Article citation information:

Kuľka, J., Kopas, M., Faltinová, E., Mantič, M., Bigoš, P. Kinematic linkages in the hinged undercarriage of a mobile working

machine. Scientific Journal of Silesian University of

Technology. Series Transport. 2016, 91,

81-88. ISSN: 0209-3324.

DOI: 10.20858/sjsutst.2016.91.8.

Jozef KUĽKA[1],

Melichar KOPAS[2],

Eva FALTINOVÁ[3],

Martin MANTIČ[4],

Peter BIGOŠ[5]

KINEMATIC LINKAGES IN THE HINGED UNDERCARRIAGE

OF A MOBILE WORKING MACHINE

Summary. The main purpose of this article is to present a possible description of

kinematic characteristics concerning the direction of travel of a selected

mobile working machine in motion, namely, a hinged loader. This description is

presented in the form of equations, which define the circumferential velocity

as well as the angular velocity of the vehicle wheels during a ride involving a

curve. In this way, it is also possible to describe a function of the axle

differential.

Keywords: hinged loader, kinematic linkages, direction of

travel, riding a curve, travel speed

1. INTRODUCTION

Similar

to other engineering entities, optimization of the design process and operation

of mobile working machines requires the application of computer simulations

based on dynamic models, which are created in relation to real objects.

The

predominant characteristics of the dynamic model, which has to simulate the

real machine, can be determined after the performed analysis of the concerned

kinematic linkages in the given object. The detailed kinematic analysis is often

constrained due to real software and hardware possibilities or limitations.

Therefore, the overarching complexity of the individual design components

of the real machine, including the undercarriage, working equipment and driving

system, cannot be integrated into the created model as a whole [6,7].

Taking

into consideration the above-mentioned conditions, it is also useful to

describe the axle differential function during the vehicle ride involving

a curve by means of kinematic linkages that support wheel rolling without

slippage.

2. DRIVING IN THE DESIRED DIRECTION OF TRAVEL

Much of the worldwide production of

loaders involves the wheeled undercarriage with the articulated framework, such

that the both parts of the undercarriage are jointed by a couple of hinges [1,3].

The position of the vertical hinge

enables mutual turning of the framework parts in the two-sided angular range of

35° to 45°, i.e., it is used to ride a curve.

The horizontal hinge is designed in order to eliminate bending and

torsional moments, which are responsible for loading the framework of vehicle.

As both axles have the same wheel track and the same tyres, the rolling

resistance is reduced.

The mechanism for driving in the

desired direction of travel is specific to the hinged undercarriages, which are

different from undercarriages of the other mobile working machines.

The following are known as driving systems that work with the desired

direction of travel [5]:

o

Manual

driving systems

o

Driving

systems with a servo unit

o

Machine

driving (with an external source of power)

There are many

variants in the construction of driving mechanisms, which are designed in line

with the requirements concerning the precision of the vehicle positioning as

well as the forces that result in loading the undercarriage [8,9]. Individual driving systems are described in [2] and

[5].

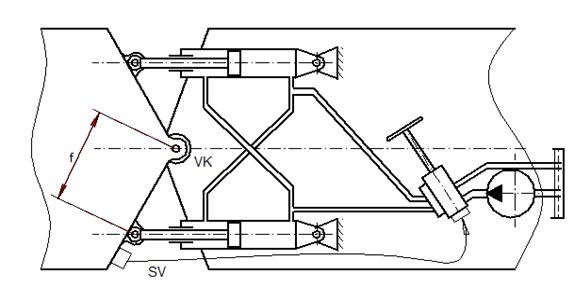

The simplest

principle consists of the application of two double-acting linear hydraulic

motors (hydraulic cylinders) combined with a vertical hinge. The axles are

fixed steadily to the individual machine sections.

In the case of direct (linear)

travel, the hydraulic cylinder lengths are the same, while any change in the

hydraulic cylinder lengths causes a mutual turning of both machine sections

around the vertical hinge VK (Fig. 1). A crosswise interconnection of the

working volumes between the hydraulic cylinders ensures the same reaction from

the driving system when turning to the left or the right.

The mutual position of the machine

sections is controlled by the feedback SV (Fig. 1). The feedback can be

arranged using:

·

mechanical

linkage, which is applied to a leverage mechanism

·

hydraulic

linkage, which is mostly equipped with a measuring hydraulic generator

Fig. 1 Scheme of the driving mechanism arrangement

3. KINEMATIC LINKAGES OF TRAVEL WHEELS

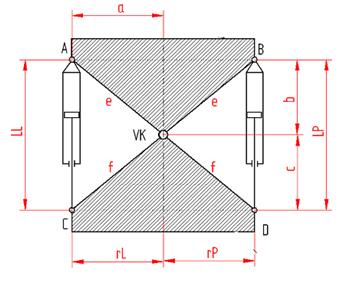

Fig. 2 schematically illustrates the driving mechanism, which is

designed to turn the hinged loader by means of linear hydraulic motors

(hydraulic cylinders). The linear shifting of the pistons in the hydraulic

cylinders (piston retracting or pushing out) causes a mutual turning of

the front and rear parts of the wheel loader around the vertical hinge VK.

The scheme in Fig. 2

corresponds to the arrangement in Fig. 1. Meanwhile, Fig. 2 is in effect a simplified

form of Fig. 1.

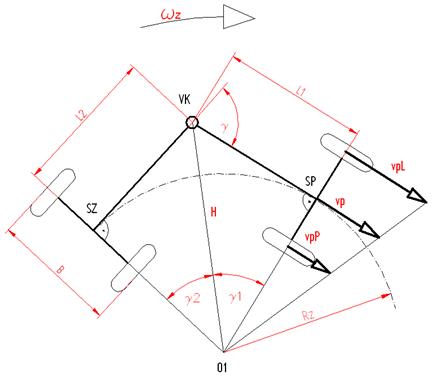

Curved travel involves

the motion of the vehicle on a curved trajectory around

the instantaneous centre of the wheel loader rotation O1. The point O1 is

a cross-point of the prolonged axles, according to Fig. 3.

Thus, vehicle turning

is caused by a mutual turning of the front and rear parts of the wheel

loader around the vertical hinge VK.

In a case involving

the constant travelling speed ![]() , the circumferential speed of the wheels on both sides of

the vehicle will be different during curved travel.

, the circumferential speed of the wheels on both sides of

the vehicle will be different during curved travel.

If the

circumferential speed of the wheel, which is situated on the internal side of the

curve, is signed ![]() , then the circumferential speed of the wheel rotating on the

external side of the curve is signed

, then the circumferential speed of the wheel rotating on the

external side of the curve is signed ![]() . It is evident that

. It is evident that ![]() .

.

Fig. 2

Scheme of geometric dimensions of a driving mechanism that supports the desired direction

of travel

A, B – positions of turning points for

cylinders in hydraulic motors; C, D – positions of turning points for piston

pins of hydraulic motors; LL, LP – length of the left and the right hydraulic

motor; VK – vertical hinge

Fig. 3 Curved travel, horizontal

projection

O1 – instantaneous centre of the

wheel loader rotation; SP – centre of the front axle;

SZ – centre of the rear axle; VK –

vertical hinge; L1, L2 – distances of axles from the vertical hinge; B – wheel

track; ![]() – instantaneous

turning radius;

– instantaneous

turning radius; ![]() – angular speed relating to the centre of rotation

– angular speed relating to the centre of rotation

The travel speed of the loader can be expressed

as follows:

![]() ,

(1)

,

(1)

where![]() is the angular speed relating to the centre of rotation,

while

is the angular speed relating to the centre of rotation,

while![]() is the instantaneous turning radius.

is the instantaneous turning radius.

The circumferential speed ![]() of the wheel, which is

situated on the internal side of curve, can then be written in the following form:

of the wheel, which is

situated on the internal side of curve, can then be written in the following form:

![]() ,

(2)

,

(2)

which

means that the circumferential speed ![]() of the wheel on the

external side of curve will be:

of the wheel on the

external side of curve will be:

![]() .

(3)

.

(3)

In the case of the cranked loader

configuration, the turning angle between the front and rear parts of the

vehicle is ![]() (Fig. 3), whereas:

(Fig. 3), whereas:

![]() ,

(4)

,

(4)

where ![]() is the turning angle

of the loader front part, while

is the turning angle

of the loader front part, while![]() is the turning angle at the rear of the loader.

is the turning angle at the rear of the loader.

According to the right-angled triangles ∆(O1,SP,VK) and ∆(O1,SZ,VK), the length of the hypotenuse

H equates to ![]() as well as

as well as ![]() (see Fig. 3).

(see Fig. 3).

By comparing

both relations, which are valid for the value H of the hypotenuse length, the following

equation is obtained:

![]() .

(5)

.

(5)

From Equation

(5),

![]() .

(6)

.

(6)

If ![]() ,

then

,

then ![]() and Equation (6) is

modified as follows:

and Equation (6) is

modified as follows:

![]() .

(7)

.

(7)

Using the goniometric rule, ![]() , Relation (7) can be rewritten as follows:

, Relation (7) can be rewritten as follows:

![]() . (8)

. (8)

After an adjustment of Equation (8),

![]() .

(9)

.

(9)

The relation, which is valid for

![]() , is obtained from (9) above:

, is obtained from (9) above:

.

(10)

.

(10)

According to Fig. 3, it simultaneously follows from

triangle ∆(O1,SP,VK) that:

![]() (11)

(11)

By comparison the left sides from Equations

(10) and (11), the following relation is obtained:

(12)

(12)

From Equation (12), the value of the

instantaneous turning radius![]() can be determined:

can be determined:

![]() . (13)

. (13)

From Equation

(1), the following is obtained:

![]() .

(14)

.

(14)

The circumferential speed ![]() of the wheel, which is

situated on the internal side of the curve, as well as the circumferential

speed

of the wheel, which is

situated on the internal side of the curve, as well as the circumferential

speed ![]() of the wheel on the

external side, can be obtained after applying Relation (14) to Equations (2)

and (3), as follows:

of the wheel on the

external side, can be obtained after applying Relation (14) to Equations (2)

and (3), as follows:

(15)

(15)

.

(16)

.

(16)

At the same time, it is valid that:

![]() and

and ![]() ,

,

where![]() is the dynamic wheel radius.

is the dynamic wheel radius.

Thus, the values of the angular

speed![]() of the wheel, which is situated on the internal side,

and the angular speed

of the wheel, which is situated on the internal side,

and the angular speed ![]() of the external side

wheel are as follows:

of the external side

wheel are as follows:

,

(17)

,

(17)

. (18)

. (18)

According to Equations

(17) and (18), a significant difference between the angular speed values of the

wheels rotating on the both sides of axle is evident.

This fact corresponds to the

function of the axle differential of the given wheel loader, whereas Relations

(17) and (18) represent the analytical description of its function.

4. CONCLUSION

This paper presents a

kinematic analysis of driving in the

desired direction of travel in the case of a hinged wheel loader.

The analysis of

kinematic relations, which occur during the driving process, involves a basic

assumption, which is necessary for the creation of the resulting dynamic model

of the wheeled undercarriage for a mobile working machine [4].

Equations (17) and

(18) represent the final result of the performed kinematic analysis of the

loader travel involving a curve. These equations are useful for the next stage of

vehicle travel simulation.

This

paper was elaborated in the framework of the following projects: VEGA1/0197/14 –

research on new methods and innovative design solutions in order to increase

efficiency and reduce emissions of transport vehicle driving units, together

with the evaluation of possible operational risks; VEGA 1/0198/15 – research on

innovative methods for emission reduction of driving units used in transport

vehicles and optimization of active logistic elements in material flows in

order to increase their technical level and reliability; and KEGA 021TUKE–4/2015 – development of

cognitive activities focused on innovations in educational programmes in the discipline

of engineering, as well as building and modernizing specialized laboratories

specified for logistics and intra-operational transport.

References

1.

Dudzinski Piotr. 2005. Lenksysteme fuer Nutzfahrzeuge. [In German: Steering systems for commercial vehicles]. Berlin: Springer-Verlag.

ISBN: 3-540-22788-1.

2.

Kučík Pavol, Igor

Strážovec, Peter Kriššák. 2000. Hydraulický

prenos energie. Mobilné pracovné stroje. [In Slovak: Hydraulic power transmission – Mobile Machinery]. Žilina: EDIS-ŽU.

ISBN: 80-7100-725-0.

3.

Kunze Günter, Helmut

Göhring Klaus Jacob. 2002. Baumaschinen.

Erdbau und Tagebaumaschinen. [In German: Construction. Earthworks and mining equipment]. Braunschweig:

Vieweg und Sohn. ISBN: 3-528-06628-8.

4.

Heisler Heinz.

2002. Advanced Vehicle Technology.

Warrendale: SAE International. ISBN: 9780080493442.

5.

Findeisen Dietmar.

2006. Ölhydraulik.Handbuch für die hydrostatische Leistungs- übertragung in der

Fluidtechnik. [In German: Oil hydraulics. Manual for

the hydrostatic power transfer in fluid technology]. Berlin:

Springer-Verlag.

ISBN: 13 978-3-540-23880-5.

6.

Vaško

M., B. Leitner, M. Sága. 2010. Computational fatigue damage prediction of the lorry

frames under random excitation. Communications

12(4): 62-67.

ISSN 1335-4205.

7.

Sága M., P. Kopas,

M. Vaško. 2010. Some computational aspects of vehicle shell frames optimization

subjected to fatigue life. Communications

12(4): 73-79.

ISSN: 1335–4205.

8.

Konieczny Ł., R. Burdzik,

J. Warczek, P. Czech, G. Wojnar, J. Młyńczak. 2015. Determination of the effect

of tire stiffness on wheel accelerations by the forced vibration test method. Journal of Vibroengineering 17(8):

4469-4477. ISSN 1392-8716.

9.

Dekys

V., A. Sapietova, O. Stevka. 2013. Understanding of the dynamical properties of

machines based on the interpretation of spectral measurement and FRF.

In. 51st International

Scientific Conference on “Experimental Stress Analysis”:

106-112. Litomerice, Czech Republic. 11-13 June 2013.

Received 12.12.2015; accepted in revised form 28.04.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License