns a spur gear model

where the number of teeth z=19, the module of teeth m=1mm, the load w=33.33N/mm

(F=500N), the gearing width b=20mm and the load width bw=15mm.

Fig. 6. Teeth deformation and stiffness when the

gearing width is not consistent with the load width, as shown in Fig. 4b

According to Fig. 5 and Fig. 6, if

the load width is less than the gearing width, the deformation at the edges of

the meshing incurs a sharp drop, while the stiffness experiences a sharp

increase.

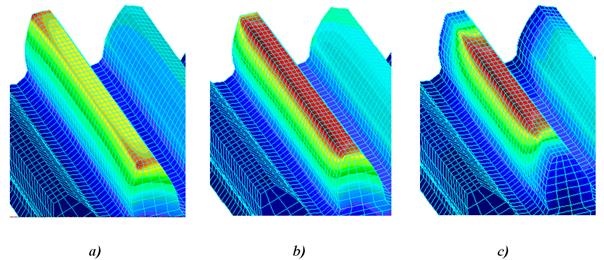

When the course of teeth deformation

occurs in which the load width is equal to or less than the gearing width,

we can also monitor the effectiveness in addressing teeth deformation by use of

the 3D FEM (Fig. 7). When dark red is displayed, this means that the maximum

deformation of the teeth along the load width is limited.

Fig. 7. Teeth deformation solution using the FEM:

a) where the gearing width is consistent with the load width; b) where the

gearing width is not consistent with the load width, as shown in Fig. 4a; and c)

where the gearing width is not consistent with the load width, as shown in Fig.

4b.

It should also be understood that

the course of deformation and stiffness across the width of the teeth,

when determined at various characteristic points on a line of action, will be

different. This is demonstrated in Fig. 8, which concerns a spur gear model where

the number of teeth z=19, the module of teeth m=1mm, the load w=33.33N/mm

(F=500N), the gearing width b=20mm and the load width bw=b=20mm.

Fig. 8. Teeth stiffness at the characteristic

points of contact

The characteristic points of contact

are defined in Fig. 9. Points A and E are the so-called external or end points along

the AE line of action. Points B and D are the so-called end points of lonely

meshing. Point C is a central contact point.

Fig. 9. Characteristic points of

contact in the spur gear

It can be seen that teeth stiffness at

the characteristic points under the same conditions change.

4. CONCLUSION

It is

possible to demonstrate, with great accuracy, teeth deformation along the width

of the load on the examined gear teeth by using the FEM. The findings in relation to this deformation

may be used to determine the stiffness of the teeth. Periodic changes in

stiffness when teeth mesh are caused by changes in the number of pairs of teeth,

which also mesh in order to create a significant noise impact on the teeth.

References

1.

Alfonso Fernandez del Rincon, Fernando Viadero, M. Iglesias, Pablo García,

A. de-Juan, Ramon . Sancibrian.

2013. „A model for the study of meshing stiffness in spur gear transmissions.” Mechanism

and Machine Theory 61: 30-58.

ISSN: 0094-114X.

2.

Medvecká-Beňová S. 2011. „Deformácia a tuhosť čelného ozubenia“. [In

Slovak: “Spur deformation and stiffness]. Strojárstvo

15(12): 8-9. ISSN: 1335-2938.

3.

Medvecká-Beňová S., P. Frankovský, R. Grega. 2015. „Influence gearing

parameters on the tooth deformation of spur gears“. Applied Mechanics and Materials 816: 27-30. ISSN: 1660-9336.

4.

Satiepka M., V. Dekýš, P. Pastorek. 2014. „Using active thermography and

lock-in method with ultrasound excitation for detection of material defects“. Scientific Journal of Silesian University of

Technology. Series Transport 84: 119-124.

ISSN: 0209-3324.

This paper

was written within the framework of the following Grant Project VEGA:

„1/0688/12 – Research and application of universal regulation system in order to

master the source of mechanical systems excitation”.

Received 08.11.2015;

accepted in revised form 29.03.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons Attribution

4.0 International License