Article citation information:

Kłosiński, J., Janusz, J. Numerical tests on the FLC system of a crane

model’s slewing movement. Scientific

Journal of Silesian University of Technology. Series Transport. 2016, 91, 51-58. ISSN: 0209-3324. DOI:

10.20858/sjsutst.2016.91.5.

Jacek KŁOSIŃSKI[1],

Jarosław JANUSZ[2]

NUMERICAL TESTS ON THE FLC

SYSTEM OF A CRANE MODEL’S SLEWING MOVEMENT

Summary. In this paper, selected results from

numerical tests on the influence of FLC settings upon the accuracy and quality

of controlling, as well as the settling times, of a crane model’s slewing

movement are presented.

Keywords: mobile crane; numerical

investigations; payload positioning; FLC controller

1. INTRODUCTION

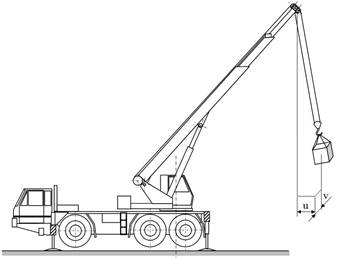

Typically, the swinging of payloads

carried by cranes represents an essential impediment in their work. Moreover,

this phenomenon may also have a direct influence on the safety of operators, as

well as pose a risk to objects in the surroundings of the service area a

particular crane. A proper strategy for controlling a crane’s work movements

can lead to an essential reduction in the amplitude of payload swinging during the

performance of versatile movements [2, 8] and/or after their termination (Fig. 1).

Fig.

1. Scheme of a mobile crane in the course of moving a payload

The application of a control system upon

working motions also allows for an increase in the precision of payload positioning

in the target point of motion, as well as a reduction in the sensitivity towards

distortions. The general principle is that a properly chosen controller has an

essential role to play in control systems. For standard controllers,

establishing their settings also depends on the dynamics of the considered object.

It seems that an application involving controllers, which are based upon fuzzy

logic, could be very beneficial; however, in this particular case, one should

properly chose the structure and the settings of the controller. In the

present paper, we describe investigations in which the settings of the chosen

types of controllers based on a fuzzy logic were analysed, along with their

influence on the precision and quality of controlling as well as on the time when

working motion was performed. The numerical investigations were performed using

the prepared mathematical model of a crane, which was mounted on a vehicle

chassis together with its driving system. The investigations were restricted to

controlling the slewing motion of the rotational bodywork of the crane,

thereby allowing for payload displacement by a chosen (set) slewing angle [1,

3, 7].

2. matHematIc

Model OF the MOBILE CRANE

Within the simulation

investigations, the mathematical model of the crane described in paper [2] was

utilized. It was derived by taking into account the following assumptions:

-

The

bodies of the chassis and the bodywork of the determined masses and inertial moments

were rigid, with six degrees of freedom; moreover, mutual slewing of the bodywork

in relation to the chassis possible.

-

The

support system was replaced by a system of springs; masses of springs were

neglected.

-

Slewing

of the bodywork was conducted by means of a hydraulic drive system driven via a

mechanical gear of determined stiffness; moreover, the stiffness of the jib was

also taken into account (in the direction that was compliant with its slewing

around the vertical axis), while masses and moments of inertia concerning the elements

of mechanical gear were neglected.

-

The

jib was considered as a stiff rod of constant length, known mass and moment of inertia.

-

The

payload was hung from/attached to a non-extensible, weightless and (flabby)

flexible rope, that was wound on the drum of a hoisting winch placed on the end

of the jib; the hanging payload was considered to be mathematical pendulum.

-

Backlashes

and friction, which occurred in the support system, jib and mechanical gear,

were neglected

-

Damping

in the system was taken into account.

-

The

characteristics of elastic connections and damping elements, found within the assumed

intervals in the deflection of elements, were assumed as linear.

-

The

supports were assumed as unilateral, as well as having the capacity to lose

contact with the ground.

The crane model, together with the

model of the driving system, was considered as a controlling object, which was connected

to the controller model of controller equipped with fuzzy logic in order to create

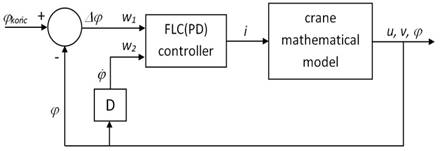

the model of the control system. It is presented as a block diagram in Fig. 2.

Fig. 2. Functional scheme of the control

system of the mobile crane

In the system under consideration,

we applied a first version proportional-differential (PD) controller, where the

input signals were Dj, i.e., the difference between the value of the

set slewing (rotational) angle of a jib and the value of the current rotational

angle ![]() , as well as being a derivative of rotational angle

, as well as being a derivative of rotational angle ![]() . The controller was assumed to be of the Mamdani type, equipped

with the assumed base of rules and the base of triangular membership functions

[3]. The investigations were performed in relation to different values in

the amplification of input and output signals of the controller. Some chosen

results of the performed simulation investigations are also presented in papers

[4, 5, 6].

. The controller was assumed to be of the Mamdani type, equipped

with the assumed base of rules and the base of triangular membership functions

[3]. The investigations were performed in relation to different values in

the amplification of input and output signals of the controller. Some chosen

results of the performed simulation investigations are also presented in papers

[4, 5, 6].

3. NumerIcAL InVeSTIGATIONS OF

THE CONTROL SYSTEM EQUIPPED WITH FLC CONTROLLER

The numerical investigations were performed

using specially prepared software, based on MATLAB. In the written program, it

was possible to change the amplification of input and output signals of

the controller. The courses of the chosen variables in the model – for the

chosen variant for the values of amplification coefficients w1 and w2, as well as for the assumed slewing angle of a jib –

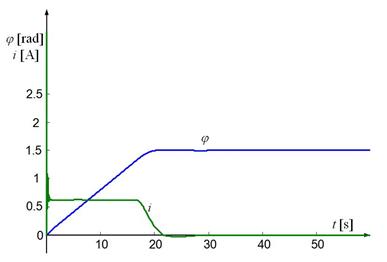

are shown in the figures below. In Fig. 3, the course of the slewing

motion angle and the controlling signal (generated by a controller) are

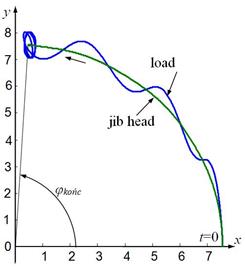

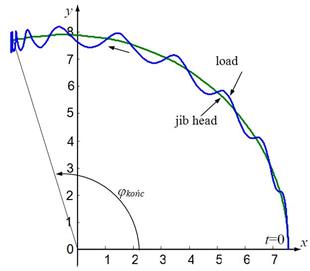

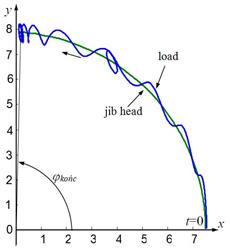

presented. In Fig. 4, the trajectory of the payload motion in relation to the motion

of the jib ending is presented.

Fig. 3. The angle of rotation j and control signal i

Fig. 4. Trajectories of the jib head

and the payload for control system simulation

These characteristics were used to

determine the time stabilization of motion (achieving an accuracy of less than 5%

of the set value) and the amplitude of payload swinging that remains after the slewing

motion has ended. The relationships for both quantities in relation to the values

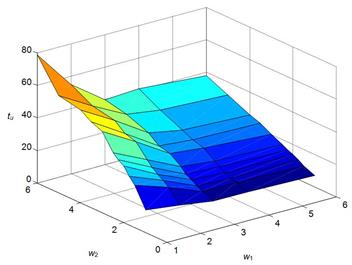

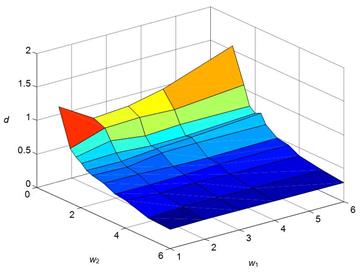

of coefficients w1 and w2 are presented in Fig. 5 and

Fig. 6 in the form of spatial charts. We can see that, for some combinations of

w1 and w2, the times of the stabilization

of responses or the amplitude of payload swings, which remain after motion has terminated,

can be sufficiently high that the utilization of these amplifications would be improper

from technical point of view.

Fig. 5. Diagrams: time regulation tu vs. amplification coefficients of the controller input w1, w2

Fig. 6. Diagrams: maximum amplitude of the

payload swings remain after the rotating movement ends vs. amplification coefficients of the controller input w1, w2

The performed investigations also

considered the behaviour of the considered model in the following cases:

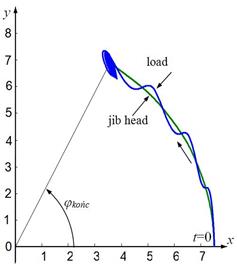

a) When operator determines

the value of the slewing motion of the jib (target rotational angle), i.e.,![]() ; then, after a particular time from the beginning of the motion,

the operator changes the decision to increase the target rotational angle (the trajectory

of payload movement for this case is shown in Fig. 7).

; then, after a particular time from the beginning of the motion,

the operator changes the decision to increase the target rotational angle (the trajectory

of payload movement for this case is shown in Fig. 7).

b) When the activity is

similar to that described above, but an operator reduces the target rotational

angle due to changing the decision (Fig. 8).

c) When the activity is

similar to that described above, but the decision about whether to change the

rotational angle is taken by the operator after the set value of the rotational

angle is overcrossed (Fig. 9).

d) When the activity is

similar to that described above, but the operator changes the decision about

the target rotational angle on two occasions (Fig. 10).

Fig. 7. Trajectories of the jib head

and the payload for control system simulation:

at time t=20s, φkońc changes from

1.5rad to 1.8rad

Fig. 8. Trajectories of the jib head

and the payload for control system simulation:

at time t=20s, φkońc changed from 1.5rad to 1rad

Fig. 9. Trajectories of the jib head

and the payload for control system simulation:

at time t=20s, φkońc changes from 1rad to 0.8rad

Fig. 10. Trajectories of the jib

head and the payload for control system simulation:

at time t=20s, φkońc changes from 1.5rad to 1rad; at time t=25s, it returns to 1.5rad

4. ConCLUSIONS

Control systems, in which fuzzy logic-based controllers are applied, offer

several advantages:

-

The choice of a controller and the establishment of its setting can be

done without a complete identification of the object of control.

-

Even a proximate

choice of a membership function and a base of rules usually offers satisfactory

quality of control (at least for properly chosen amplifiers of input and output

signals of the controller).

- A complicated imposing function, which controls the system,

does not need to be set on an input of the system.

A disadvantage of the discussed

approach is the lack of possibility in achieving a total reduction in payload swinging

after the termination of movement. It is caused by particular properties of the

object that were applied in the simulation investigations, as well as the static

character of the controller. The model of the mobile crane is an object with a

relatively low level of stability, due to neglecting the effect of damping and movement

resistance, which together result in controlling that is complicated and/or

difficult. The performed simulation investigations have proved that an

application of a different type of FLC controller (e.g., P- type) does not reduce

errors in the positioning of the payload in the end point of the planned

movement.

References

1.

Cho S.K., H.H. Lee.

2002. “A fuzzy-logic antiswing controller for

three-dimensional overhead cranes.” ISA

Transactions 41: 235-243.

2.

Kłosiński J. 2005.

“Swing-free stop control of the slewing motion of the mobile crane”. Control Engineering Practice 13: 451-460.

3.

Kłosiński J. 2011.

“Fuzzy logic-based control of a mobile crane slewing motion”. Mechanics and Mechanical Engineering 15(4):

73-80.

4.

Kłosiński

J., J. Janusz, R. Nycz. 2014. „The impact

of an FLC controller’s settings on the precision of the positioning of a

payload transferred by a mobile crane”. Acta

Mechanica et Automatica 8(4): 181-184.

5.

Kłosiński

J., J. Janusz. 2015. „Wpływ typu i

nastaw regulatora w układzie regulacji ruchu obrotowego żurawia na dokładność

pozycjonowania ładunku”. TTS Technika Transportu Szynowego 12: 787-791. [In Polish: “Influence of the type and parameters of

the controller in the control system of a slewing crane motion on the accuracy

of payload positioning”. Railway

Transport Technology 12: 787-791].

6.

Kłosiński

J., J. Janusz. 2016. „Badania

numeryczne układów regulacji ruchu obrotowego modelu żurawia samochodowego”. [In Polish: “Numerical investigations into the control

systems of the rotation model of a mobile crane”]. In 29th Conference on Development Problems for Working Machines.

Institute of Mechanized Construction and Rock Mining, Warsaw, Poland. 25-27

June 2016, Zakopane, Poland.

ISBN: 978-83-86040-23-0.

7.

Smoczek

J. 2014. “Fuzzy crane control with sensorless payload deflection feedback for

vibration reduction.” Mechanical Systems

and Signal Processing 46: 70-81.

8.

Terashima K., Y. Shen,

K. Yano. 2007. “Modeling and optimal control

of a rotary crane using the straight transfer transformation method”. Control Engineering Practice 15:

1179-1192.

Received 11.12.2015;

accepted in revised form 04.05.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons Attribution

4.0 International License