Article citation information:

Kohl, O., Pesik, L. Evaluation of a drivers seats dynamic properties. Scientific Journal of Silesian University of

Technology. Series Transport. 2016, 91,

59-69. ISSN: 0209-3324.

DOI: 10.20858/sjsutst.2016.91.6.

Ondrej KOHL[1],

Lubomir PESIK[2]

EVALUATION OF A DRIVERS SEATS DYNAMIC

PROPERTIES

Summary. The springing support in a drivers seat is a very serious issue, such

that manufacturers are increasing their efforts to optimize the dynamic

properties of this kind of seat. The main optimization criterion is vibration

insulation efficiency with regard to health research and associated health

standards and regulations. This article deals with the definition of the

optimal drivers seat properties in relation to two examples of springing

systems with different kinds of damping. The first case involves the springing

support of a drivers seat that uses a pneumatic spring and a telescopic

hydraulic damper. In the second case, the damping effect is achieved

by two pneumatic springs whose forces effect a phase shift due to a throttle

valve located in the connecting piping system.

Keywords: drivers seat,

vibration minimization, oscillation, stiffness, damping

1. INTRODUCTION

The

springing support in a drivers seat (Fig. 1) consists of a guide mechanism, in

which is placed a pneumatic spring. Parallel to the air spring is a guide

mechanism, which is connected to a damper (Fig. 2). Force effects ![]() and

and ![]() are phase-shifted by

are phase-shifted by ![]() .

.

Fig. 1 Vehicle drivers seat

Fig.

2. Springing seat support with a hydraulic damper

In

the original authors solution, there are two air springs that, by themselves, create

force effects that act against each together. They are pneumatically connected

through the throttle valve, which achieves phase-shifting as a result of their

force effects ![]() and

and ![]() , and in turn a damping

oscillatory motion (Fig. 3).

, and in turn a damping

oscillatory motion (Fig. 3).

When

the vehicle is moving, the seat is kinetically energized by the movement of the

floor. The excitation function ![]() is, in fact, in respect of frequency and

amplitude, very diverse, while its character depends on the road surface,

vehicle suspension and speed. Manufacturers of drivers seats asses the dynamic

properties of the springing support and the vibration insulation effect

based on their own practices and policies. Typically, measurement and

evaluation of the feedback

is, in fact, in respect of frequency and

amplitude, very diverse, while its character depends on the road surface,

vehicle suspension and speed. Manufacturers of drivers seats asses the dynamic

properties of the springing support and the vibration insulation effect

based on their own practices and policies. Typically, measurement and

evaluation of the feedback ![]() to the excitation signal

to the excitation signal ![]() take place when a vehicle is driving within a test

polygon. General evaluation, enabling an objective comparison of driver's seats

from different manufacturers, in terms of vibration insulation efficiency, is

practically non-existent.

take place when a vehicle is driving within a test

polygon. General evaluation, enabling an objective comparison of driver's seats

from different manufacturers, in terms of vibration insulation efficiency, is

practically non-existent.

Fig.

3. Springing seat support with two air springs

2. MECHANICAL MODEL

The

basis for evaluating the driver's seat suspension system is undoubtedly the

creation and compilation of a mechanical model and solving equations of motion.

For

the commonly known system shown in Fig. 2, the equation of motion can be

written by simplifying assumptions of linearization dynamic parameters in the following

form:

![]() , (1)

, (1)

where ![]() is the reduced mass of the moving parts of the

seat including the driver,

is the reduced mass of the moving parts of the

seat including the driver, ![]() is the coefficient of vibration damper

damping,

is the coefficient of vibration damper

damping, ![]() is the spring stiffness,

is the spring stiffness, ![]() and

and ![]() are the springs and dampers transfers,

are the springs and dampers transfers,![]() is the displacement of the base under the

kinematic excitation, and

is the displacement of the base under the

kinematic excitation, and ![]() is the absolute displacement of the object.

is the absolute displacement of the object.

It is then possible to rewrite Equation (1) as follows:

![]() , (2)

, (2)

where ![]() is the relative displacement of the object and

the base.

is the relative displacement of the object and

the base.

For

pneumaticmechanical systems, as shown in Fig. 3, it is possible to write the equation

of motion in the following form:

![]() , (3)

, (3)

where ![]() is the construction damping coefficient, while

is the construction damping coefficient, while

![]() and

and ![]() are transfers of springs in mechanism.

are transfers of springs in mechanism.

The

springs of the resilient differential pneumatic support have their geometrical

characteristics given by polynomial functions of effective surfaces ![]() and

and ![]() , as well as volumes

, as well as volumes ![]() and

and ![]() . The forces in the

springs are also represented as follows:

. The forces in the

springs are also represented as follows:

![]() (4)

(4)

and

![]() (5)

(5)

![]() and

and ![]() represent deformations of the springs,

represent deformations of the springs, ![]() and

and ![]() represent air pressures in the springs, and

represent air pressures in the springs, and ![]() and

and ![]() represent effective surfaces of the springs.

The equation of motion in the support with the mass

represent effective surfaces of the springs.

The equation of motion in the support with the mass ![]() of the supported object is simple:

of the supported object is simple:

![]() , (6)

, (6)

where ![]() is the relative displacement of the object and

the base,

is the relative displacement of the object and

the base, ![]() is the displacement of the base under the

kinematic excitation,

is the displacement of the base under the

kinematic excitation, ![]() is the absolute displacement of the object,

is the absolute displacement of the object, ![]() is the construction damping of the mechanism,

and

is the construction damping of the mechanism,

and ![]() is the static load of the mechanism. The

function

is the static load of the mechanism. The

function ![]() is the equivalent force from the springs:

is the equivalent force from the springs:

![]() ,

(7)

,

(7)

where ![]() and

and ![]() are transmission ratios of the springs.

are transmission ratios of the springs.

Air pressures inside the springs obey the state equation of ideal gas:

![]() , (8)

, (8)

and

![]() (9)

(9)

where ![]() and

and ![]() are masses of the air enclosed inside the

springs,

are masses of the air enclosed inside the

springs, ![]() is the specific gas constant, and

is the specific gas constant, and ![]() and

and ![]() are temperatures of the air inside the

springs.

are temperatures of the air inside the

springs.

The air exchange

between the springs is described by isentropic airflow through the throttle

valve. In the next two equations, the rate of air exchange depends on pressures

![]() and

and ![]() ; the pressure

; the pressure ![]() denotes the higher pressure of

denotes the higher pressure of ![]() and

and ![]() at a given time, while

at a given time, while ![]() represents the remaining one. The sign of the

flow rate is determined by the two pressures that are higher. The rate of air

mass is then calculated thus:

represents the remaining one. The sign of the

flow rate is determined by the two pressures that are higher. The rate of air

mass is then calculated thus:

(10)

(10)

for

subcritical flow conditions where ![]() ; otherwise,

; otherwise,

. (11)

. (11)

Critical pressure ratio ![]() is determined thus:

is determined thus:

![]() (12)

(12)

where ![]() is specific heat ratio for the air. In Equations

(9) and (10),

is specific heat ratio for the air. In Equations

(9) and (10), ![]() is the discharge coefficient and

is the discharge coefficient and ![]() is the cross-section of the throttle valve.

is the cross-section of the throttle valve.

The

differential Equation (8), which is supplemented by a differential equation for

air mass inside the springs, describes the pneumatic-mechanical system

being presented in this article. As we have considered a closed pneumatic

system, the air masses are bound by the following condition:

![]() (13)

(13)

Given that

thermal effects are within the scope of this article, temperatures ![]() and

and ![]() are considered as state variables. The evolution

of the air temperatures in time is described by the following differential

equations, which are derived from internal energy conservation (first law of

thermodynamics):

are considered as state variables. The evolution

of the air temperatures in time is described by the following differential

equations, which are derived from internal energy conservation (first law of

thermodynamics):

![]() (14)

(14)

![]() (15)

(15)

where ![]() is the isochoric thermal capacity of the air,

is the isochoric thermal capacity of the air, ![]() is the ambient temperature, and

is the ambient temperature, and ![]() is the coefficient of heat transfer. For

the purpose of this article, the heat transfer coefficient is presumed to

involve both the conductive and convective heat transfer.

is the coefficient of heat transfer. For

the purpose of this article, the heat transfer coefficient is presumed to

involve both the conductive and convective heat transfer.

3. EVALUATION OF SPRINGING SUPPORT

Based

on the solutions of equations of motion in the preceding section, a

transmission frequency characteristics can be obtained, which are usually

concerned with the displacement amplitude of the oscillatory movement of the

seat. According to these data, the function of the spring base, due to

changes in the position of the driver in relation to the vehicle controls, can

be evaluated, thereby allowing the appropriate size of the damping coefficient

to be set.

Regarding

the springing support with a hydraulic damper, as shown in Fig. 2, the

transmission frequency characteristics are based on those presented in Fig. 4.

Fig. 4. Transmission

frequency characteristics of springing support with a linear hydraulic damper

Particular

damping characteristics correspond to the relative damping coefficient of 0.01,

and 0.1 to 0.5 with step 0.1. Generally, it is possible to say that damping has

a positive effect when the system is erected near to its natural frequency.

Outside of this region, the damping importance, with respect to the

displacement amplitude, is either small or rather negative.

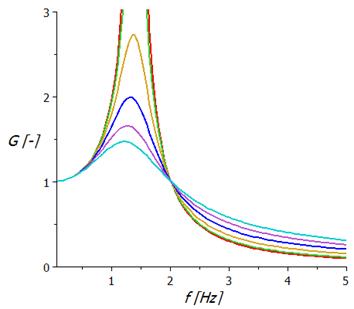

Regarding

the springing support, as shown in Fig. 3, the transmission frequency

characteristics are based those presented in Fig. 5.

Individual

characteristics correspond to different intensities throttling the flow of

compressed air between the two air springs in the support. The diameters of the

holes are graded from 1 mm to 3.5 mm in steps of 0.5 mm. The damping character

of the oscillation in this case is favourable in the wider frequency range and

the gain does not exceed the value of 1.5.

Fig. 5. Transmission frequency

characteristics of springing support with two air springs

Another evaluation

criterion relating to vibration insulation for a drivers seat concerns

acceleration value and frequency, which act on the driver and adversely affect

driving comfort.

Fig. 6 presents acceleration

transmission frequency characteristics of springing support with a linear

hydraulic damper. It shows that damping decreases displacement amplitude, but

significantly increases the acceleration values. This fact means that vibration

insulation system seats, located outside the resonance region, require

negligible damping.

Fig. 6. Acceleration amplitude

frequency characteristics of springing support with a linear hydraulic damper

Fig.

7 presents the acceleration amplitude frequency characteristics of springing

support with two air springs.

This

springing system significantly reduces amplitude acceleration values compared

to the classic springing support design. Acceleration amplitudes increase

almost linearly with excitation frequency.

Fig. 7. Acceleration amplitude

frequency characteristics of springing support with two air springs

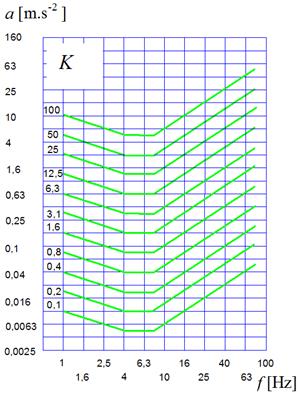

Fig. 8. Amplitude and frequency dependence in

relation to the comfort of the seated human on acceleration

Vibration isolation properties of

the drivers seat can be quantified on the basis of hygiene standards. Medical

research has indicated that the result is defined by the sitting person's

comfort under the influence of acceleration with a certain amplitude and

frequency. Fig. 8 presents graphs taken from the internationally valid

standards ISO 2631, ISO 5982 and VDI 2057.

Using these findings

could contribute to an objective evaluation of vibration insulation properties

of drivers seats, as well as remove the element of subjective assessment,

which currently dominates among the manufacturers of drivers seats.

Using the coefficient

![]() , the vibration insulation level of

the drivers seat properties can be deduced. In Fig. 9, dependence on the

coefficient

, the vibration insulation level of

the drivers seat properties can be deduced. In Fig. 9, dependence on the

coefficient ![]() is calculated according to the seats

excitation frequency with a hydraulic telescopic shock absorber, while Fig. 10 presents

this dependence on the seat involving two pneumatic springs.

is calculated according to the seats

excitation frequency with a hydraulic telescopic shock absorber, while Fig. 10 presents

this dependence on the seat involving two pneumatic springs.

Fig. 9. Frequency dependence the

coefficient of seated human loading on the acceleration of a seat with a hydraulic

telescopic shock absorber

Fig. 10. Frequency dependence the

coefficient of a sitting human loading on the acceleration of a seat with two

air springs

4. CONCLUSION

There

are many technical problems that are connected with the need to minimize

vibrations, especially in the automotive industry. There are many types of

equipment that produce an excitation through the movement of the foundation. A typical

example in this respect a drivers seat. Although vibration isolation is

possible for these objects, there are further problems that come from a variable

excitation frequency. It is clear that the condition in terms of the sufficient

difference between the force excitation frequency and resonant frequency of the

dynamic systems cannot be ensured at all times. In these cases, it is necessary

to use special supports with the possibility of changing the stiffness, as well

as tune the natural frequency of the system appropriately. In this article, two

possible designs for a drivers seat were presented. One of them is the

classical solution with a hydraulic damper. The second one is an original

solution by the authors, involving two pneumatic springs in the guide

mechanism.

This

original solution comes in the form of a pneumatic spring system with a

differential configuration and throttling of the airflow between the springs.

The springs act against each other. This system can be used in order to produce

benefits to the vibration isolation of objects by using kinematic excitation,

e.g., drivers seats, ambulance couchettes etc. Based on the frequency

spectrum of excitation, it is possible to choose the optimum cross-section of

the throttling element, along with achieving efficient damping of vibrations in

a relatively broad range of low excitation frequencies. Similar results can be

seen in the measurements obtained in a real system.

Evaluation

of both seats is made on the basis of simulating vibration excitation at

constant amplitude support displacements at frequencies between 0 and 5 Hz. The

obtained frequency characteristics of kinematic quantities are further

processed in terms of vertical acceleration coefficient determination regarding

the seated human loading.

Calculation

results showed that a qualitatively higher level of vibration insulation

properties was found in the seat with two air springs.

References

1.

D. J. Whitehouse.

2011. Handbook of surface and

nanometrology. Boca Raton: CRC Press.

2.

Zeman V., Z.

Hlaváč. 2010. Kmitání mechanických

soustav. [In Czech: Mechanical

vibration]. Plzeň: Západočeská univerzita v Plzni.

3.

Peík L., A.

Skarolek. 2012. Heat transfer effects on vibration isolation differential

pneumatic system. Transactions of the

Universities of Koice: 109-114. Koice: Research reports from the

Universities of Koice. ISSN 1335-2334.

4.

Peík L., A.

Skarolek. 2011. Tuning of vibration isolation differential pneumatic system

by means of throttle valve. Transactions

of the Universities of Koice: 191-196. Koice: Research reports from the

Universities of Koice. ISSN 1335-2334.

5.

Dresig

H., F. Holzweißig. 2008 Maschinendynamik.

[In German: Machine

dynamics] Berlin: Springer Verlag.

6.

Harris

C. M. 2005. Shock and Vibration Handbook.

New York: McGraw-Hill.

7.

Homiin

J., P. Kaay. 2014. Experimental verification of the possibility using

pneumatic flexible shaft couplings for the extremal control of torsional

oscillating mechanical system. Diagnostyka

15(1): 11-16. ISSN 1641-6414.

8.

PL

216901 B1. Układ mechaniczny

strojony w sposób płynny. [In Polish: Mechanical

system tuned smoothly]. Homiin Jaroslav. 2014. Warsaw: Polish Patent

Office.

9.

Grega

R., J. Krajňák. 2012. The

pneumatic dual-mass flywheel. Scientific Journal of Silesian University of

Technology. Series Transport 76: 19-24. ISSN: 0209-3324.

10. Urbanský M., J. Homiin. 2015. Design of a mobile platform for a mobile

torsional oscillating mechanical system.

Inżynier 21. Wieku: 389-394. ISBN: 978-83-65182-29-6.

11.

Kužka

J., M. Mantič. 2014 Effect of operational

condition changes on the durability of the rope for pusher of circular wagon tipper.

Applied Mechanics and Materials 683:

28-32. ISSN 1660-9336.

12.

Grega

R. et al. 2015 The chances for reduction of vibrations in mechanical system

with low-emission ships combustion engines. International Journal of Maritime

Engineering 157 (A4): 235-240. ISSN 1479-8751.

13.

Medvecká-Beňová

S., J. Krajňák. 2015. Modifications to a gearbox that increase the performance

of a winding machine for steel sheets. IT-strojár: 1-3.

ISSN 1338-0761.

14.

Medvecká-Beňová

S., J. Vojtková. 2014. Application

of asymmetric profile in gearing in gearings with eccentric gears. Scientific Journal of Silesian University of

Technology. Series Transport 85: 89-93. ISSN: 0209-3324.

15.

Homiin

J., M. Urbanský. 2015. Partial

results of extremal control of mobile mechanical system. Diagnostyka 16(1): 35-39. ISSN 1641-6414.

16.

Homiin

J., P. Kaay, M. Urbanský. 2011. High-flexibility characteristics of

pneumatic flexible shaft couplings. Pneumatyka 79(2): 26-29. ISSN 1426-6644.

17.

Mantič M., J. Kužka, J. Krajňák, M. Kopas, M. Schneider. 2015. Influence of selected digitization methods on final

accuracy of 3D model. Production Management and Engineering Sciences: 475-480. Proceedings of the International Conference

on Engineering Science and Production Management (ESPM 2015). Tatranská

trba, High Tatras Mountains, Slovak Republic, 16-17 April 2015. Edited by

Majerník M., D. Naqib, B. Martin. Boca Raton: CRC

Press (Taylor & Francis Group). ISBN: 978-1-138-02856-2.

18.

Medvecká-Beňová

S., M. Mantič, R. Grega. 2014. The

stress analysis in dangerous section of gear teeth. Applied Mechanics and Materials 611: 279-283.

ISBN 978-3-03835-189-4. ISSN 1660-9336.

19.

Vojtková

J., 2011. Force proportions

of the worm in planetary toroidal roller gear.

Transactions of the Universities of

Koice 2: 77-82. ISSN 1335-2334.

20.

Kopas

M., E. Faltinová. 2012. Optimisation

aspects in design process of specific structural element in bulk solid storage bin.

Transactions of the Universities of

Koice 3: 19-24. ISSN 1335-2334.

21.

Grega

R., J. Krajňák. 2013. The

application of pneumatic flexible coupling in conveyor drive. Technológ 5(4): 51-54. ISSN 1337-8996.

22.

Grega

R., J. Homiin, P. Kaay, J. Krajňák. 2011. The analysis of vibrations after changing shaft coupling

in drive belt conveyer. Scientific

Journal of Silesian University of Technology. Series Transport 72: 23-31.

ISSN: 0209-3324.

Received 03.01.2016; accepted in revised form 11.05.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License