Article citation information:

Mantič, M., Kuľka, J., Kopas, M., Faltinová, E., Petróci, J. Special device for continuous deceleration of freight cableway trucks. Scientific Journal of Silesian University of Technology. Series

Transport. 2016, 91, 89-97. ISSN:

0209-3324.

DOI: 10.20858/sjsutst.2016.91.9.

Martin MANTIČ[1],

Jozef KUĽKA[2],

Melichar KOPAS[3],

Eva FALTINOVÁ[4],

Ján PETRÓCI[5]

SPECIAL DEVICE FOR CONTINUOUS DECELERATION OF freight CABLEWAY TRUCKS

Summary. This paper is focused on the design of an auxiliary braking device for freight

cableway trucks. The device provides continuous deceleration for the trucks

before they arrive at the unloading station. It presents an alternative to

manual deceleration, which poses safety hazards and is therefore a less

suitable option. The design distinctly accommodates the spatial disposition at

the unloading station and involves minimal interventions to the existing

steel structure. Above all, it aims to increase safety by eliminating the need

for human input in the process of decelerating the trucks before they are

emptied. The proposed design solution was successfully applied in a real

operation.

Keywords: cableway, truck, friction brake,

braking force, design solution

1. INTRODUCTION

This paper focuses on the construction

of an auxiliary device for material cableways. Cableways convey material in trucks

pulled by a wire rope. Depending on whether the trucks move along ground rails

or taut cables above the ground, either aerial cableways or cable railways are

involved. Aerial cableways transport people and material over great distances

or in an impassable terrain. The trucks move along taut cables suspended

in air. The diversity of the terrain bears no influence on the function of the

cableway, such that the space under it can be otherwise used. Aerial cableways

can span valleys, mountains, rivers, roads and buildings. They are suitable for

conveying both bulk material and unit loads [1, 8]. According to the construction

type, there are bi-cable cableways, with a track cable and a haul rope, and

mono-cable cableways, with a single cable used for both support and propulsion.

Either circular or shuttle cableways according to the direction of movement [3,

4, 5]. Taking into consideration the above-mentioned facts concerning the

cableway’s construction, it is possible to say that one of the most important

constructional parts of the cableway is simply the cable, which is

designed as a steel wire rope. The steel wire rope is usually wound from six

strands or it consists only of one strand and is constructed by laying several

strands around a core. Two kinds of steel wire rope are applied in the case of a

bi-cable cableway, i.e., the single-strand rope together with the six-strand

rope. The single-strand rope fulfils a supporting function, while the main task

of the six-strand rope is traction [6, 7].

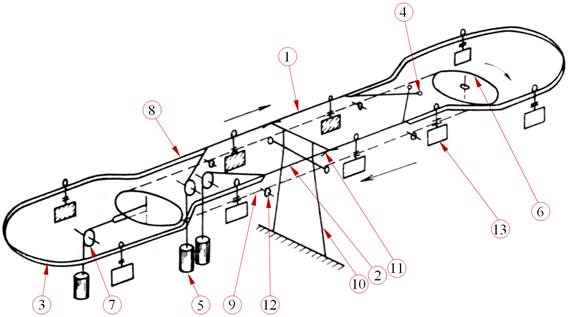

The

device on which this paper focuses involves a material cableway in a cement

plant, which currently specializes in producing ground limestone and dolomites.

It conveys limestone lumps from the quarry to the lime plant. It is a material

aerial bi-cable circular system with a detachable grip for the truck. The

concept behind the aerial bi-cable circular cableway is illustrated in the

diagram in Fig. 1.

Fig. 1. Diagram of the aerial

bi-cable circular cableway [2]

1 – track cable on the loaded

side, 2 – track cable on the unloaded side, 3 – rail, 4 – track cable

anchorage, 5 – track cable tensioning, 6 – drive, 7 – haul rope tensioning, 8 –

attachment point,

9 – haul

rope, 10 – support, 11 – saddle, 12 – haul rope sheave, 13 – load truck

The cableway was commissioned in

1948 and overhauled in 2005. Its transport capacity is 60 t/h. The bottom

station is located at 370 m above sea level, while the top station is located at

660 m above sea level, meaning the cableway rises 290 m. There are 44 trucks,

which service the cableway.

2. CURRENT SITUATION

The design presents a solution for

the cableway’s unloading station. When the trucks are detached from the haul

rope, they roll along the gravity rail at 2.5 m/s by their weight to the point

where they are decelerated in order to be emptied. Once unloaded, they roll by

inertia to the point where they are reattached to the haul rope.

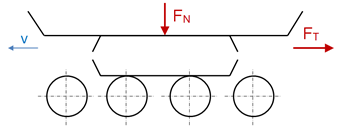

The trucks used to be decelerated by

friction brakes, which created down pressure on the truck wheels between

the rail and the steel load-carrying structure at the unloading station (Fig.

2).

Fig. 2. Deceleration of a truck by

friction brake

A wooden block was used as a

friction element. This deceleration mode, however, was not effective enough,

due to rapid wear to the braking element, as well as frequent damage (wood

chipping) caused by the impact of moving trucks.

Fig. 3. Manual truck deceleration

Alternatively, the operating staff

would decelerate the trucks manually before they were emptied (Fig. 3). This

solution was effective, but it was inadequate due to the safety hazards it

posed for the operators.

To eliminate these shortcomings, the

operation has demanded a new conceptual solution design. It has to ensure the trucks

are decelerated by a mechanical braking system without human input. The

operating staff would only be responsible for emptying the decelerated trucks.

Empty trucks must retain enough speed to keep rolling along the gravity rail to

the point where they are reattached to the haul rope.

3. SOLUTION DESIGN

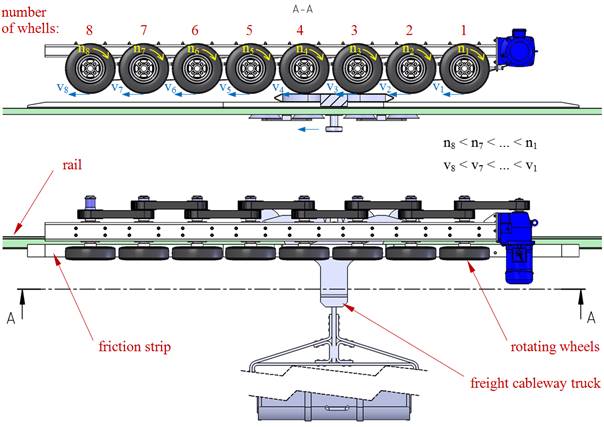

It is necessary to decelerate the trucks detached from the haul rope

from 2.5 m/s to 0.5 m/s. The new solution assumes minimal interventions to the

existing steel structure at the unloading station. It also needs to allow

for the spatial constraints associated with its installation. The engineering

design of the new solution is based on a principle of continuous deceleration

of the trucks by using rotating wheels. Each wheel has a different frequency of

rotation achieved by the interconnected toothed belts and reduction gears.

Deceleration is ensured, due to the friction occurring between the truck wheels

and the set of rotating wheels as their speed decreases (Fig. 4). Questions concerning dynamic phenomena, which occur during acceleration

or braking, and mechanical losses are analysed in [9, 10, 11].

Fig.

4. Block diagram of the braking system

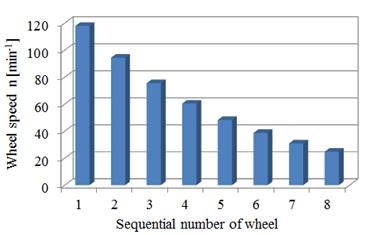

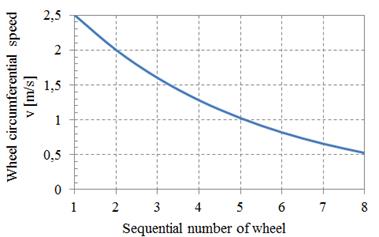

The toothed belts with the reciprocal meshing factor of 1.25 ensure the rotary

motion of the wheels (Fig. 6). The meshing achieves gradual reduction in

shaft revolutions (Fig. 5) and, consequently, in the circumferential speed from

2.5 m/s at the front wheel to approximately 0.5 m/s at the back wheel

(Fig. 6).

Fig. 5. Speeds of rotating

wheels

Fig. 6.

Circumferential speeds of brake wheels

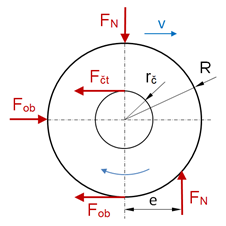

The calculation of the necessary power is based on the force ratios (Fig.

7), where FN denotes the contact force, R denotes the wheel radius,

v denotes the speed, Fob denotes the circumferential force, e

denotes the arm of the rolling resistance, rč

denotes the arm of the pivot’s resistance, and Fčt denotes the

pivot’s frictional resistance.

|

|

|

Fig. 7. Force ratios

According to the

distribution of forces illustrated in Fig. 7, the circumferential force Fob

can be formulated as in Equation (1) and the required power as in Equation

(2).

![]() (1)

(1)

![]() (2)

(2)

where hc is the total efficiency of the whole assembly.

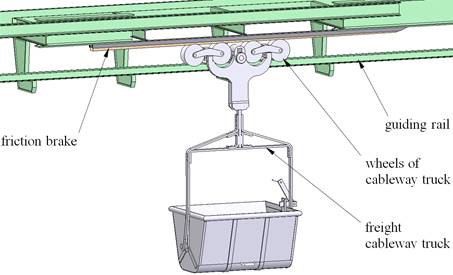

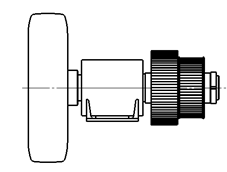

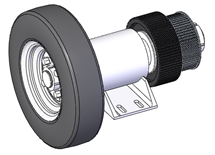

In

terms of its construction, the braking system is made of braking segments (Fig.

8) with an alternating arrangement of toothed belts, which provide continuous

and reciprocal speed reduction.

Fig. 8. View of

the braking element

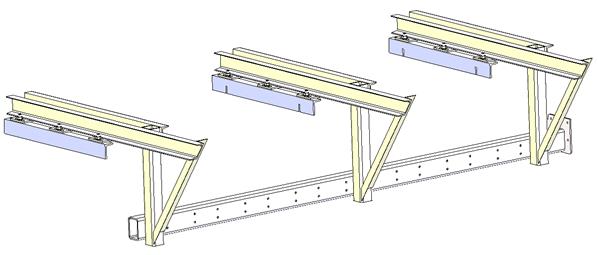

The

braking segments are located on adjustable support brackets (Fig. 9), where a drive

(a geared motor) is also mounted. Tensioning of the belts between the individual belt pulleys is individually

designed for each of the braking segments by means of the tensioning screws.

Application of commercially accessible belt stretchers was impossible with

regard to the dimensional dispositions.

The

bracket accommodates the space disposition of the existing structure, as well

as the options available for its set-up and simple installation. The down

pressure for the brake is designed in order to be exerted by the sliding

mechanism in the support bracket, as well as by pumping up the tires.

Fig. 9. Support

bracket of the braking system

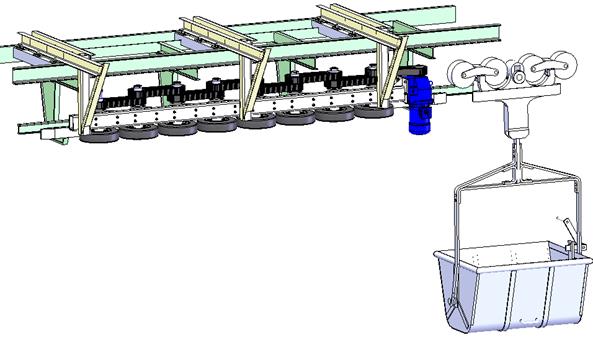

Fig. 10

presents the overall view of the conceptual solution for the braking system

mounted on the existing steel structure.

Fig. 10.

Solution model of the braking system

The braking system was installed

experimentally in a real operation for testing the whole equipment, as

well as for tuning the operational parameters and possible constructional

modifications. The ideal approach of the cableway truck towards the first

braking wheel is important with regard to the elimination of undesirable

vibrations in the construction.

This special braking system is now

being utilized successfully during discharging of the cableway trucks within

the discharging station of the freight cableway.

4. CONCLUSION

The designed braking

device has sought to increase the level of safety for the operators as they

empty the freight cableway trucks. The system is designed to operate with eight

braking segments under continuous drive. Continuous deceleration of the

circumferential speed of the presser wheel in the braking system ensures speed

reduction for the incoming trucks at the unloading station. The next step will focus

on an engineering design for the discharging system, which will ensure the

complete elimination of human input in this section of the cableway in the near

future.

This

paper was elaborated in the framework of the following projects: VEGA 1/0198/15

– research on innovative methods for emission reduction of driving units used

in transport vehicles and optimization of active logistic elements in material

flows in order to increase their technical level and reliability; and KEGA 021TUKE–4/2015 – development of

cognitive activities focused on innovations in educational programmes in the discipline

of engineering, as well as building and modernizing specialized laboratories

specified for logistics and intra-operational transport.

References

1.

Dražan F., K. Jeřábek.

1979. Manipulace s materiálem. [In

Czech: Materials handling.] Prague:

SNTL/ALFA.

2.

Dražan F., L. Kupka

et al. 1966. Transportní zařízení. [In

Czech: Transportation equipment]. Prague:

SNTL/SVTL.

3.

Remta F. 1953. Visuté lanové dráhy. [In Czech: Aerial ropeways]. Prague: SNTL.

4.

Cvekl Z., F.

Dražan et al. 1976. Teoretické základy

transportních zařízení. [In Czech: Theoretical

foundations of transport equipment]. Prague: SNTL/ALFA.

5.

Jasaň V., J. Košábek,

N. Szuttor, 1989. Teória dopravných

a manipulačných zariadení. [In Slovak: Theory of transport and handling equipment].

Bratislava: ALFA.

ISBN: 80-05-00125-8.

6.

Boroška

J., J. Hulín, O. Lesňák. 1982. Oceĺové

laná. [In Slovak: Steel ropes]. Bratislava:

ALFA.

7.

Costello G. A.

1997. Theory of Wire Rope. New York: Springer-Verlag.

ISBN 0-387-98202-7.

8.

Pajer G., H. Kuhnt,

F. Kurth. 1988. Stetigförderer. [In

German: Continuous conveyors]. Berlin:

VEB Verlag Technik. ISBN: 3-341-00452-1.

9.

Łazarz B., G.

Wojnar, H. Madej, P. Czech. 2009. Evaluation of gear power losses from

experimental test data and analytical methods. Mechanika 6(80): 56-63.

ISSN 1392-1207.

10.

Konieczny Ł., R. Burdzik,

J. Warczek, P. Czech, G. Wojnar, J. Młyńczak. 2015. Determination of the effect

of tire stiffness on wheel accelerations by the forced vibration test method. Journal of Vibroengineering 17(8):

4469-4477.

ISSN: 1392-8716.

11.

Sága M., R. Bednár,

M. Vaško. 2011. “Contribution to modal and spectral interval finite element analysis”.

In 10th International

Conference on “Vibration Problems ICOVP”:

269-274. Edited by Náprstek J., J. Horáček, M. Okrouhlík, B. Marvalová, F.

Verhulst, J. T. Sawicki. Liberec, Czech Republic.

Dordrecht: Springer Science+Business Media B.V. ISBN 978-94-007-2068-8.

Received 02.11.2015; accepted in revised form 29.03.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License